Megatron ETA25PM Series Owner's manual

FB031

September 7. 2016

Page 1von 9

Programming manual for A(PM) multiturn rotary encoders with

programmable effective electrical angle and sense of rotation

(output signals 4…20 mA, 0-10V or 0-5V)

MEGATRON Elektronik GmbH & Co . KG

Hermann-Oberth-Strasse 7

85640 Putzbrunn / Munich

Germany

Programming Manual

for series ETA25PM, ETA25FPM, ETA25KPM,

HTA36PM,MABxxAPM

Series

ETA25PM

ETA25PM

ETA25PM

Design

Option

F

R

K

Series

ETA25PM

MABxxAPM

Design

Option

TS

(On request, only with

MOQ orderable)

-

Series

ETA25FPM

ETA25KPM

Design

Option

-

-

Series

HTA36 PM

HTA36 PM

HTA36 PM

Design

Option

S (solid shaft)

H (hollow shaft –

screw fixation)

HK (hollow shaft –

clamp fixation)

Table 1: Overview of the user programmable multiturn sensors

FB031

September 7. 2016

Page 2von 9

Programming manual for A(PM) multiturn rotary encoders with

programmable effective electrical angle and sense of rotation

(output signals 4…20 mA, 0-10V or 0-5V)

MEGATRON Elektronik GmbH & Co . KG

Hermann-Oberth-Strasse 7

85640 Putzbrunn / Munich

Germany

1. State of delivery

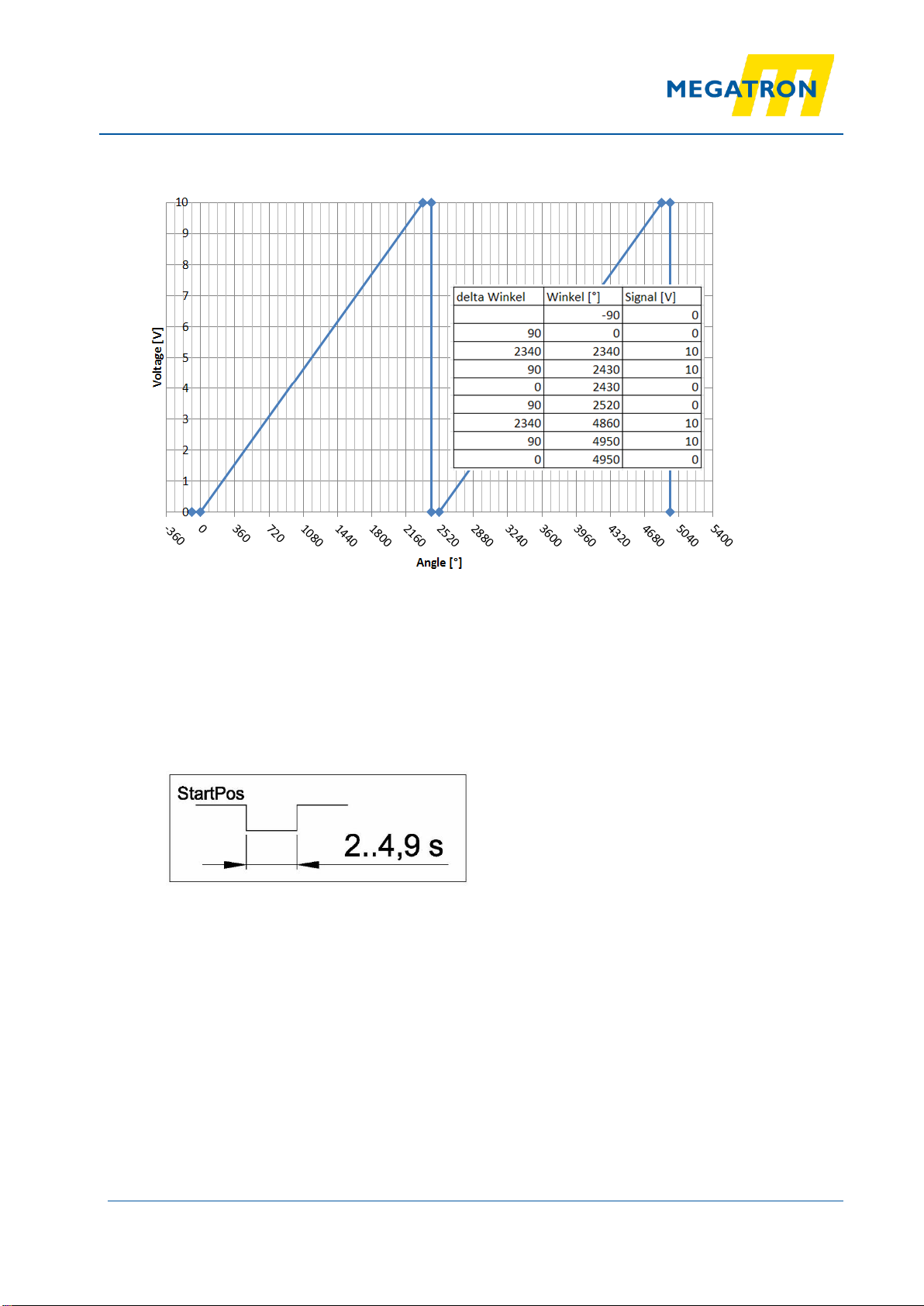

2. Picture 1: Signal output multi-turn encoder state of delivery

At the state of delivery there is an electrical angle of 10 turns adjusted (3600°).

The signal is increasing if you turn the shaft clockwise while you view on the shaft end.

Before the starting point and after the end of the signal transition there is a plateau of a half turn each

side (180°). That means the signal has a periodicity of 11 turns.

FB031

September 7. 2016

Page 3von 9

Programming manual for A(PM) multiturn rotary encoders with

programmable effective electrical angle and sense of rotation

(output signals 4…20 mA, 0-10V or 0-5V)

