Marvel 4570105 User manual

Table of contents

Other Marvel Refrigerator manuals

Marvel

Marvel ML24BC Manual

Marvel

Marvel ML15BC User manual

Marvel

Marvel MOKR224-SS31A User manual

Marvel

Marvel MORE124-SS31A User manual

Marvel

Marvel MLCP215 User manual

Marvel

Marvel MABV224 User manual

Marvel

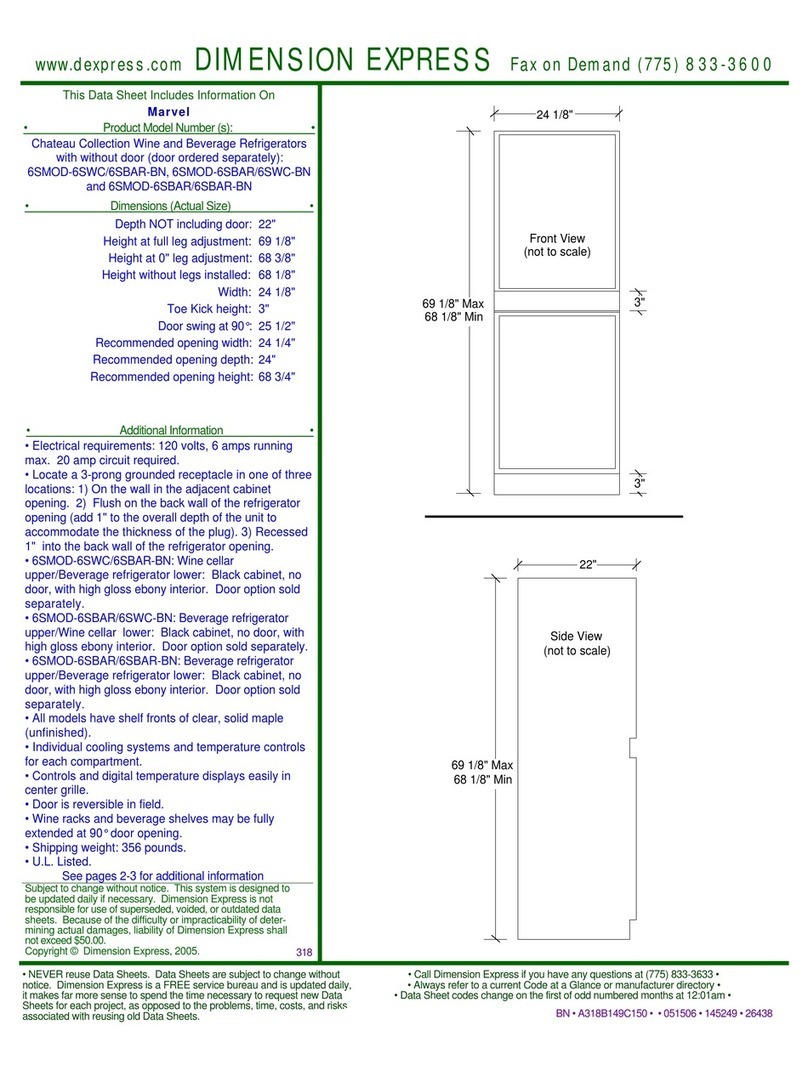

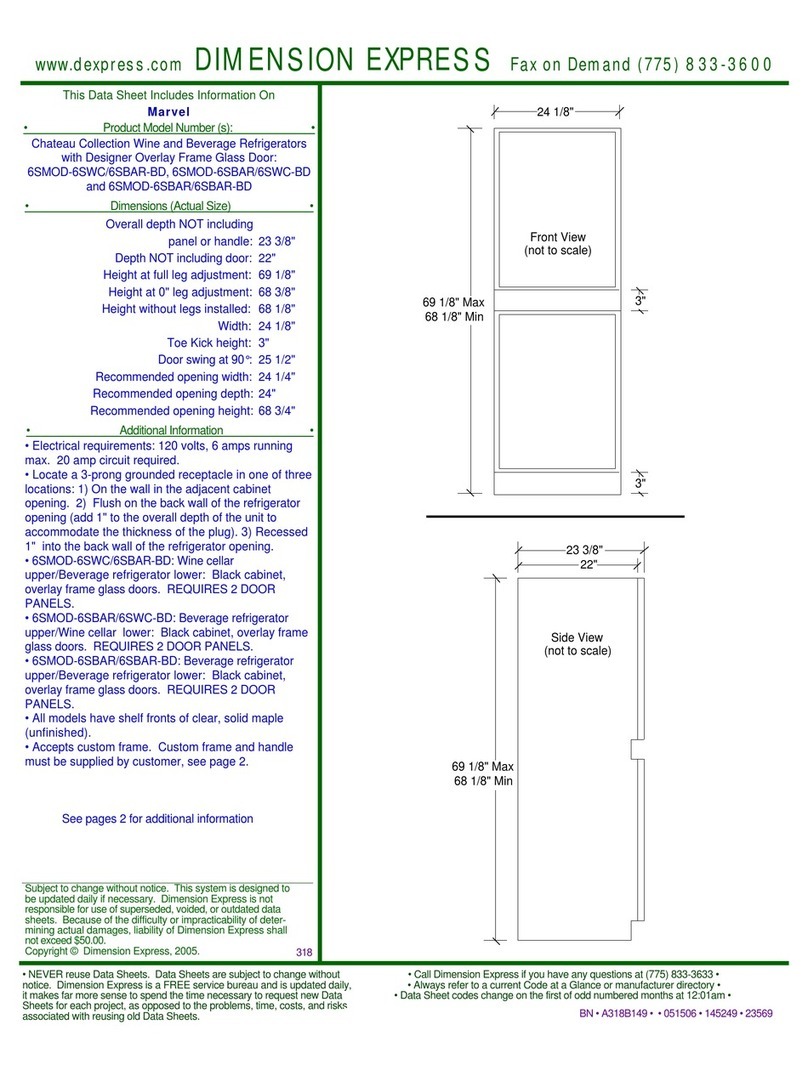

Marvel 6SMOD-6SBAR/6SBAR-BD User manual

Marvel

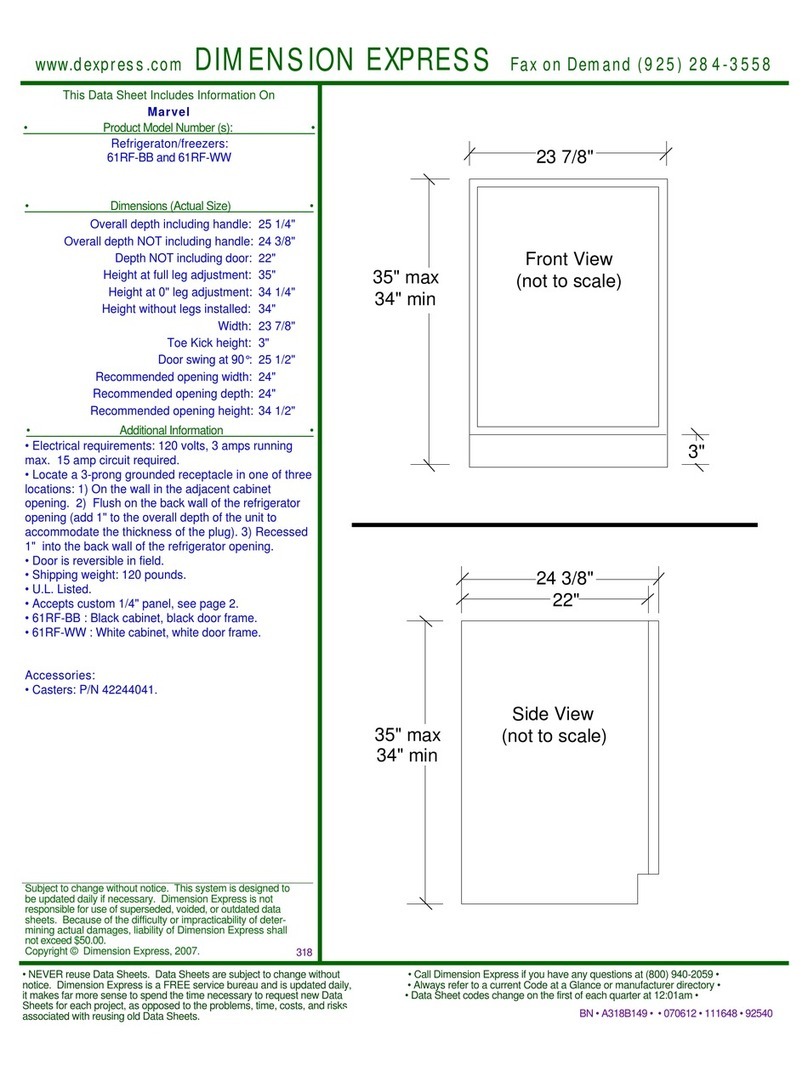

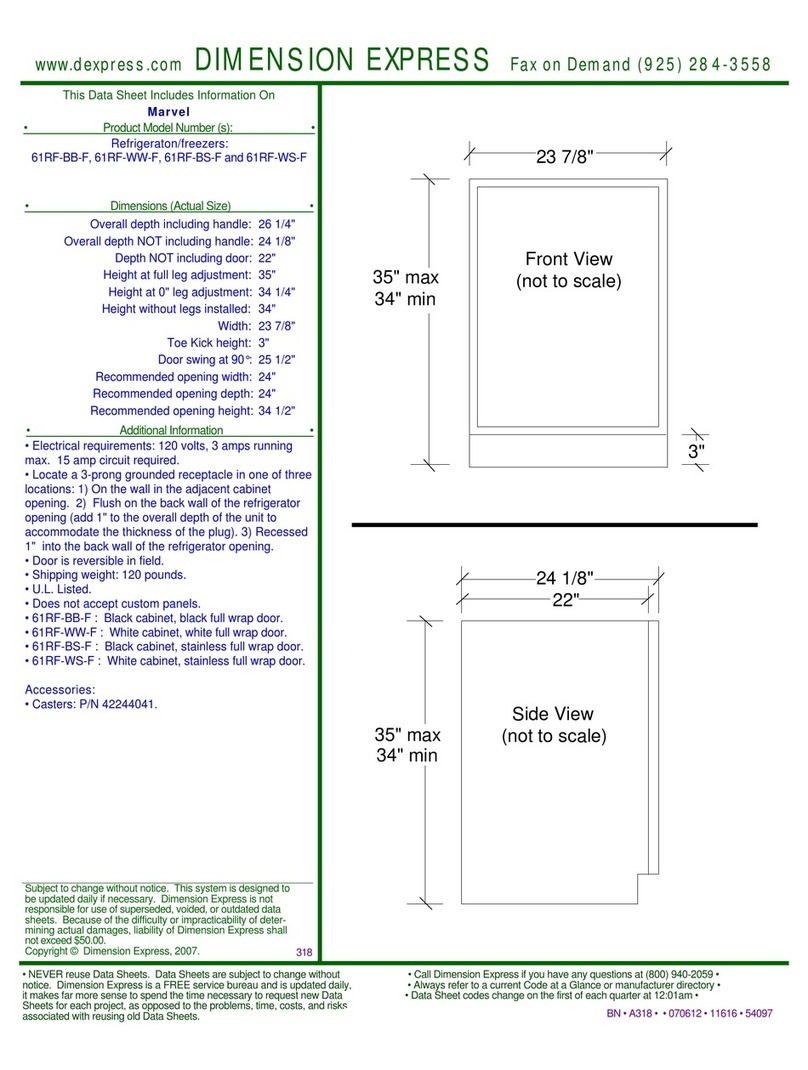

Marvel 61RF-BB User manual

Marvel

Marvel MPBD424-SG31A User manual

Marvel

