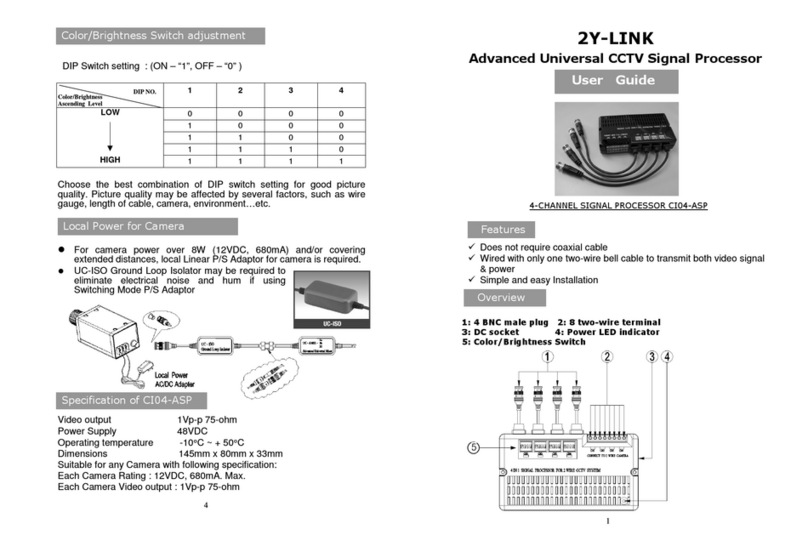

If your signal is an “absolute” type (that eans it has two red LEDs for the stop position while all others are yellow) then you

will have to cut the exposed lead on the diode D4 shown in Figure 5 above on the Signal Ani ator board. Use a pair of

diagonal cutters to ake the cut. Be sure that the two cut ends no longer touch each other by separating the slightly. Failure

to do so won’t cause any da age but it ay cause the center yellow LED to illu inate when the signal is in the stop position.