MEGATRON Elektronik GmbH & Co . KG

Hermann-Oberth-Strasse 7

85640 Putzbrunn / Munich

Germany

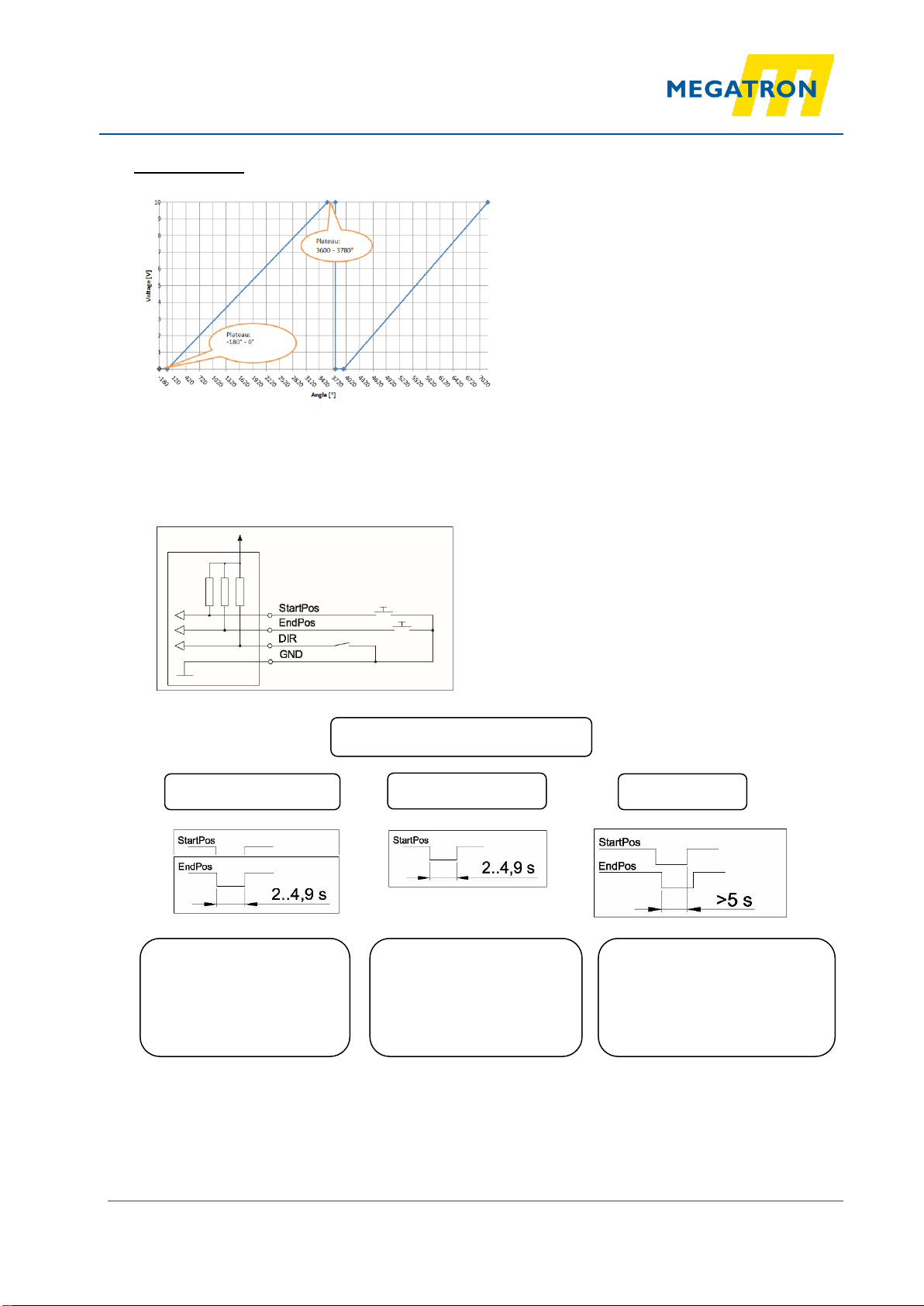

2.2 Function of the Control Inputs StartPos, EndPos and turning Direction DIR (CW,

CCW)

