4ENGLISH

6. Always keep proper footing and operate the

chain saw only when standing on xed, secure

and level surface. Slippery or unstable surfaces

such as ladders may cause a loss of balance or

control of the chain saw.

7. When cutting a limb that is under tension be

alert for spring back. When the tension in the

wood bres is released the spring loaded limb may

strike the operator and/or throw the chain saw out

of control.

8. Use extreme caution when cutting brush and

saplings. The slender material may catch the saw

chain and be whipped toward you or pull you o

balance.

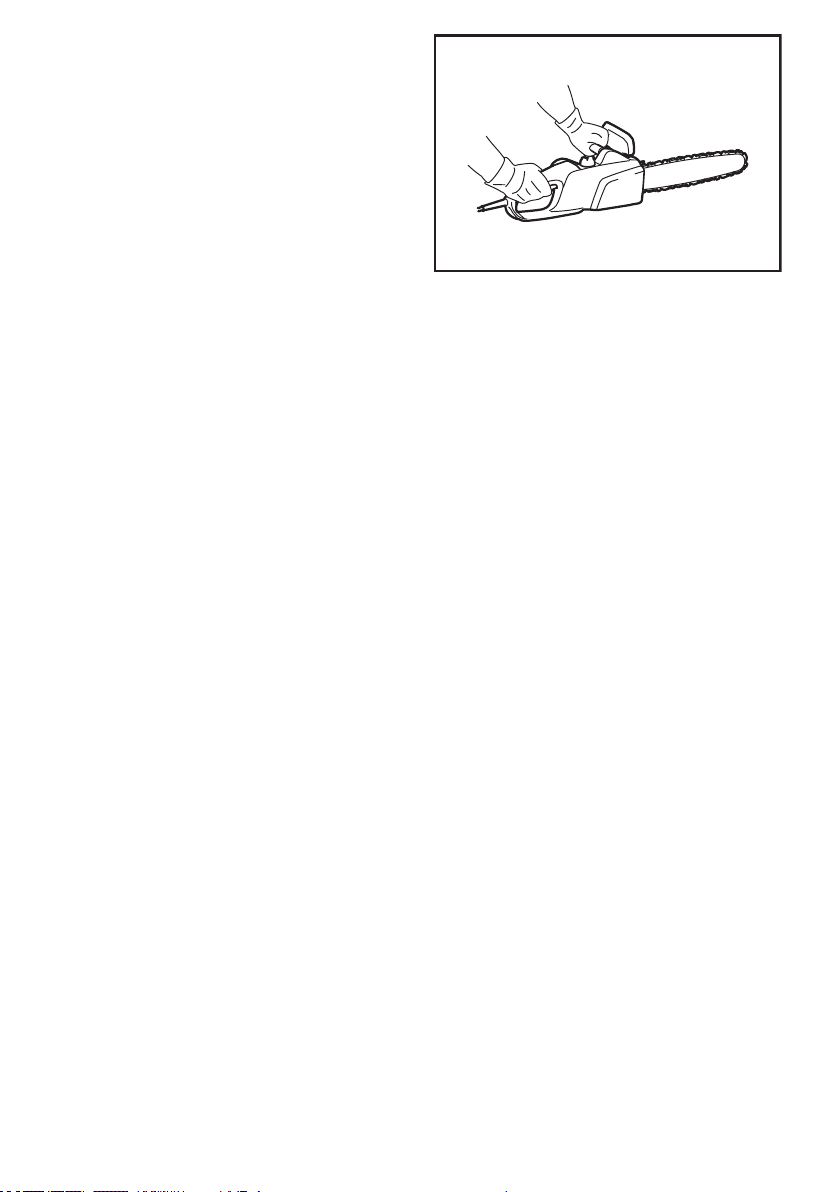

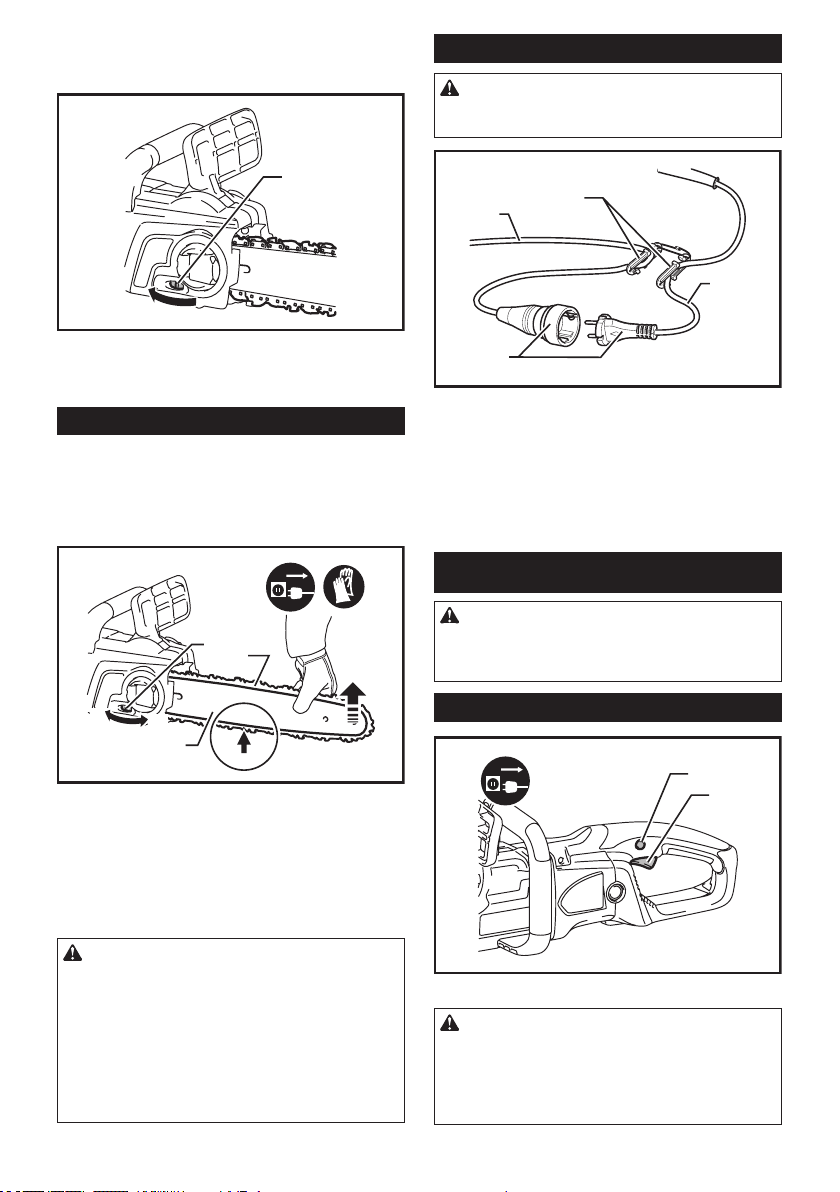

9. Carry the chain saw by the front handle with

the chain saw switched o and away from your

body. When transporting or storing the chain

saw always t the guide bar cover. Proper

handling of the chain saw will reduce the likelihood

of accidental contact with the moving saw chain.

10. Follow instructions for lubricating, chain ten-

sioning and changing accessories. Improperly

tensioned or lubricated chain may either break or

increase the chance for kickback.

11. Keep handles dry, clean, and free from oil and

grease. Greasy, oily handles are slippery causing

loss of control.

12. Cut wood only. Do not use chain saw for pur-

poses not intended. For example: do not use

chain saw for cutting plastic, masonry or non-

wood building materials. Use of the chain saw

for operations dierent than intended could result

in a hazardous situation.

13. Causes and operator prevention of kickback:

Kickback may occur when the nose or tip of the

guide bar touches an object, or when the wood

closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a sudden

reverse reaction, kicking the guide bar up and

back towards the operator.

Pinching the saw chain along the top of the guide

bar may push the guide bar rapidly back towards

the operator.

Either of these reactions may cause you to lose

control of the saw which could result in serious

personal injury. Do not rely exclusively upon the

safety devices built into your saw. As a chain saw

user, you should take several steps to keep your

cutting jobs free from accident or injury.

Kickback is the result of tool misuse and/or incor-

rect operating procedures or conditions and can

be avoided by taking proper precautions as given

below:

