Marine Power BASE Series User manual

BASE AND PARPAC ENGINE MANUAL

VERSION 1

2www.MarinePowerUSA.com

1. Warranty

1. MARINE POWER (“the Company”) warranties each

new MARINE POWER BASE or PARPAC engine

properly registered with MARINE POWER to be free

from defects in material and workmanship.

2. The warranty period for a MARINE BASE OR

PARPAC engine is one (1) year parts AND BENCH

LABOR (MAXIMUM LABOR $500.00) only from

the date of sale. Receipt of a properly completed

Warranty Registration / Sea Trial form must be re-

ceived by Marine Power for any warranty claim to

be honored. All subsequent purchasers must inform

MARINE POWER in writing and with a payment of

a $300.00 transfer fee, of the sale of the engine to

continue the warranty. If notification is not received

by MARINE POWER within fifteen (15) days of the

resale; the warranty will be null and void.

3. In the case of commercial use, this Warranty shall

be in effect for ninety (90) days from the date of

startup, but no longer than six (6) months from

the first date of retail purchase. MARINE BASE

and PARPAC warranty claims will be for parts

and BENCH labor only. Total labor charges cannot

exceed $500.00.

4. The Company’s obligation is limited to repairing

or replacing those parts defective in material and

workmanship only. At Marine Power’s option, it

may replace such part with a part of equal quality

as shall be necessary to remedy any malfunction

resulting from a defect in material or workmanship

as covered in this Warranty. MARINE POWER will

make all necessary repairs under this Warran-

ty free of charge at the MARINE POWER factory.

Optionally, MARINE POWER may provide for the

repair or replacement of any defective part at the

selling dealership or a service center of MARINE

POWER’s choice. MARINE POWER will make

payment reimbursements for labor to replace such

part as previously provided in the then current flat

rate manual.

5. MARINE POWER, distributor, or dealer must be

advised in writing of any warranty related problem

prior to the expiration of the Warranty.

6. This Warranty will not apply to:

A) Use of an accessories or parts not manufactured

or sold by MARINE POWER.

B) Neglect, failure to follow maintenance sched-

ules, accident, abnormal operations, misuse,

negligence, improperly maintained, improperly

operated or installed, racing, or engine mod-

ification. Problems arising from installation,

application, exhaust to engine, fuel lines to the

engine, propping, cooling to the engine or engine

damage due to defective electrical hookups.

C) Rust, corrosion or effects of weather.

D) Damage caused by water entering engine via the

intake, exhaust or submersion.

E) Detonation or operation with fuels, oils or

lubricants which are not suitable for use with

this product. Detonation causes: Poor fuel

quality, overloading of engine, improper gear

or propeller selection, engine overheating,

excessive back pressure, incorrect ignition

timing, excessive total timing.

F) Reimbursement for: haul-out, launch, towing,

storage charges, rental charges of any type,

inconvenience of any type, loss of time or

income, expense of returning a MARINE POWER

product to a service facility, towing, lodging, loss

or damage to personal property.

G) Carburetor after the first five (5) hours of opera-

tion. Fuel, air and float adjustments are part of

the installation.

7. Reasonable access must be provided to the

product for warranty service. Removal and/or

replacement of boat partitions or material because

of boat design for necessary access to the product

is not covered.

8. Warranty service must be requested by delivering

the product for inspection to the retailer from whom

the product was purchased or any convenient

marine service center.

9. Proof of Warranty must be provided at time of

3www.MarinePowerUSA.com

1. Warranty

request for warranty service. A properly completed

Warranty Registration / Sea Trial form must be on

file with MARINE POWER.

10. Distributors, dealers and service providers are not

agents for MARINE POWER. The Company’s obliga-

tion under this warranty is strictly and exclusively

limited to the repair or replacement of defective

parts and does not authorize any person to create

for it any obligation of liability in connection with

this product nor does the Company assume any

obligation due to incorrect or defective installation

by the dealer.

11. All incidental and/or consequential damages are

excluded from this Warranty. Implied warranties

are limited to the life of this Warranty. All implied

warranties including merchantability, fitness for a

particular purpose, or otherwise are disclaimed in

their entirety after expiration of the appropriate one

(1) year warranty period. This Warranty gives you

specific rights, and you may also have other rights,

which may vary from state to state. Some jurisdic-

tions do not allow the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

12. MARINE POWER reserves the right to change or

improve design of any product previously assem-

bled without notice and without obligation.

