ASSEMBLY

TOOLS REQUIRED: 7/16" Wrench, Pliers, Screwdriver (11/16" Wrench needed to adjust Clutch Tension)

NOTE: Reference to left or right side

of the mower is from operator's

position at the handle, facing fonNard.

The lawn mower is fully assembled

except for the handle throttle control,

drive control rod and clutch control

rod. Everything is packed and shipped

in one container.

ASSEMBLY:

1. CARTON REMOVAL

Cut the back panel, lay down pull

mower backwards.

2. PARTS ID

3. TOOLS REQUIRED

7/16" Wrench, Pliers, Screwdriver

(11/16" Wrench needed to adjust

Clutch Tension)

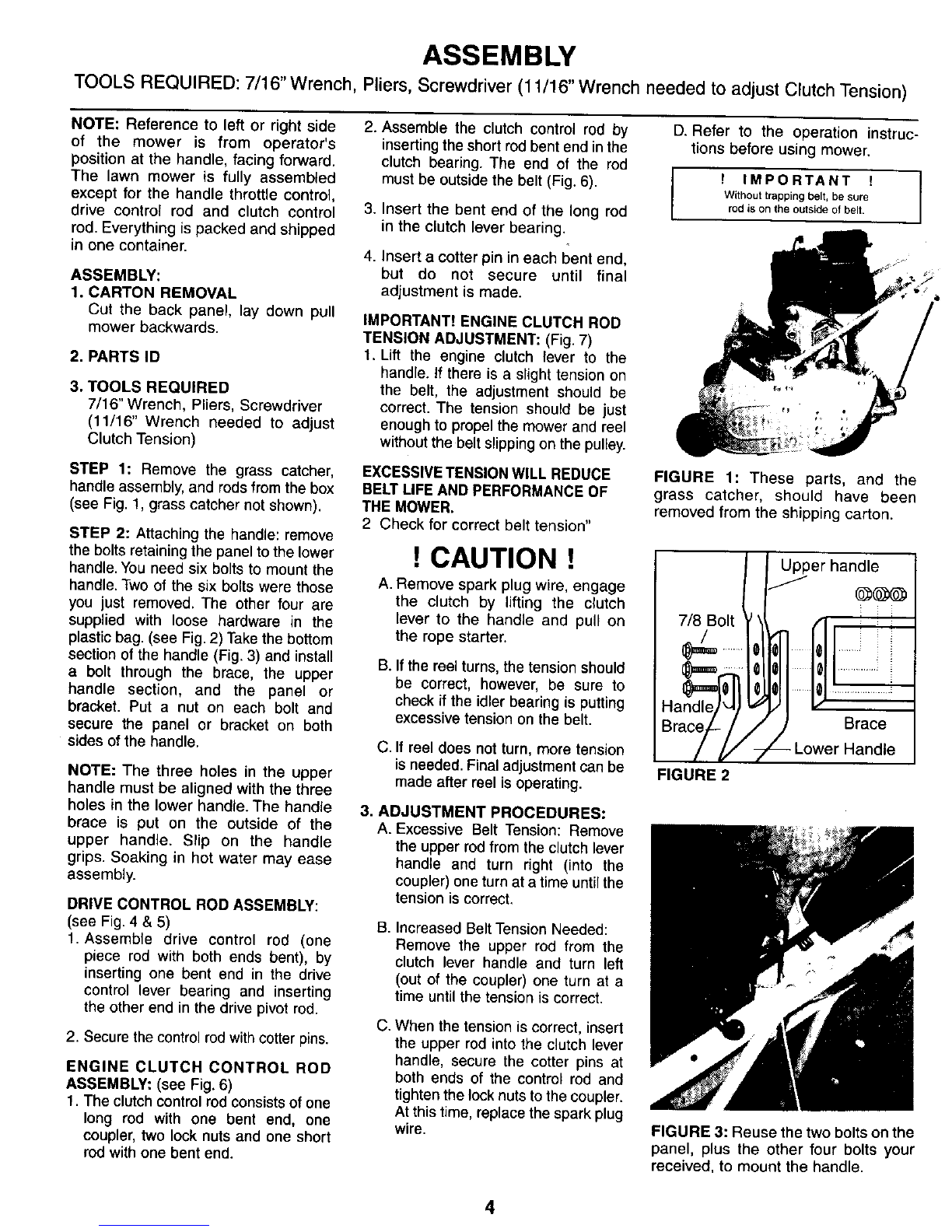

STEP 1: Remove the grass catcher,

handle assembly, and rodsfrom the box

(see Fig. 1, grass catcher not shown).

