Marvel MLCP215-SS01A User manual

OWNER’S GUIDE & SERVICE MANUAL

MARVEL UNDERCOUNTER REFRIGERATION

Model: MLCP215-SS01A

WELCOME

Welcome to the Marvel Experience!

Congratulations on your purchase of the industry’s quietest

clear ice machine with the best ice clarity and purity. Your

new investment is protected by a limited warranty for the

rst year, and hermetically sealed refrigeration system parts

are covered for an additional 4 years.

Here’s your guide to the operation and maintenance of your

Marvel Clear Ice Machine to ensure years of enjoyment. If

you have any questions, please contact Marvel Customer

Service or Tech Support at:

Phone: (616) 754-5601

Email:

Got a Marvelous Design?

We would love to see how your Marvel product looks in its

new home. You can send us photos of your installed

might feature your Marvel home design on our website and

social media!

Warranty Registration

It is important you register your product warranty after

taking delivery of your appliance. You can register online at

www.marvelrefrigeration.com.

The following information will be

required when registering your

appliance:

Serial Number

Date of Purchase

Dealer’s name and address

The serial number can be found on the serial plate which is

located inside the cabinet on the left side near the top.

Online registration

available at

marvelrefrigeration.com

TABLE OF CONTENTS

Tip: Click on any section below to jump directly there

Safety

Important Safety Instructions

Installation

Unpacking Your Appliance

Electrical

Cutout & Product Dimensions

Side-by-Side & Stacking Installations

Door Reversal

Installing The Water Supply

Maintenance

Care and Cleaning

Stainless Steel Maintenance

Service

Obtaining Service

Troubleshooting

Wire Diagram

Product Liability

Warranty Claims

Ordering Replacement Parts

System Diagnosis Guide

Compressor Specifications

Troubleshooting Extended

Thermistor

Warranty

3

IMPORTANT SAFETY INSTRUCTIONS

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and

situations that may occur. Common sense, caution and

care must be exercised when installing, maintaining or

operating this appliance.

Recognize Safety Symbols,

Words and Labels

!WARNING

WARNING - You can be killed or seriously injured

if you do not follow these instructions.

!CAUTION

CAUTION -Hazards or unsafe practices which could

result in personal injury or property/product damage.

NOTE

NOTE -Important information to help assure a

problem-free installation and operation.

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause birth defects or

other reproductive harm.

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause cancer.

!WARNING

WARNING - This unit contains R600a (isobutane)

which is a ammable hydrocarbon. It is safe for

regular use. Do not use sharp objects to expedite

defrosting. Do not damage refrigerant circuit.

4

UNPACKING YOUR APPLIANCE

!WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in personal injury.

Remove Interior Packaging

Your appliance has been packed for shipment with all parts

that could be damaged by movement securely fastened.

Remove internal packing materials and any tape holding

internal components in place. The getting started guide is

shipped inside the product in a plastic bag along with the

warranty registration card and other accessory items.

Important

Keep your carton and packaging until your appliance has

been thoroughly inspected and found to be in good condi-

tion. If there is any damage, the packaging will be needed

as proof of damage in transit. Afterwards, please dispose of

all items responsibly.

!WARNING

WARNING - Dispose of the plastic bags which can

be a suocation hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving out facility. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE

RETAILER.

NOTE

!CAUTION

If the appliance was shipped, handled or stored in other

than an upright position for any period of time, allow the

appliance to sit upright for a period of at least 24 hours

before plugging in. This will assure oil returns to the

compressor. Plugging the appliance in immediately may

cause damage to internal parts.

!WARNING

WARNING - Help Prevent Tragedies

Child entrapment and suocation are not problems of

the past. Junked or abandoned refrigerators are still

dangerous, even if they sit outside for “just a few hours”.

If you are getting rid of your old refrigerator, please

follow the instructions below to help prevent accidents.

Before you throw away your old refrigerator or freezer:

• Take o the doors or remove the drawers.

• Leave the shelves in place so children may not

easily climb inside.

5

ELECTRICAL

Do not remove

ground prong

!WARNING

Electrical Shock Hazard

• Do not use an extension cord with this appliance.

They can be hazardous and can degrade product

performance.

• This appliance should not, under any

• circumstances, be installed to an un-grounded

• electrical supply. Do not remove the grounding

prong from the power cord.

• Do not use an adapter.

• Do not splash or spray water from a hose on the

appliance. Doing so may cause an electrical shock,

which may result in severe injury or death.

Electrical Connection

A grounded 115 volt, 15 amp dedicated circuit is required.

This product is factory equipped with a power supply

cord that has a three-pronged, grounded plug. It must be

plugged into a mating grounding type receptacle in

accordance with the National Electrical Code and

applicable local codes and ordinances. If the circuit does

not have a grounding type receptacle, it is the responsibility

and obligation of the customer to provide the proper power

supply. The third-ground prong should not, under any

circumstances, be cut or removed.

NOTE

Ground Fault Circuit Interrupters (GFCI) are prone to

nuisance tripping which will cause the appliance to shut

down. GFCI’s are generally not used on circuits with power

equipment that must run unattended for long periods of

time, unles required to meet local building codes and

ordinances.

