2

Innehåll

A. VEHICLE DESCRIPTION............................................................................................................................5

Vehicle....................................................................................................................................................7

Performance.........................................................................................................................................14

EN-norms..............................................................................................................................................16

Load diagram........................................................................................................................................18

B. TRANSPORT AND FIRST START .........................................................................................................19

Crane transport ....................................................................................................................................19

Secure the vehicle during transport.....................................................................................................19

First start-up.........................................................................................................................................20

Towing Maxtruck 2T.............................................................................................................................20

C. BATTERY-SERVICE, CHARGING, CHANGE..........................................................................................21

Battery types ........................................................................................................................................22

Change of battery.................................................................................................................................23

Charging the battery ............................................................................................................................24

Battery charge indictor.........................................................................................................................24

D. OPERATION.......................................................................................................................................25

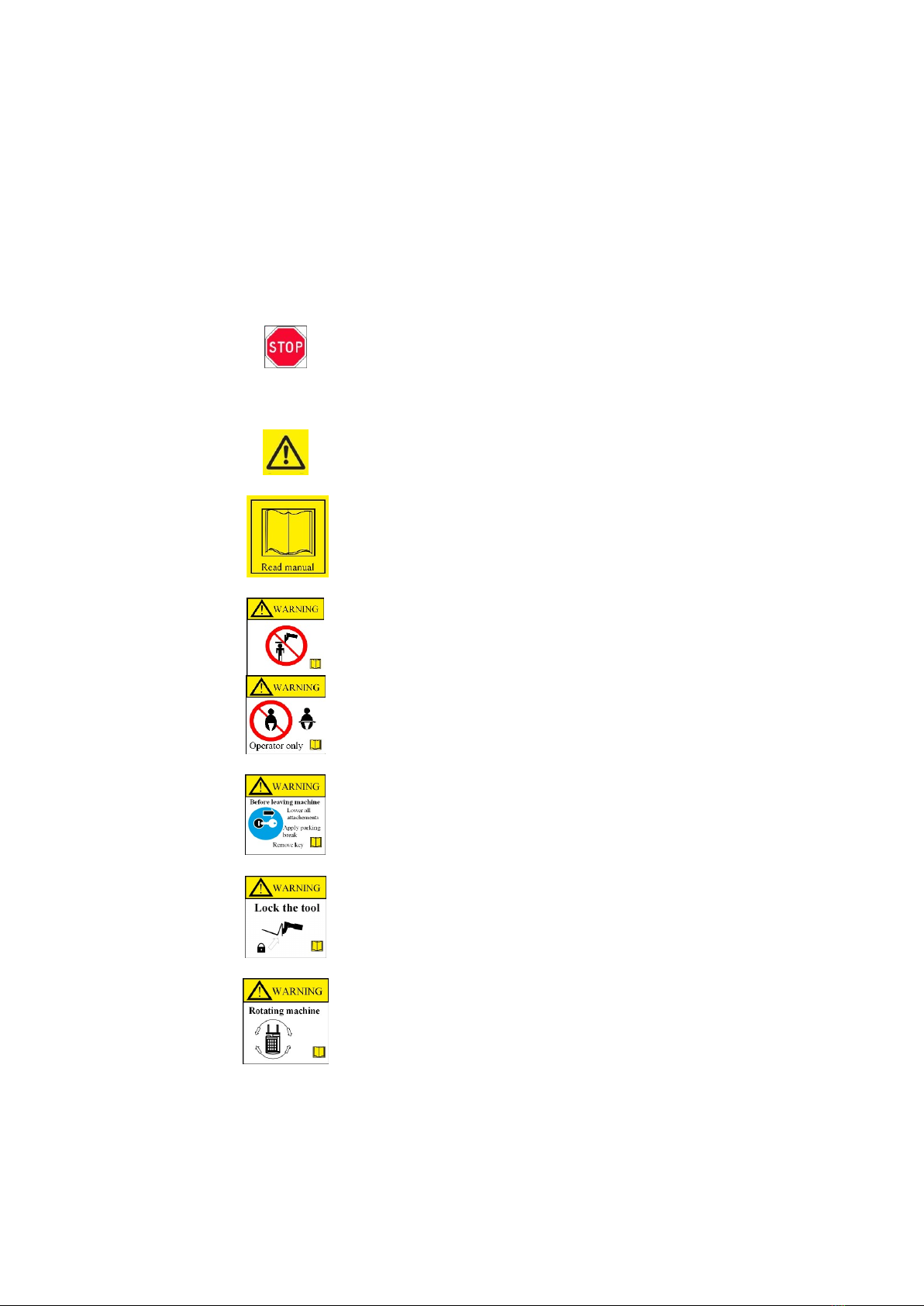

Safety rules for the operation of the vehicle .......................................................................................25

Repairs..................................................................................................................................................26

Danger zone .........................................................................................................................................26

Seatbelt ................................................................................................................................................29

Load handling .......................................................................................................................................31

Driving ..................................................................................................................................................32

Driving in slopes ...................................................................................................................................33

Steering wheel ratio to wheels.............................................................................................................34

Steering of Maxtruck 2T .......................................................................................................................34

Breaking the forklift..............................................................................................................................34

Operation of the lift functions..............................................................................................................35

Fork spread (optional equipment) .......................................................................................................36

Fork side shift (optional equipment)....................................................................................................36

Tool Changing Unlocking/locking.........................................................................................................36

Taking up, transporting lowering of load.............................................................................................37

Taking up the load................................................................................................................................37

Transport of load..................................................................................................................................37