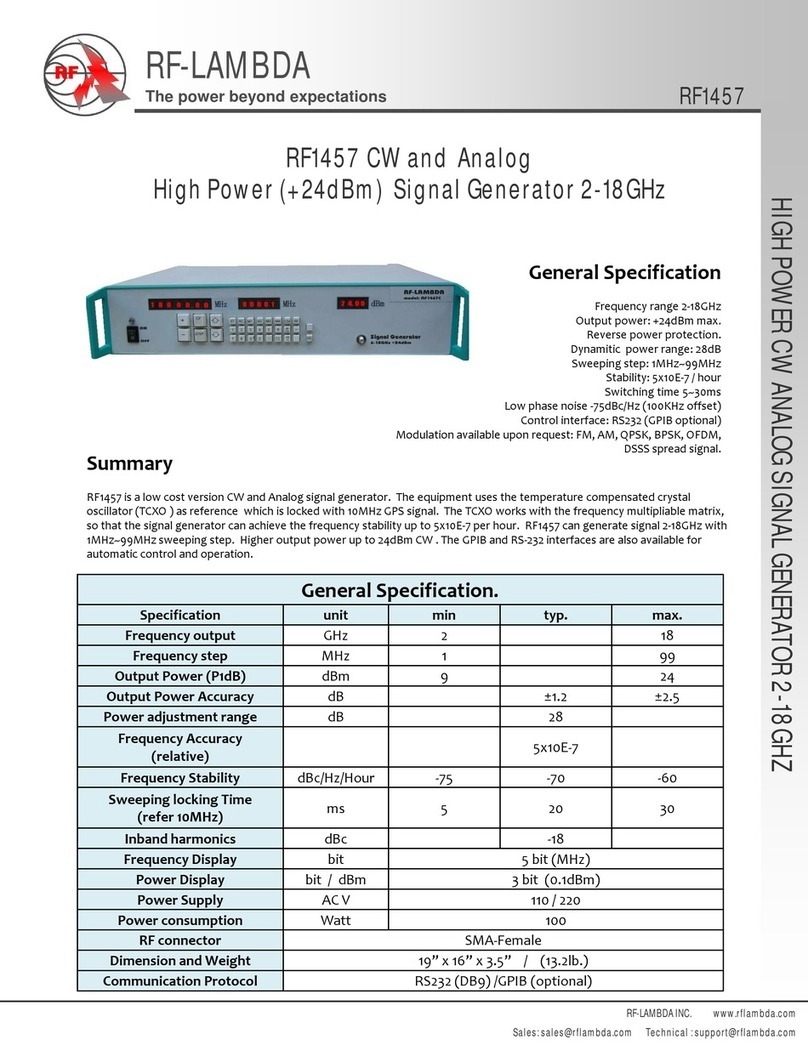

Mounting and wiring the IR components

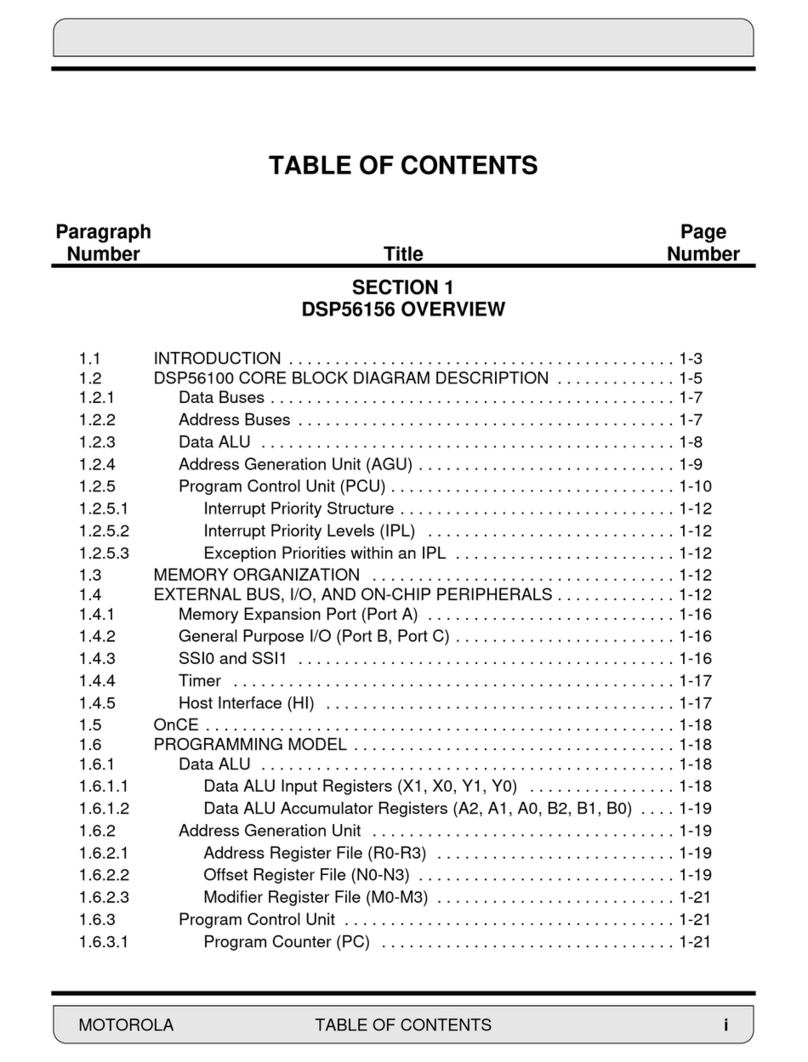

The IR co ponents should be ounted between the rails. Drill two 11/64” holes,

through the ballast, roadbed, and sub-roadbed. These holes should be located one tie

apart (Figure 7a) and drilled at approxi ately a 45 to 60 degree angle fro horizontal as

illustrated in the side view in Figure 7b. The benefit of ounting the at an angle is

reduced false triggering fro overhead light and increased detection reliability in s aller

scales or irregular botto s on rolling stock. For the s aller scales this drilling ay end

up hitting the ties. Take your ti e so you don’t angle the ! Insert the leads of one IR

e itter (white and black wires) into one of the holes (it doesn’t atter which one!) fro

the top of your layout. Repeat for the IR detector (blue and black wires). The tops of the

co ponents should sit no higher than the top of your ballast for opti al IR perfor ance;

in so e cases (e.g. false triggering) it ay be necessary to locate the co ponents a little

below the ballast line. You can extend the leads with si ilar (or larger) wire. We

reco end soldering and insulating these connections. We also reco end using

ter inal blocks/strips since you’ll have ultiple DC and GND connections to ake.

