Contents

Page 2

Table of contents

1About this operating manual....................................................................................3

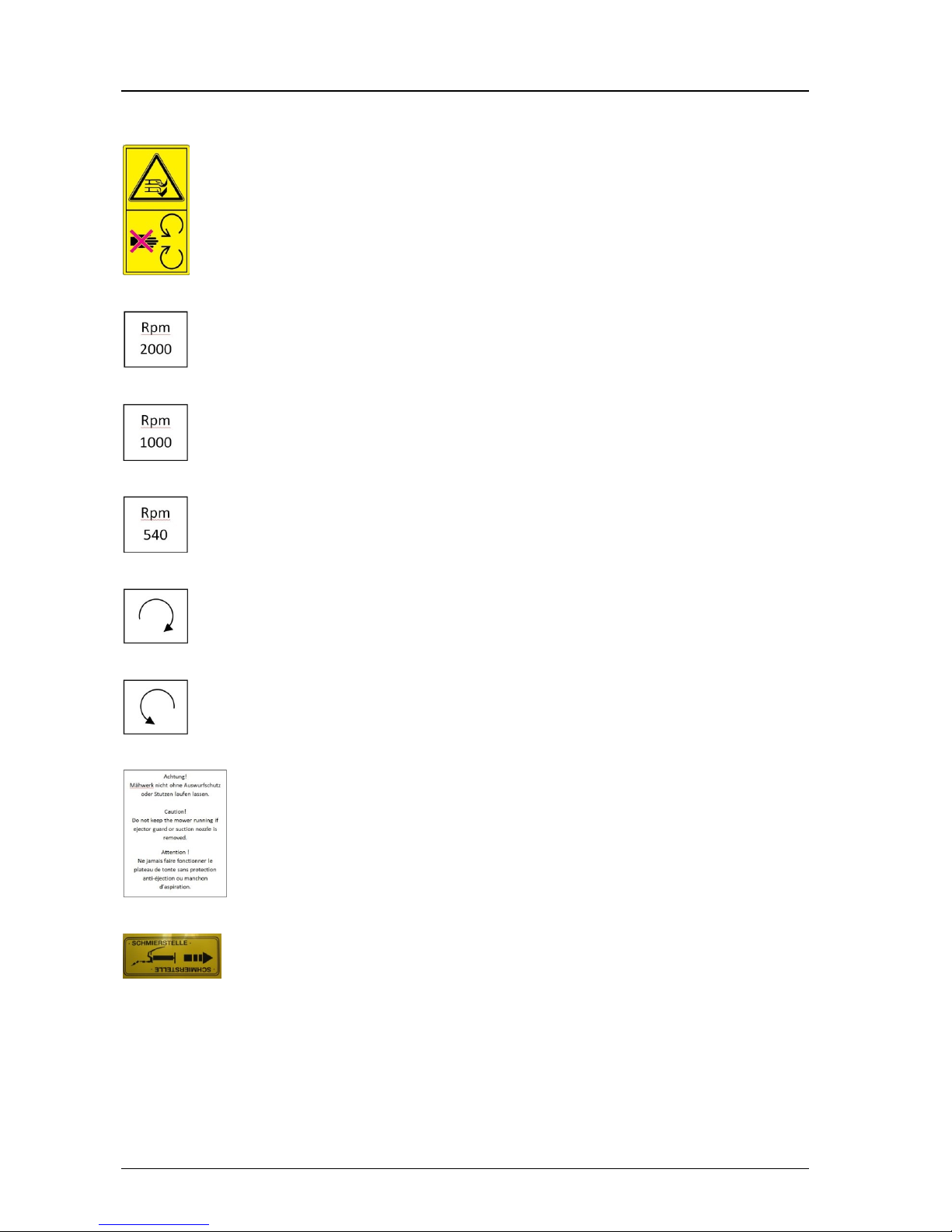

2Safety.........................................................................................................................4

2.1 Intended use ...............................................................................................................4

2.2 Qualifications of personnel ..........................................................................................4

2.3 General safety instructions..........................................................................................4

2.4 Special safety notices .................................................................................................4

3Task and use .............................................................................................................7

3.1 Task............................................................................................................................7

3.2 Function ......................................................................................................................7

3.3 General instructions for mowing ..................................................................................7

4Mounting the implement...........................................................................................8