6

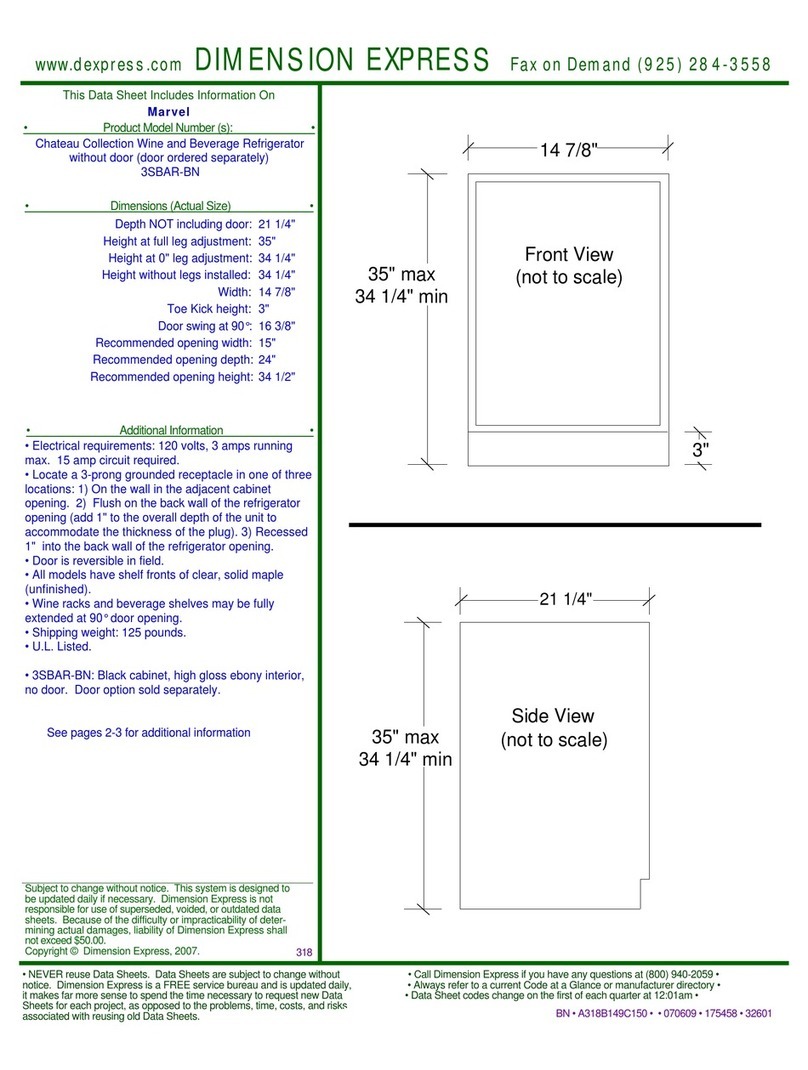

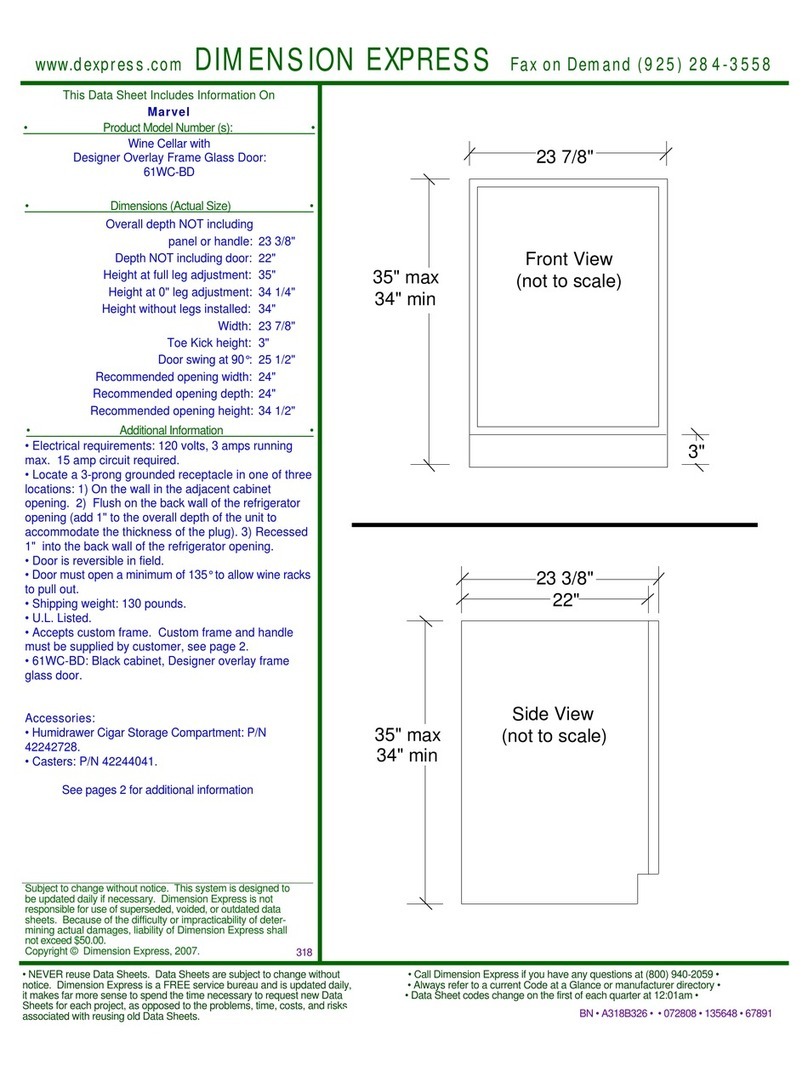

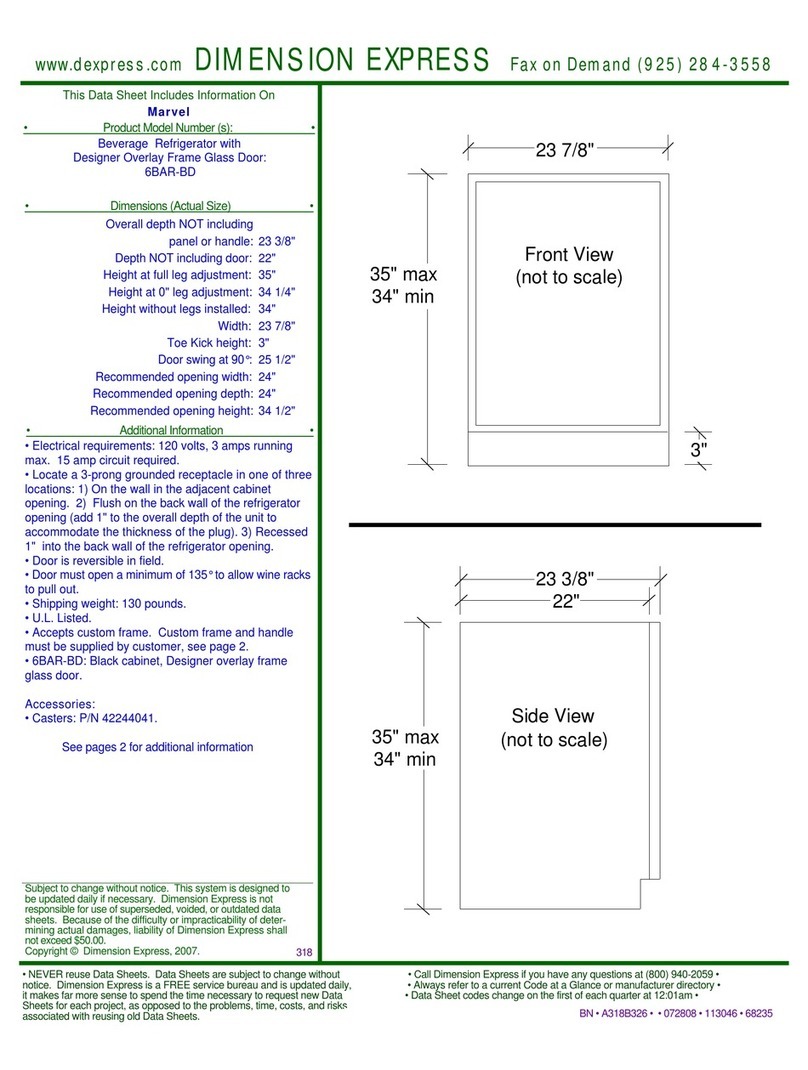

CUTOUT AND PRODUCT DIMENSIONS

ROUGH-IN OPENING DIMENSIONS CABINET DIMENSIONS

"A" "B" "C" "D" "E" "F" "G" "H" "J"

15"

(38.1 cm)

34" to 35"

(85.7 cm to 88.3 cm)

24"

(61 cm)

(37.8 cm)

(86.4 cm to 88.9 cm)

(60 cm)

1/2

(64.8cm)

(94.9 cm)

5/8

(42.2 cm)

Solid Door

Shown

"A"

"B"

"C"

"D"

"E"

If necessary, to gain clearance inside the rough-in

opening, a hole can be cut through the adjacent

cabinet and the power cord routed through this hole to

a power outlet. Another way to increase the available

opening depth is to recess the power outlet into the

rear wall to gain the thickness of the power cord plug.

Not all recessed outlet boxes will work for this applica-

tion as they are too narrow, but a recessed outlet box

equivalent to Arlington #DVFR1W is recommended for

this application.