13. In the event that a warranty claim is required

outside of the continental United States, with the

exception of Alaska and Hawaii, there may be

additional charges to the engine owner. Any/

All litigation must be filed within the State of

Louisiana, Parish of Tangipahoa. MARINE

POWER will not warrant any engine sold outside the

continental United States, with the exception of

Alaska and Hawaii, unless competent and trained

personnel and available to provide service to the

engine as solely determined by Marine Power.

Note: Check flywheel ring gear position

before installing in boat. Bottom

mount starters require forward

positioned ring gears. Top mount rear

entry starters require rear positioned

ring gears.

4www.MarinePowerUSA.com

2. Engine Identication

Engine Type

Crankshaft Horsepower* (HP/KW)

Displacement (Liter/CID)

Bore & Stroke (Inches)

Compression Ratio

Maximum RPM @ Wide Open Throttle

Idle RPM in Forward Gear

Fuel Pump Pressure

Oil Pressure @ 2000 RPM

Minimum Oil Pressure @ Idle

Thermostat (Raw Water)

Thermostat (Fresh Water)

Spark Plug Type

Spark Plug Gap

Timing @ Idle RPM

Total Max. Timing Advance @ 4000 RPM

Firing Order

Recommended Battery Rating

Crankcase Oil**

Crankcase Oil Capacity (Aluminum Pan)

Crankcase Oil Capacity (Sheet Metal Pan)

* Rated by Marine Power, Inc. in accordance with SAE J607, Prop Shaft rating will vary according to drive used.

** Synthetic oil may be substituted.

3.0L / 181 CID

Inline 4

140/104

3.0L/181 CID

4.00 x 3.60

9.25:1

4300 - 4600 RPM

650 - 800 RPM

4 - 7 PSI

20 - 60 PSI

10 PSI

143° F (62° C)

160° F (71° C)

AC 42 LT

.035 IN (0.9MM)

2° (ADTC)

19°

1-3-4-2

Min. 350 amps (CCA)

15W-40

Approximately 4 quarts

5.7L / 350 CID (Carbureted)

V8

315/235

5.7L/350 CID

4.00 x 3.48

9.4:1

4300 - 4600 RPM

650 - 800 RPM

4 - 7 PSI

20 - 60 PSI

10 PSI

143° F (62° C)

160° F (71° C)

AC MR43LTS

.035 IN (0.9MM)

8° (BDTC)

26°

1-8-4-3-6-5-7-2 (LH)

1-2-7-5-6-3-4-8 (RH)

Min. 350 amps (CCA)

15W-40

Approximately 6 quarts

Approximately 5 quarts

5.7L / 350 CID (MPI)

V8

325/342

5.7L/350 CID

4.00 x 3.48

9.4:1

4200 - 5000 RPM

650 - 800 RPM

4 - 7 PSI

20 - 60 PSI

10 PSI

143° F (62° C)

160° F (71° C)

AC 41-101

.060 IN (1.52MM)

10° (BDTC)

29°

1-8-4-3-6-5-7-2 (LH)

1-2-7-5-6-3-4-8 (RH)

Min. 350 amps (CCA)

15W-40

Approximately 6 quarts

Approximately 5 quarts

7.4L / 454 CID (Std. Carbureted)

V8

330/246

7.4L/454 CID

4.25 x 4.00

8.0:1

4300 - 4600 RPM

650 - 800 RPM

4 - 7 PSI

20 - 60 PSI

10 PSI

143° F (62° C)

160° F (71° C)

AC MR43T

.035 IN (0.9MM)

0° (BDTC)

20°

1-8-4-3-6-5-7-2 (LH)

1-2-7-5-6-3-4-8 (RH)

Min. 350 amps (CCA)

15W-40

Approximately 10 quarts

Approximately 8 quarts

5www.MarinePowerUSA.com

2. Engine Identication

Engine Type

Crankshaft Horsepower* (HP/KW)

Displacement (Liter/CID)

Bore & Stroke (Inches)

