macromatic PMD Series User manual

Installation and Wiring

1. Mount the relay on 35mm DIN rail in a suitable enclosure. Use one or two #12-30* solid or stranded copper or copper-clad aluminum con-

ductors —a terminal tightening torque of 7 in-lbs should be used.

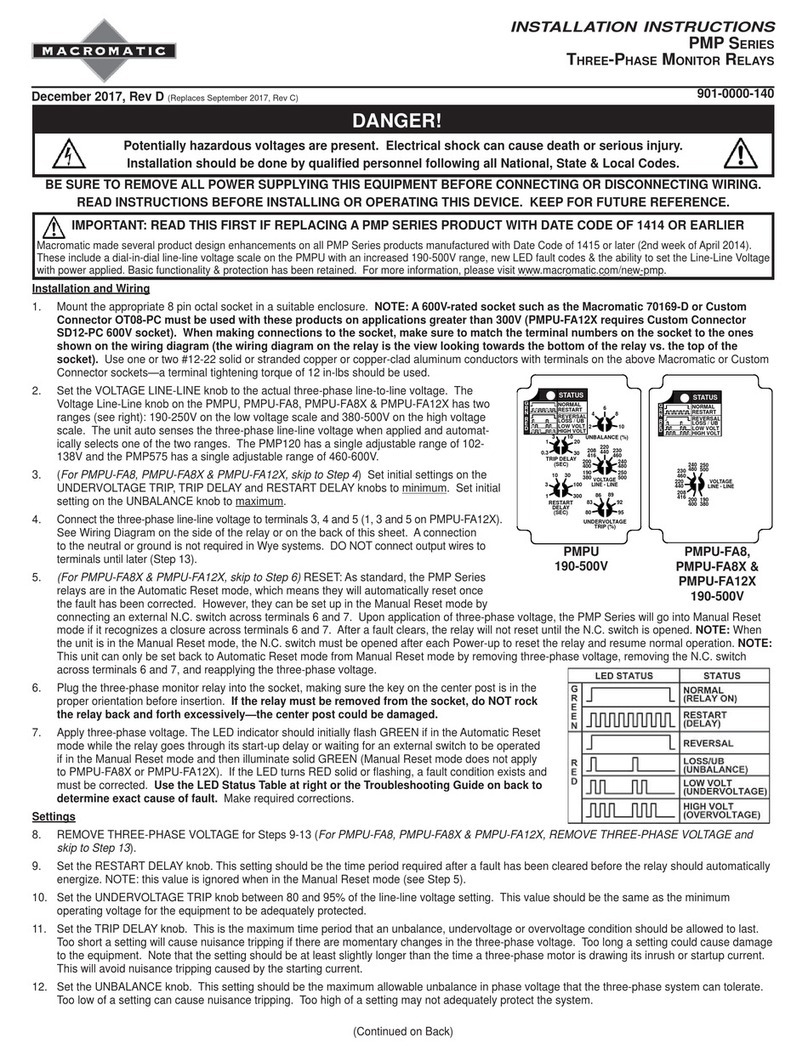

2. Set the VOLTAGE LINE-LINE knob to the actual three-phase line-to-line voltage. The Voltage Line-Line knob on

the PMDU has two ranges (see right): 190-250V on the low voltage scale and 380-500V on the high voltage

scale. The unit auto senses the three-phase line-line voltage when applied and automatically selects one of

the two ranges. The PMD120 has a single adjustable range of 102-138V and the PMD575 has a single adjust-

able range of 460-600V.

3. Set initial settings on the UNDERVOLTAGE TRIP, TRIP DELAY and RESTART DELAY knobs to minimum. Set

initial setting on the UNBALANCE knob to maximum.

4. Connect the three-phase line-line voltage to terminals 1, 2 and 3 (see Wiring Diagram on the side of the relay

or on the back of this sheet). A connection to the neutral or ground is not required in Wye systems. DO NOT

connect output wires to terminals 7-12 until later (Step 12).

5. RESET: As standard, the PMD Series relays are in the Automatic Reset mode, which means they will

automatically reset once the fault has been corrected. However, they can be set up in the Manual Reset mode

by connecting an external N.C. switch across terminals 4 and 5. Upon application of three-phase voltage, the

PMD Series will go into Manual Reset mode if it recognizes a closure across terminals 4 and 5. After a fault

clears, the relay will not reset until the N.C. switch is opened. NOTE: When the unit is in the Manual Reset

mode, the N.C. switch must be opened after each Power-up to reset the relay and resume normal operation.

NOTE: This unit can only be set back to Automatic Reset mode from Manual Reset mode by removing three-phase voltage, removing the

N.C. switch across terminals 4 and 5, and reapplying the three-phase voltage.

6. Apply three-phase voltage. The LED indicator should initially flash GREEN if in theAutomatic Reset mode while the relay goes through its

start-up delay or waiting for an external switch to be operated if in the Manual Reset mode

and then illuminate solid GREEN. If the LED turns RED solid or flashing, a fault condition

exists and must be corrected. Use the LED Status Table at right or the Troubleshooting

Guide on back to determine exact cause of fault. Make required corrections.

Settings

7. REMOVE THREE-PHASE VOLTAGE for Steps 8-12.

8. Set the RESTART DELAY knob. This setting should be the time period required after a

fault has been cleared before the relay should automatically energize. NOTE: this value is

ignored when in the Manual Reset mode (see Step 5).

