ECOBOILER COUNTERTOP WATER BOILER/PUSH BUTTON

ECOBOILER PB5

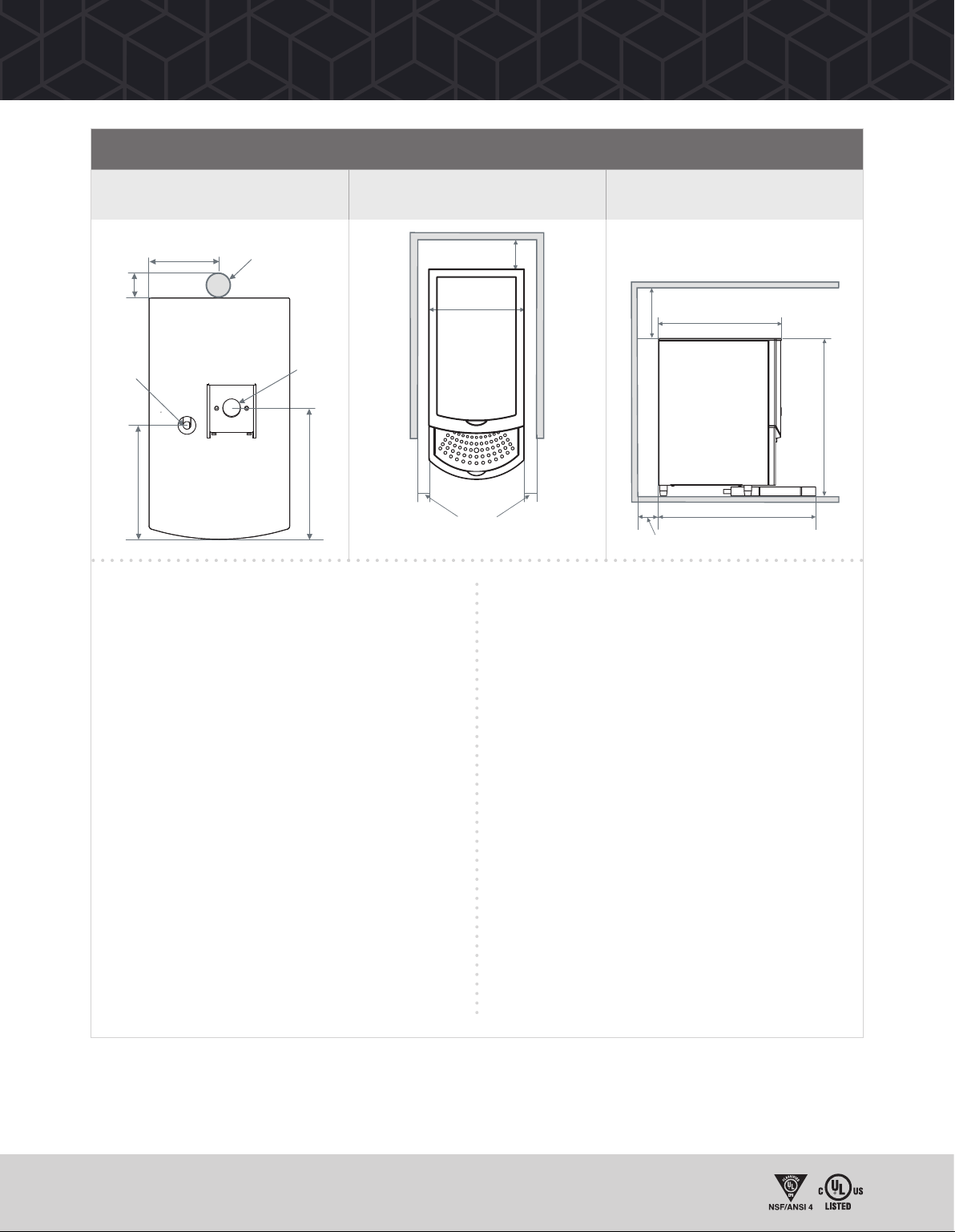

COUNTER CUTOUT CABINET CLEARANCE ECOBOILER PB5 1000665US

2”/50mm*

13.8”/350mm

18.3”/464mm

2”/50mm

2”/50mm

* Required for ventilation if the machine

is installed in an enclosed cabinet.

8.3”/211mm

18.3”/465mm

14.3”/363mm

Plan View

7.9”/200mm

6.8”/173mm

Water

2”/50mm

4.1”/105.5mm 2.5”/64mm Hole Saw

ELECTRICAL INSTALLATION PROCEDURE

When installing the machine, always observe the local

regulations and standards. The appliance is supplied with a

NEMA L6-20P moulded power cord. A suitable mains power

supply socket should be available within easy access of the

appliance so that it can be disconnected easily after install.

PLUMBING INSTALLATION PROCEDURE

• Ensure that the equipment is installed according to local

plumbing & water regulations.

• Mains water pressure required (limits): 14.5 -145psi

(100 -1000kPa, 0.1 - 1MPa).

• Requires inline water filter within your water

specifications.

• The machine is supplied with a 3/8 NPT connection.

• Connect straight tailpiece of the hose to the stop valve

fitting. Make sure that the pre-attached sealing washer

is fitted.

• Turn on the water to flush any impurities, dust etc

from the inlet hose and water pipe. Allow several litres

through, especially for new installations.

• Connect the hose to the inlet valve of the boiler.

Make sure a sealing washer is fitted.

• Turn on water and check for leaks.

OPERATING BOILER FOR THE FIRST TIME

• Check that all installation procedures have been

carried out.