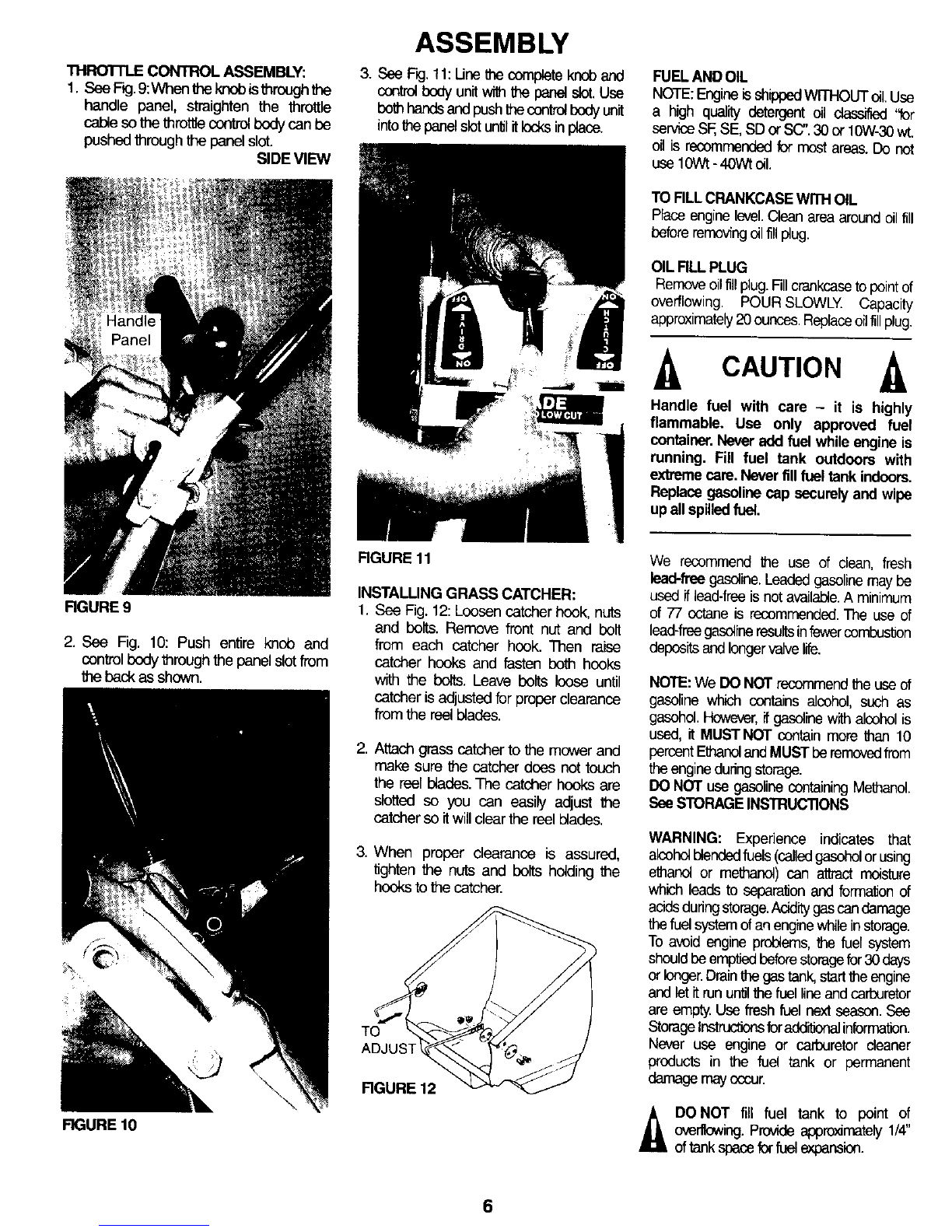

STEP 2: Attaching the handle: remove

the bolts retaining the panel to the lower

handle. You need six bolts to mount the

handle. Two of the six bolts were those

you just removed. The other four are

supplied with loose hardware in the

plastic bag. (see Fig. 2) Take the bottom

section of the handle (Fig. 3) and install

a bolt through the brace, the upper

handle section, and the panel or

bracket. Put a nut on each bolt and

secure the panel or bracket on both

sides of the handle.

NOTE: The three holes in the upper

handle must be aligned with the three

holes in the lower handle. The handle

brace is put on the outside of the

upper handle. Slip on the handle

grips. Soaking in hot water may ease

assembly.

DRIVE CONTROL ROD ASSEMBLY:

(see Fig. 4 & 5)

1. Assemble drive control rod (one

piece rod with both ends bent), by

inserting one bent end in the drive

control lever bearing and inserting

the other end in the drive pivotrod.

2. Secure the control rod with cotter pins.

ENGINE CLUTCH CONTROL ROD

ASSEMBLY: (see Fig. 6)

1. The clutchcontrolrodconsistsof one

long rod with one bent end, one

coupler, two lock nuts and one short

rod with one bent end.

2. Assemble the clutch control rod by

inserting the short rod bent end in the

clutch bearing. The end of the rod

must be outside the belt (Fig. 6).

3. insert the bent end of the long rod

in the clutch lever bearing.

4. Insert a cotter pin in each bent end,

but do not secure until final

adjustment is made.

IMPORTANT! ENGINE CLUTCH ROD

TENSION ADJUSTMENT: (Fig. 7)

1. Lift the engine clutch lever to the

handle. If there is a slight tension on