Compression Ratio

Maximum RPM @ Wide Open Throttle

Idle RPM in Forward Gear

Fuel Pump Pressure

Oil Pressure @ 2000 RPM

Minimum Oil Pressure @ Idle

Thermostat (Raw Water)

Thermostat (Fresh Water)

Spark Plug Type

Spark Plug Gap

Timing @ Idle RPM

Total Max. Timing Advance @ 4000 RPM

Firing Order

Recommended Battery Rating

Crankcase Oil**

Crankcase Oil Capacity (Aluminum Pan)

Crankcase Oil Capacity (Sheet Metal Pan)

* Rated by Marine Power, Inc. in accordance with SAE J607, Prop Shaft rating will vary according to drive used.

** Synthetic oil may be substituted.

7.4L / 454 CID (MPI)

V8

340/253

7.4L/454 CID

4.25 x 4.00

9.0:1

4200 - 4600 RPM

650 - 800 RPM

39 PSI

20 - 60 PSI

10 PSI

143° F (62° C)

160° F (71° C)

AC MR43T

.035 IN (0.9MM)

0° (BDTC)

-

1-8-4-3-6-5-7-2 (LH)

1-2-7-5-6-3-4-8 (RH)

Min. 350 amps (CCA)

15W-40

Approximately 10 quarts

Approximately 8 quarts

7.4L / 454 CID (Premium HP)

V8

380/282

7.4L/454 CID

4.25 x 4.00

8.6:1

4600 - 5000 RPM

650 - 800 RPM

-

20 - 60 PSI

10 PSI

143° F (62° C)

160° F (71° C)

AC MR43T

.035 IN (0.9MM)

12° (BDTC)

30°

1-8-4-3-6-5-7-2 (LH)

1-2-7-5-6-3-4-8 (RH)

Min. 350 amps (CCA)

15W-40

Approximately 10 quarts

Approximately 8 quarts

8.2L / 502 CID (Carbureted)

V8

400/298

8.2L/502 CID

4.47 x 4.00

8.75:1

4300 - 4800 RPM

650 - 800 RPM

4 - 7 PSI

20 - 60 PSI

10 PSI

143° F (62° C)

160° F (71° C)

AC MR43T

.035 IN (0.9MM)

12° (BDTC)

30°

1-8-4-3-6-5-7-2 (LH)

Min. 350 amps (CCA)

15W-40

Approximately 10 quarts

Approximately 8 quarts

8.2L / 502 CID (MPI)

V8

420/313

8.2L/502 CID

4.47 x 4.00

8.75:1

4600 - 5000 RPM

650 - 800 RPM

39 PSI

20 - 60 PSI

10 PSI

143° F (62° C)

160° F (71° C)

AC MR43T

.035 IN (0.9MM)

12° (BDTC)

-

1-8-4-3-6-5-7-2 (LH)

Min. 350 amps (CCA)

15W-40

Approximately 10 quarts

Approximately 8 quarts

6www.MarinePowerUSA.com

Water Can Enter the Engine Cylinders

Through the Intake or Exhaust System.

Beware of these situations:

1. Following Wakes: Sudden slow-downs may cause the

boat wake to flow over the transom of your boat. Most

engine hatch covers are not watertight. Water spilling

into the engine compartment can easily enter the air in-

take, especially if the engine is running.

2. Engine Shutdown: Sudden engine shutdown while the

boat is moving may force water into the exhaust system.

3. Improper Installation: Refer to exhaust pipe section. An

exhaust system without flappers and the specified incline

increases the likelihood of water entering the engine.

4. Improper Hoisting: Operators are sometimes tempted to

reduce hoisting time for propeller changes by hoisting

only the boat stern. Such hoisting can cause residual wa-

ter in the exhaust system to enter engine cylinders.

Water entering engine cylinders will cause the engine to lock

because water does not compress. To remedy this situation,

take the following steps:

1. Change engine oil and filters.

2. Remove all spark plugs.

3. Remove coil wire.

4. Crank engine for 15 seconds.

5. Replace spark plugs and reattach coil wire.

6. Start engine - if there are any abnormal sounds STOP

ENGINE immediately and contact your MARINE POWER

dealer.

Water Inversion

Water inversion is water that is pulled back into the exhaust

which usually ends up in the piston cylinder. Most of the time

this happens under the following conditions:

• Shutting off engine at high RPM’s.