7

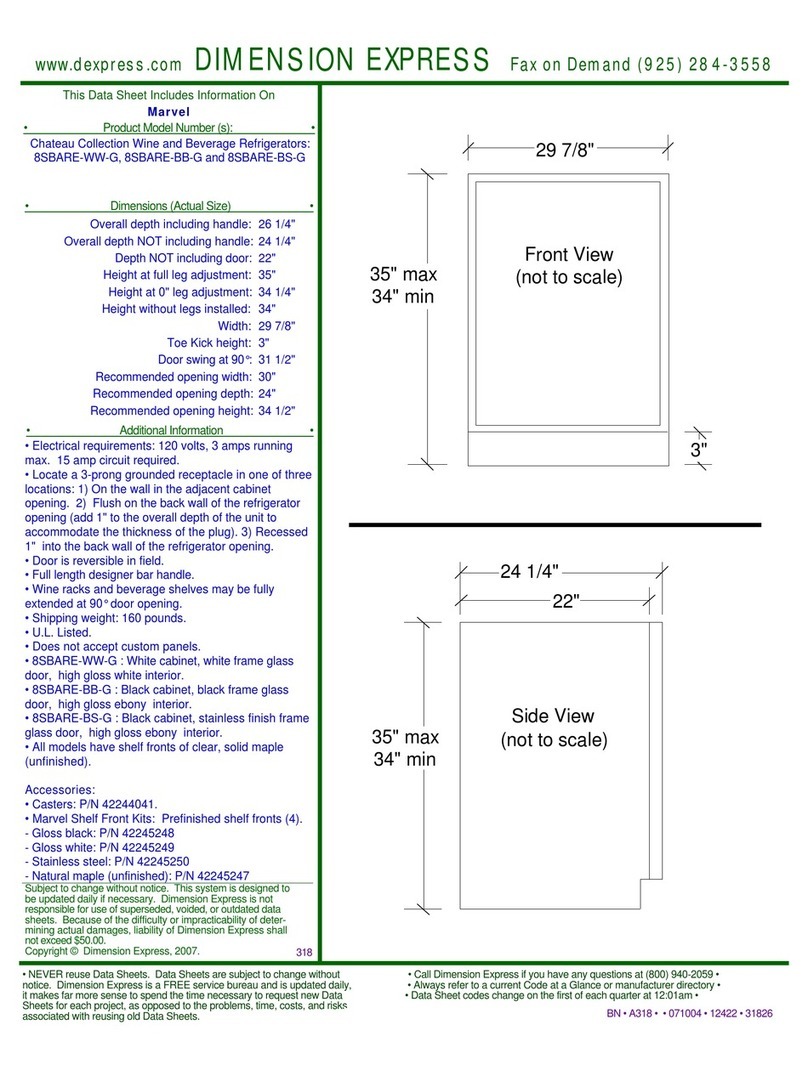

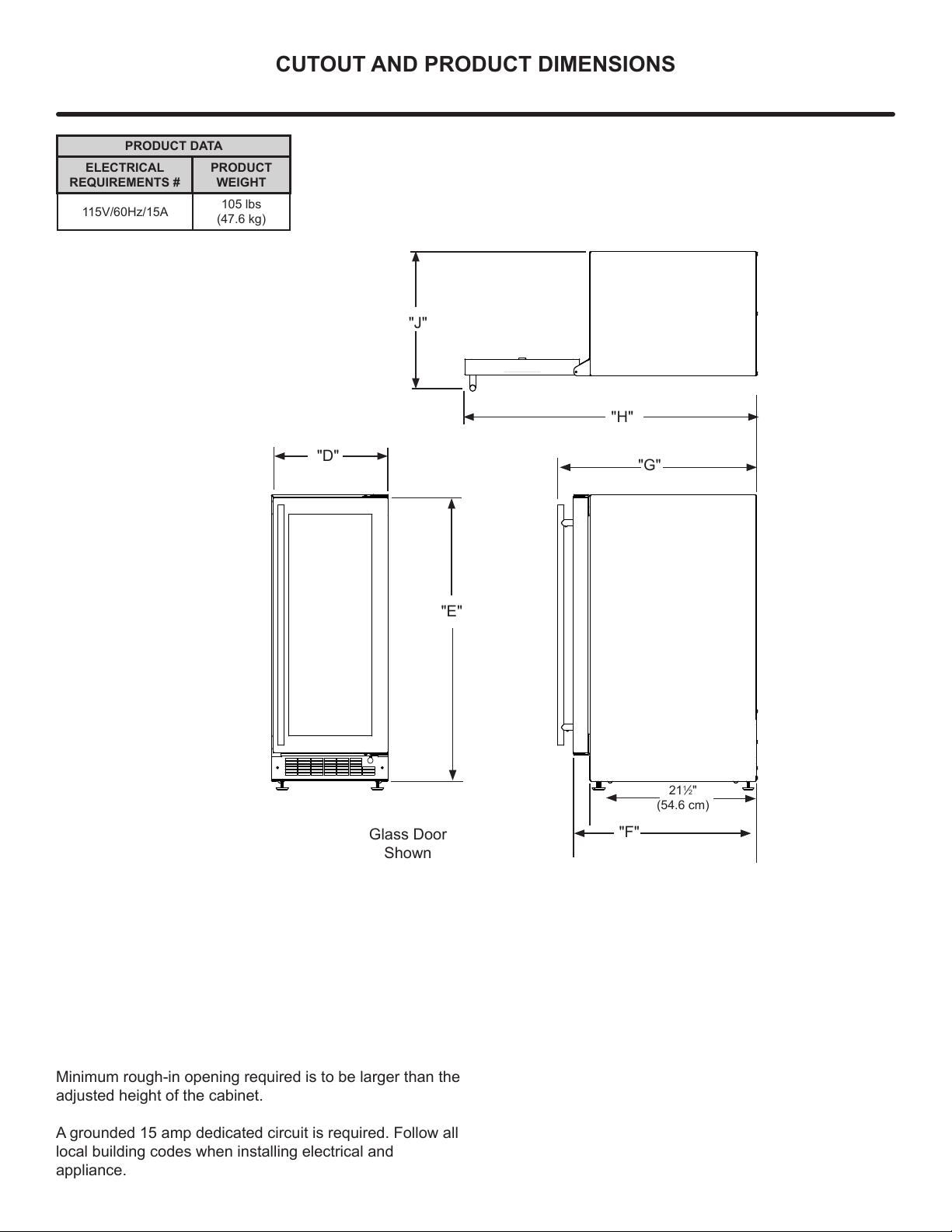

CUTOUT AND PRODUCT DIMENSIONS

PRODUCT DATA

ELECTRICAL

REQUIREMENTS #

PRODUCT

WEIGHT

115V/60Hz/15A 105 lbs

(47.6 kg)

Minimum rough-in opening required is to be larger than the

adjusted height of the cabinet.

A grounded 15 amp dedicated circuit is required. Follow all

local building codes when installing electrical and

appliance.

Glass Door

Shown

"F"

2112"

(54.6 cm)

"D"

"E"

"H"

"J"

"G"

