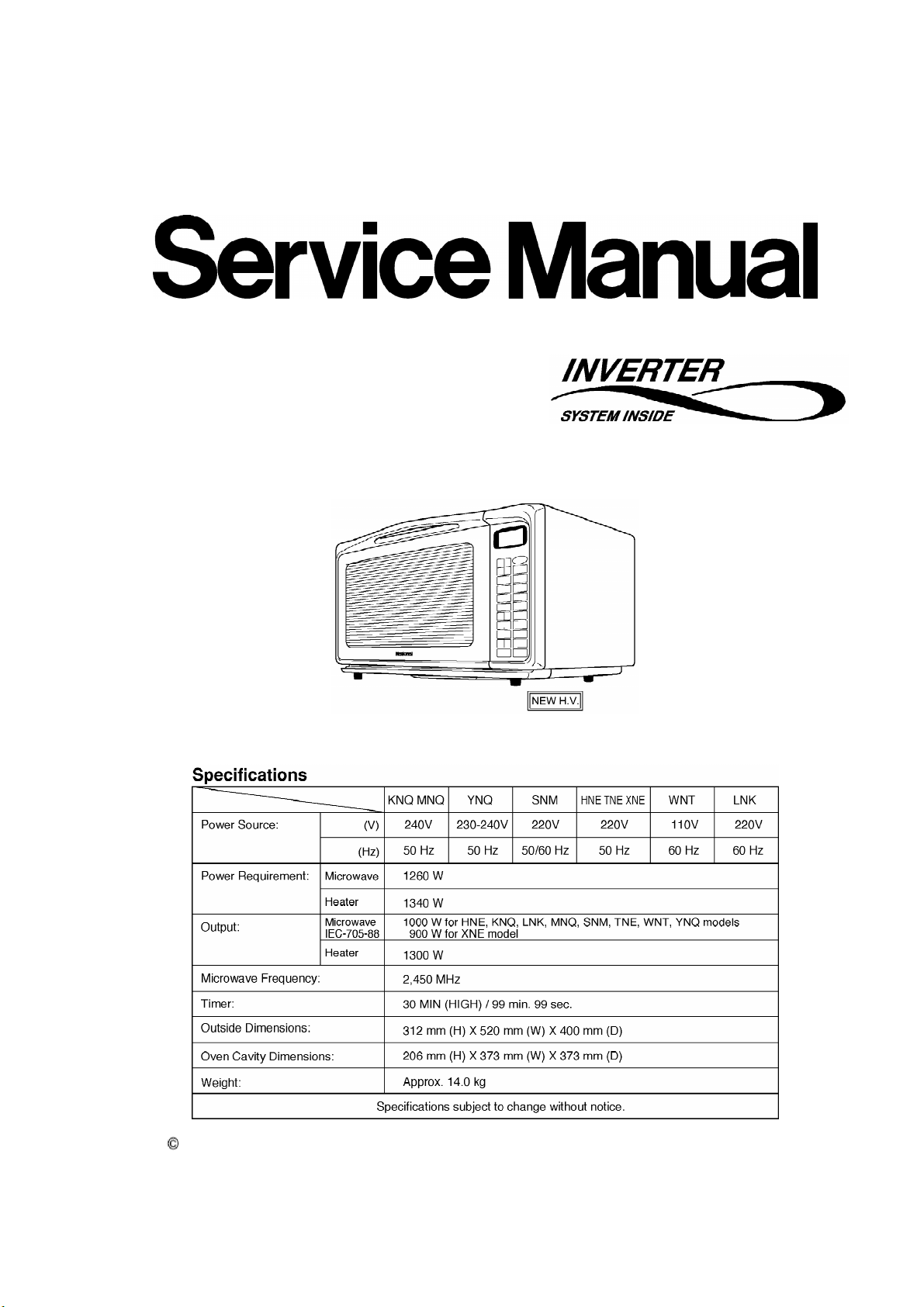

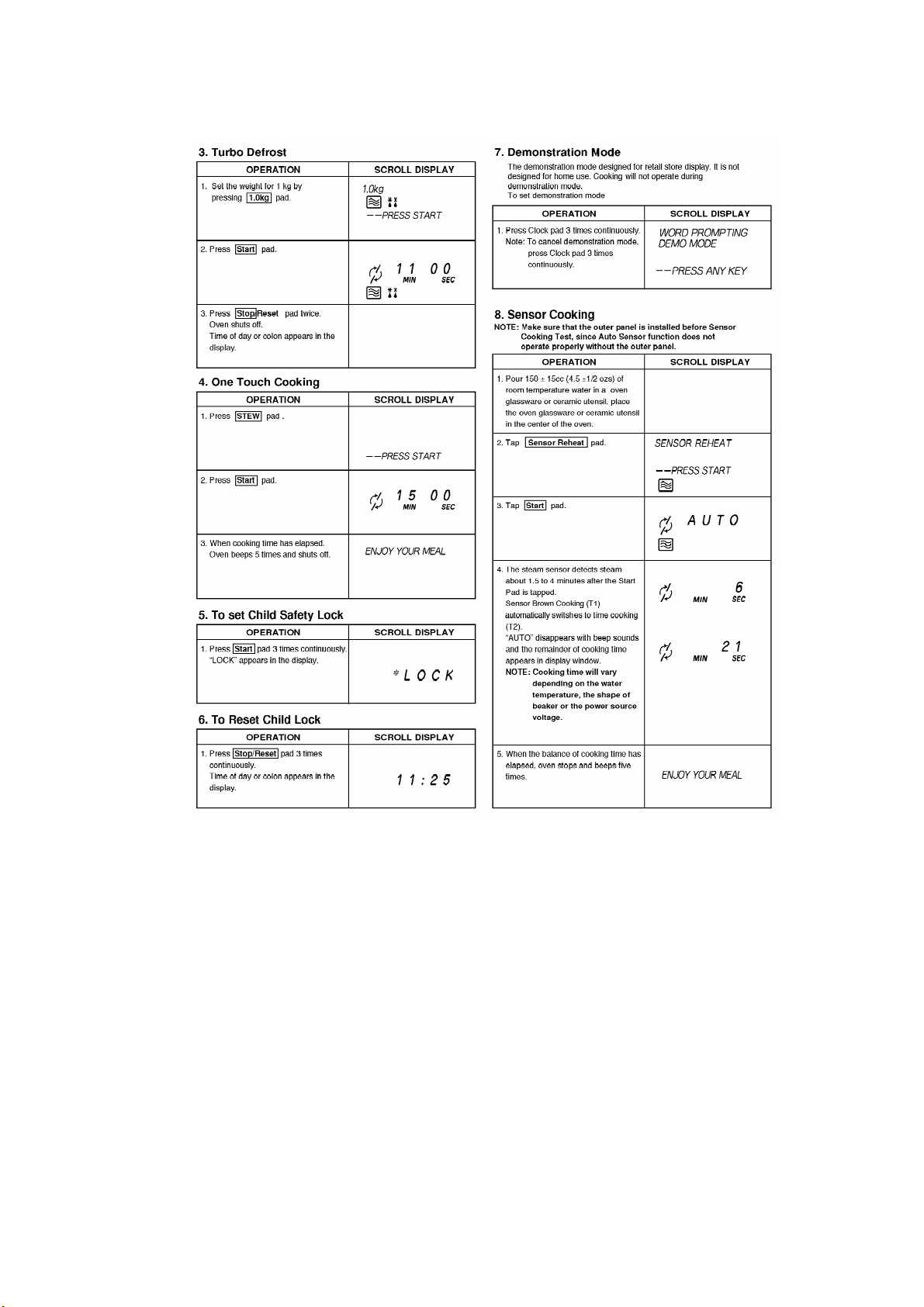

7.2. Grill cooking

The digital programmercircuit generates the powerrelay4 control signal at ON time during grill

cooking.

7.3. Combination cooking

Combination cooking is accomplishedbymicrowave and grill cooking. The digital programmer

circuit controls ON-OFF time of powerrelay1 and 4 as showninthe table.

NOTE: Aftergrill and combination cooking, fanmotorrotates for1 minute tocool ovenand

electric components.

7.4. Auto Defrost, One Touch Menu and Auto Reheat Control

Whenthose autocontrol feature is selectedand Start padis pressed:

1. The digital programmer circuitdetermines the power level and

cooking time to complete cooking and indicates the operating

state inthe display. The tableshowsthe corresponding cooking

times for respective weight bycategories.

2. When cooking time inthe displaywindow has elapsed, the oven

turns off automaticallybythe controlled signal from the digital

programmer circuit.

NOTE: Afterone touchmenu and autoreheat cooking, fanmotorrotates for1 minute tocool

ovenand electric components.

10