• Ensure water valve is on.

• Plug boiler into a suitable socket and press power

button on the front of the machine marked ‘Power’.

NOTE: On the T5 the ‘Power’ button light also acts as

the “Ready/Status” indicator.

• The “power on” light will glow green and the machine will

fill to a safe level, above the elements, before heating.

• The “Ready/Status” light will cycle two red flashes while

the machine is filling to the safe level.

• After this amount of water has heated to about 96ºC

the boiler will draw more water in until the temperature

drops by 1 or 2 degrees. The boiler will then heat again.

This heat fill cycle continues until the boiler is full.

• Whilst the machine is above the safe level and filling,

the “Ready/Status” light will glow orange.

• The “Ready/Status” light will glow green when the

machine is both full and up to normal operating

temperature, allow approx 15 minutes.

• The boiler is now ready for use.

NOTE: Because the boiler is electronically controlled no

priming is necessary. The element cannot switch on until

a safe level of water is reached.

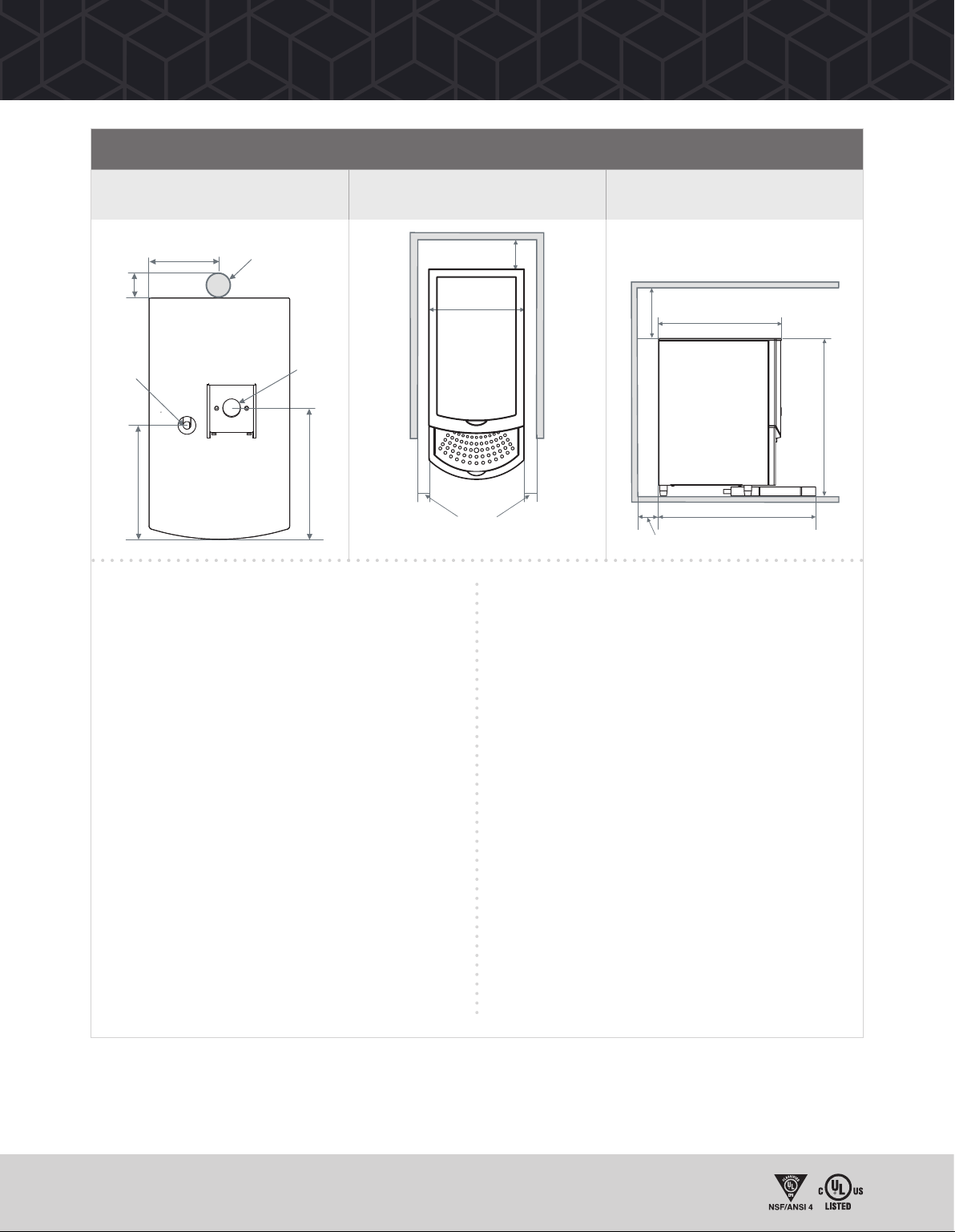

2”/50mm*

13.8”/350mm

18.3”/464mm

2”/50mm

2”/50mm

* Required for ventilation if the machine

is installed in an enclosed cabinet.

8.3”/211mm

18.3”/465mm

14.3”/363mm

Plan View

7.9”/200mm

6.8”/173mm

Power Water

2”/50mm

4.1”/105.5mm 2.5”/64mm Hole Saw

13.8”/350mm

18.3”/464mm

2”/50mm

2”/50mm

* Required for ventilation if the machine

is installed in an enclosed cabinet.

8.3”/211mm

18.3”/465mm

14.3”/363mm

Plan View

7.9”/200mm

6.8”/173mm

Power Water

2”/50mm

4.1”/105.5mm 2.5”/64mm Hole Saw