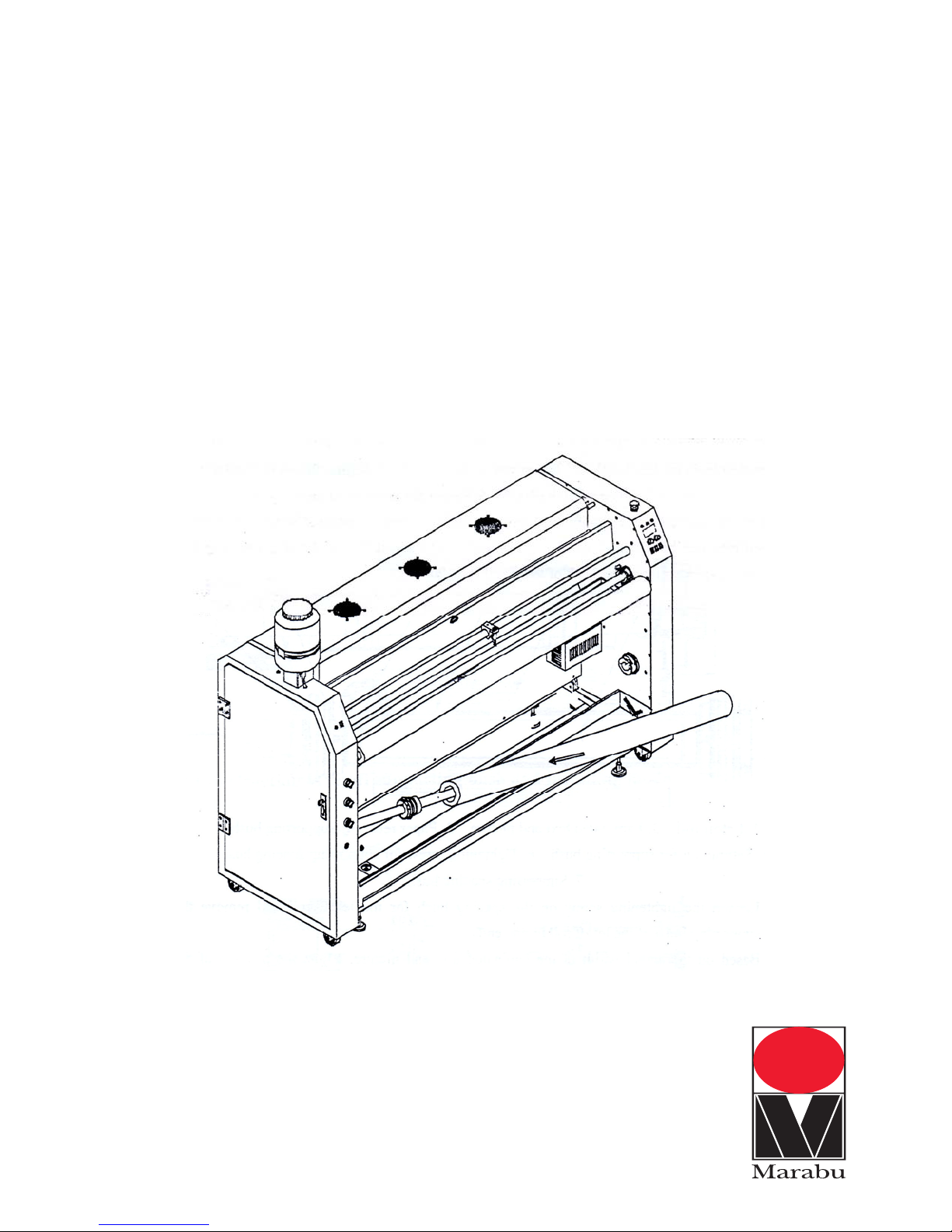

StarLam1600RUserManual

5

Be careful when wearing a necktie, necklace, wristband or long hair when operating the

machine. Care should be taking to bind loose clothing, secure jewelry and manage hair so as not to get

rolled up and bound in the machine. Serious injuries can occur if proper precautions are not taken. Do

not insert any material that is not intended for use with the machine. This can lead to unnecessary

damage of the equipment.

