INSTALLATION, OPERATION & MAINTENANCE MANUAL CNW Centrifugal Fiberglass Fan Bulletin 10-02-February 2017

M.K. Plastics Corp. Montréal, Québec, Canada +1-514-871-9999 www.mkplastics.com Page 7 of 12

CNW fans that are Direct Drive Arrangement 4 are supplied

with a motor shaft that is drilled and tapped to

accommodate the fan shaft. Contact M.K. Plastics if a

motor replacement is ever necessary.

Should the motor prove defective within a one-year period,

contact M.K. Plastics directly, or you may contact your

nearest motor service representative.

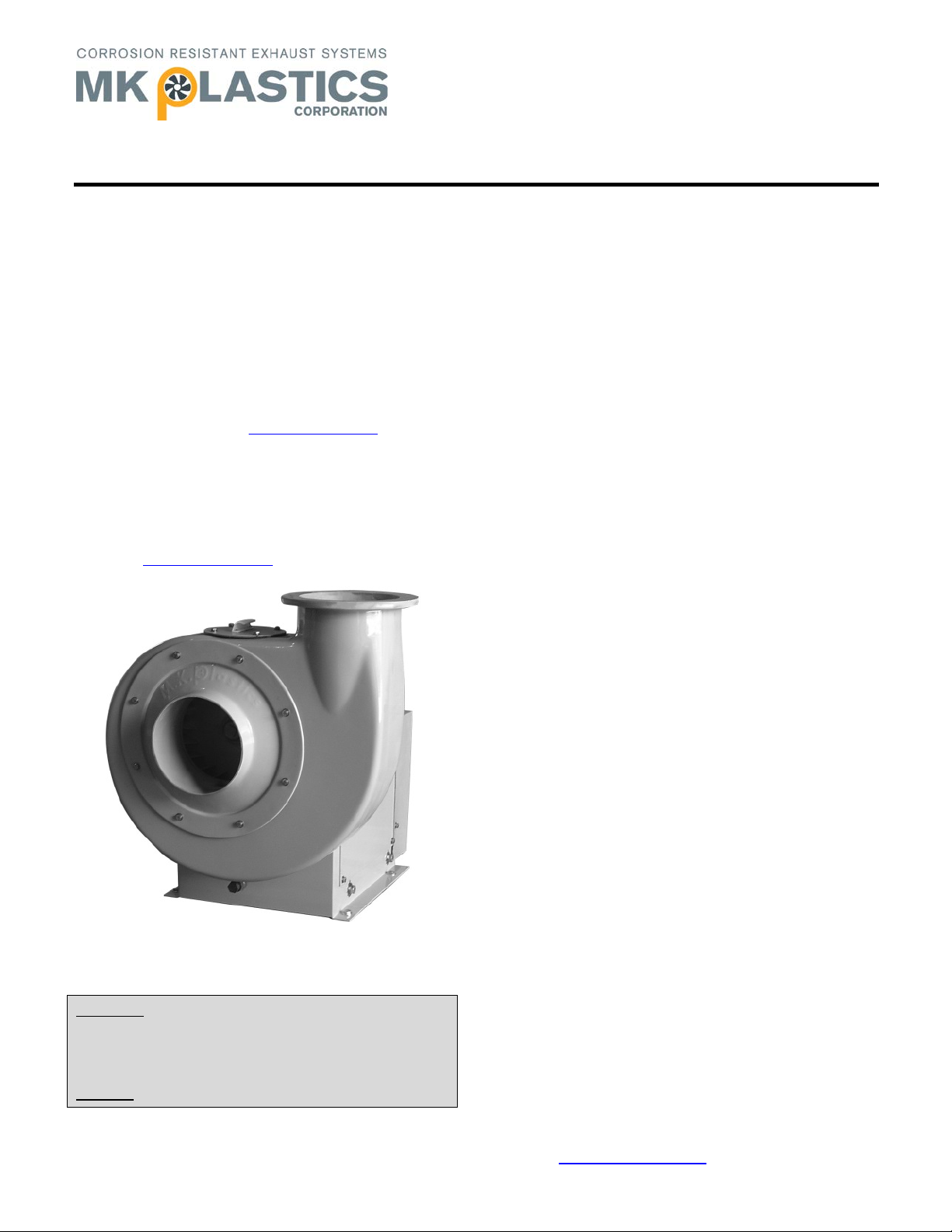

Wheel and Shaft Maintenance

Periodically inspect the shaft and wheel for dirt buildup,

corrosion, and signs of excess stress or fatigue. The wheel

can be inspected via the Access Door. Clean the

components as necessary. If the wheel is removed for any

reason, make sure that it is securely attached to the shaft

before restarting the fan.