• Water comes up the exhaust after a quick slowdown.

• Long periods of idling.

• Exhaust drop not sufficient.

Usually the water is not found until the next time the boat is

used. In some cases, this may not be for weeks. In the case

of a salt water environment this is catastrophic due to the

rusting.

To minimize the problem MARINE POWER requires the instal-

lation of flappers at the transom and in the exhaust hose just

after the exhaust riser or elbow.

Detonation and/or Pre-Ignition

Detonation is most commonly known as “pinging”, “spark

knock” or “fuel knock”. It is the abnormal combustion of the

fuel which causes the fuel to explode severely within the

combustion chamber.

In a four-cycle engine, normal combustion or burning starts

at the spark plug and a wave of flames move across the

combustion chamber. This results in an even pressure rise in

the combustion chamber which pushes the piston downward.

Detonation begins as normal combustion with the spark-

ignited flame progressing across the combustion chamber

while applying the heat and pressure to the unburned portion

of fuel. Instead of continuing to burn evenly, the last portion of

the fuel explodes violently which in turn cases overheating of

the pistons, valves and spark plugs.

This may occur at any speed and is not often detected, serious

and tragic engine damage may occur.

There are many causes of detonation, with the most common

being the use of a low-octane gasoline or improperly timed

ignition. Detonation may also occur when using the proper

octane gasoline if engine maintenance has been neglected.

Possible causes include:

1. Poor or improper fuel quality/octane.

2. Improper initial ignition timing setting.

3. Improper propeller selection.

4. Engine overload, such as operating twin-engine boat with

only one engine.

5. Improper cooling operation resulting in engine overheating.

6. Fuel starvation or vapor lock resulting from poor fuel

quality/lean out.

7. Malfunctioning carburetor causing lean mixture.

8. Operating engine that is out of proper tune, dead cylinder,

3. Precautions/Instructions

7www.MarinePowerUSA.com

defective distributor cap.

9. Excessive exhaust backpressure by restricted exhaust

mufflers or outlets.

Proper Engine Break-In

CAUTION First twenty-five (25) hours vary the RPM. Avoid

sustained periods of wide open throttle. Some EFI engines

will not reach WOT until engine is up to normal operating

temperatures.

AT NO TIME SHOULD THE ENGINE BE OPERATED

BEYOND THE SPECIFIED MAXIMUM RPM RATING.

FAILURE TO ADHERE TO THERE RECOMMENDATIONS

WILL VOID THE TERMS OF WARRANTY.

To insure maximum life of your MARINE POWER engine, the

following engine break-in schedule is recommended:

First hour - Perform sea trial.

IMPORTANT! During the break-in period, pay close attention

to the following steps.

1. OIL LEVEL: Check the oil level before each engine start

up and every eight (8) hours of continuous operation. It

should be understood that internal combustion engines

will use a certain amount of oil during operation as a

cooling and lubricating agent (especially during break-in

period). Oil consumption should decrease after approxi-

mately 100 hours of operation.

IMPORTANT! The space between “FULL” and “ADD” marks

on the dipstick represent one quart. It is not necessary to add

oil unless the level is at or below the “ADD” mark.

CAUTION Engine dipstick level may change due to the angle

of installation. Ensure that “high” oil level is properly marked

accordingly.

CAUTION When adding crankcase oil, DO NOT OVERFILL. If

crankcase is overfilled, it will cause foaming or aeration of oil

in the oil pan. This will effect oil pressure which may result in

severe internal engine damage.

2. VOLTMETER: Normal reading is 13.0 - 14.5 volts at 2,000

RPM.

3. OIL PRESSURE: Not less than 10 PSI at idle.

4. NORMAL OPERATING TEMP: Raw water cooling - less

than 165 degrees. Closed cooling - between 160 and 190

degrees.

5. IDLE RPM: Normal reading is 650 - 800 RPM in gear.

Note: For Jetpac applications, normal reading is 800 -

1,000 RPM.

6. THROTTLE AND SHIFT CONTROLS: Check that movement

is not constrictive. Verify that linkage is adjusted so that

engine may reach Wide Open Throttle (WOT).