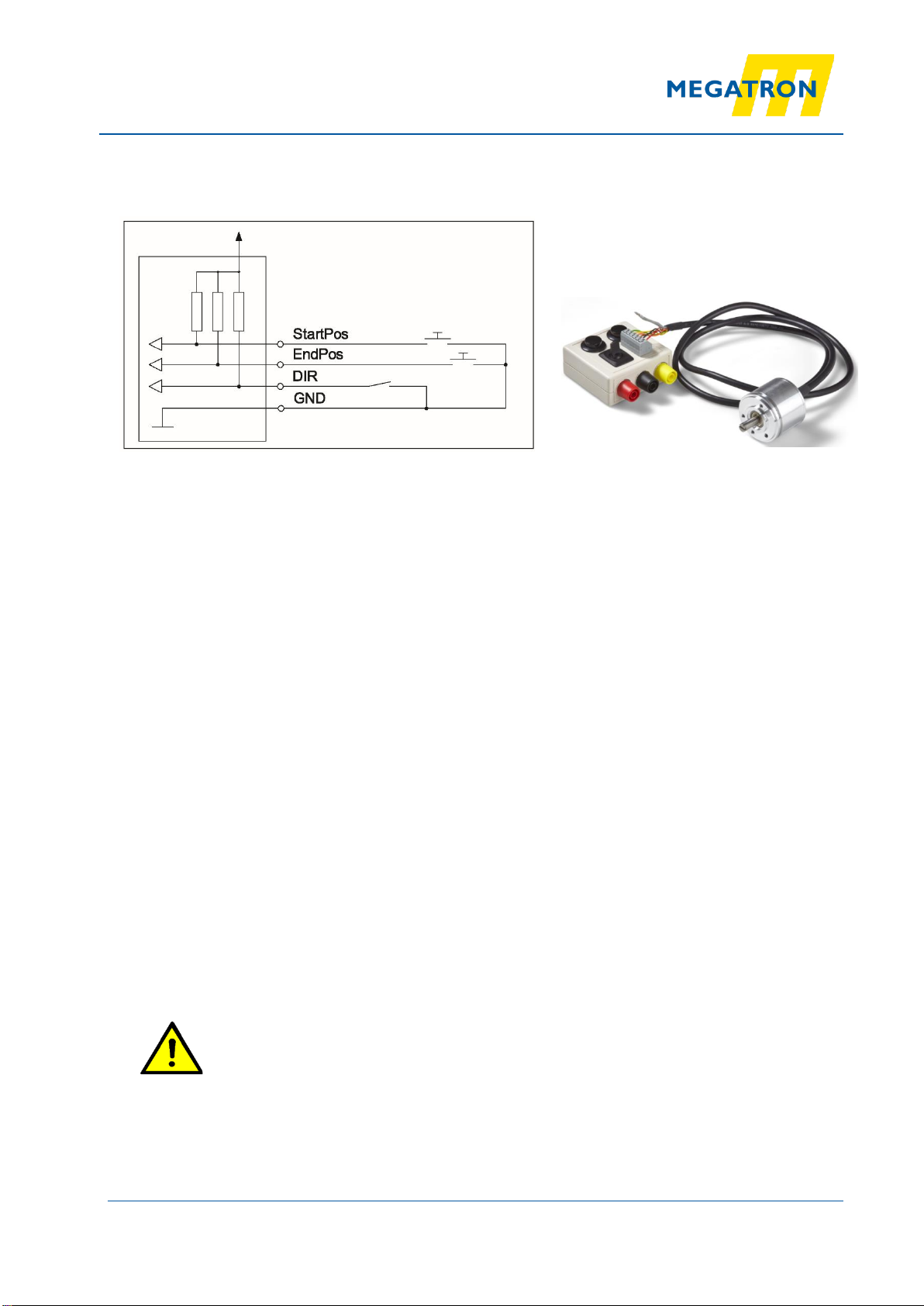

Picture 2: Interface to adjust the encoder signal Picture 3: Optional external

(internal Pull-Up: 470 Ohm against 3.3V) programmer orderable from Megatron

In order to parameterize a programmable multiturn angle sensor, a circuit must be made as shown

in picture 2, consisting of two push buttons and one switch. Alternatively, an external programmer

(picture 3, smart box) can be ordered from Megatron, which has already integrated the circuit as shown

in picture 2.

This manual is applicable to both, for a self-built circuit (as shown in picture 2) or an

external programmer (picture 3, smart-box).

Further information regarding the external programmer can be found on the last page (page 9) of this

manual.

The control inputs StartPos, EndPos and DIR can be switched by manual contacts or you can connect it

with a control unit (PLC). Please take care to connect the ground potential of the encoder properly with

the control unit. The signal inputs should be driven by relais contacts or open-collector outputs. If you put

24V at the signal inputs you would not harm the sensor because it is protected. But you should avoid this

because it could interfere your output signal in the measurement mode.

That means after you have adjusted the sensor (details see below) there should NOT be a 24V voltage

source at the control inputs.

The input line DIR to define the direction of rotation is read in the adjusting mode and in the reset mode

(but not in the reference mode).

If you need a CCW sense of rotation you should connect the input DIR with ground.

For CW sense of rotation you can leave the input not connected.

Please take care

If you program start and stop, the turning sense has to be conform with the DIR input

signal. That means in case of DIR signal input “High” (or not connected) you should

turn the shaft clockwise to adjust the end position afterwards. If you need a counter

clockwise signal output you have to tie the DIR input down to ground. If you do not stick

to this rule your sensor does not function correctly.

Please note that the start and end position is stored in a flash memory. Because of this

you should not do more than 10 000 adjusting cycles.

