1

L

OGIC

TECHNOLOGIES

R

AIL

"Sophisticated

Model Railroad

Electronics"

TM

21175 Tomball Pkwy Phone: 281) 251-5813

Suite 287 email: info@logicrailtech.com

Houston, TX 77070 http://www.logicrailtech.com

Block Animator

Tomar semaphore motor, bulb-based &

LED-based, common-anode position

light signal instructions

Revised 10/20/18

Getting started

Thank you for purchasing a Logic Rail Technologies product! Please familiarize yourself ith all the instructions prior to

installing this board. These instructions cover the version of the Block Animator that provides 3-aspect signaling for Tomar

semaphore motors, bulb-based signals (including position light signals), and LED-based, common anode (positive) ired

position light signals.

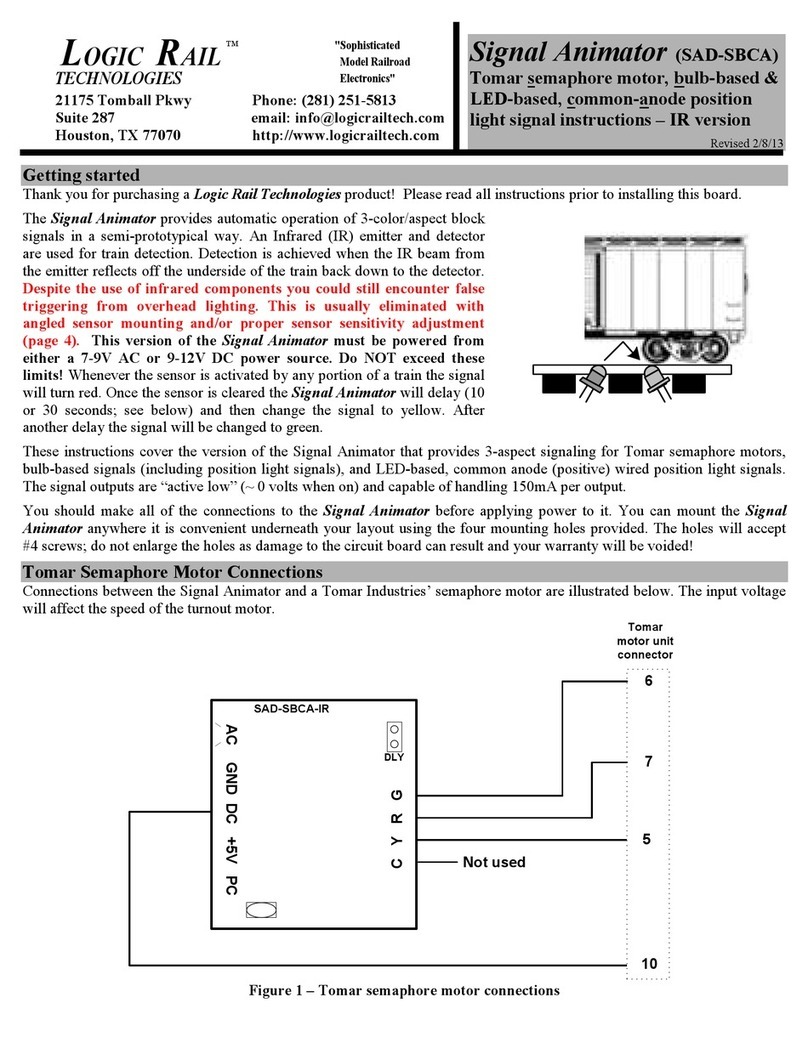

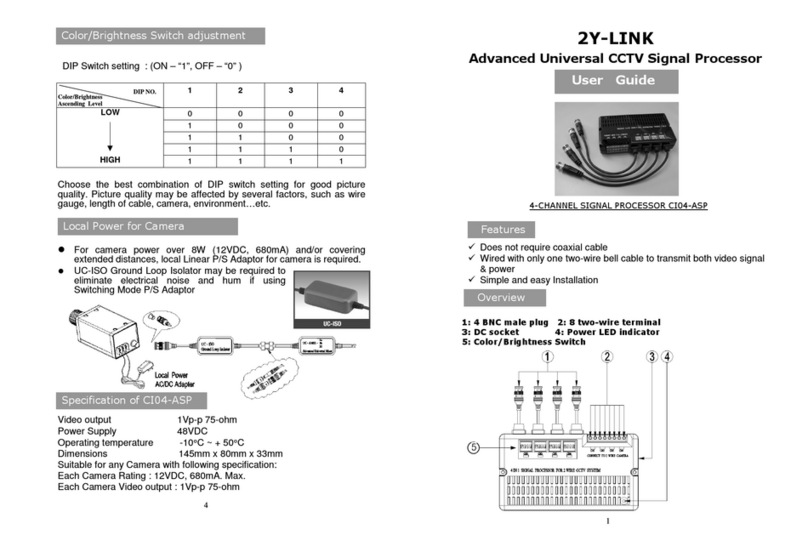

The Block Animator (BA) provides automatic operation of t o 3-aspect block signals in a semi-prototypical ay. Four

photocells are used for bidirectional train detection. The layout of the signals (or semaphores) and photocells is illustrated

belo .