7. EXHAUST, OIL, WATER AND FUEL SYSTEM: Inspect for

leaks. Be sure to check riser bolt tightness after 10 hours

and every 50 hours of operation. Refer to Maintenance

Schedule.

It is very important to re-tighten exhaust manifold riser

bolts after 10 hours of operation. Failure to do so can cause

non-warrantable engine damage.

General Information

ENGINE ROTATION

Directional references used in this section are given as if

standing behind the boat, looking forward:

• Front of boat is bow.

• Rear of boat is stern.

• Right side is starboard.

• Left side is port.

The raw water (or seawater) pump is located at the front of

the engine on the crankshaft pulley. Engine rotation can be

determined by looking at the stern end of the engine and

observing the flywheel rotation. Do not assume engine

rotation by looking at the propeller rotation; it may not be the

same. This information is critical when ordering parts for your

engine.

Left Hand Engines: CCW or Normal Rotation Right Hand

Engines: CW or Opposite Rotation.

PROPELLER WARNING

WARNING! MARINE POWER does not warranty items

damaged due to detonation. The propeller selected should

allow the engine to operate at or near the recommended

wide open throttle RPM range with a normal load. Wide Open

Throttle RPM range is listed in Engine Identification Section.

3. Precautions/Instructions

8www.MarinePowerUSA.com

WARNING! Using a propeller too large will not allow the

engine to reach its rated RPM range which will create an over-

loaded condition and possible destructive detonation that can

be harmful to the engine’s performance and life.

PROPELLER INFORMATION

Diameter, pitch or coupling of a propeller will affect

engine RPM and boat performance. Configuration of the blade

also effects performance. Even propellers from different

manufacturers with the same pitch and diameter will perform

differently.

Testing for a correct propeller is accomplished by operating

the boat (with an average load) at Wide Open Throttle (WOT)

RPMs should be at the high end of the specified range and

checked with an accurate tachometer. This will allow the

engine not to fail below the RPM specified range under a

heavy load condition. If the engine RPM is above or below the

specified range, a change in the diameter and/or pitch of the

propeller is required. Newly installed engines operating 100

- 300 RPM below wide open throttle is usually a propeller

problem.

Delco EST Ignition

USING THE TIMING TOOL: Carbureted Engine.

For EFI Engines - Refer to original manufacturer’s instructions

but verify that engine is not timed outside of specifications

noted in this manual.

The 3.0 liter (181CID) does not have to be timed unless the

distributor is moved during installation. It is timed at the

factory. IMPORTANT! The 3.0 engine is timed at minus 2

degrees, raising the timing will cause the engine to detonate

and blow cylinder head gaskets.

The timing tool is used in setting the initial engine timing on

MARINE POWER carbureted engines. This connector by-passes

the electronic spark timing of the engine and allows the initial

timing to be adjusted by rotating the distributor. Use the follow-

ing procedure (become familiar with entire procedure before

beginning):

1. Connect a timing light to the number one (1) spark plug

wire. Connect the timing light power lead to a 12 volt

power source. (DO NOT CONNECT TO 12 VOLTS ON

ALTERNATOR.)

2. Start engine and allow to warm to operating tempera-

ture. Space linkage so that engine idles at 1,000 - 1,200

RPM.

3. WHILE ENGINE IS RUNNING, install the timing tool

supplied with your engine into the terminal connector on

the distributor.

4. Loosen distributor clamp just enough to rotate distributor

in place.

Note: An adjustable timing light is required to set initial and

total timing.

5. Secure the bare wire and of the timing tool to battery

positive (+) voltage (the most convenient location of this

voltage is on the cranking motor solenoid.) If desired, a

suitable clip, such as an alligator clip may be permanently

attached to the bare wire end of the timing tool to hold

it in place. Once connected the engine idle will drop to

approximately 600 RPM. It is important that the initial

linkage spacing in Step 2 allows the engine to drop to

around 600 with the timing tool connected to 12 volts.

The step spacing may have to be adjusted so that the

engine does settle at 600 RPM after connecting the tool.

6. Rotate distributor to set mechanical timing.

REFER TO THE APPROPRIATE “ENGINE IDEN-

TIFICATION” SECTION OF THIS MANUAL FOR

CORRECT TOTAL AND INITIAL TIMING FOR YOUR

ENGINE. IMPORTANT: The 3.0 engine is timed at

minus 2 degrees, raising the timing will cause

the engine to detonate and blow cylinder head

gaskets.

