Model BK-229 Parts List

Ref. Parts No. Description Quantity

1A57-6-2001-108 Foot pedal 1

2* 677-5-0070-101 E-clip 2

3A57-6-2003-102 Foot pedal axle 1

4D05-6-1001-106 Manifoldplug 1

5A57-6-3007-105 Noisesuppressor 1

6666-5-0160-107 C-clip 1

7* 573-7-0070-207 Back-upring 2

8* 511-7-0070-104 O-ring 2

9A57-6-4002-201 Oiloutlet valve 1

10 512-2-0043-108 Compressionspring 1

11 601-7-0009-001 Steel ball 1

12 511-7-0410-102 O-ring 1

13 649-1-0050-055 Allen Screw 6

14* 515-3-0051-104 Copperwasher 6

15 A57-6-1603-202 Reservoirtop plate 1

16 644-1-0060-05311 Screw 1

17 503-9-0050-106 Steel ball seat 1

18 601-7-0006-005 Steel ball 1

19* 532-3-0127-106 Specialwasher 2

20 A59-6-1017-102 Highpressurevalve 1

21 A17-6-1216-102 Valvestem 1

22 512-2-0067-010 Compressionspring 1

23 A17-5-1603-300 Pressure adjust nut 1

24 601-7-0008-009 Steel ball 1

25 A59-6-1015-108 Oilentrancevalve 1

26 520-8-0134-101 Filter 1

27* A57-6-1602-109 Gasket 1

28 A57-6-1601-107 Reservoir 1

29 649-1-0060-122 Allen Screw 4

30 A57-6-1002-105 Motorcover 1

31 A17-6-2105-108 Gasket 2

32 A17-4-2100-500 Air piston assy. 1

33 A57-6-1003-107 Cylinder 1

34 A57-3-1011-108 Piston assy. 1

35 512-2-0410-017 Compressionspring 1

36 A57-6-1014-102 Pistoncover 1

37 A57-6-2023-108 Bushing 1

38 573-7-0120-105 Back-upring 1

39* 522-7-0120-007 U-cup 1

40 A59-6-1013-105 Pump piston 1

41 A57-6-1016-106 Washer 1

42 H18-6-8103-104 Specialwasher 1

43 A57-6-1001-204 Base 1

44 A57-6-1605-105 Gasket 1

45 511-7-0140-200 O-ring 2

46 512-2-0092-101 Compressionspring 1

47 649-1-0040-007 Allen Screw 1

48 A57-6-5004-109 Air entrance cap 1

49 511-7-0053-104 O-ring 1

50 A57-6-5001-103 Airentrance base 1

51 A17-6-1105-103 Plastic cap (air) 1

52 A57-6-5003-107 Airentrancevalve 1

53 511-7-0080-309 O-ring 1

54 649-1-0050-046 Allen Screw 6

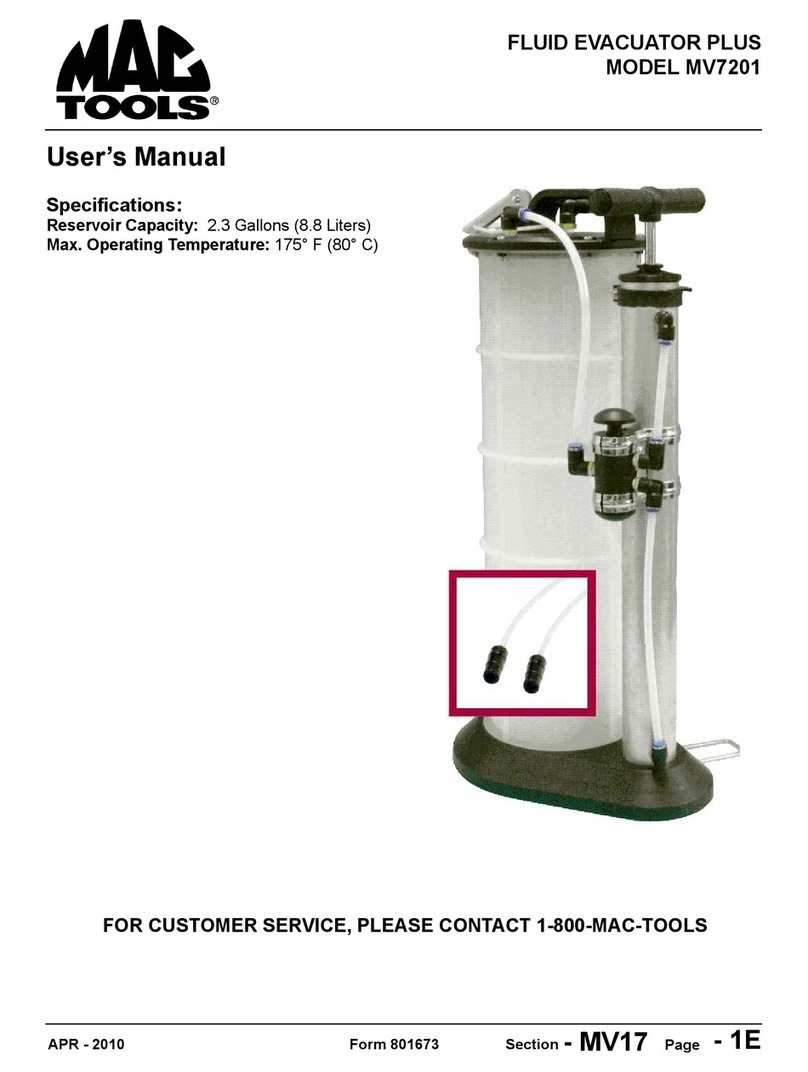

55a A57-3-5007-107 Shippingplug (red) 1

55b A57-3-1900-109 Air vent plug (black) 1

56 512-2-0061-100 Compressionspring 1

57 644-1-0040-204 Screw 1

58* 512-2-0033-105 Compressionspring 1

59 503-9-0035-100 Steel ball block 1

60 601-7-0003-009 Steel ball 1

61 A57-6-3003-305 Releasevalve 1

62 A57-6-3004-307 Releasevalveseat 1

63* 511-7-0100-309 O-ring 1

64* 573-7-0130-209 Back-upring 1

65 552-2-0010-105 Compressionspring 1

66* A57-6-3002-206 Releasevalvepin 1

67 A57-6-3001-112 Releasevalve guide 1

68* 511-7-0050-300 O-ring 1

69* A57-6-1604-103 Gasket 1

70 A17-6-1002-103 Noisesuppressor 1

71 666-5-0250-108 C-clip 1

72 A57-6-4001-209 Oilmanifold 1

—A57-3-9901-101 Repair kit 1

Ref. Parts No. Description Quantity

* Repair kit includes 2, 7, 8, 14, 19, 27, 39,

58, 63, 64, 66, 68, 69

7BK229-M0