Once you have wired the IR co ponents and verified their operation you ay wish to

put a dab of white glue or silicone caulk where the wires exit the holes underneath the

layout. This will help to hold the co ponents in place; ake sure you don't get any

substance (e.g. ballast or glue) on the top surface of the IR co ponents as this ay

prevent the fro operating properly. In extre e cases where you ay be getting

interference fro overhead lighting you can ount the IR detector in so e plastic or

etal tubing. You can also recess the IR detector slightly below the ties and roadbed.

Figure 4a

Figure 4b

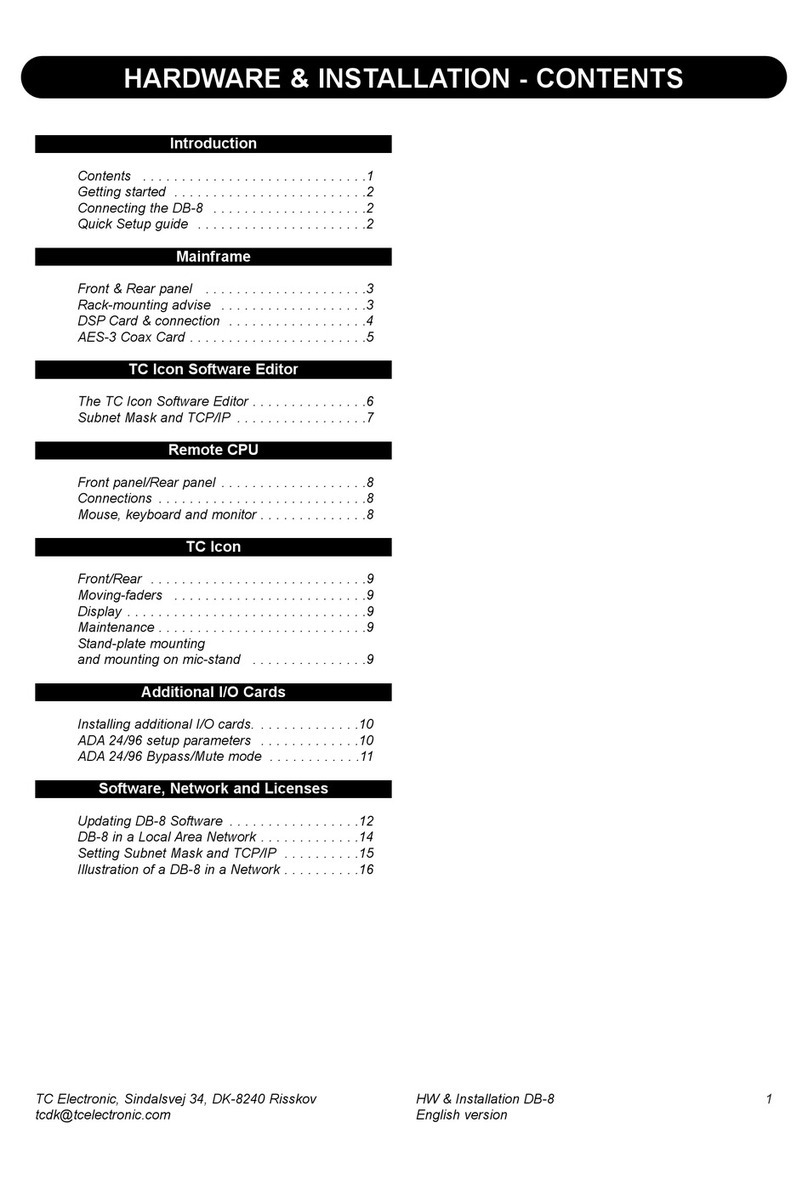

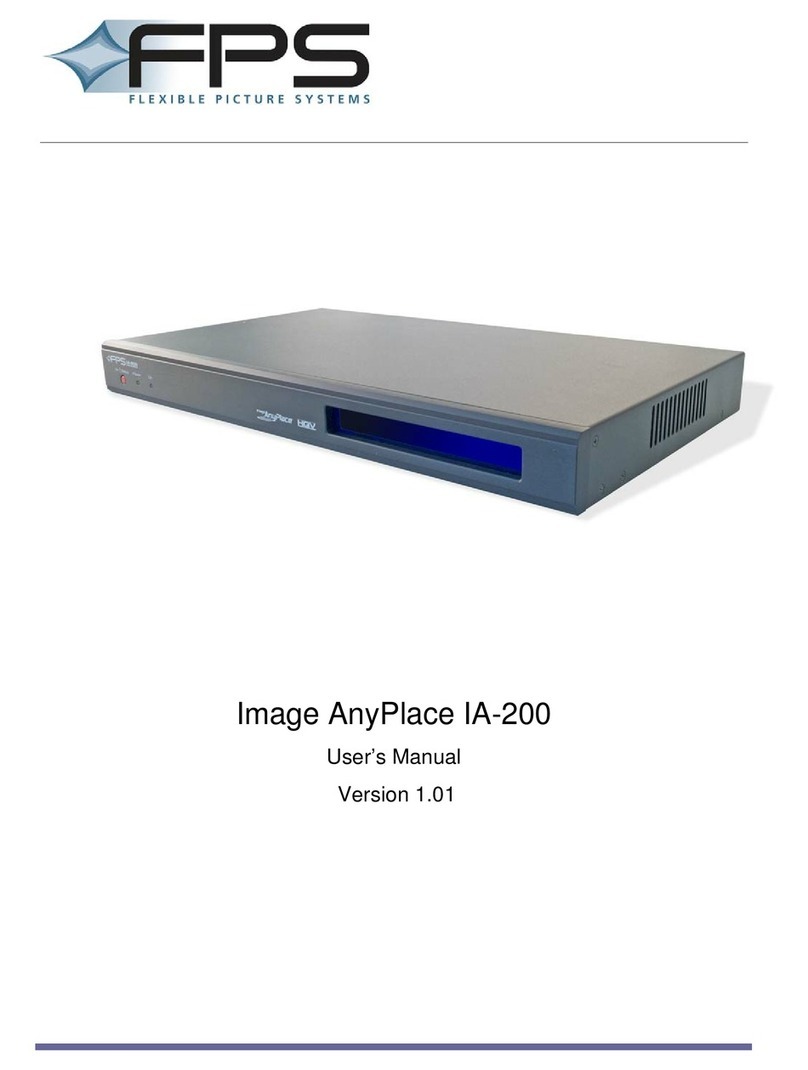

Figure 8 illustrates the wiring for the IR co ponents. The 180 oh 1 Watt resistor is included with the Signal Animator

WARNING: The 180 ohm 1 watt resistor may become hot to the touch –

take care so that you don’t burn yourself!

When properly wired the e itter will have a very faint red glow co ing fro it. You can also look at the e itter through a

digital ca era and see the infrared light!

For safety reasons do NOT point the IR e itter directly into your eye or stare at the

IR e itter!!!

Figure 8 – IR component wiring

You can adjust the sensitivity of the IR detector by inserting a s all screwdriver in the co ponent labeled "VR1". Turning

the screwdriver clockwise will increase its sensitivity. With a piece of rolling stock covering the sensor turn the VR1 fully

counter-clockwise and then slowly clockwise until the signal changes to red. Then slightly turn the screwdriver a little ore

clockwise. Move the rolling stock away fro the sensor and verify proper signal operation (delay, yellow, delay, green).

