frequencies, pot VR1 is ctu lly l belled BOOST,

with r nge of 0 to 24 dB.

Switch S1 ctiv tes the 20 HZ C T (high-p ss,

infr sonic, or "subsonic") filter with n 18

dB/oct ve slope below 20 Hz, to void the

mplific tion of in udible but potenti lly

destructive low-frequency sign ls. Switch S2

combines the Left nd Right ch nnels t

frequencies below the spe ker's origin l corner

frequency (provided the settings for Fs, Qs,

BOOST, nd Qb re identic l for both ch nnels)

to c ncel out-of-ph se R MBLE sign ls. Switch

S4 provides BYPASS function to elimin te the

equ lizer from the sign l p ther, nd Swith S3

llows the user to reg in t pe monitoring

c p bility, in the event th t the BASSIS is used in

the sole t pe loop of receiver or pre mp.

OPTION 1

If you re constructing your own enclosure for

the BASSIS, you m y choose to c lcul te the

v lues of fixed resistors which reflect your

p rticul r spe ker's Fs nd Qs, nd which provide

fixed mount of boost. This llows you to

elimin te ll but

Single potentiometer -- which controls the

d mping (Qb). Since the setting of the Qb control

influences the level of b ss bout the new corner

frequency (comp re Figures 6 nd 7), you ret in

control of the net b ss extension. To implement

this option, follow the ssembly procedure

det iled in the next section of this m nu l, except:

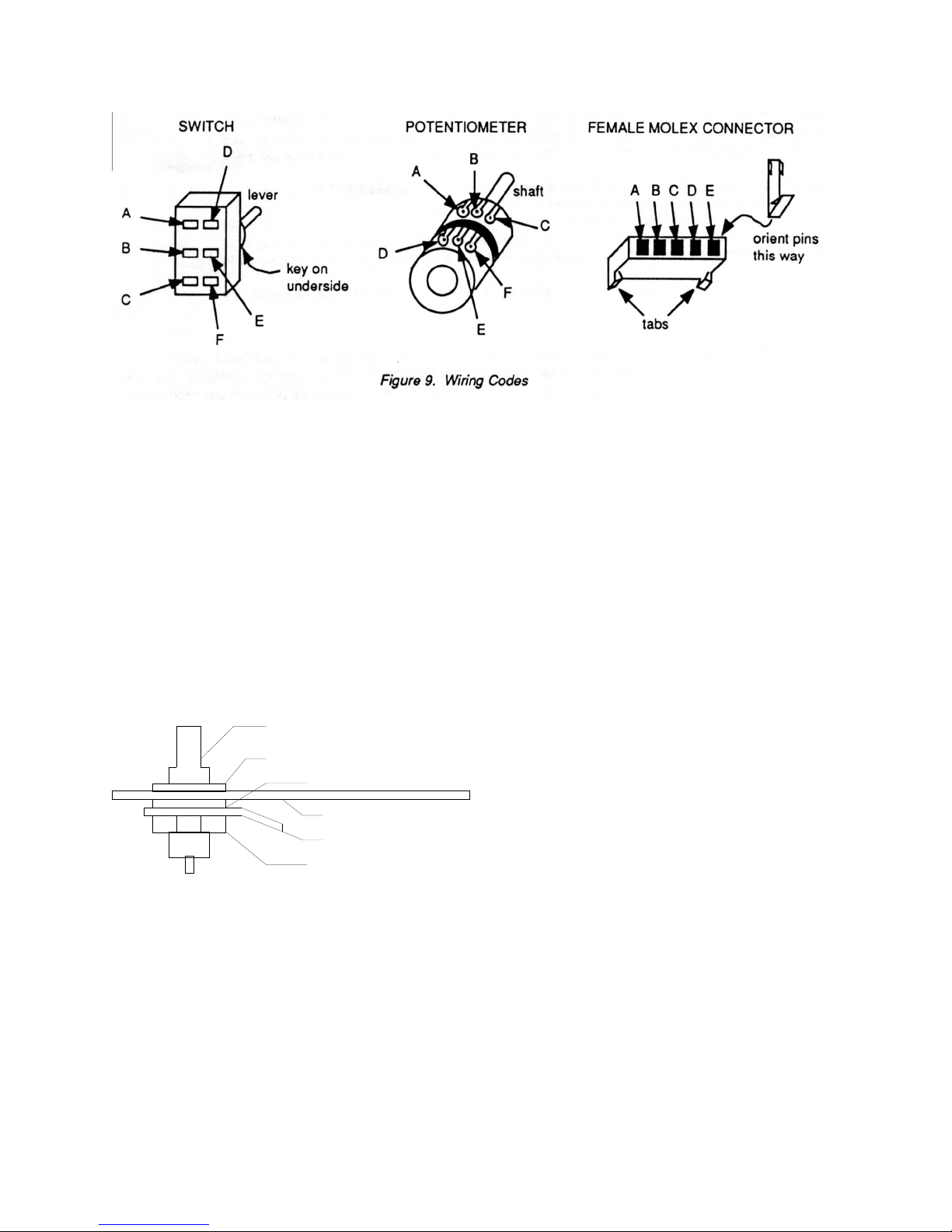

( ) le ve out the Molex connectors which tt ch

the BOOST nd Fs pots to the PC bo rd; (b) wire

only th t p rt of Molex connector P2 which

tt ches the Qb pot to the PC bo rd; (c)

rec lcul te the v lues of resistors R7, R8, R16,

R4, nd R26 ccording to your spe kers'

ch r cteristics nd the desired mount of boost:

R7 = R8 = 1/(6.28 x Fs x C1)

R16 = R19 x Qs

R4 = R26 = R28 x 10 boost/40.

Where BOOST is given in dB. Now you c n use

du l 10k line r pot to djust the d mping (Qb)

of the Left nd Right ch nnels simult neously.

Or, if you w nt to elimin te the rem ining control

s well, remove VR4 nd rec lcul te R11 for the

desired (fixed) v lue of Qb:

R11 = R2 x Qb.

OPTION 2

There is sp ce in the st nd rd BASSIS

enclosure for n ddition l power supply for

constructors interested in true du l-mono

oper tion. Simply follow the steps in the

"Assembly" section of this m nu l, but wire the

inputs of second + 15 V power supply to the

power cord s well, nd power the Right-ch nnel

PC bo rd from this power supply.

OPTION 3

On the other h nd, if the BASSIS is to be

used with single-ch nnel, independently-

mplified subwoofer, then only single PC bo rd

need be ssembled, nd sm ller enclosure m y

be employed. Assembly is the s me s

described in this m nu l, except th t the switches

m y be SPDT r ther th n DPDT.

ASSEMBLY (KIT VERSION)

The p rts for stereo implement tion include:

two BASSIS printed circuit bo rds nd

components, one + 15 V power supply ssembly

(such s M rch nd Electronics' Model PS10), nd

one enclosure with h rdw re. The Appendices of

this m nu l cont in det iled Over ll P rts List

s well s PC Bo rd P rts List. You will first

ssemble the circuit bo rds, then mount them in

the enclosure nd tt ch the front p nel controls.

GENERAL WIRING PRACTICE

The tools necess ry to ssemble the BASSIS

include: 15 - 30W soldering pencil, rosin-core

solder, wire cutters, nd Phillips-he d

screwdriver. Other useful tools re:

desoldering tool or solder wick (to remove excess

solder), project holder, long-nose pliers, nd

wire stripper. A cle n, well-lit working re will

minimize frustr tions.

When soldering component to the circuit

bo rd, first mount the component so th t it fits

snugly g inst the silkscreened side of the bo rd.

Next, he t the component le d nd the circuit

bo rd tr ce (on the foil side) simult neously with

the soldering pencil nd pply solder until it melts

nd flows round the component le d. With

pr ctice the entire process should t ke only 5

seconds or so. Remove the pencil nd llow the

connection to cool for few seconds before

moving. Cut off the excess le d close to the

solder joint. If solder bridge w s in dvertently

m de to nother tr ce, remove the solder

c refully with desoldering bulb or br id. Keep

the tip of the soldering pencil cle n by wiping on

d mp sponge every few minutes.

Components c n be identified s follows.

Resistors use the 4-b nd color code in the ch rt

shown below. The fifth b nd is lw ys brown,

indic ting 1% toler nce. For ex mple, resistor

M rch nd Electronics Inc www.m rch ndelec.com

6