the belt, the adjustment should be

correct. The tension should be just

enough to propel the mower and reel

without the belt slipping on the pulley.

EXCESSIVETENSION WILL REDUCE

BELTLIFE AND PERFORMANCE OF

THE MOWER.

2 Check for correct belt tension"

CAUTION !

A. Remove spark plug wire, engage

the clutch by lifting the clutch

lever to the handle and pull on

the rope starter.

B. Ifthe reel turns, the tension should

be correct, however, be sure to

check if the idler bearing is putting

excessive tension on the belt.

C. If reel does not turn, more tension

is needed. Final adjustment can be

made after reel is operating.

3. ADJUSTMENT PROCEDURES:

A. Excessive Belt Tension: Remove

the upper rodfrom the clutchlever

handle and turn right (into the

coupler)one turnat atime untilthe

tension is correct.

B, Increased Belt Tension Needed:

Remove the upper rod from the

clutch lever handle and turn left

(out of the coupler) one turn at a

time until the tension is correct.

C. When the tension is correct, insert

the upper rod into the clutch lever

handle, secure the cotter pins at

both ends of the control rod and

tighten the lock nuts to the coupler.

At this time, replace the spark plug

wire.

D. Refer to the operation instruc-

tions before using mower.

f IMPORTANT !

Without trapping belt, be sure

rod is on the outside of belt.

FIGURE 1: These parts, and the

grass catcher, should have been

removed from the shipping carton.

Upper handle

/f

7/8 Bolt _ _\ /3 i :

Ha_ ......

Brace_-// ;Brace

/_/" 7 -- Lower Handle

FIGURE 2

FIGURE 3: Reuse the two bolts on the

panel, plus the other four bolts your

received, to mount the handle.

4