8

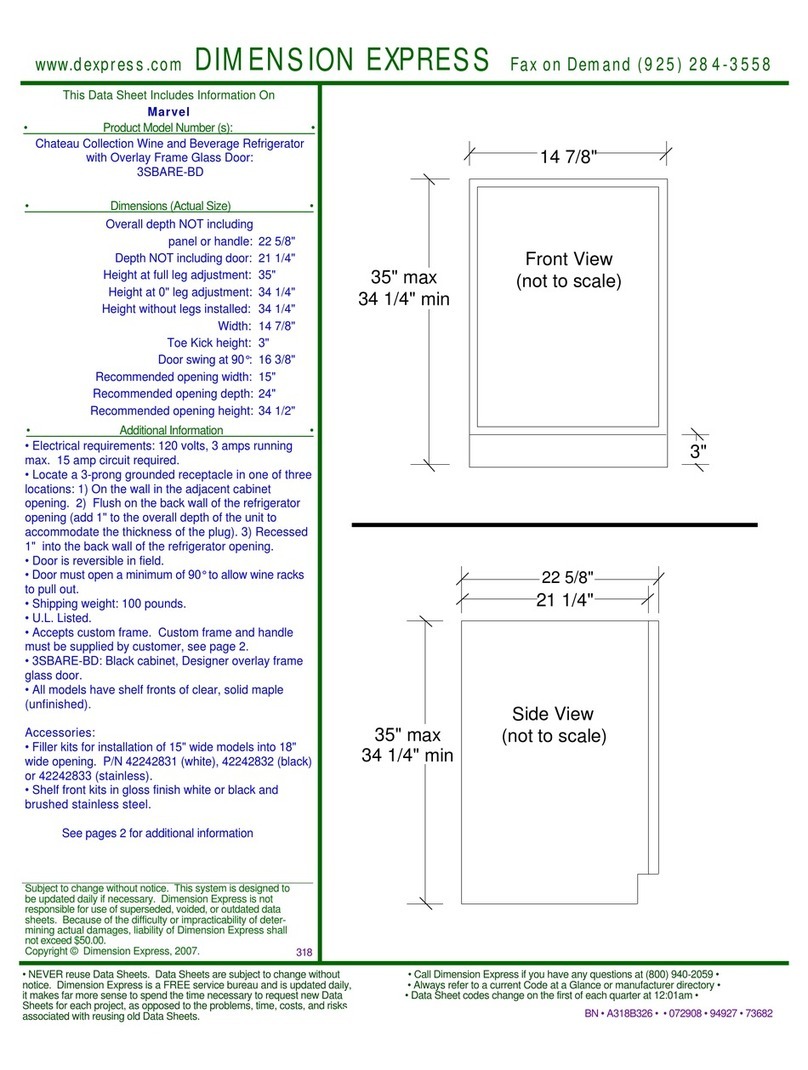

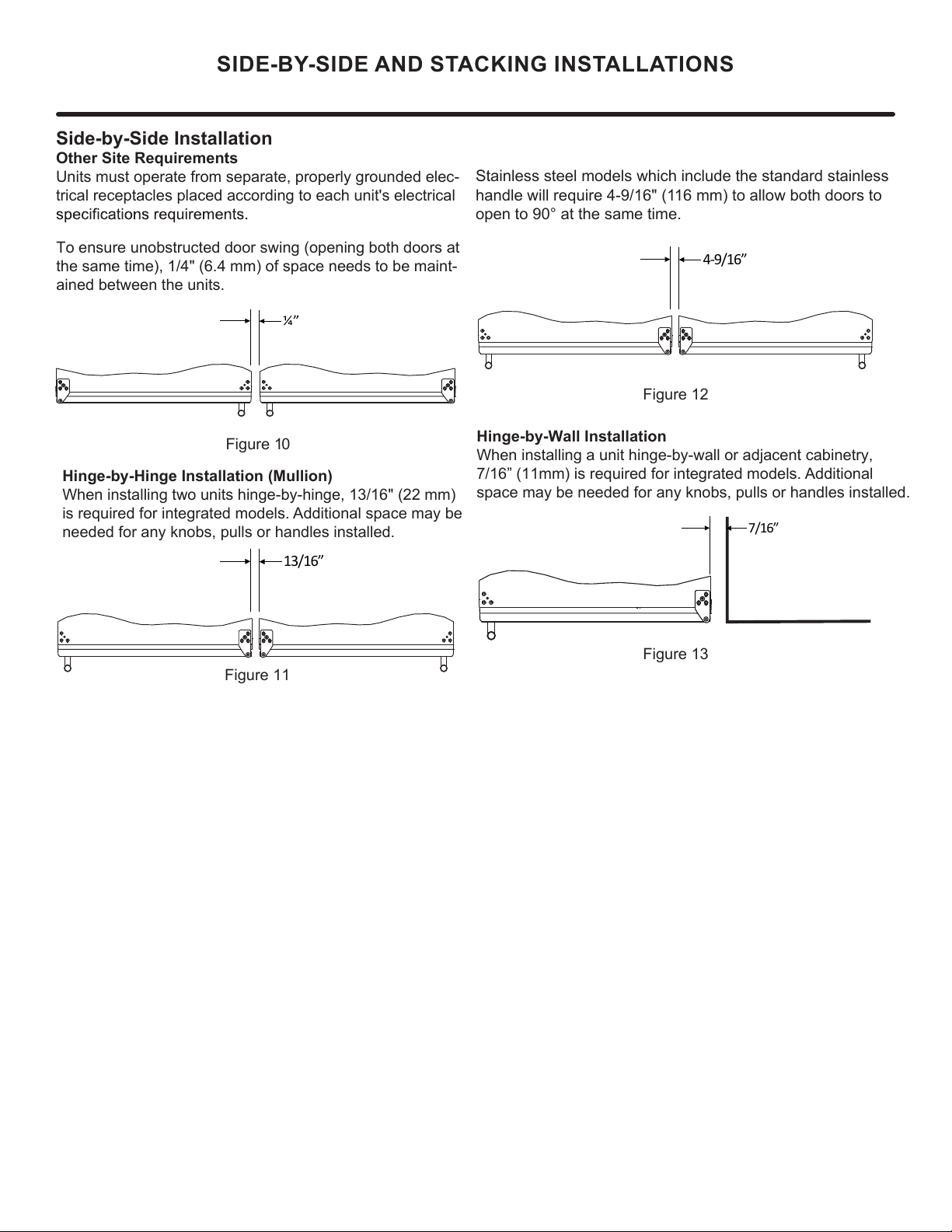

SIDE-BY-SIDE AND STACKING INSTALLATIONS

Side-by-Side Installation

Other Site Requirements

Units must operate from separate, properly grounded elec-

trical receptacles placed according to each unit's electrical

To ensure unobstructed door swing (opening both doors at

the same time), 1/4" (6.4 mm) of space needs to be maint-

ained between the units.

Hinge-by-Hinge Installation (Mullion)

When installing two units hinge-by-hinge, 13/16" (22 mm)

is required for integrated models. Additional space may be

needed for any knobs, pulls or handles installed.

Stainless steel models which include the standard stainless

handle will require 4-9/16" (116 mm) to allow both doors to

open to 90° at the same time.

Figure 10

Figure 11

Figure 12

Figure 13

Hinge-by-Wall Installation

When installing a unit hinge-by-wall or adjacent cabinetry,

7/16” (11mm) is required for integrated models. Additional

space may be needed for any knobs, pulls or handles installed.

¼”

13/16”

7/16”

4-9/16”

9

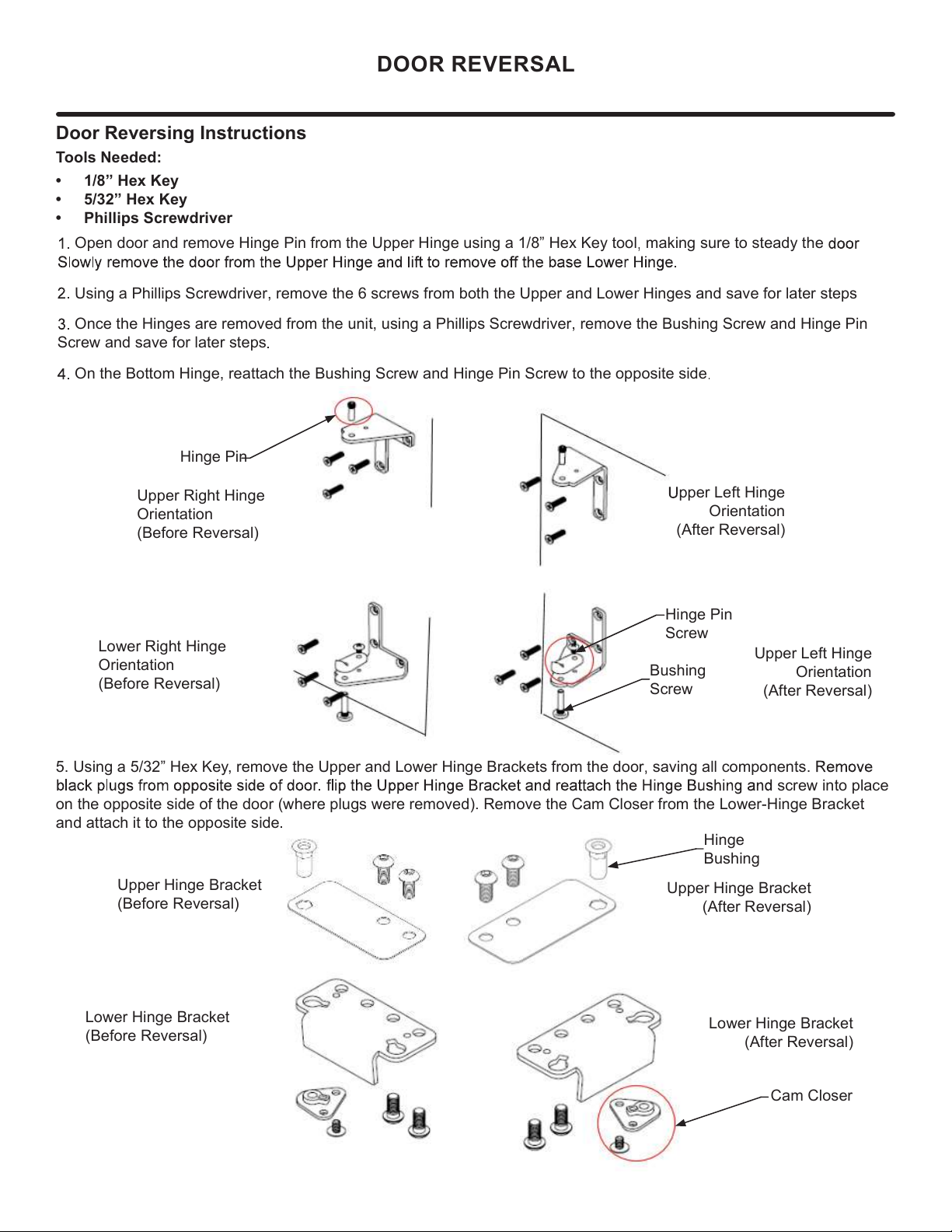

Door Reversing Instructions

Tools Needed:

• 1/8” Hex Key

• 5/32” Hex Key

• Phillips Screwdriver

Open door and remove Hinge Pin from the Upper Hinge using a 1/8” Hex Key tool making sure to steady the

Using a Phillips Screwdriver, remove the 6 screws from both the Upper and Lower Hinges and save for later steps

Once the Hinges are removed from the unit, using a Phillips Screwdriver, remove the Bushing Screw and Hinge Pin

Screw and save for later steps

On the Bottom Hinge, reattach the Bushing Screw and Hinge Pin Screw to the opposite side