Photocell

W1

Photocell

E1

Photocell

W2

Photocell

E2

Signal

EB

Signal

WB

W E

The BA operates the signals as described next. In the absence of any trains the t o signals ill be green. No consider a

train traveling eastbound. When photocell W1 is covered signal WB ill change from green to red and ill remain red as the

train continues eastbound and subsequently covers signal W2. When the train then covers photocell E2 signal EB ill change

from green to red. Once the train has totally uncovered photocells W1 and W2 then signal WB ill change from red back to

green. As the train continues eastbound to ards photocell E1 signal EB ill remain red. Once the train has passed over

photocell E1 and totally uncovers both it and photocell E2 signal EB ill change to yello ; this mimics the behavior of the

train entering the “next block.” After a time delay (10 or 30 seconds; see belo ) signal EB ill change to green. Signal

operation for a estbound train is similar ith signal EB changing from green to red and back to green hile signal WB

changes from green to red to yello and back to green.

You should make all of the connections to the BA before applying po er to it. You can mount the BA any here it is

convenient underneath your layout using the four mounting holes provided. The holes ill accept #4 scre s; do not enlarge

the holes as damage to the circuit board can result and your arranty ill be voided!

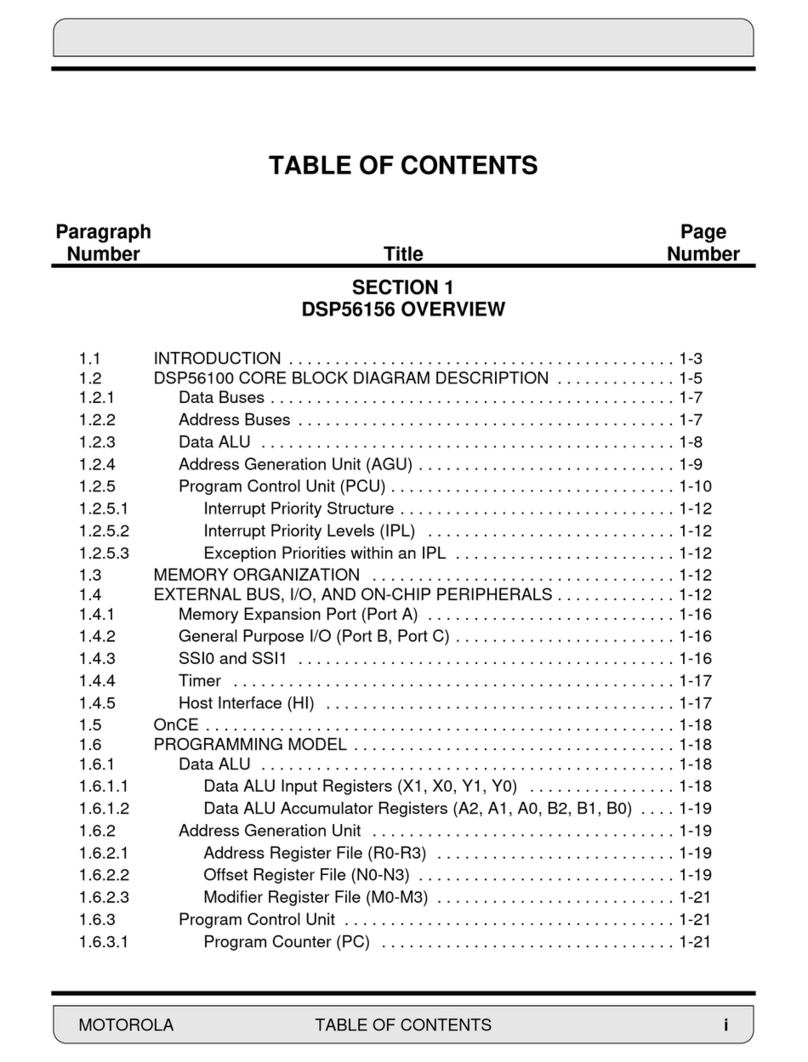

The BA board has a set of 6 configuration s itches on it. Each s itch is described belo .

Switch Name Meaning when OFF/OPEN Meaning when ON/CLOSED

SETUP BA is in normal operating mode BA is in photocell setup mode

DELAY Yello to Green delay is 30 seconds Yello to Green delay is 10 seconds

SIG_EB MUST use this setting Do not use this setting

SIG_WB MUST use this setting Do not use this setting

YELHUE Not used Not used

APPRL Approach Lighting is Disabled Approach Lighting is Enabled

Approach Lighting

The concept of Approach Lighting is quite simple. A signal (excluding semaphores) remains dark (not illuminated) until a

train approaches it (i.e. the block in advance of the signal is occupied). This has been primarily used in the estern U.S. in

remote locations here signal equipment operates on battery po er. Having the signals unlit most of the time saves battery

po er as ell as prolongs the life of the bulbs. The “rule” for illumination is simple: the signal shall be illuminated hen the

preceding block is occupied. The BA supports this feature ( hen the APPRL s itch is ON/CLOSED) and orks as follo s.

Signal EB ill be illuminated henever an eastbound train covers photocell W1 and ill keep signal EB illuminated until

photocell E2 is covered and then subsequently uncovered. Note that if the eastbound train covers and then uncovers photocell

W1 but after 35 seconds hasn’t covered photocell E2, then the BA ill assume the train has actually reversed direction and

ill turn the signal off. Similarly, signal EB ill also be illuminated henever a estbound train covers photocell E2 and

ill keep signal EB illuminated until photocell W1 is covered and then subsequently uncovered. The same 35 second

“timeout” mechanism is in effect for this direction of travel too. Signal WB ill operate in a similar manner ith respect to

photocells E1 and W2. You can turn approach lighting on or off at any time. Hopefully it is obvious that if you turn this

feature off then the signals ill be illuminated all the time!