Mazda CX-9 Grand Touring 2007 User manual

Other Mazda Automobile manuals

Mazda

Mazda 1990 323 Instruction manual

Mazda

Mazda 2007 Mazdaspeed 3 Guide

Mazda

Mazda 2010 CX-7 Guide

Mazda

Mazda RX-7 1989 User manual

Mazda

Mazda 2014 CX-5 Guide

Mazda

Mazda 2007 Mazdaspeed 3 Guide

Mazda

Mazda European Roadside Assistance User manual

Mazda

Mazda 2015 5 User manual

Mazda

Mazda MX-5 2021 User manual

Mazda

Mazda PROTEGE 5 User manual

Mazda

Mazda CX-5 2017 User manual

Mazda

Mazda 2002 626 User manual

Mazda

Mazda CX-9 User manual

Mazda

Mazda B3000 2006 User manual

Mazda

Mazda Mazda6 Instruction manual

Mazda

Mazda 626 Station Wagon Instruction manual

Mazda

Mazda 2013 CX-9 User manual

Mazda

Mazda RX-8 Guide

Mazda

Mazda 121 Instruction manual

Mazda

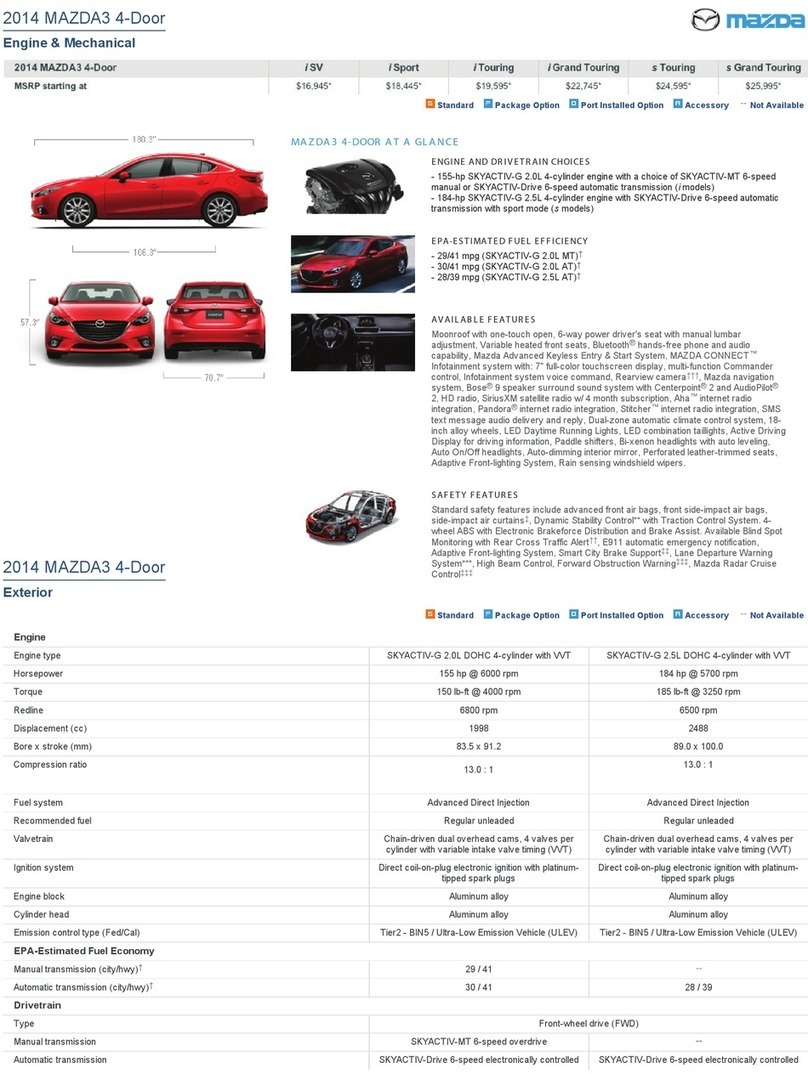

Mazda 2014 3 4-Door User manual