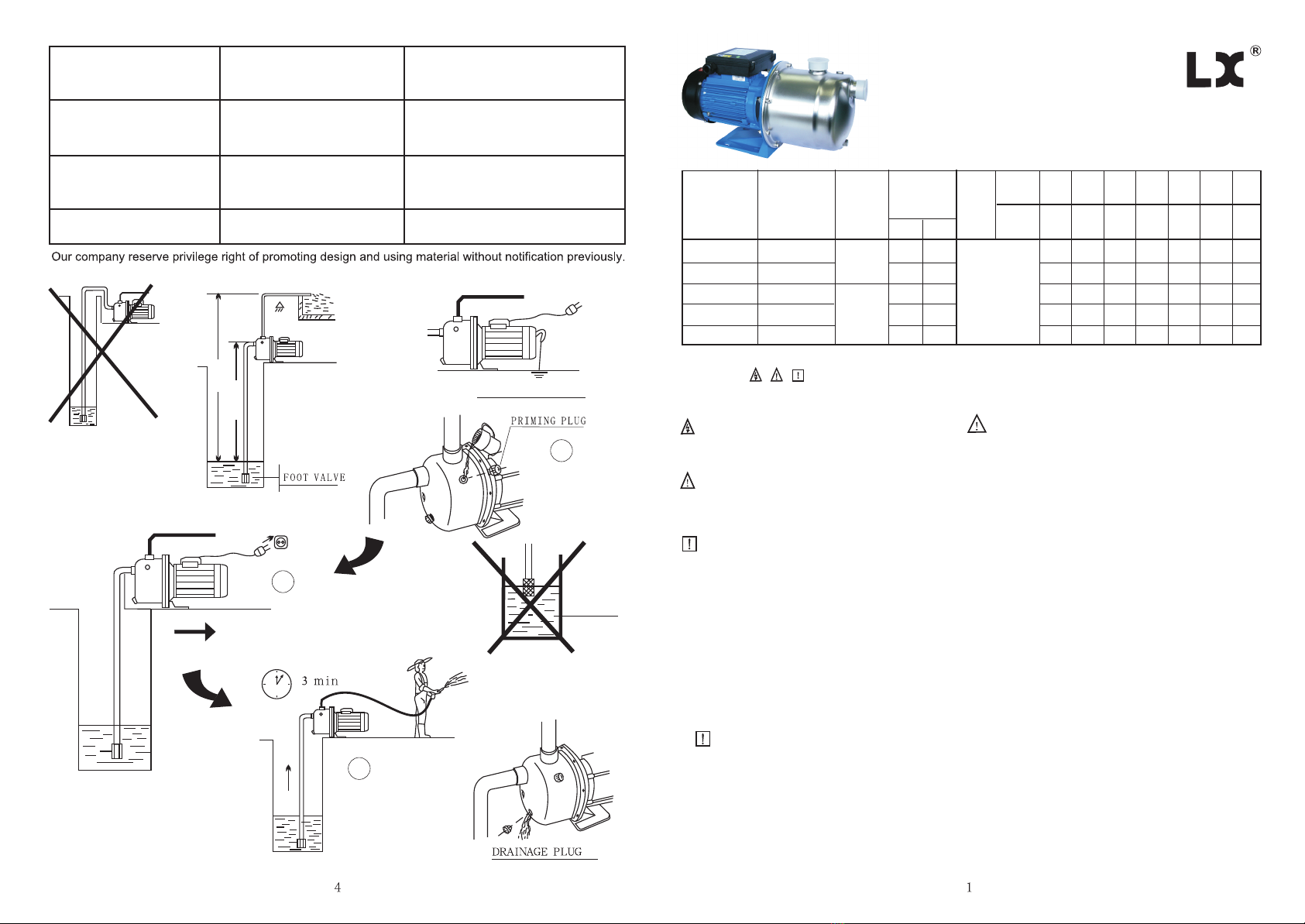

BJZ SERIES STAINLESS

STEEL SELF-PRIMING JET PUMP

INSTRUCTION MANUAL

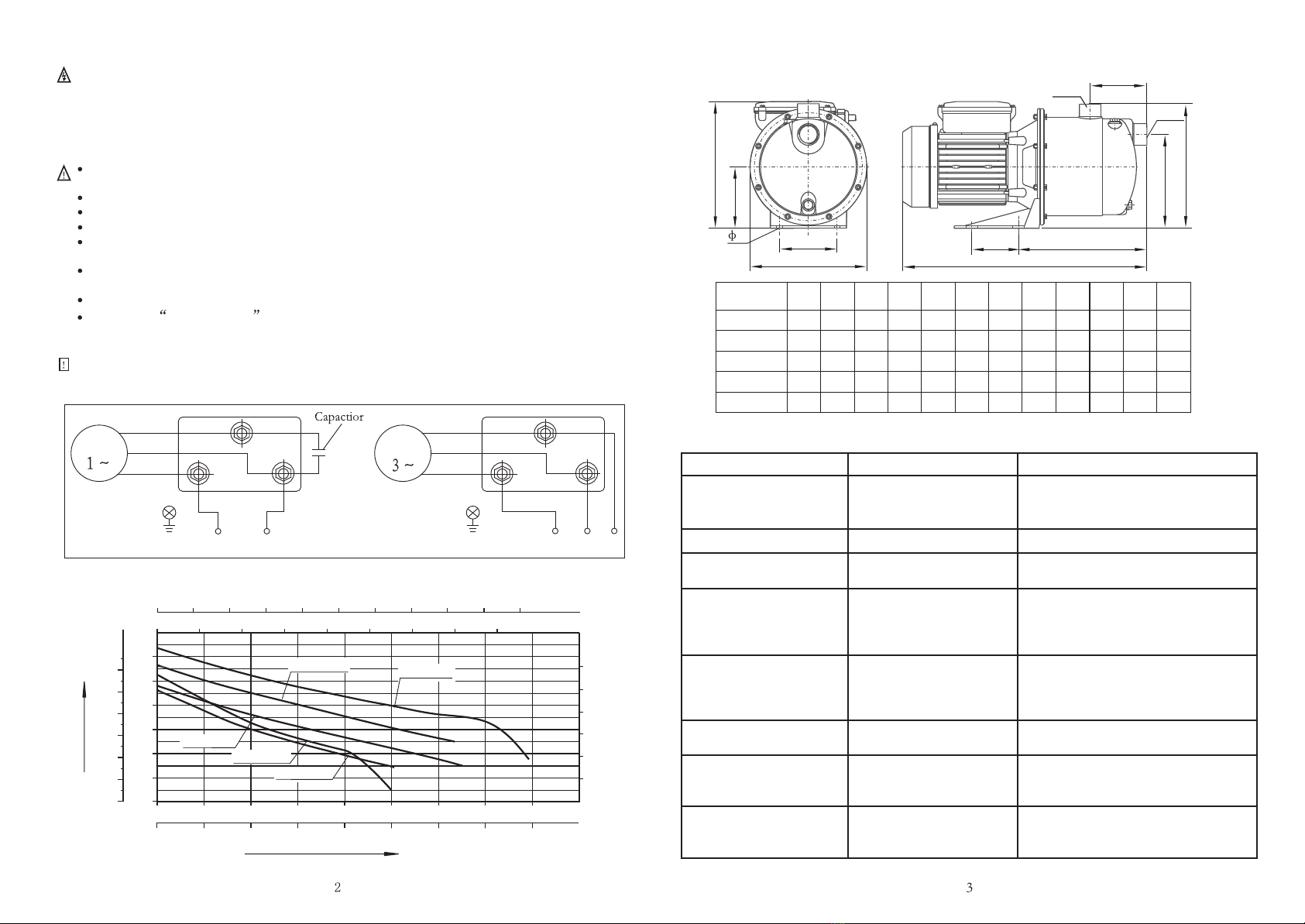

1.Specification

This manual has been conceived to offer the adequate information on the installation, operation and maintenance of our

electro pumps. We suggest you read it thoroughly. These are centrifugal horizontal electro pumps with self-priming capacity

and supplied with century system so to reach suctions of up to 9 mts. Connect a foot valve and the pump will get an im-

0

mediately self-priming.They have been designed to operate with clean water at a maximum temper-ature of 45 C.

Operating with any kind of water, other than that just described should be avoided. These pumps have been built with

first quality materials which submitted to strict hydraulic and electric controls and verified thoroughly.

Following these present instructions and the electrical chart, will help you to achieve a correct installation. If failure to do

this could result in motor overcharge and any other consequences, which we wish to be relieved of.