FB031

September 7. 2016

Page 4von 9

Programming manual for A(PM) multiturn rotary encoders with

programmable effective electrical angle and sense of rotation

(output signals 4…20 mA, 0-10V or 0-5V)

MEGATRON Elektronik GmbH & Co . KG

Hermann-Oberth-Strasse 7

85640 Putzbrunn / Munich

Germany

3. Programming Modes

3.1 Teach-In Mode

With the angle adjust mode you can define (teach in) the start- and end position and the turning

sense in accordance with the sensor shaft movement.

Picture 4: Start of the angle adjust mode

To activate the angle adjust mode please switch the input line StartPos according to the above

picture. At the same time you set the start position. That means the beginning of the signal

transition is adjusted at the current shaft position. Afterwards the sensor should be moved to the

end position. Please take care to do this in accordance with the signal input DIR. At the beginning

of the movement away from the start position (0V or 4mA) the sensor does not know the correct

slope. Because of this the output signal slope is based on the maximum number of turns 10V/200

rev. (16mA/200 rev.)

When you set the end position the maximum signal level is set at the current shaft position

(10V respectively 20mA).

Picture 5: Setting of the end position and closing the angle adjustment mode.

Afterwards the internal micro controller calculates the signal characteristic line. For this purpose

the distance to the next full turn is rounded up and the difference angle is divided into two equal

parts that are set as plateaus beyond the StartPos and the EndPos.

FB031

September 7. 2016

Page 5von 9

Programming manual for A(PM) multiturn rotary encoders with

programmable effective electrical angle and sense of rotation

(output signals 4…20 mA, 0-10V or 0-5V)

MEGATRON Elektronik GmbH & Co . KG

Hermann-Oberth-Strasse 7

85640 Putzbrunn / Munich

Germany

Example how the signal characteristic and the plateaus are calculated

Picture 5: Example how to adjust StartPos, sense of rotation (DIR) and the EndPos

Signalslope over 6.5 rev. = 6,5 * 360° = 2340°

Periodicity 7,0 rev. = 7,0 * 360° = 2520°

Difference 180°

Width of the plateaus 2x90°

3.2 Reference mode

Picture 6: Readjustment of the zero position

After setting the control input StartPos according to the above time interval, the zero

point (minimum signal level) is moved to the current shaft position. The electrical signal

angle and the turning sense are not affected. The signal input DIR is not considered.

This function is helpful if the sensor was moved without power supply more than

±179° and due to this lost the reference to the zero point of the multi turn information.

FB031

September 7. 2016

Page 6von 9

Programming manual for A(PM) multiturn rotary encoders with

programmable effective electrical angle and sense of rotation

(output signals 4…20 mA, 0-10V or 0-5V)

MEGATRON Elektronik GmbH & Co . KG

Hermann-Oberth-Strasse 7

85640 Putzbrunn / Munich

Germany

3.3 Reset Mode –to reset the electrical Angle to Delivery State

Picture 7: Resetmode

If you switch both control inputs StartPos and EndPos according to picture 6, the

electrical angle will be reset to the delivery state (10-turns).

Furthermore the zero position of the signal will be moved to the current signal position

and the turning sense is set according to the state of the DIR input.

That means if DIR is not connected you will get a clockwise signal characteristic

4. Technical Data

Table 2: Technical Data

The single turn encoders (MAB36APS, MAB40APS, MAB50APS) have been cancelled

because you can utilize all the functions with the adjustment procedurtes of the multiturn

encoders. But please note that the timing requirements have been changed in comparision

with the former firware.

Minimum electrical angle

10°

Maximum electrical angle

72 000° (200 Udr.)

Maximum number of adjustment cycles

(flash-storage write cycles)

10 000

Resolution

>= 360°

180°

90°

45°

12 Bit

11 Bit

10 Bit

9 Bit

FB031

September 7. 2016

Page 7von 9

Programming manual for A(PM) multiturn rotary encoders with

programmable effective electrical angle and sense of rotation

(output signals 4…20 mA, 0-10V or 0-5V)

MEGATRON Elektronik GmbH & Co . KG

Hermann-Oberth-Strasse 7

85640 Putzbrunn / Munich

Germany

Programming

State of delivery: 10-turn + 2x Plateau (0,5 rev). The zero point is not positioned.