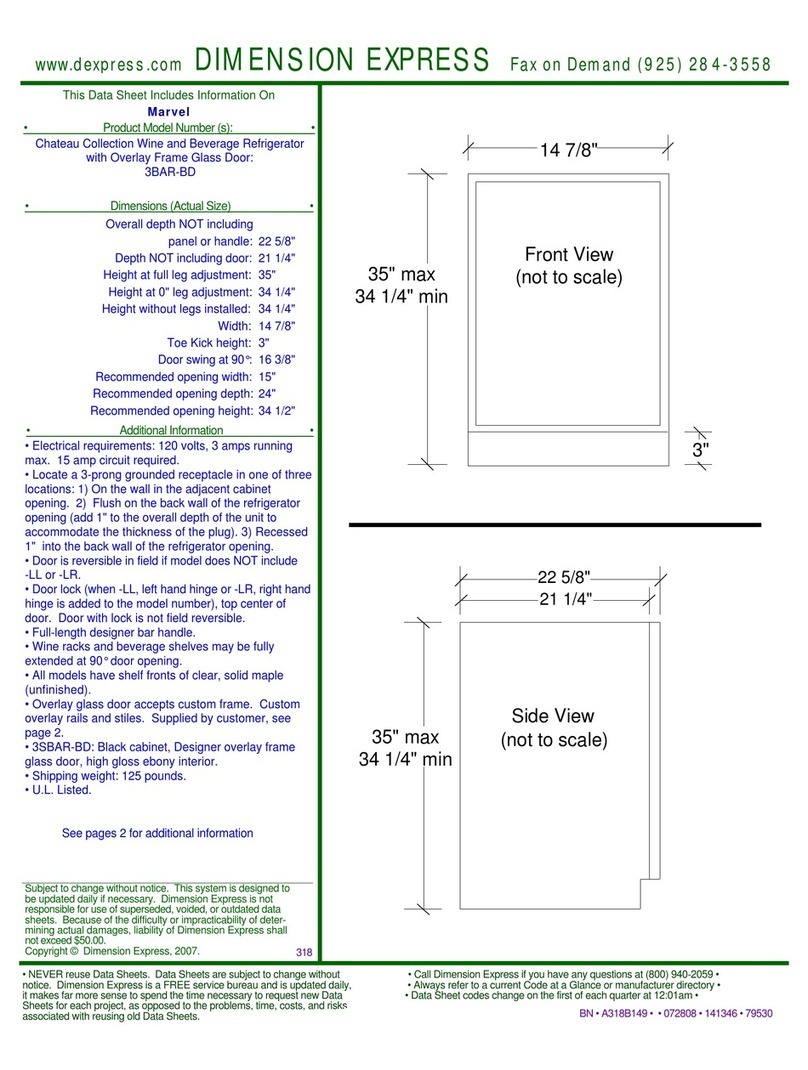

Marvel 3BAR-BD User manual

Marvel

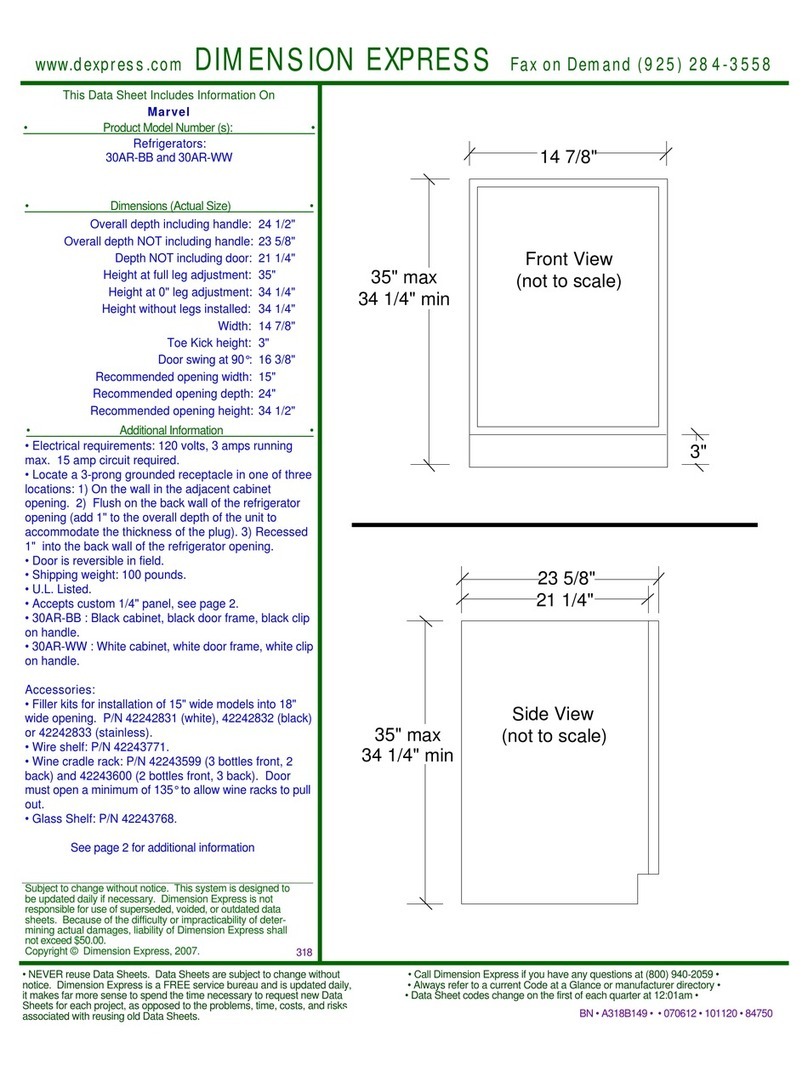

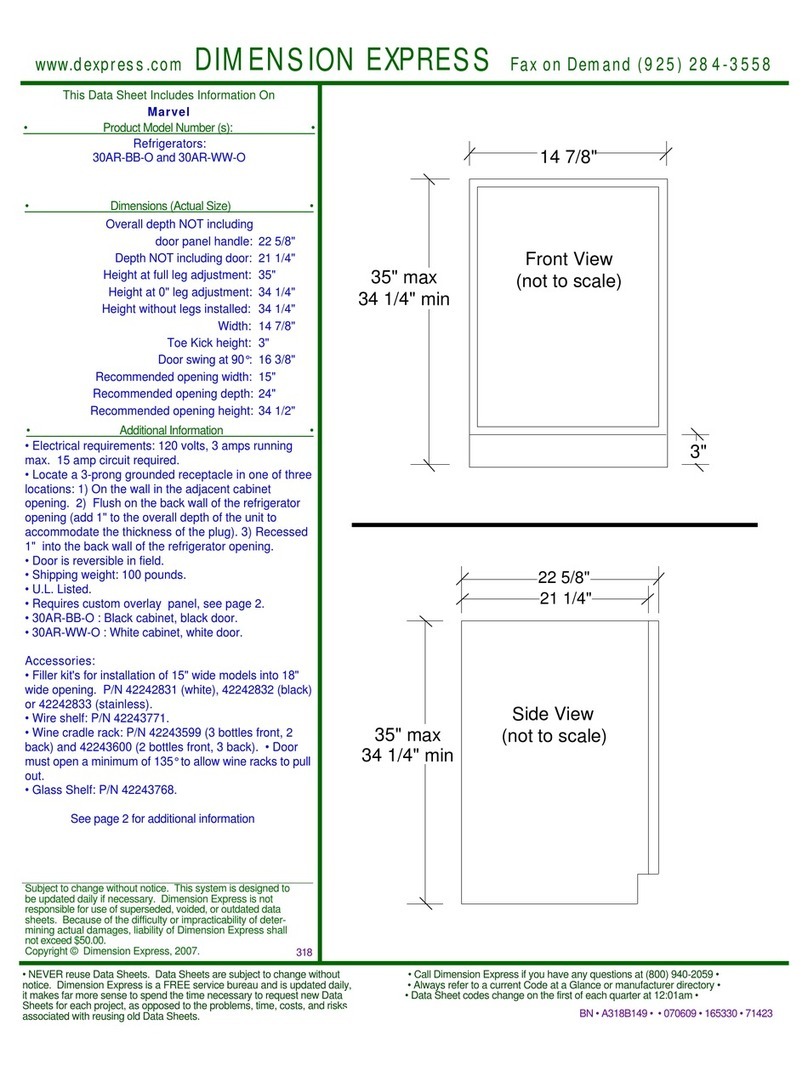

Marvel 30AR-BB User manual

Marvel

Marvel MPWC415-IS31A User manual

Marvel

Marvel MPRE424-SG81A User manual

Marvel

Marvel MLCL215-SG01A User manual

Marvel

Marvel 30AR-BB-O User manual

Marvel

Marvel MLRE124-IS11A User manual

Marvel

Marvel 6ORDE-SS-F User manual

Marvel

Marvel 61RF-BB-F User manual

Marvel

Marvel MPWD424-IS31A User manual

Marvel

Marvel MARE224IS41A User manual

Popular Refrigerator manuals by other brands

Frigidaire

Frigidaire FRS23R4C Factory parts catalog

La Germania

La Germania DPV212R manual

Gorenje

Gorenje NRS9182VX1 Detailed instructions for use

Beko

Beko TLDA 567 Installation, operation & food storage instructions

Amica

Amica VKS 1562 Series operating instructions

Silver King

Silver King SKRU27-EGUS2 Installation and owner's manual