4

STARTING REGULATIONS

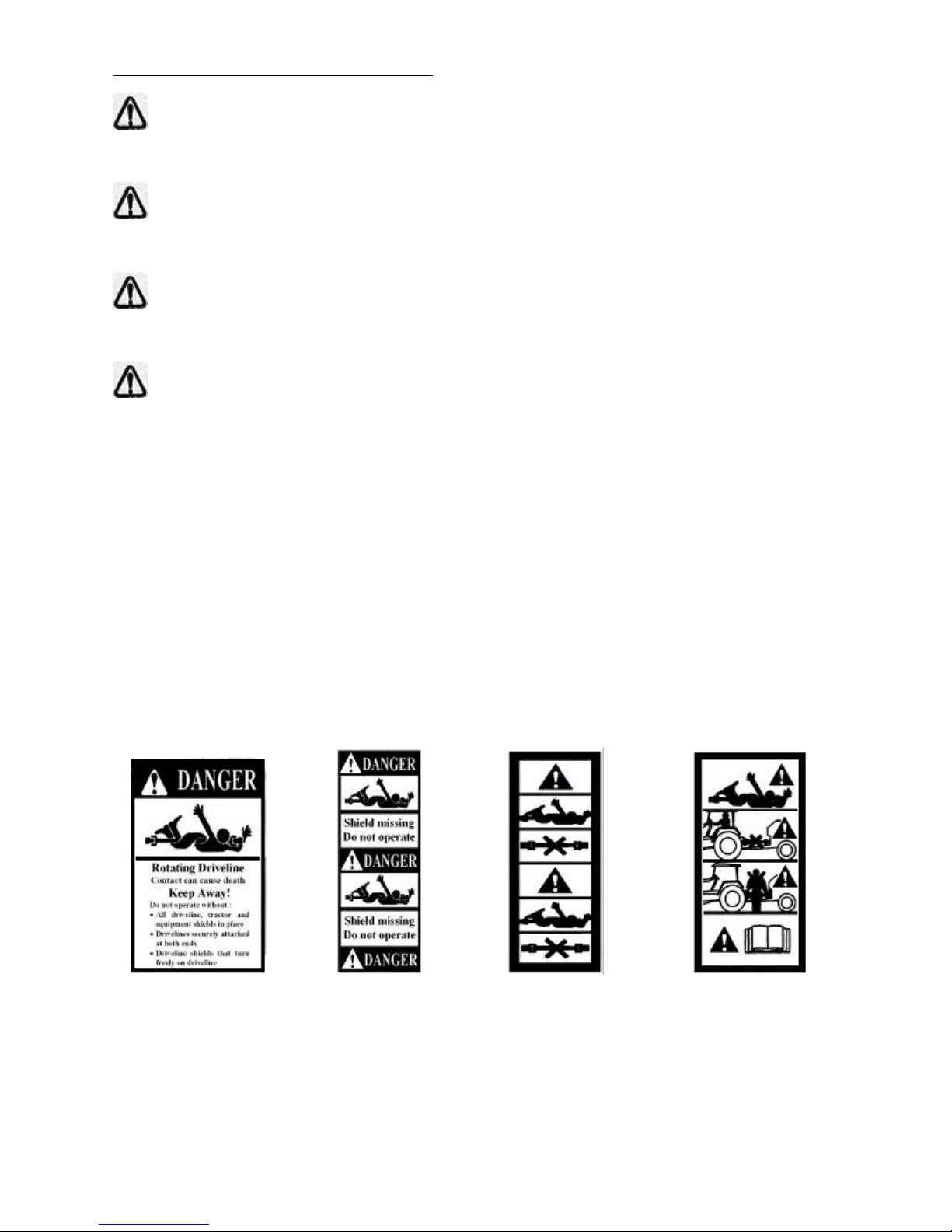

1. Always check that any imminently dangerous condition has been appropriately eliminated before using

the implement. Check that all guards and safety shields are installed, efficient and correctly mounted in

place.

