Steca UGP 5.9 User manual

Popular Air Compressor manuals by other brands

Black Ridge

Black Ridge BR3000 instruction manual

Power Fist

Power Fist 8670978 user manual

Central Pneumatic

Central Pneumatic 39750 Assembly and operating instructions

ALLPOWER

ALLPOWER APC4011 owner's manual

Central Pneumatic

Central Pneumatic 68149 Set up and operating instructions

Alink

Alink AG-10A user manual

SereneLife

SereneLife SLPUMP30 user manual

Central Pneumatic

Central Pneumatic 62913 Owner's manual & safety instructions

Prime Source

Prime Source Speroni Pumps Grip-Rite GR 2000 owner's manual

Central Pneumatic

Central Pneumatic 92403 Assembly and operation instructions

Tuff stuff

Tuff stuff OVERLAND TS-7-1000 instruction manual

Black Ridge

Black Ridge BR140D manual

Central Pneumatic

Central Pneumatic 47915 Assembly and operating instructions

Power Fist

Power Fist 8003631 owner's manual

Air Lift

Air Lift Ride Control 59516 installation guide

airmaster

airmaster TIGER 11/260 Operation & maintenance instructions

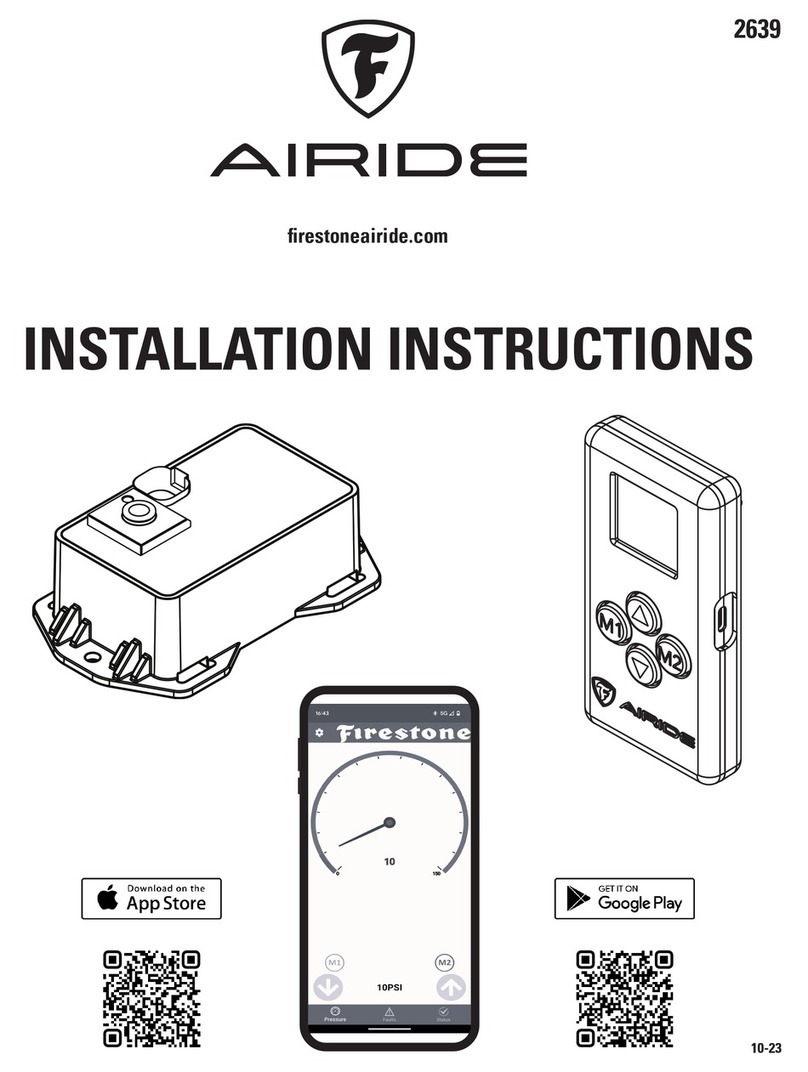

Firestone

Firestone AIRIDE 2639 installation instructions

Central Pneumatic

Central Pneumatic 68067 Owner's manual & safety instructions