7

Special Information on Handling Switchable Permanent Magnets

The magnetic surface of the incorporated Maglogix® MXL permanent magnet is located on the underside of the

magnetic drill stand and generates the magnetic holding force through magnetic flux when activated. The magnet

can be activated independently of the mains voltage by pressing the lever down. For the magnet to be released the

black safety tab must be pushed by using the ball of your hand and the lever pulled upwards. The machine remains

attached to the workpiece even in the event of a power failure.

Material thickness

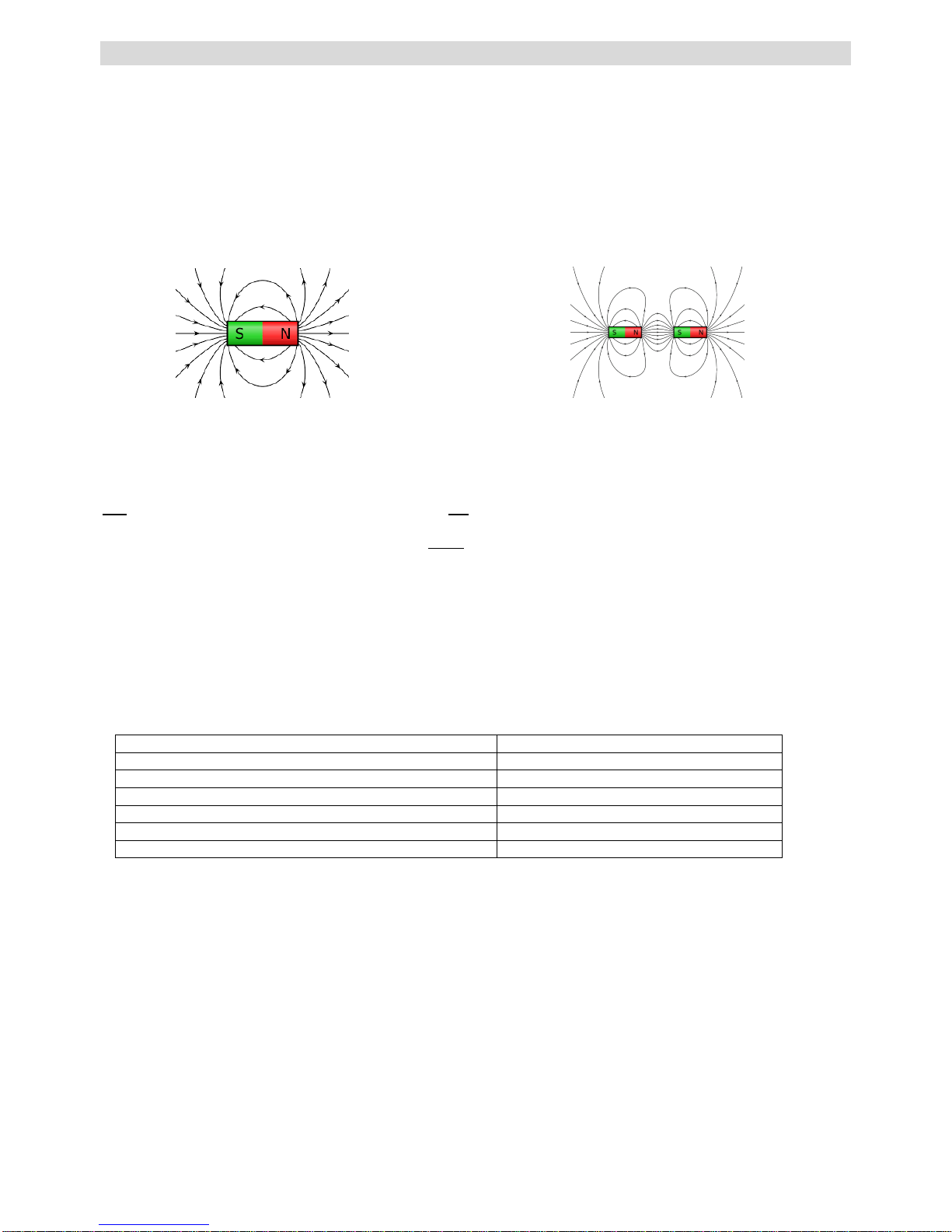

The magnetic flux (north to south field lines) of the permanent magnet requires a minimum material thickness to

flow completely into and across the material below the magnetic contact area. Beyond this minimum material

thickness, the maximum holding force continues to decrease (see Detailed Performance Data, Table 1).

Conventional switchable permanent magnets have a deep penetrating singular (north to south) magnetic field. The

way conventional switchable permanent magnets hold onto steel would be similar to stapling paper together using

one large heavy staple in the center of the page, and not bending the legs together.

The compact multi-field magnetic array of the Maglogix®switchable permanent magnets would be similar to

stapling paper together in a circular pattern with many small lightweight staples close together, and bending the

legs together to achieve an even greater holding force. An infinate number of small magnetic field arrays are the

principle behind the Maglogix®patented switchable magnetic clamps.

Material

Every material reacts in different ways to the penetration of magnetic field lines. The breakaway force of the

magnetic contact area is determined by using common (low carbon) A36 steel. The given load-bearing capacity of

the magnet should be De-Rated based on Table 1. It is up to the user to determine adequate magnetic holding

force for alloys not shown in this table.

Table 1

Surface quality

If a kind of “air gap” is produced between the magnet and the workpiece, this reduces the holding force. In the

same way, paint, rust, scale, surface coatings, grease or similar substances all form an air gap between the

workpiece and the switchable magnet, reducing the holding force.

Maximum operating temperature

The high-power permanent magnets installed in the magnetic clamp will maintain their load-bearing capacity up to

a maximum operating temperature of 176°F (80°C). Exceeding this maximum operational temperature may cause

irreversible damage.