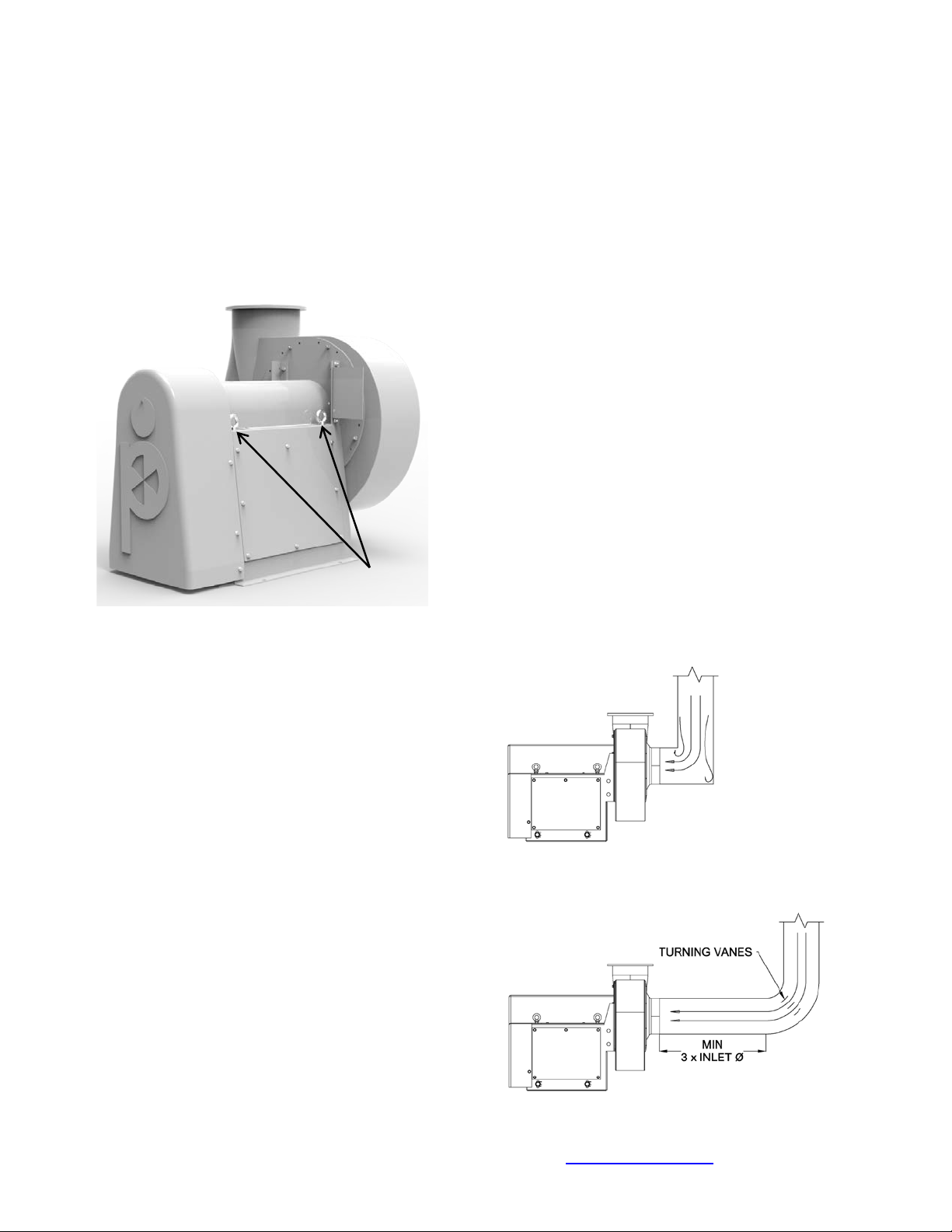

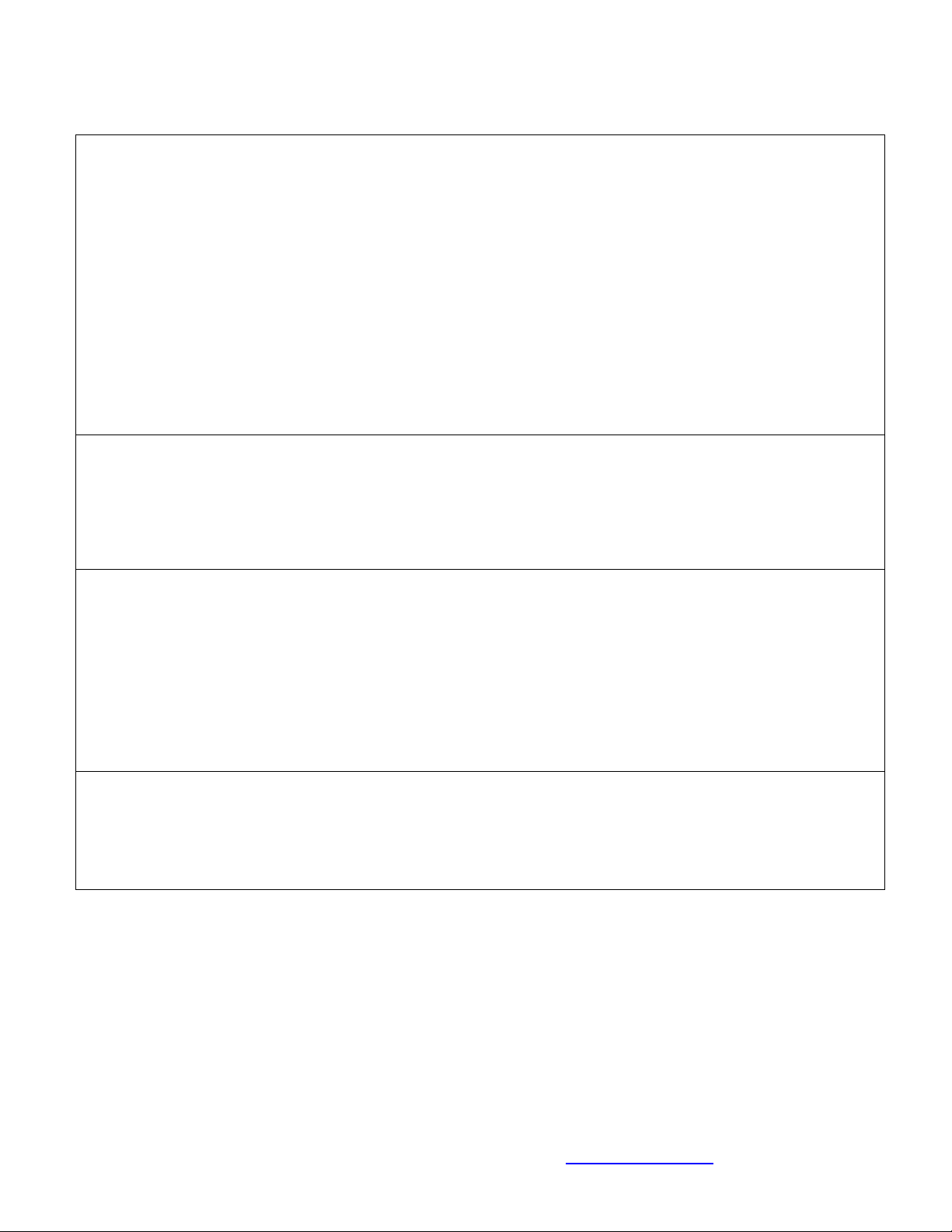

Drainage Detail

All CNW fans come with outlet drains due to water or

condensation that may accumulate. Proper disposal of the

water is necessary. Connect the drain outlet to a drainage

system (by others.) Piping must have adequate pitch for

proper runoff and be supported (if needed) to prevent the

possibility of sagging and overflow. The trap should be

filled before start-up.

“A” must be greater than system static pressure

“B” must be greater than ½ of the system static pressure.