4.1 Mounting the front mower on the tractor vehicle..........................................................9

4.2 Mowers with mechanical drive ....................................................................................9

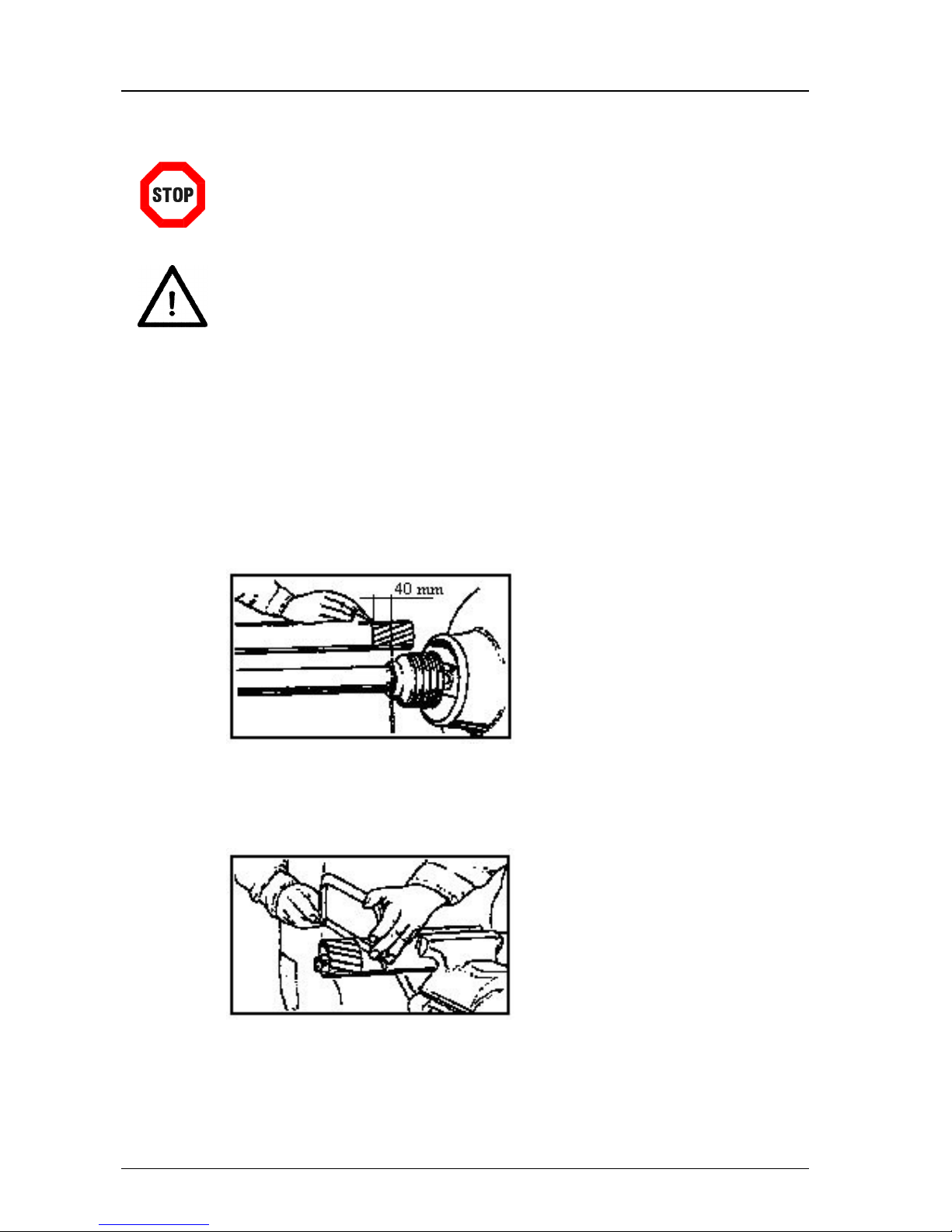

4.2.1 Adapting the universal joint shaft.................................................................................9

4.2.2 Mounting the universal joint shaft..............................................................................11

4.2.3 Dismounting the universal joint shaft.........................................................................12

4.3 Mowers with hydraulic drive ......................................................................................12

4.4 Mounting the suction port..........................................................................................12

5Operation.................................................................................................................14

5.1 Adjusting the cutting height .......................................................................................14

5.2 Adjusting the air intake..............................................................................................15

6Maintenance ............................................................................................................16

6.1 Maintenance after 50 operating hours or after a longer standstill period....................16

6.2 Mounting the V-belt...................................................................................................16

6.3 Sharpening the mower blades...................................................................................17

6.4 Faults........................................................................................................................18

6.5 Repair .......................................................................................................................18

7Disposal...................................................................................................................19

8Guarantee ................................................................................................................19

9Technical data .........................................................................................................19

10 List of illustrations..................................................................................................20

11 EC Declaration of Conformity ................................................................................22