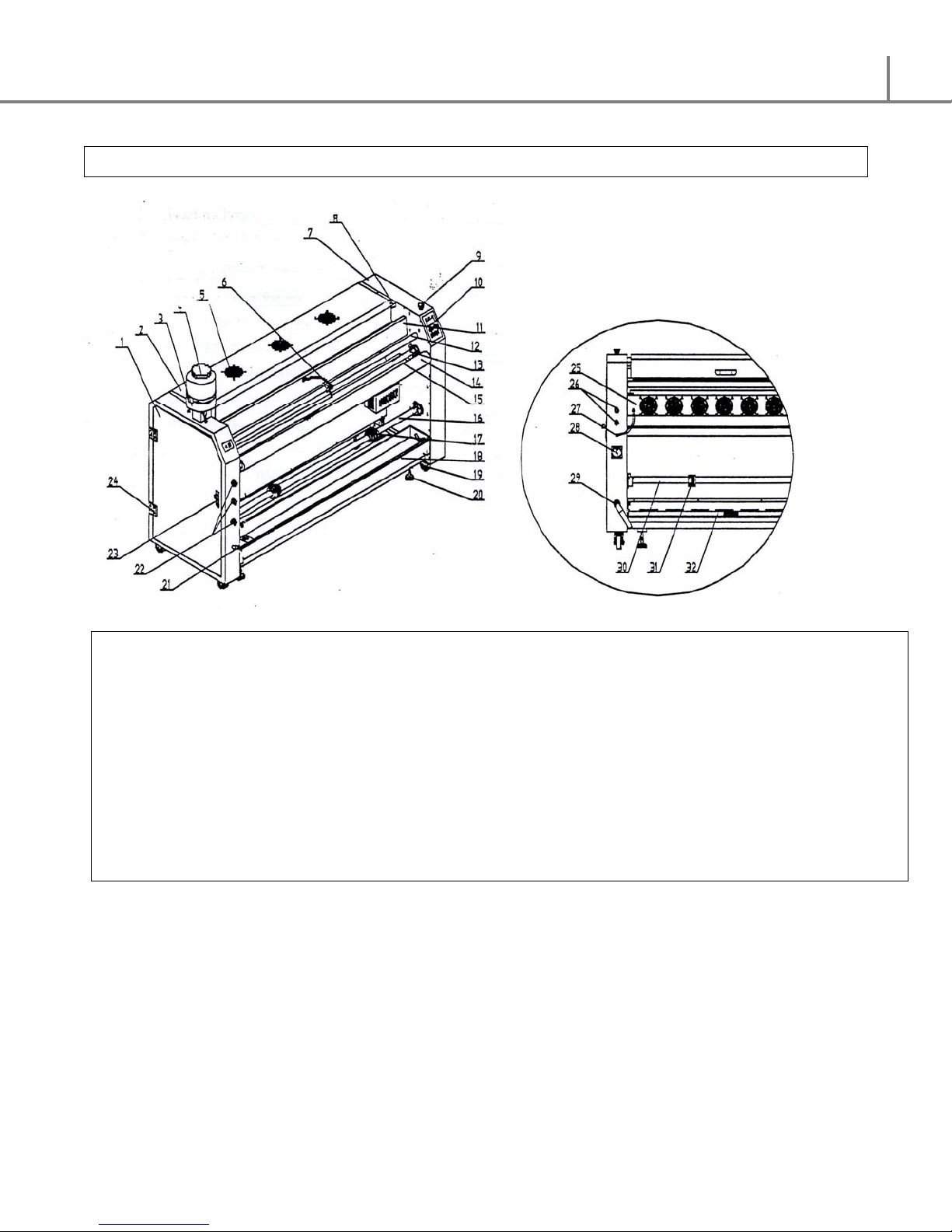

Raise the heating box lightly when lifting the heating box. Do not place hands onto the guide

roll, racks, or side of machine to avoid hand injury.

The left and right box doors can be removed after opening. If the doors need opening take care

to lift and remove them to avoid dropping them.

Use only water based liquid laminate. Using certain solvent based flammable liquids may

increase the chance of a fire or explosion. Please use caution to select and use a liquid laminate

compatible with this equipment.

The machines power source shall be connected to a sufficient proper safety breaker with

nominal current rating. Breaker operating current shall be no less than 40 Amps.

If the laminator needs service, only authorized personnel should open the electrical boxes. A

qualified professional or the manufacturer shall be asked to take responsibility for the maintenance and

repair.

Switch off the main power supply when performing maintenance to the equipment. When it is

necessary to open the electrical apparatus box the main power supply to the machine should be shut off.

This includes the main power supply line. Maintenance to the machine while in a live electrical working

environment should not be allowed. Do not touch the circuit controlling part in the electrical control

box.