2. Never allow inadequately trained personnel to use the implement.

3. Before starting, always check that there are no persons, particularly children and animals, within the

operative range of the implement. Examine the work area in order to become familiar with the type of

soil in question. Check that there are no obstructions or objects in the area that could be caught up by

the implement and thrown up at a distance. Clean all such objects from the area.

4. Never work near roads, paths, housing areas or places potentially frequented by people, vehicles,

animals, etc. If such action is inevitable, check that these areas are deserted be-fore beginning work and

while on the job.

5. Never start the tractor before being correctly seated in the driving position. Never start a faulty

implement, even when such a condition is only suspected. Contact your nearest dealer, or the person in

charge, and ask for the implement to be inspected.

GENERAL OPERATION

1. Never ever use the mower under influence of alcohol or the effect of medicines such as tranquillisers,

sedatives, stimulants, drugs or any other substance as could slow or alter the reflexes or sight.

2. Never ever work when there are persons on the implement .No one must ride on the tractor apart from

the driver unless this is explicitly allowed by the tractor manufacturer. The tractor must be equipped with

a roll-bar and/or all other safety devices prescribed by the current laws in force. To ensure his personal

safety, the operator must use these devices correctly. Consult and strictly comply with the instructions in

the tractor use and maintenance manual.

3. The operator should never allow himself to be distracted when working. He should pay great attention

and concentrate on what he is doing. Constantly keep the vehicle under control and always remember

how to quickly stop and switch off both the tractor and implement.

4. Always check that children, adults and animals keep at an adequate safety distance from the mower

when it is in use.

5. Take great care when working on sloping surfaces. It is preferable to work upwards or downwards rather

than crosswise in order to avoid the risk of over-turning. Always check and comply with the tractor

manufacturer's instructions, particularly in relation to the maximum gradient on which it is possible to

work. When working on slopes, it is advisable to reduce the work speed, gradually varying the speed

and direction of the vehicle during manoeuvres. Never repeatedly stop and start the machine.

6. Never operate on wet, slippery grass or soil or where the tyre grip is precarious. If such action is

inevitable, always work at low speed to ensure the operator's safety. Pay great attention to any

obstructions, stones or other objects which could hit the knives. The tractor engine must always be

turned off, and the ignition key must be removed from the dashboard when intervening on the machine.

For example, when it is necessary to detach the machine from the tractor or if grass or other objects that

might have become tangled up in it must be removed.

7. Before dismounting from the tractor, always disengage the power takeoff (P. T.O.), turn off the engine,

remove the ignition key from the dashboard, insert the brake, and do not approach the machine before

the tools have come to a complete stop.

8. After having hit an obstacle, simultaneously stop the tractor and machine tool, turn off the engine,

remove the ignition key from the dashboard, insert the brake, and check for any possible damage. If the

machine has been damaged, all repairs must be carried out before continuing the working process.

Always carry out any required repairs before continuing work. When the knives are turning, always keep

the limbs well away from moving parts and those which heat during operation such as the over gear unit.

Never ever attempt to check or adjust the belt tension while the implement is operating. Always stop it

before this operation. Never ever lubricate the machine while it is operating, or when the PTO is

engaged.

9. Never smoke while refuelling. Never refuel near smouldering, sparking material or open flames.

10. Always check whether the soil around the tractor is slippery. Clean all mud from the soles of the shoes

before mounting the tractor. Keep the steps, bearing surfaces, handrails, shackles and tractor pedals

(brake, clutch and accelerator) clean and free from all foreign bodies such as oil, grease, mud or snow in

order to prevent all possibility of slipping or tripping.

11. Keep the operator support areas on the tractor free from mud or any thing else that could cause the

operator to slip when the implement is mounted or demounted from the tractor. Never jump on or off the

tractor. Always keep both hands and one foot well anchored. Never use the control levers or hose pipes

as holds. These are mobile parts and do not offer a safe grip. Involuntary activation of a control could

also cause the tractor or implement to accidentally move. Before the machine is released from the

tractor, it should be rested on the ground in a stable position using the support foot where installed.