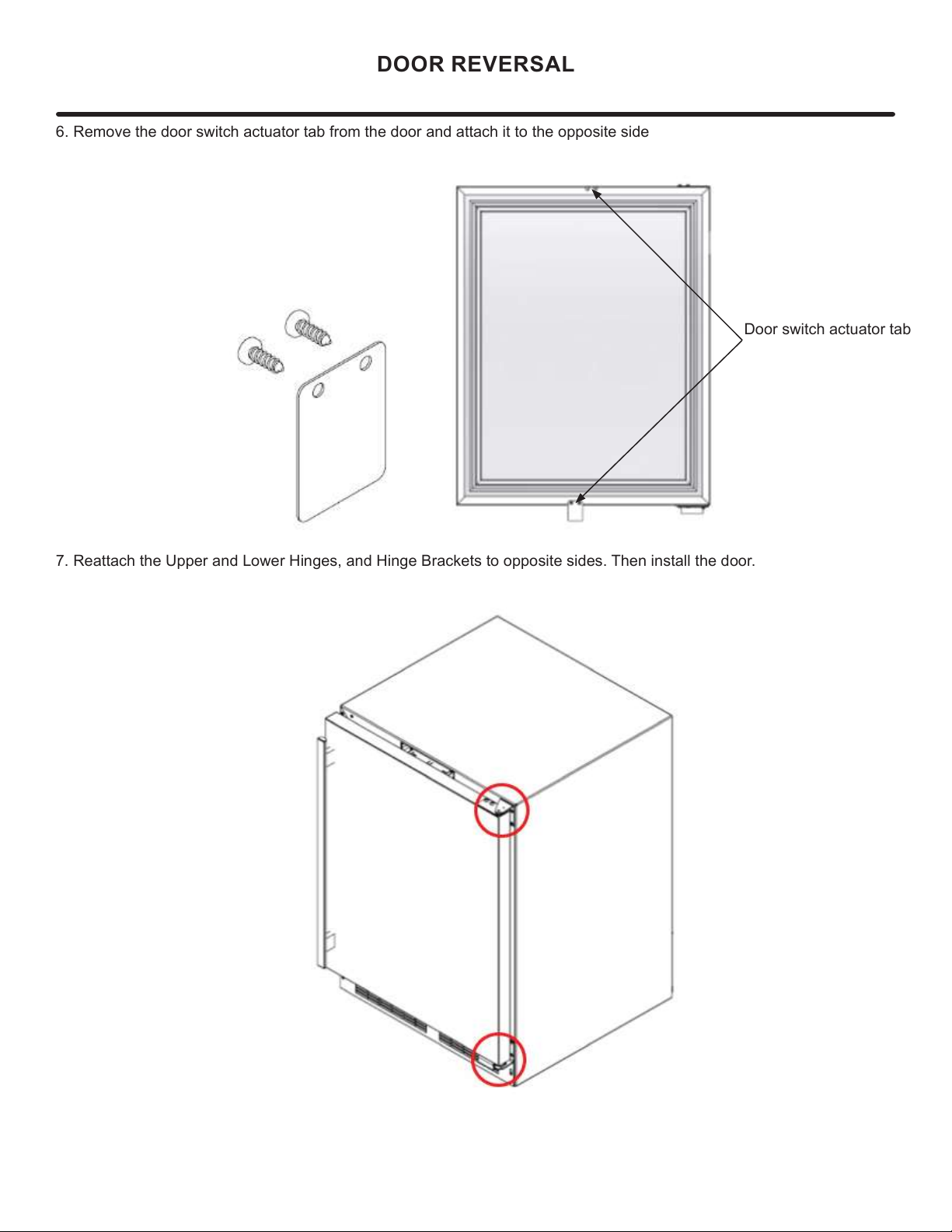

Lower Hinge Bracket

(Before Reversal)

Upper Hinge Bracket

(After Reversal)

Lower Hinge Bracket

(After Reversal)

5. Using a 5/32” Hex Key, remove the Upper and Lower Hinge Brackets from the door saving all components.

screw into place

on the opposite side of the door (where plugs were removed). Remove the Cam Closer from the Lower-Hinge Bracket

and attach it to the opposite side

DOOR REVERSAL

Hinge Pin

Upper Right Hinge

Orientation

(Before Reversal)

Hinge Pin

Screw

Bushing

Screw

Lower Right Hinge

Orientation

(Before Reversal)

pper Left Hinge

Orientation

(After Reversal)

Upper Left Hinge

Orientation

(After Reversal)

Hinge

Bushing

Cam Closer

Upper Hinge Bracket

(Before Reversal)

10

6. Remove the door switch actuator tab from the door and attach it to the opposite side

DOOR REVERSAL

Door switch actuator tab

7. Reattach the Upper and Lower Hinges, and Hinge Brackets to opposite sides. Then install the door.

11

INSTALLING THE WATER SUPPLY

Water Hookup

TO PREVENT DAMAGE TO YOUR ICE MACHINE AND/

OR VOID YOUR WARRANTY, FOLLOW ALL WATER

SUPPLY GUIDELINES AS LISTED BELOW.

Plumbing installation must observe all state and local

codes. All water and drain connections MUST BE made by

a licensed/qualied plumbing contractor. Failure to follow

recommendations and instructions may result in damage

and/or harm.

Water Supply

When connecting the water supply, please note the

following:

• Water Mineral Content must meet the following:

◦ TDS: less than 200 ppm (mg/l)

◦ Hardness: Less than 200 mg/l (12 gpg)

• Water supply MUST NOT be from a water softener.

• A TDS meter is included with your unit

• Water Treatment Options

◦ TDS level of 200 ppm or higher and/or a hardness

of 12-19 gpg can be treated by Marvel’s in-line water filter

accessories available at marvelrefrigeration.com:

• S41016343-ACCY — Standard

• S41016344-ACCY — Large

• S41016345-ACCY — Filter head 3/8”

NPT, initial setup requires head & filter

• Use bypass level 6

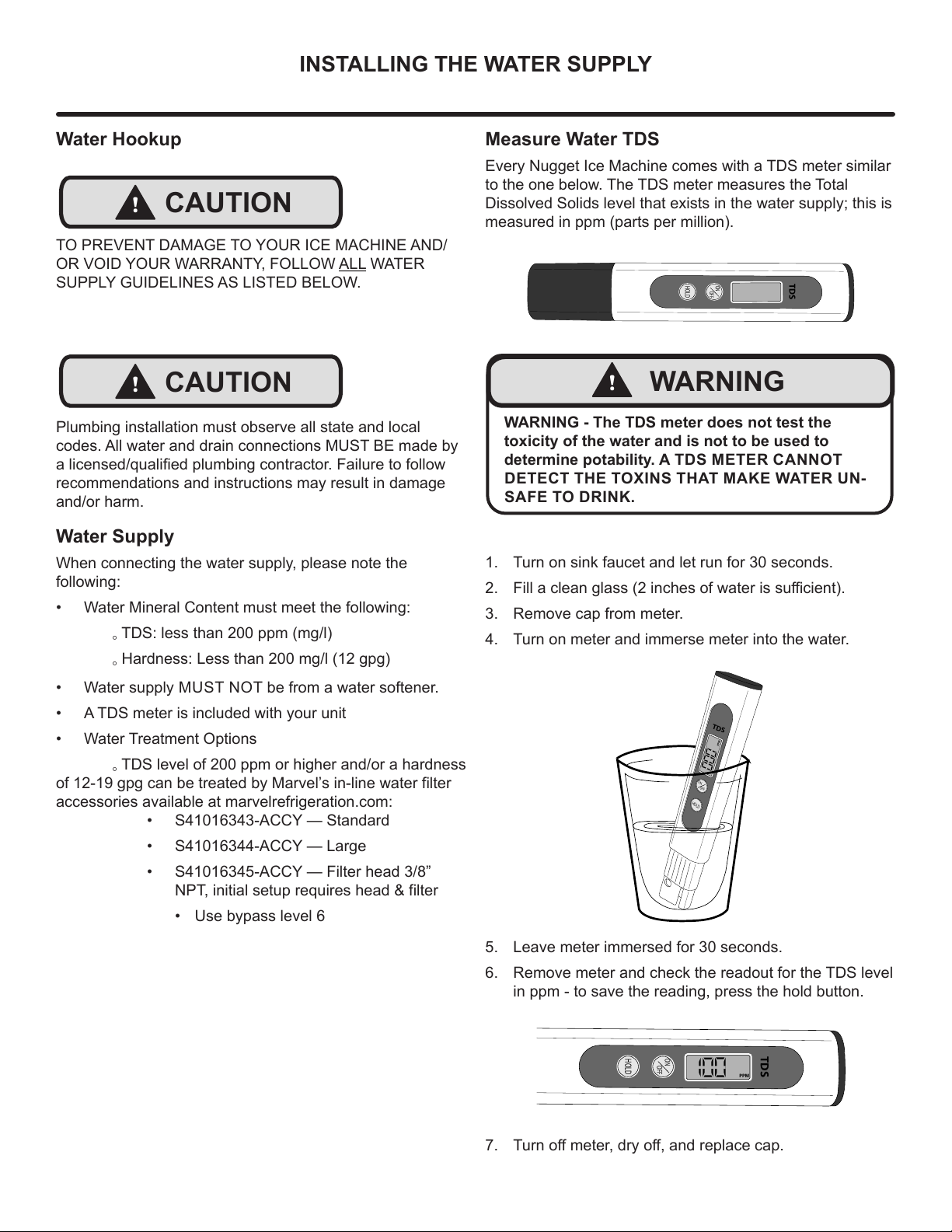

Measure Water TDS

Every Nugget Ice Machine comes with a TDS meter similar

to the one below. The TDS meter measures the Total

Dissolved Solids level that exists in the water supply; this is

measured in ppm (parts per million).