7. Tighten distributor clamp to hold in position when initial

timing is obtained.

8. Recheck timing.

9. Remove the timing tool from distributor.

10. Check total timing at 4,000 RPM. (See Engine Identifica-

tion Section.)

11. Disconnect and remove the timing light.

Fuel Lines

IMPORTANT! In repower applications, inspect all fuel

lines for possible restrictions. Fuel tanks should be installed

3. Precautions/Instructions

9www.MarinePowerUSA.com

below the height of the fuel system. It is recommended that an

anti-siphon valve be included in the fuel tank.

A 3/8” minimum (inner-dimension) “Type A1” USCG Approved

tubing is recommended for the fuel line from the tank to the

engine for all 181/3.0L, 262/4.3L and 350/5.7L engines. All

7.4L and larger engines must be 1/2” minimum inner dimen-

sion. It should be adequately secured and provided with a

flexible section near the engine to reduce vibration to the line.

Fittings for the tubing should conform to current Coast Guard or

American Boating & Yacht Council standards. It is also

recommended that older copper fuel lines be replaced with an

approved fuel line.

Fuel tanks should be of a size adequate with the full require-

ments and should be anchored securely and vented in such a

manner to conform to Coast Guard regulations. The fuel tank

filling arrangements should conform to all safety regulations,

and must be outboard. The installation of an approved fuel

shut off valve at the tank is mandatory.

Verify that carbureted engines have 5 - 7 psi fuel pressure.

EFI engine fuel pressure should meet original manufacturers

specifications. WARNING: INADEQUATE FUEL PRESSURE

WILL DESTROY A NEW ENGINE.

Crankcase Ventilation

Open vent tubes maybe routed directly to flame arrestor. If

PVC valves are used, they must be routed to a vacuum port on

the carburetor base or intake manifold.

Exhaust Piping

IMPORTANT! The boat manufacturer or installing dealer (or

individual) is responsible for properly locating the engine and

installing the exhaust system. Improper installation may allow

water to enter the exhaust manifolds and engine cylinders and

severely damage the engine. Damage caused by water in the

engine will not be covered by the MARINE POWER Warranty,

unless this damage is a result of defective parts or workman-

ship by MARINE POWER.

ENPACS, SPORTPACS, and TOWPACS are equipped with a

wet exhaust system in which exhaust is mixed with water in

the exhaust risers. This water cools the exhaust and allows

the use of heat resistant rubber hose on the riser outlets.

Follow these general guidelines when designing and install-

ing the exhaust system.

Use heat resistant hose that complies with specifications SAE

J2006 or UL 1129 (ABYC standard). Exhaust hoses should be

4” on dual outlet systems. 8.2L and larger engines should use

5” on single outlet systems.

Sharp bends should be avoided.

Exhaust hoses should be connected straight on the riser

outlets.

Exhaust back pressure test should be preformed to ensure

that exhaust components are adequately sized. Exhaust back

pressure should be between 1-3 psi. Some back pressure is

necessary to prevent water intrusion. Do not go below 1 psi.

Exhaust risers must be the suggested distance above the

water line. Install riser spacers if necessary.

A minimum of 18” of exhaust hose must be installed

between the exhaust risers and the collector, Y-pipe,

muffler or first angular fitting. This portion of the

exhaust hose must have a downward slope of 1-1/4”/ft.

for conventional inboards and a downward slope

of 7/8”/ft. for V-drives. Some OEM installations may

different from these specifications but these installations

have been carefully evaluated by MARINE POWER and the

OEM.

After the first 18” the exhaust system must have a drop of

1/2”/ft. Measure exhaust riser height as shown. Minimum

exhaust riser height should be 15” on 7.4 and 8.2L engines.

All others should be 13”.

The slope in the exhaust hose and components must be routed

so that no low point exists in the system where water may

be retained. The muffler, collector and exhaust hoses must be

adequately supported for proper routing and to prevent over-

stressing the exhaust manifolds and risers.

Internal flappers may be required on naturally aspirated 7.4

and 8.2L engines.