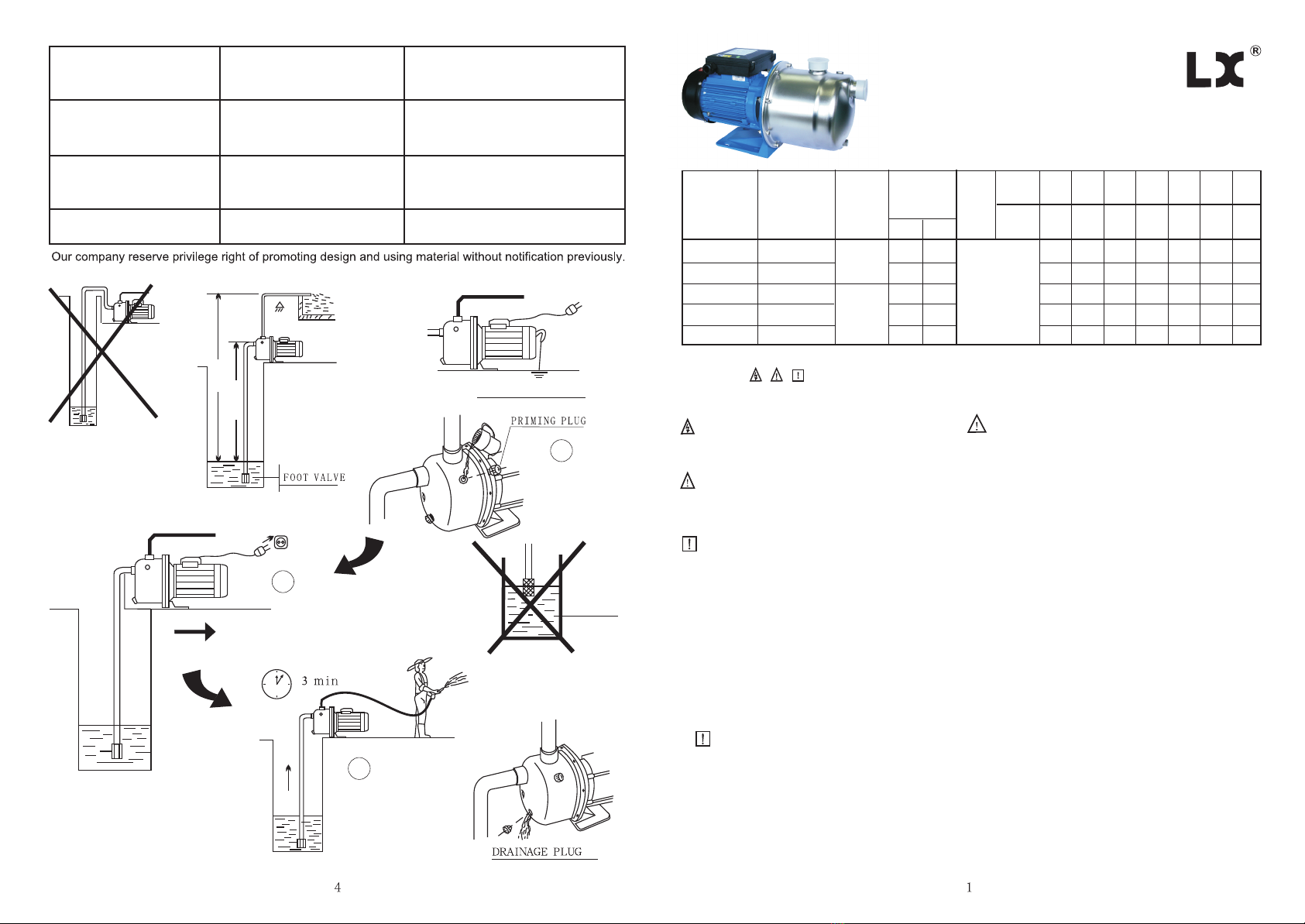

2.Installation

The electric pumps must be placed as possible to the water level in order to obtain the minimum suction lift and

reduce the loss of head. If the installation is be permanent. pump should be attached to the floor or ground using

the holes pump bracket.

They should be installed in dry place and safe form any possible flooding.

3.Pipe assembly

The suction pipe must be resistant to depression and be kept submerged 30 cms below water level to prevent the formation

of whirs and its inscrutability consequence: Air leaks if suction lift is over 7 mts. the use of a pipe of a bigger diameter than

the admission port of the pump is recommended. the unions or connections must be absolutely water-tight. It is recom-

mended to reduce pipe bends to the minimum inclination of 2%. The discharge pipe should have a diameter equal or

bigger than of the pump outlet. In any case should the suction or discharge pipes rest on top of the pump.

2

3

1

Head

Max 9m

RELIABLE GROUNDED

Disassemble and take it to your

official Service Dealer.

Room not properly aired.

There is no suction.

Motor runs butit

gives no pressure.

Air entry.

Seal unions andjoints properly.

Flow is insufficient. Venturi clogged.

There is no suction.

Motor runs butit gives

no pressure.

Pump was not primed. Fill pump bodywith water.

Motor over-heating.

Motor starts and stops

continuously.

Provide good ventilation.

WATER

220V/60Hz,110V/60Hz models are availably on request

This symbol together with one of the following words"Danger"or Warning indicates the risk level deriving

from failure to observe prescribed safety precautions.

DANGER

Wams that failure to observe

the precautions involves a

risk of damage to perons and

/or things.

WARNING

Wams that failure to observe

the precautions involves a

risk of damaging the pump and

/or the plan.t

DANGER

risk

electric shock

Wams that failure to observe

the precautions involves a

risk of electric shock.

This appliance isnot intended foruse by persons

(including children)with reducedphysical, sensory

or mental capabilities,orlackof experience and knowledge,

unlessthey have beengiven supervision or instruction con-

cerning use ofthe app lianceby a personresponsible for

their safety. children shouldbe supervised to ensurethat

they do notplay with theappliance.

Type y attachmentdamaged suppl ycords to berepl aced

by the manufacturer, service agent orsimilarly qualified

person to avoidhazard.

0.37

0.55

0.75

1.0

1

1

1

1

kW

BJZ037(T)

BJZ75(T)

BJZ100(T)

BJZ150(T)

8.5

9

0.3 0.9 1.2 1.8 2.4 3.0 3.6

31 25 23 19 14 9

34 29 26 23 19 16 13

38

47

32

42

30

39

25

34

22

31

19

30

13

29

1

1

1

1

L/min

3

m/h

5 15 20 30 40 50 60

(m)

Q

Model

Power(P )

2

MAX.

Suction

(m)

Bore

(inch)

in out

Flow

Head

11

BJZ060(T)

0.55 38 29 26 21 17 4

-

-