1. Turn on sink faucet and let run for 30 seconds.

2. Fill a clean glass (2 inches of water is sucient).

3. Remove cap from meter.

4. Turn on meter and immerse meter into the water.

5. Leave meter immersed for 30 seconds.

6. Remove meter and check the readout for the TDS level

in ppm - to save the reading, press the hold button.

7. Turn o meter, dry o, and replace cap.

!CAUTION

!CAUTION

ON

OFF

HOLD

TDS

!WARNING

WARNING - The TDS meter does not test the

toxicity of the water and is not to be used to

determine potability. A TDS METER CANNOT

DETECT THE TOXINS THAT MAKE WATER UN-

SAFE TO DRINK.

TDS

ON

OFF

HOLD

PPM

ON

OFF

HOLD

TDS

PPM

12

INSTALLING THE WATER SUPPLY

Based upon the TDS measurement, see the below table

to determine the correct lter required to protect the ice

machine.

Water Quality 1-3 Users 4+ Users

200 TDS and/or

12 gpg hardness

or less

Required

Standard Filter

Change 1x per

year

Required

Large Filter

Change 1x per

year

201-400 TDS and/

or 12-19 gpg hard-

ness

Required

Large Filter

Change 1x per

year

Required

Large Filter

Change 2x per

year

400+ TDS, and/or

20+ gpg hardness

Contact your local water professional

• The water pressure should be between 20 and 120 psi

(138 and 827 kPa).

• The water line MUST have a shut-o valve in the

supply line.

• The water line should be looped into 2 coils. This will

allow the unit to be removed for cleaning and servicing.

Make certain that the tubing is not pinched or damaged

during installation.

Do not use any plastic water supply line. The line is under

pressure at all times. Plastic may crack or rupture with age

and cause damage to your home.

Do not use tape or joint compound when attaching a

braided exible water supply line that includes a rubber

gasket. The gasket provides an adequate seal – other

materials could cause blockage of the valve.

Failure to follow recommendations and instructions may

result in damage and/or harm, ooding or void the product

warranty.

Use new hose set. Do not reuse old hose set.

Turn o water supply and disconnect electrical supply to

unit prior to installation.

Use caution when handling back panel. The edges could

be sharp.

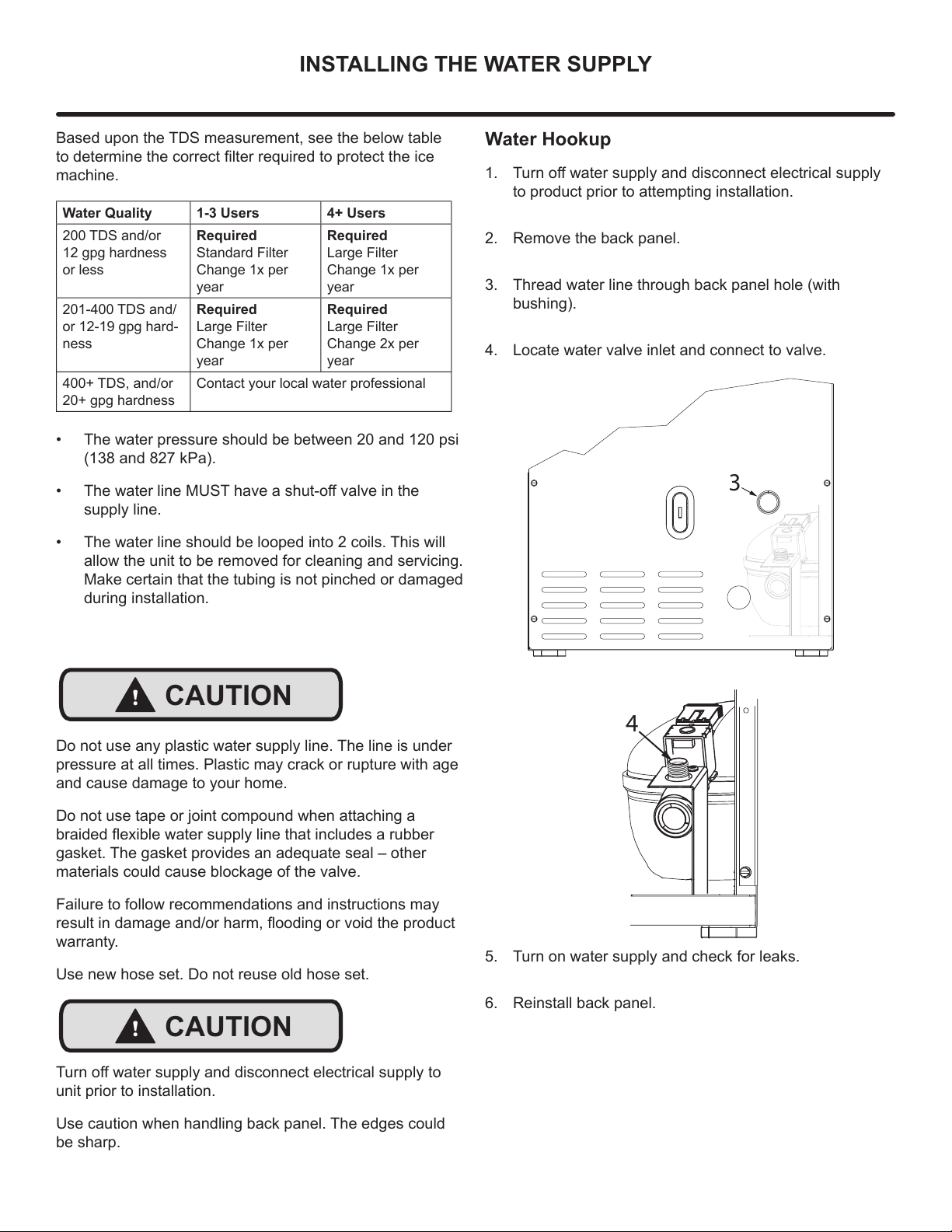

Water Hookup

1. Turn o water supply and disconnect electrical supply

to product prior to attempting installation.

2. Remove the back panel.

3. Thread water line through back panel hole (with

bushing).