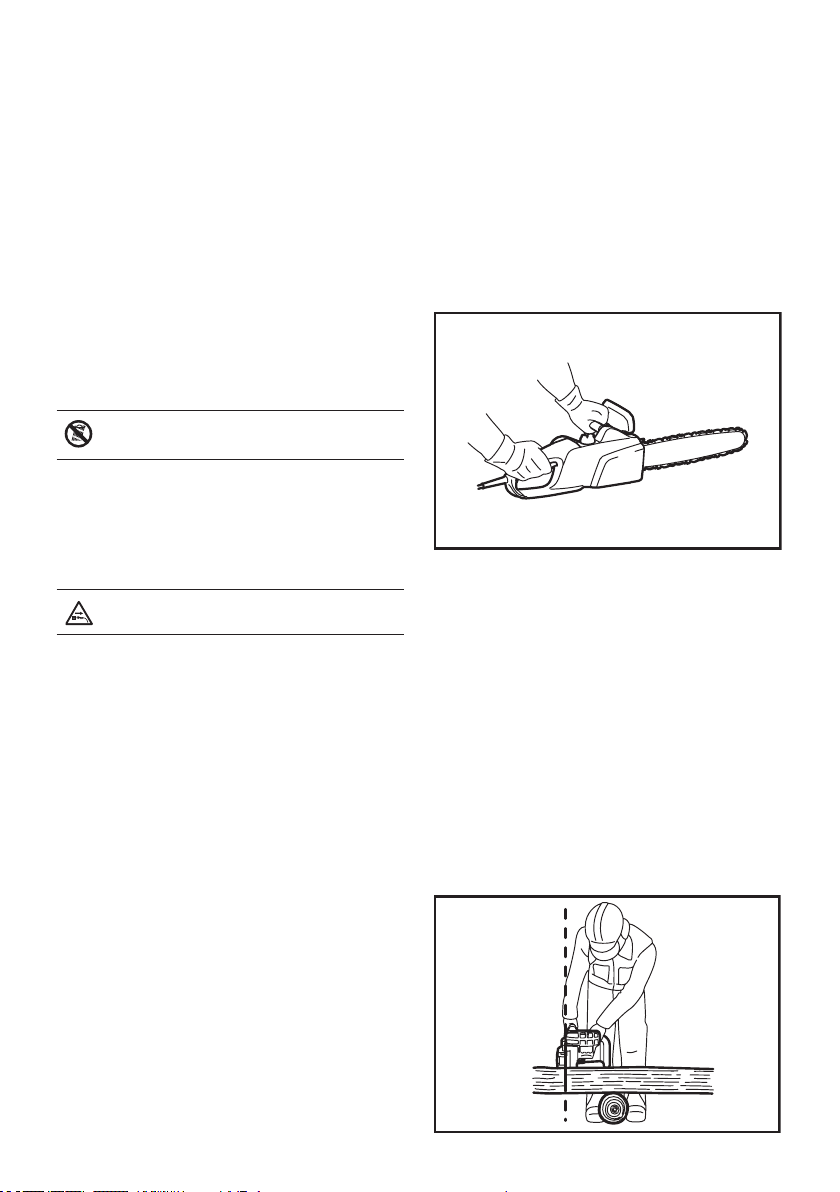

— Maintain a rm grip, with thumbs and

ngers encircling the chain saw handles,

with both hands on the saw and position

your body and arm to allow you to resist

kickback forces. Kickback forces can be

controlled by the operator, if proper precau-

tions are taken. Do not let go of the chain

saw.

— Do not overreach and do not cut above

shoulder height. This helps prevent unin-

tended tip contact and enables better control

of the chain saw in unexpected situations.

— Only use replacement bars and chains

specied by the manufacturer. Incorrect

replacement bars and chains may cause

chain breakage and/or kickback.

— Follow the manufacturer’s sharpening

and maintenance instructions for the saw

chain. Decreasing the depth gauge height

can lead to increased kickback.

ADDITIONAL SAFETY RULES

1. Read the instruction manual in order to familiarize

yourself with operation of the chain saw.

2. Before using the chain saw for the rst time,

arrange to have instruction in its operation. If this

is not possible, at least practice cutting round

timber on a trestle before beginning work.

3. The chain saw must not be used by children or

young persons under 18 years of age. Young

persons over 16 years of age may be exempted

from this restriction if they are undergoing training

under the supervision of an expert.

4. Working with the chain saw requires a high level of

concentration. Do not work with the saw if you are

not feeling t and well. Carry out all work calmly

and carefully.

5. Never work under the inuence of alcohol, drugs

or medication.

Proper use

1. The chain saw is intended solely for cutting wood.

Do not use it for example to cut plastic or porous

concrete.

2. Only use the chain saw for operations described in

this instruction manual. Do not, for example, use it

to trim hedges or for similar purposes.

3. The chain saw must not be used for forestry work,

i.e. for felling and limbing standing timber. The

chain saw cable does not provide the operator

with the mobility and safety required for such

work.

4. The chain saw is not intended for commercial use.

5. Do not overload the chain saw.