Applications with through transom exhausts must be equipped

with exhaust flappers to prevent the reverse flow of water into

the engine. Exhaust outlets should be above the water line

with the boat at rest to minimize engine back pressure.

Every exhaust connection should be secured with at

least two hose clamps. The clamps should be stainless

steel and at least 1/2” wide.

3. Precautions/Instructions

10 www.MarinePowerUSA.com

Scheduled Maintenance By Owner

* Engine Start-Up Each Day and Once Every Eight (8) Hours of Operation.

Service Engine After Every 50 Every 100

Startup 10 Hours of Hours of Hours of

Each Day Operation Operation Operation

Check Engine Oil Level * 33

Inspect Fuel Lines and Connections for Leaks 33

Check Coolant Level in Tank (If Equipped with Closed Cooling) 33

Inspect and Clean Sea Strainer (If Equipped) 33

Inspect Entire Power Package for Leaks (Water, Fuel, Oil, Exhaust, etc.) 333

Inspect Belts for Tension and Wear 333

Inspect Battery (Terminals and Fluid Levels) 333

Check Battery Connection to Engine 333

Touch Up Exterior Surface with Marine Power Paint 333

Inspect Zinc Anodes in Heat Exchanger for Deterioration (If Equipped with Closed Cooling) 333

Check Power Steering Fluid (If Equipped) 3

Check Transmission Fluid Level 333

Lubricate Starter Pinion and Shaft 33

4. Engine Maintenance

11www.MarinePowerUSA.com

4. Engine Maintenance

Scheduled Maintenance By Qualified Technician

Service Engine After Every 50 Every 100

Startup 10 Hours of Hours of Hours of

Each Day Operation Operation Operation

Change Engine Oil and Filters 333

Change Filter on Fuel/Water Separator 33

Check Engine Mounts (Tightness) 333

Check Riser and Manifold Bolts for Tightness 3333

Check for Loose, Damaged or Missing Engine Parts 33

Check Wire Harness Plugs for Corrosion and Connections 33

Inspect Distributor for Cracks or Deterioration 33

Check Condition of Spark Plugs (Replace if Necessary) 33

Inspect Hoses for Deterioration 33

Replace Impeller in Seawater Pump 33

Check Propeller and Shaft Alignment 3

Check and Adjust Ignition Timing (Carbureted Engine Only) 3

Check and Adjust Carburetor 3

Clean and Inspect Flame Arrestor and Crank Case Vent Hose 33

Clean and Inspect Carburetor Filter 33

Change Transmission Fluid 3

Change Coolant (If Equipped with Closed Cooling) 3

Clean Seawater Section of Heat Exchanger 3

Copyright 2016 Marine Power

All rights reserved. No part of this book may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying,

recording or any information storage and retrieval system, without permission in writing from MARINE POWER HOLDING, LLC.

Marine Power 17506 Marine Power Industrial Park, Ponchatoula, LA 70454 USA www.MarinePowerUSA.com