The sense of rotation is CW (with DIR input not connected). If you need sense of rotation

CCW please connect DIR with GND meanwhile programming.

Afterwards you can disconnect (but this is not a must).

Programming Modes

Teach-In Mode

Reference Mode

Reset Mode

Teach StartPos and EndPos

Take care:

Startpos is the minimum signal

level.

Please take care to connect the

DIR-Input accordingly!

Moves the zero position to the

current position.

The programmed angle is not

affected

Moves the zero position to the

current position.

The sense of rotation is

programmed according to the input

signal.

Output siganal10-turn with Plateaus

Programming interface with internal

„Pull-Up-Resistors“

FB031

September 7. 2016

Page 8von 9

Programming manual for A(PM) multiturn rotary encoders with

programmable effective electrical angle and sense of rotation

(output signals 4…20 mA, 0-10V or 0-5V)

MEGATRON Elektronik GmbH & Co . KG

Hermann-Oberth-Strasse 7

85640 Putzbrunn / Munich

Germany

Programming instructions for special version: ETA25PM 6,35 12 2410 (with integrated switch

and push button switches for programming procedure)

Programming status at delivery:

(START and ZERO position not set to a mechanical reference)

Teach-in procedure (Teach-in modus):

▪Turn sensor to desired START position and press START button

LED starts flashing RED at 4 Hz for 2s and changes to 2 Hz from 2s to 5s

▪Release button when LED starts flashing at 2 Hz after 5s LED lights in RED continuously (=

confirmation of START position)

▪Turn sensor to desired END position and press END button:

The RED LED light disappears and starts flashing GREEN at 4 Hz for 2s and changes to continuously

light in GREEN for 5s

▪Release button when LED starts to light continuously after 5s the LED goes out (= confirmation of

END position)

In case of false sense of rotation (e.g. CW/CCW-switch set to CW, teach-in was done CCW) LED starts

to flash alternating from RED to GREEN (= fault indication) after 4-8s

FYI: START position at teach-in is set to ZERO-degree location of effective electrical travel

Setting ZERO-degree location (Reference modus):

▪Turn sensor to desired ZERO position and press START button

▪LED starts flashing RED at 4 Hz for 2s

▪Release button when LED starts to flash

LED lights in RED continuously for 5s and goes out afterwards (= confirmation of ZERO position)

Reset to status at delivery (Reset modus):

▪Press START and END button simultaneously

▪LED starts flashing RED and GREEN at 4 Hz for 5s

▪Release buttons when LED starts to light continuously

LED lights continuously in RED and GREEN for 5s and goes out (= confirmation of reset)

FB031

September 7. 2016

Page 9von 9

Programming manual for A(PM) multiturn rotary encoders with

programmable effective electrical angle and sense of rotation

(output signals 4…20 mA, 0-10V or 0-5V)

MEGATRON Elektronik GmbH & Co . KG

Hermann-Oberth-Strasse 7

85640 Putzbrunn / Munich

Germany

Programmer (Smart-Box) for (A)PM

Multiturn rotary encoders

Subject to change without notice.

1

2

3

5

4

Switch for

sense of

rotation

END

push

button

START

push

button

Clamping

terminals

for electrical

connection

to rotary

encoder

Banana

sockets for

connection

with power

supply

RED

BLACK

YELLOW

1

2

3

4

5

This manual suits for next models

4

Popular Media Converter manuals by other brands

Sonos

Sonos Multi-Room Music System user guide

Data Conversion Systems

Data Conversion Systems dCS Puccini U-Clock user manual

AxelTech

AxelTech Falcon Series user manual

Schnick-Schnack-Systems

Schnick-Schnack-Systems DPB Pixel-Router Pro user guide

Matrox

Matrox 6150 Encoder user guide

B.M.C.

B.M.C. DAC I quick start guide