“C” 1” water seal Figure 19

Drainage Detail

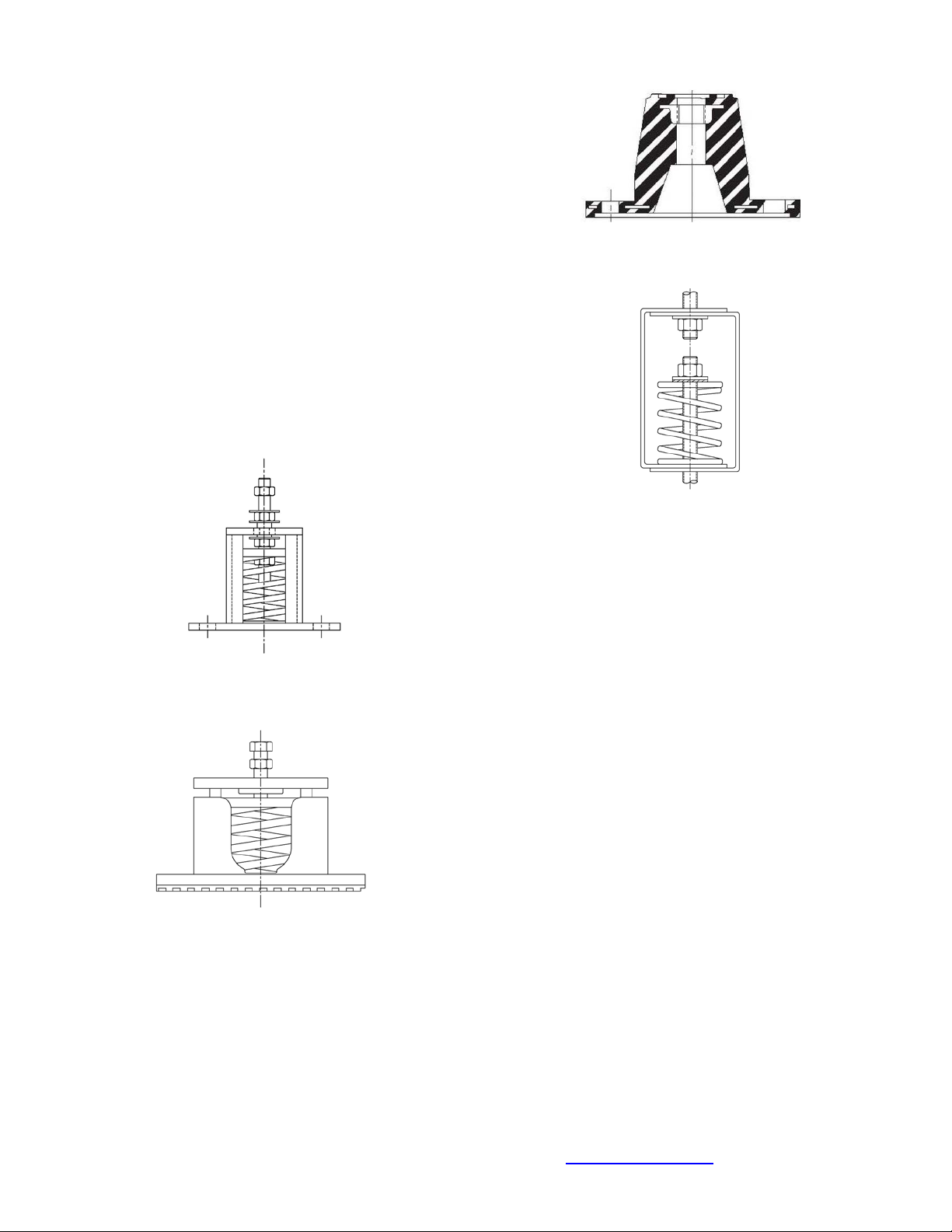

Fan Bearings

All CNW fans are equipped with solid pillow block bearings.

They are equipped with an integral set screw lock.

Fan Bearing Lubrication:

All CNW Fans use only Self-Lube pillow block bearings.

Bearings are factory charged with the correct amount of

grease and do not require further grease charge.

Re-lubrication is not required. See Figure 20.

Figure 20

Solid Pillow Block Bearing

Note: The motor bearing lubrication should be per the

motor manufacturer’s instructions.

Fan Bearing Replacement:

Fan bearing replacement intervals are defined by the fan

operator. M.K. Plastics does not define a schedule for

bearing replacement, as it is dependent on the

environment, usage and maintenance of each specific fan

installation. With proper installation, operation and

maintenance however, CNW bearings should last several

years. All CNW fans are equipped with NSK, RHP Self-

Lube cast iron pillow block units, NP or MP series.

Indicators that bearings need replacement include

excessive noise, vibration or heat in the vicinity of the

bearings.

In applications where contact with the exhaust poses a

serious contamination factor, the bearings can be removed

without removing the wheel and inlet cone. In this case, the

shaft must be held in place with suitable straps or bracings

firmly secured around the bearing support frame. The shaft

must be supported to restrict any lateral movement of both

the shaft and impeller.

Removal of Wheel, Shaft & Bearings:

1. Take note or make a sketch of the position on the

shaft of both bearing races, setscrews and the

wheel and sheave. If you are replacing the shaft

as well, these notes or sketch will give you

reference.

2. Mark the location and orientation of the inlet to

the casing and remove. Note the clearance

between the wheel and the inlet cone. This will

give you access to the wheel.

3. Remove the drive sheave from the shaft.

4. Start wheel removal by unscrewing the front

protective cap and then the nut, washers and

threaded stud assembly that holds the cap to the

fan shaft. Unscrew the setscrew collar. The wheel

can now be removed from the fan shaft. CNW

fans do not have bushings, the wheel is held in

place on the shaft with the threaded rod assembly,

the setscrew collar and key.

5. Remove the bearing housing mounting bolts and

remove the shaft and bearings as one unit. Keep

any existing shims in place.

6. The bearings are attached with set screws;

unscrew and slide the assembly off as one piece.

Tap on the bearing with a wood block and hammer

to remove if necessary.

7. If the existing shaft is being used, check the

shaft for nicks, burrs and damage. Remove any