This manual suits for next models

1

Table of contents

Other Marine Power Engine manuals

Popular Engine manuals by other brands

Remington

Remington 495 Operation manual

Lombardini

Lombardini 15 LD 500 Workshop manual

Briggs & Stratton

Briggs & Stratton Vanguard 430000 user manual

Honeywell

Honeywell Modutrol IV Series 61 manual

Multiplex

Multiplex PERMAX BL-O 2816-0850 F operating instructions

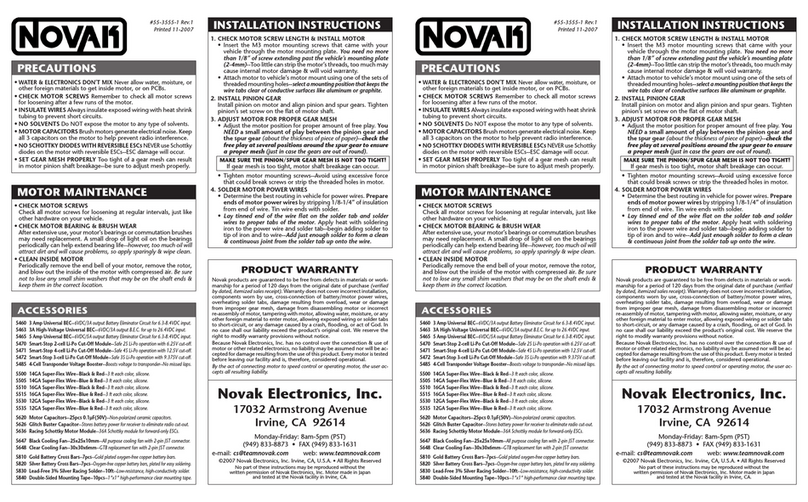

NOVAK

NOVAK FIFTY-FIVE - REV1 11-2007 installation instructions

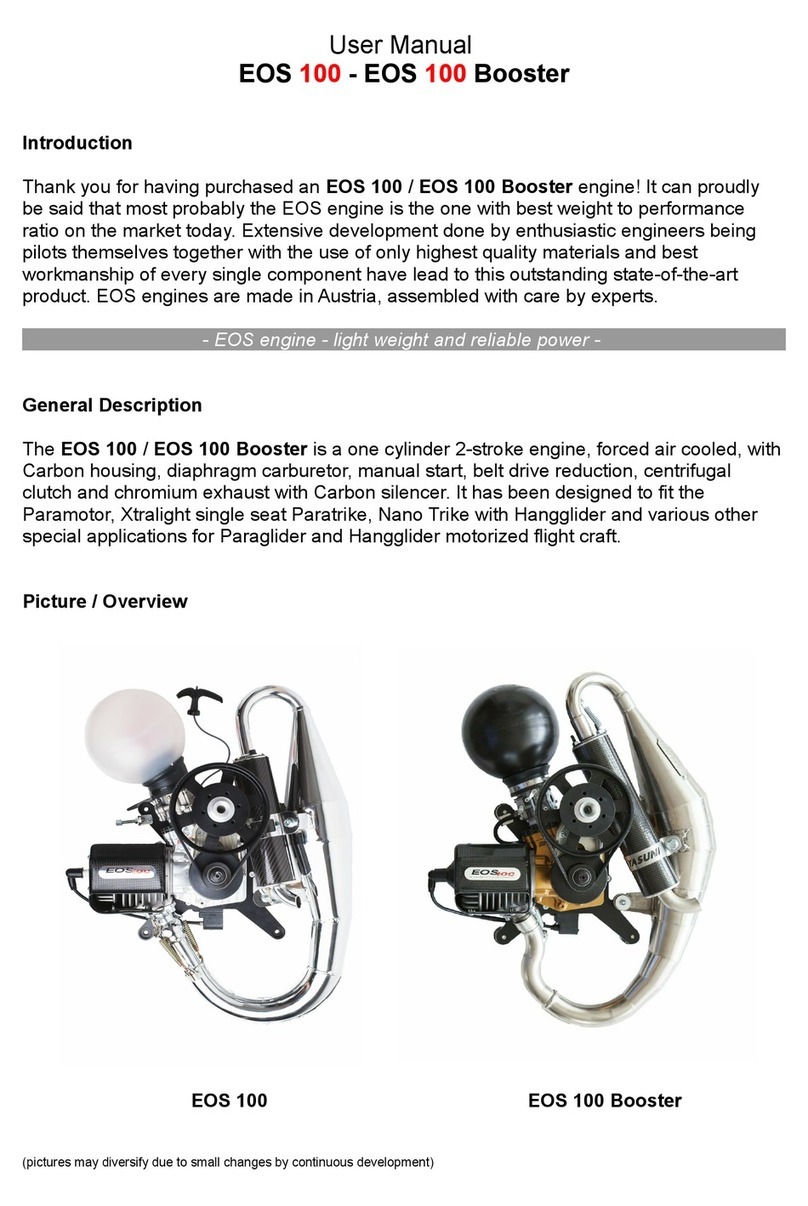

O.S. engine

O.S. engine MAX-21XM Owner's instruction manual

Sole Diesel

Sole Diesel SV-140 instruction manual

Generac Power Systems

Generac Power Systems GTV-760 owner's manual

Kohler

Kohler Command PRO EFI Service manual

Billet Specialties

Billet Specialties Tru Trac 13225 installation manual

Kohler

Kohler Confidant ZT710 owner's manual