Operating Manual MNL 100 2

D

De

ea

ar

r

c

cu

us

st

to

om

me

er

rs

s

With the purchase of a laser from the MNL 100 series, you

have selected a state-of-the-art Nitrogen Laser.

The laser satisfies sophisticated needs and demanding

goals in various applications within the industrial area. The

following properties reveal the advantages of the MNL 100.

High pulse power

Minimal beam divergence

Minimal time jitter

Pulse halfwidths in the sub- and nanosecond range

Long lifetime

Low operating costs

These properties make the laser attractive for applications

where high quality, stable output and cost-effectiveness are

required.

The MNL is mainly used in

MALDI-TOF-Mass spectroscopy

Laser-induced fluorescence spectroscopy

Time-resolved spectroscopy

laser-induced plasma spectroscopy

Laser ablation

Micro-structuring

Cell dissection under the microscope

Laser acoustics

Calibration of fast sensors

Pump source of dye lasers

Amplification of ultra-short laser pulses

Technological processes like laser-induced bonding,

hardening and cleaning

Special applications in the environment and

biotechnology

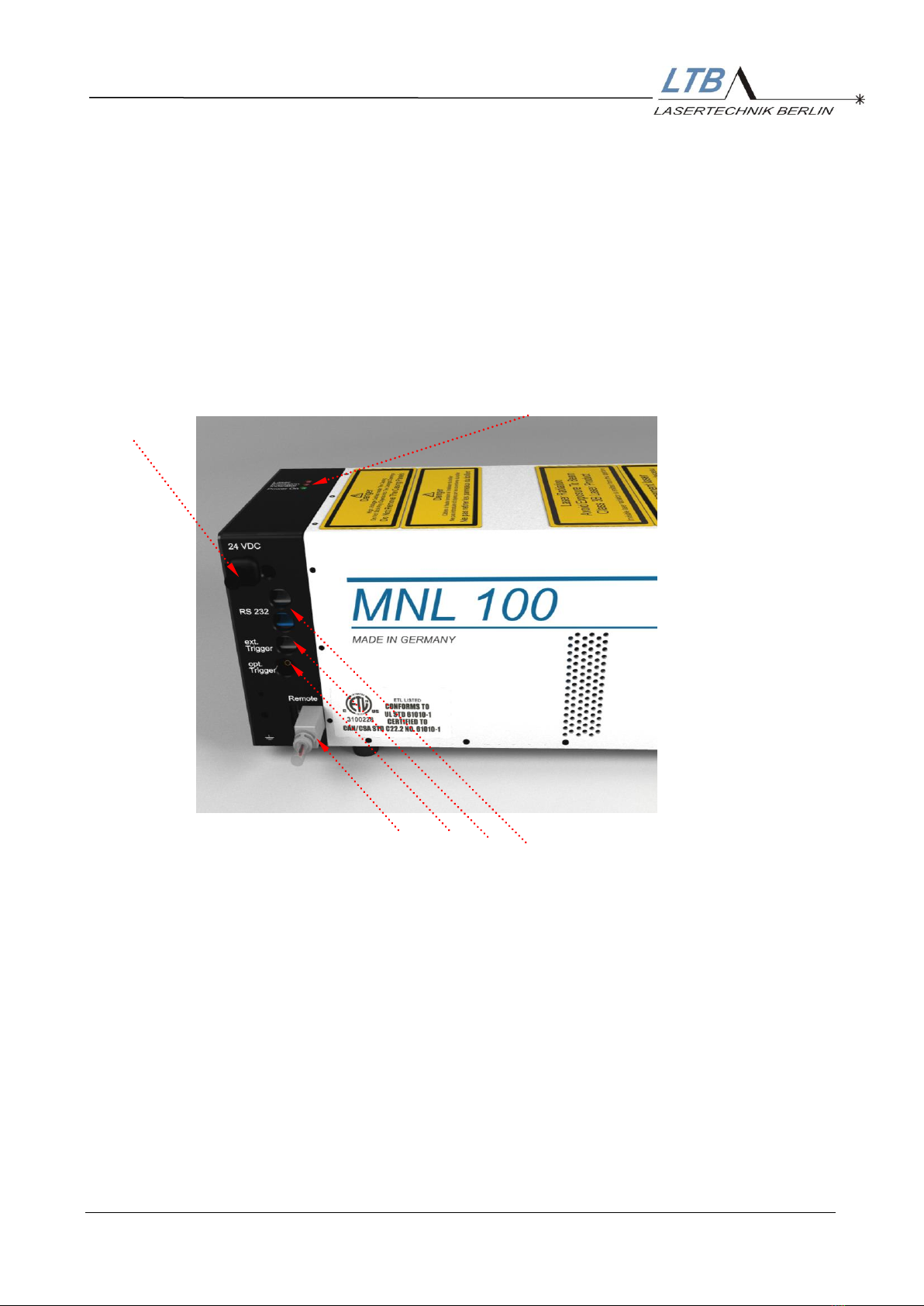

The laser operates on the principle of transversal excitation.

The energy is stored in a capacitor arrangement at about

12 kV. A fast high-current discharge will be triggered by

means of a solid-state high-voltage switch thus generating

laser radiation. All laser functions are controlled and

monitored by an internal laser controller.

Your laser has been carefully tested for all operating states

with LTB’s end test program and left the firm in a good

condition.

LTB wishes you much success in working with the laser on

your projects. If this operation manual does not answer all

your questions, please do not hesitate to contact us.