7

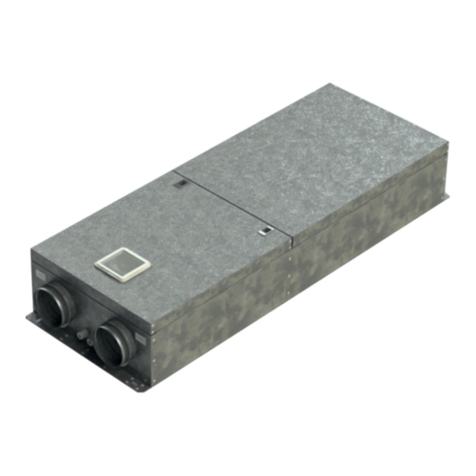

Statement of installations

Examples of smoke damper installing

The smoke damper can be installed into a solid wall construction made e.g. of normal

concrete/masonry, porous concrete with minimum thickness 100 mm or into solid ceiling

construction made e.g. of normal concrete/porous concrete with minimum thickness 150 mm.

Recommended installation openings are specified in Fig. 5.

The smoke damper can be installed into a gypsum wall construction with minimum thickness

100 mm

The smoke damper can also be installed outside of wall (ceiling) construction.

Damper installed in a solid wall construction. Space between damper and wall is filled

by mortar, gypsum or another approved fire sealing system for damper installation. ES 30 6

Damper installed in a solid wall construction. Space between damper and wall is

filled by mineral stone wool (min. density 140 kg/m³) or another approved fire

insulation system. Surface is covered by fire protection mastic (Promastop P,K) or

equal min. thickness 1 mm.

ES 30 7

Damper installed in a gypsum wall construction. Space between damper and wall is

filled by mortar, gypsum or another approved fire sealing system for damper

installation.

ES 30 8

Damper installed in a gypsum wall construction. Space between damper and wall is

filled by mineral stone wool (min. density 140 kg/m³) or another approved fire

insulation system. Surface is covered by fire protection mastic (Promastop P,K) or

equal min. thickness 1 mm.

ES 30 9

Damper installed in a solid ceiling construction. Space between damper and ceiling

is filled by mortar, gypsum or another approved fire sealing system for damper

installation.

ES 30 10

Damper installed in a solid ceiling construction. Space between damper and wall is

filled by mineral stone wool (min. density 140 kg/m³) or another approved fire

insulation system. Surface is covered by fire protection mastic (Promastop P,K) or

equal min. thickness 1 mm.

ES 30 11

Damper installed outside of a solid wall construction. Space between damper and

wall is filled by mortar, gypsum or another approved fire sealing system for damper

installation.

ES 30 12

Damper installed outside of a solid wall construction. Space between damper and

wall is filled by mineral stone wool (min. density 140 kg/m³) or another approved fire

insulation system. Surface is covered by fire protection mastic (Promastop P,K) or

equal min. thickness 1 mm.

ES 30 13

Damper installed outside of a gypsum wall construction. Space between damper and

wall is filled by mortar, gypsum or another approved fire sealing system for damper

installation.

ES 30 14

Damper installed outside of a gypsum wall construction. Space between damper and

wall is filled by mineral stone wool (min. density 140 kg/m³) or another approved fire

insulation system. Surface is covered by fire protection mastic (Promastop P,K) or

equal min. thickness 1 mm.

ES 30 15

Damper installed outside of a solid ceiling construction. Space between damper and

wall is filled by mortar, gypsum or another approved fire sealing system for damper

installation.

ES 30 16

Damper installed outside of a solid ceiling construction. Space between damper and

wall is filled by mortar, gypsum or another approved fire sealing system for damper

installation.

ES 30 17

Damper installed outside of a solid ceiling construction. Space between damper and

wall is filled by mortar, gypsum or another approved fire sealing system for damper

installation. BEWARE OF FIRE SIDE!

E 90, ES 60 18

Damper installed outside of a gypsum wall construction. Space between damper and

wall is filled by mortar and gypsum or another approved fire sealing system for

damper installation. BEWARE OF FIRE SIDE!

ES 90 19