4. Locate water valve inlet and connect to valve.

5. Turn on water supply and check for leaks.

6. Reinstall back panel.

!CAUTION

!CAUTION

3

4

13

!CAUTION

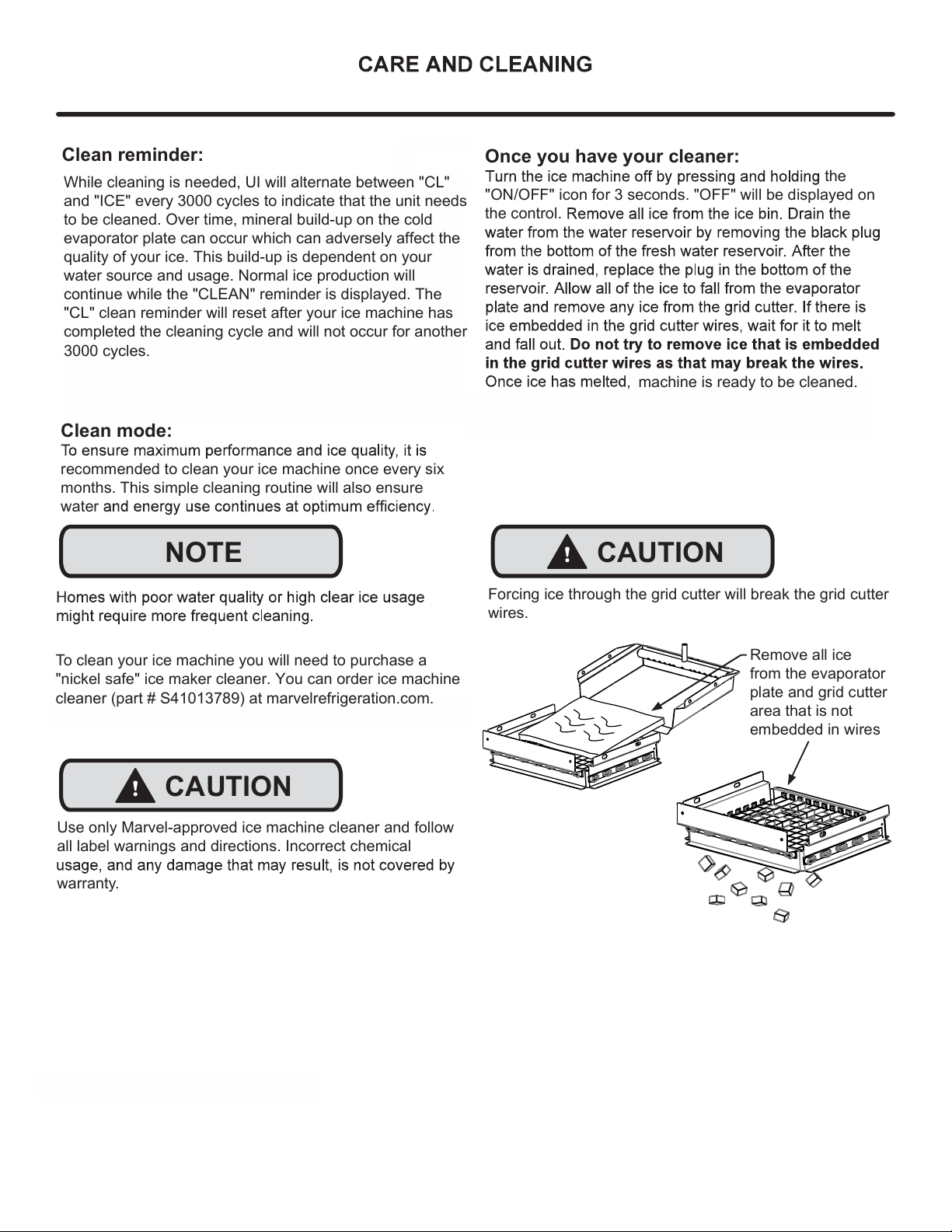

Forcing ice through the grid cutter will break the grid cutter

wires.

!CAUTION

Remove all ice

from the evaporator

plate and grid cutter

area that is not

embedded in wires

Clean reminder: CLEAN

NOTE

OFF

dependent on

your water source and usage. Normal ice production will

continue while the "CLEAN" reminder is displayed.

When

another

. If you choose to clean the appliance at

Clean mode:

recommended to clean your ice machine once every six

months. This simple cleaning routine will also ensure

water

Once you have your cleaner:

the

"ON/OFF" icon for 3 seconds. "OFF" will be displayed on

the control.

Use only Marvel-approved ice machine cleaner and follow

all label warnings and directions. Incorrect chemical

warranty.

To clean your ice machine you will need to purchase a

"nickel safe" ice maker cleaner. You can order ice machine

cleaner (part # S41013789) at marvelrefrigeration.com.

machine is ready to be cleaned.

While cleaning is needed, UI will alternate between "CL"

and "ICE" every 3000 cycles to indicate that the unit needs

to be cleaned. Over time, mineral build-up on the cold

evaporator plate can occur which can adversely affect the

quality of your ice. This build-up is dependent on your

water source and usage. Normal ice production will

continue while the "CLEAN" reminder is displayed. The

"CL" clean reminder will reset after your ice machine has

completed the cleaning cycle and will not occur for another

3000 cycles.

14

CARE AND CLEANING

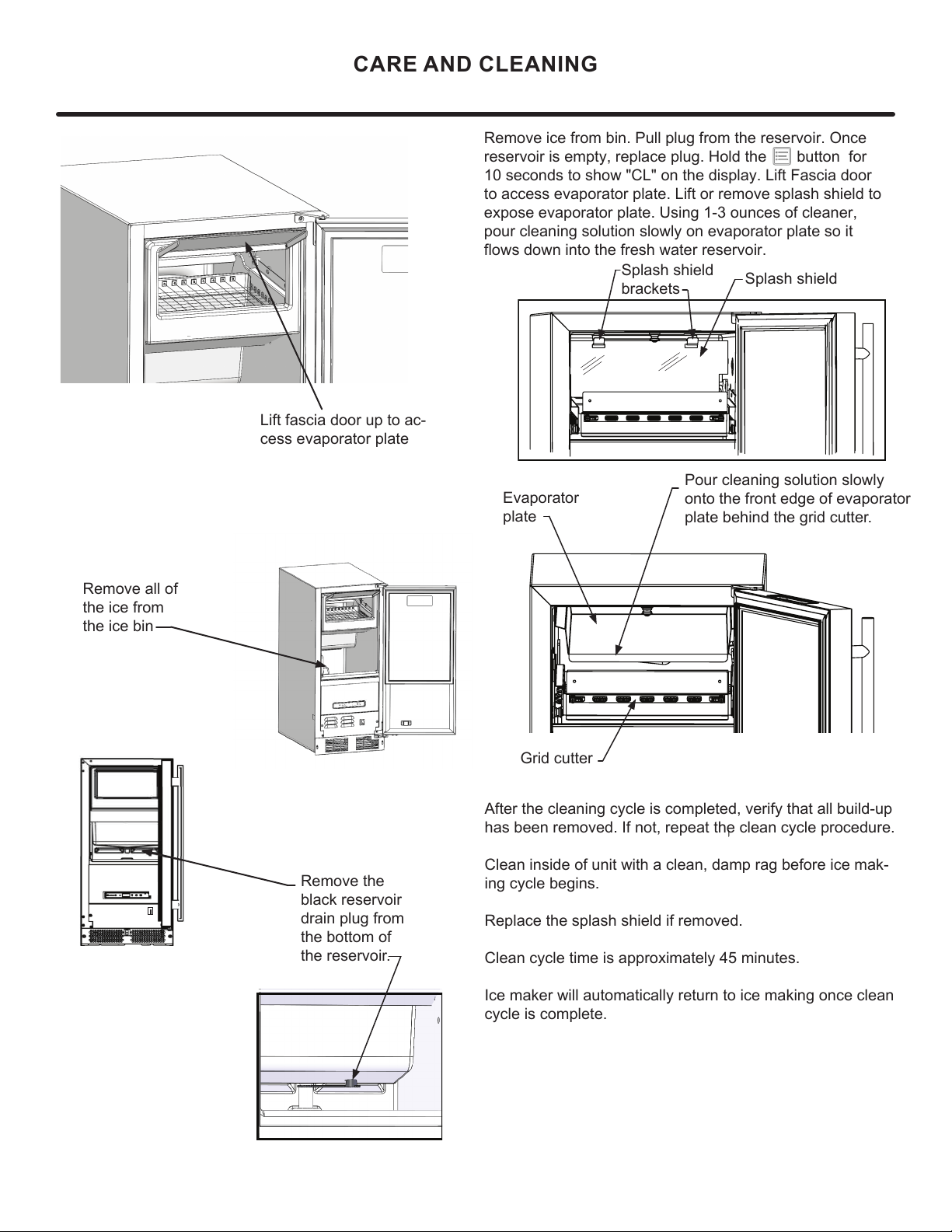

Remove all of

the ice from

the ice bin

Remove the

black reservoir

drain plug from

the bottom of

the reservoir.

Splash shield

brackets

After the cleaning cycle is completed, verify that all build-up

has been removed. If not, repeat the clean cycle procedure.

Clean inside of unit with a clean, damp rag before ice mak-

ing cycle begins.

Replace the splash shield if removed.

Clean cycle time is approximately 45 minutes.

Ice maker will automatically return to ice making once clean

cycle is complete.

Pour cleaning solution slowly

onto the front edge of evaporator

plate behind the grid cutter.

Evaporator

plate

Grid cutter

Splash shield

Lift fascia door up to ac-

cess evaporator plate

Remove ice from bin. Pull plug from the reservoir. Once

reservoir is empty, replace plug. Hold the button for

10 seconds to show "CL" on the display. Lift Fascia door

to access evaporator plate. Lift or remove splash shield to

expose evaporator plate. Using 1-3 ounces of cleaner,

pour cleaning solution slowly on evaporator plate so it

flows down into the fresh water reservoir.

15

16

STAINLESS STEEL MAINTENANCE

Background

Stainless steel does not stain, corrode, or rust as easily as

ordinary steel, but it is not stain or corrosion proof. Stain-

less steels can discolor or corrode if not maintained prop-

erly.

amount of chromium present. It is this chromium that

surface can be damaged or contaminated, which may

result in discoloration, staining, or corrosion of the base

metal.