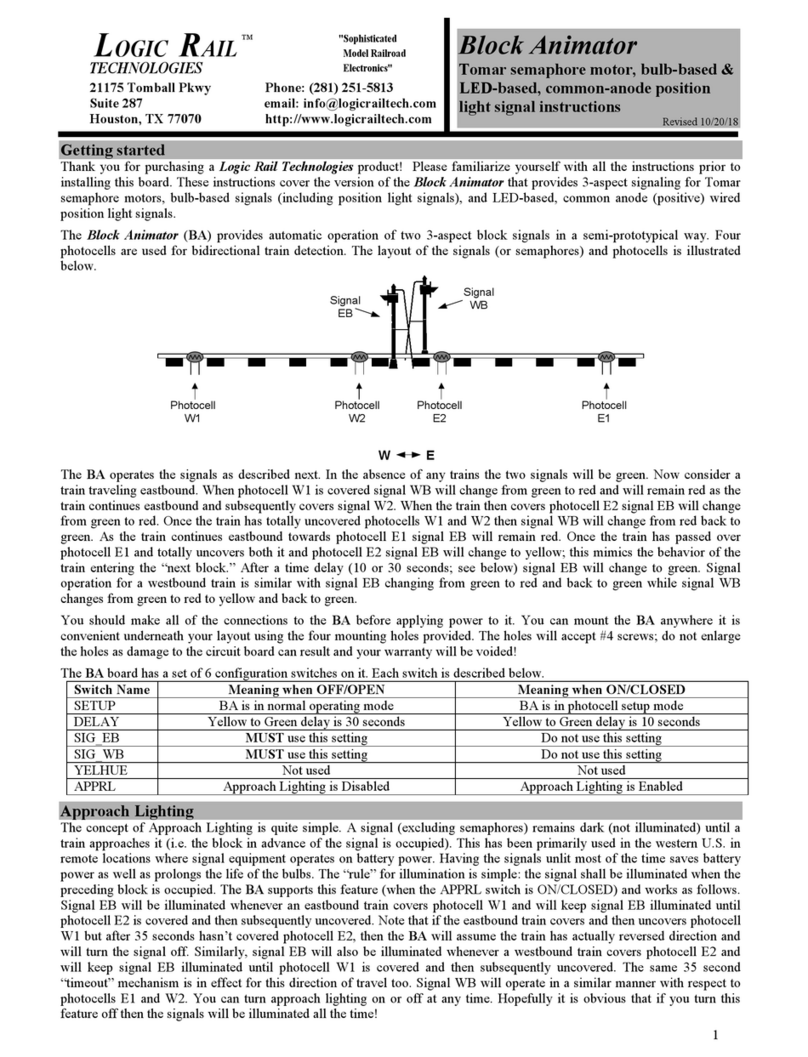

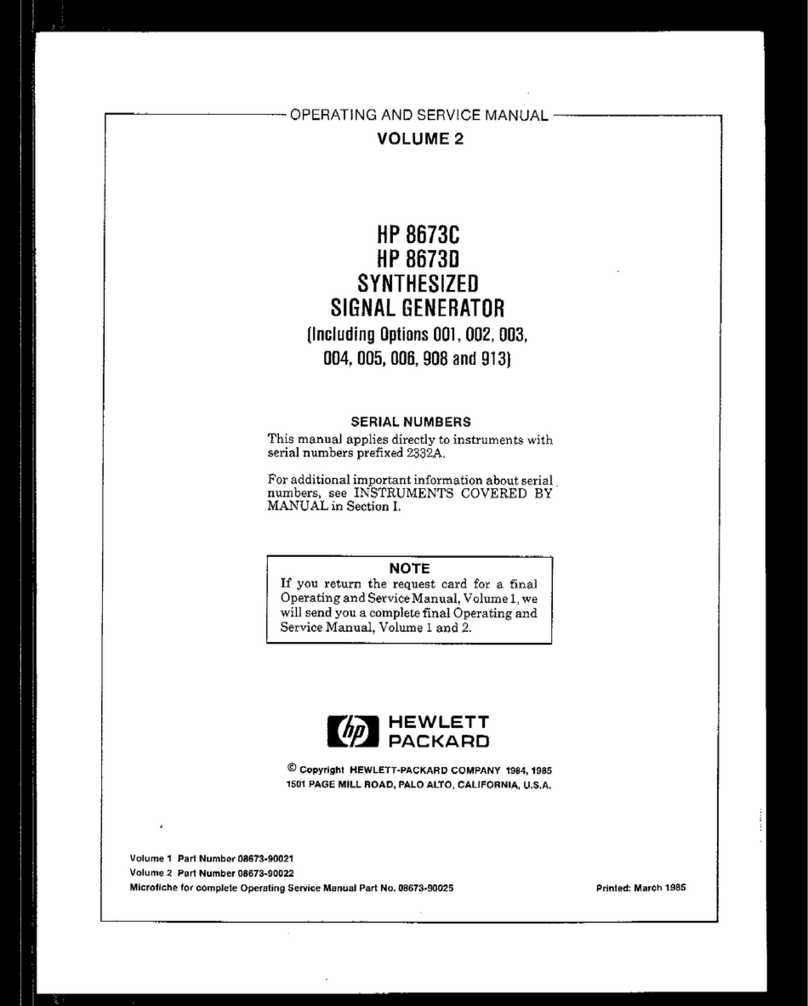

Signal delay

The signal color change delay can be either 10 seconds or 30 seconds. Choose the v

based on your own personal preference. To select 10 seconds the ju per ust be

installed over both pins on the block "DLY"; for 30 seconds the ju per ust only cover

one pin (it doesn't atter which one). You can change this as you wish even when the

power to the Signal Ani ator is on. The two options are illustrated in Figure 9.

DLY

10 s conds

DLY

30 s conds

Figure 9 – signal delay