9. Set the UNDERVOLTAGE TRIP knob between 80 and 95% of the line-line voltage setting.

This value should be the same as the minimum operating voltage for the equipment to be

adequately protected.

10. Set the TRIP DELAY knob. This is the maximum time period that an unbalance, undervoltage or overvoltage condition should be allowed

to last. Too short a setting will cause nuisance tripping if there are momentary changes in the three-phase voltage. Too long a setting

could cause damage to the equipment. Note that the setting should be at least slightly longer than the time a three-phase motor is drawing

its inrush or startup current. This will avoid nuisance tripping caused by the starting current.

11. Set the UNBALANCE knob. This setting should be the maximum allowable unbalance in phase voltage that the three-phase system can

tolerate. Too low of a setting can cause nuisance tripping. Too high of a setting may not adequately protect the system.

* Use conductors rated for 75°C or better when used in ambient air temperatures exceeding 60°C.

(Continued on Back)

INSTALLATION

INSTRUCTIONS

PMD SERIES

THREE-PHASE MONITOR RELAY

901-0000-107

January 2018, Rev H (Replaces December 2017, Rev G) DANGER!

Potentially hazardous voltages are present. Electrical shock can cause death or serious injury.

Installation should be done by qualified personnel following all National, State & Local Codes.

BE SURE TO REMOVE ALL POWER SUPPLYING THIS EQUIPMENT BEFORE CONNECTING OR DISCONNECTING WIRING.

READ INSTRUCTIONS BEFORE INSTALLING OR OPERATING THIS DEVICE. KEEP FOR FUTURE REFERENCE.

IMPORTANT: READ THIS FIRST IF REPLACING A PMD SERIES PRODUCT WITH DATE CODE OF 1521 OR EARLIER

Macromatic made several product design enhancements on all PMD Series products manufactured with Date Code of 1522 or later (4th week of

May 2015).

These include a dial-in-dial line-line voltage scale on the PMDU with an increased 190-500V range, new LED fault codes & the ability to set the Line-Line Voltage

with power applied. Basic functionality and protection have been retained. For more information, please visit www.macromatic.com/new-pmd.

Operation

12. Connect the output terminal wires to terminals 7-12 (see Wiring Diagram on the side of the relay or below).

13. When all connections are made, apply three-phase line-line voltage. The LED indicator should initially flash GREEN while the relay goes

through its restart delay or waiting for an external switch to be operated if in the Manual Reset mode and then illuminate solid GREEN

when all voltage conditions are correct.

14. If the LED does not illuminate solid GREEN during regular operation, a fault condition has occurred. REMOVE THREE-PHASE VOLTAGE,

and check for proper phase rotation, presence of all three phases, and low or high voltage conditions. Use the LED Status Table on the

first page or the Troubleshooting Guide below to determine exact cause of fault. Correct if necessary. Re-energization is automatic

upon correction of the fault condition unless using MANUAL RESET, which requires opening the N.C. switch across terminals 4 and 5 to

reset the unit (see Step 5).

Troubleshooting

If the unit fails to operate properly, check that all connections are correct per the appropriate wiring diagram on the product. Check

Troubleshooting table below. If problems continue, contact Macromatic at 800-238-7474 or e-mail [email protected] for

assistance.

INSTALLATION

INSTRUCTIONS

PMD SERIES

THREE-PHASE MONITOR RELAY

W134 N5345 Campbell Drive Menomonee Falls, WI 53051

Warranty

All catalog-listed PMD Series products manufactured by Macromatic are warranted to be free from defects in workmanship or material

under normal service and use for a period of five (5) years from date of manufacture.

Troubleshooting Guide Typical Connections

(For Load Side connection, contact Macromatic)

Diagram 800

LED STATUS SITUATION SOLUTION

GREEN Motor is not starting Either (a) the relay is going through its POWER-UP/

RESTART delay and will energize the output

contacts when completed; or (b) the relay is in the

Manual Reset mode and waiting for an external

switch to be operated before energizing the output

contacts.

GREEN Motor is not starting The relay is in the run mode and working properly.

Either another control device is preventing the

motor from starting or all wiring should be checked.

NO INDICATION Relay is not ener-

gized and/or motor

is not running

Verify L1, L2 and L3 (A, B & C) are connected to

terminals 1, 2 and 3. Measure the three line-to-line

voltages. If any of the voltages are below the spec-

ified minimum operation voltage, the relay does not

have enough power to operate. Check to see why

operating voltage is low and correct.

RED On power-up or with

motor running The relay is sensing a phase reversal or phase

out-of-sequence (rotation) condition. REMOVE

THREE-PHASE VOLTAGE and switch any two

of the three line connections to ensure the phase

sequence (rotation) is correct.

RED Either a phase loss

or voltage unbal-

ance condition

Make sure all three phases are present. Check for

a blown fuse or a loose or broken wire. Measure

all three line-line voltages and calculate the percent

unbalance—compare to UNBALANCE knob set-

ting. Determine why unbalanced condition exists

and correct it.

RED Low voltage

(Undervoltage) Measure the three line-to-line voltages. If the

average of these three voltages is below the

UNDERVOLTAGE TRIP knob setting, the relay has

tripped due to a low voltage condition. Check for

low voltage condition and correct it.

RED High voltage

(Overvoltage) Measure the three line-to-line voltages. If the

average of these three voltages is > 10% of the

VOLTAGE LINE-LINE knob setting, the relay has

tripped due to a over voltage condition. Check for

high voltage condition and correct it.

Table of contents

Other macromatic Other manuals