Care & Cleaning

Routine cleaning of the stainless steel surfaces will serve to

greatly extend the life of your product by removing contami-

nants. This is especially important in coastal areas which

can expose the stainless to severe contaminants such as

It is strongly recommended to periodically inspect and thor-

oughly clean crevices, weld points, under gaskets, rivets,

bolt heads, and any locations where small amounts of liquid

could collect, become stagnant, and concentrate contami-

nates. Additionally, any mounting hardware that is showing

signs of corrosion should be replaced.

Frequency of cleaning will depend upon the installation

location, environmental, and usage conditions.

Choosing a Cleaning Product

The choice of a proper cleaning product is ultimately that

of the consumer, and there are many products from which

to choose. Depending upon the type of cleaning and the

degree of contamination, some products are better than

others.

cleaning of most stainless steel products is to give the sur-

faces a brisk rubbing with a soft cloth soaked in warm water

and a gentle detergent, or mild mixture of ammonia. Rub-

bing should, to the extent possible, follow the polish lines of

the steel, and always insure thorough rinsing after cleaning.

Although some products are called "stainless steel clean-

ers," some may contain abrasives which could scratch the

and some many contain chlorine bleach which will dull,

tarnish or discolor the surface if not completely removed.

After the stainless surfaces have been thoroughly cleaned,

a good quality car wax may be applied to help maintain the

Stainless steel products should never be installed, or stored

in close proximity to chlorine chemicals.

Whichever cleaning product you chose, it should be used

in strict accordance with the instructions of the cleaner

manufacturer.

NOTE

17

If Service is Required:

• If the product is within the rst year warranty period

please contact your dealer or call Marvel Customer

Service at 616.754.5601 for directions on how to obtain

warranty coverage in your area.

• If the product is outside the rst year warranty period,

Marvel Customer Service can provide recommenda-

tions of service centers in your area. A listing of autho-

rized service centers is also available at www.marvelre-

frigeration.com under the service and support section.

• In all correspondence regarding service, be sure to

give the service number, serial number, and proof of

purchase.

• Try to have information or description of nature of the

problem, how long the appliance has been running, the

room temperature, and any additional information that

may be helpful in quickly solving the problem.

• Table "B" is provided for recording pertinent information

regarding your product for future reference.

For Your Records

Date of Purchase

Dealer’s name

Dealer’s Address

Dealer’s City

Dealer’s State

Dealer’s Zip Code

Appliance Serial Number

Appliance Service Number

Date Warranty Card Sent (Must

be within 10 days of purchase).

Table B

OBTAINING SERVICE

18

• Never attempt to repair or perform maintenance on

the appliance until the main electrical power has been

disconnected. Turning the appliance control "OFF"

does not remove electrical power from the unit's wiring.

• Replace all parts and panels before operating.

!WARNING

Electrocution Hazard

TROUBLESHOOTING

Before You Call for Service

troubleshooting guide below. Locate the problem in the

guide and refer to the cause and its remedy before calling

for service. The problem may be something very simple

technician.

Troubleshooting guide:

Ice Machine Operation

Ice machine does not operate

Is the ice machine’s power cord plugged in? Plug the

power cord into a grounded 3 prong outlet.

Is the electronic control showing the "ICE" position?

Check the control to be sure it is in the "ICE" position.

Is a fuse blown or a circuit breaker been tripped?

Replace a blown fuse or reset a tripped circuit breaker.

Is the temperature of the room cooler than it normally

is? The minimum room temperature is 55°F (13°C). The

bin thermistor may be sensing the room temperature and

remains low the ice machine may not restart.

Is there a drain pump in the ice machine? The drain

a few minutes as the drain pump will continue to operate

to dispose of the excess water. If there is still water in the

ice bin check the drain pump vent line and drain line for

obstructions or kinking.

The ice machine is noisy

household refrigerator. This subject is discussed on page

Do you hear water being circulated in the ice

machine? This is a normal sound as water is added once

every ice making cycle.

Is there a “whoosing” sound? Make sure water is

getting to the ice machine. Also check to make sure the

drain plug is fully seated in the water reservoir.

Is there an ice slab caught between the evaporator

plate and the grid cutter? First check to see if the ice

machine is level. If the ice machine is level run a cleaning

cycle.

Ice Production

Little or no ice production from the ice machine

Is the electronic control set to the "ICE" position?

Check the control to be sure it is in the "ICE" position.

Is water getting to the ice machine? Make sure nothing

is restricting the water supply such as a closed water

Has the ice machine just been started? A typical ice

production cycle can take up to 1¹² hours. Initial start up

cycles can take longer. Check the ice machine after 24

hours for ice accumulation in the bin.

Is the reservoir drain plug in place? Check that the

reservoir drain plug is properly seated.

Is the water distributor tube restricted? Run a cleaning

make sure they are not restricted.

? Make sure the

grille in the front of the ice machine is open for proper air

circulation.

? Move

the ice machine to an area where the ambient temperature

is below 90°F (32°C) for built-in ice machines or below

100°F (38°C) for freestanding ice machines. The ice

machine should not be placed next to a heat source such

as an oven. Check the cold water connection.

Is there scale build up in the ice machine? If there is

19

TROUBLESHOOTING

Plumbing Problems

Is the drain hose aligned over the drain? Move the ice

machine to align the drain.

Is the ice machine draining properly? Check that there

are no kinks or restrictions in the drain lines; this can

cause water to back up in the ice bin. Check that foreign

material is not blocking the ice bin drain located at the

right rear corner of the ice bin. Check the drain pump

discharge and vent line or any restrictions or kinks. Check

that the drain pump is level.

they cannot be repaired by the service technician. A

Ice Quality

Is there mineral scale build up on the evaporator

plate

Is there a high mineral content in the water? The water

Are food items being stored in the ice bin? Remove

food from the ice bin.

Unpleasant Odors

on the water supply line.

Clumps of ice

Are there clumps of ice in the bin? If the ice isn’t used

on a regular basis it will melt and form into clumps. Break

up the ice clumps with the ice scoop.

Ice cubes are too big or too small

Is there low ice consumption? Ice is slowly melting in

will return to the regular size.

Is the ice slab releasing? Clean the evaporator. See

Is the distributor tube restricted? Check the water line

to the ice machine to make sure there are no restrictions

Troubleshooting the Drain Pump

If the drain pump reservoir (not the ice machine bin)

If the ice machine is not working, check the following:

• Make sure there is power at the receptacle.

• Make sure the ice machine is turned on.

• Make sure the ice bin is not full.

Then check the drain pump:

The pump does not run:

• Make sure the pump is plugged in and there is power

to the receptacle.

• Check the inlet to the drain pump for debris and clean

as needed. Remove clamps and inlet tube from drain

pump to check for and remove debris.

• Make certain the vent line is free of kinks/sharp bends

or restrictions.

• Make certain there is enough water to activate the

of water to activate the drain pump.

The pump runs, but no water is pumped out:

• Check that the vent is clear and free of restrictions.

• Check the discharge line to make certain there are no

restrictions.

• Make sure that the discharge tubing has not exceeded

the maximum lift of eight (8) feet (2.44 meters) and the

horizontal run is not greater than twenty (20) feet (6.1

meters).

• Check to make certain the drain pump is level.

• Check that the vent is clear and free of restrictions.

The ice machine is running but not producing ice:

• Check to make sure water is not backing up in the ice

bin.

NOTE

NOTE

20

Table of contents

Other Marvel Refrigerator manuals

Marvel

Marvel MPFZ424-IS31A User manual

Marvel

Marvel 61WC-BD User manual

Marvel

Marvel ML15BC Manual

Marvel

Marvel MLWD224 User manual

Marvel

Marvel MPWC424 User manual

Marvel

Marvel 6SBARE Manual

Marvel

Marvel 4570105 User manual

Marvel

Marvel 6BAR-BD User manual

Marvel

Marvel MLCL215 User manual

Marvel

Marvel 8SBARE Manual

Marvel

Marvel AGA MP42SS2 User manual

Marvel

Marvel 3BARM Installation and operating instructions

Marvel

Marvel 80RF-BB-F Manual

Marvel

Marvel MLCP215-IS01B User manual

Marvel

Marvel MLBV215-IG01A User manual

Marvel

Marvel MLNP115-IS01A User manual

Marvel

Marvel MPWD424-SS31A User manual

Marvel

Marvel MPWC424-SS31A User manual

Marvel

Marvel 6ADA-BB Guide

Marvel

Marvel MPFZ424-SS31A User manual