4 Assembly

7

4 Assembly

Vacuclave 550

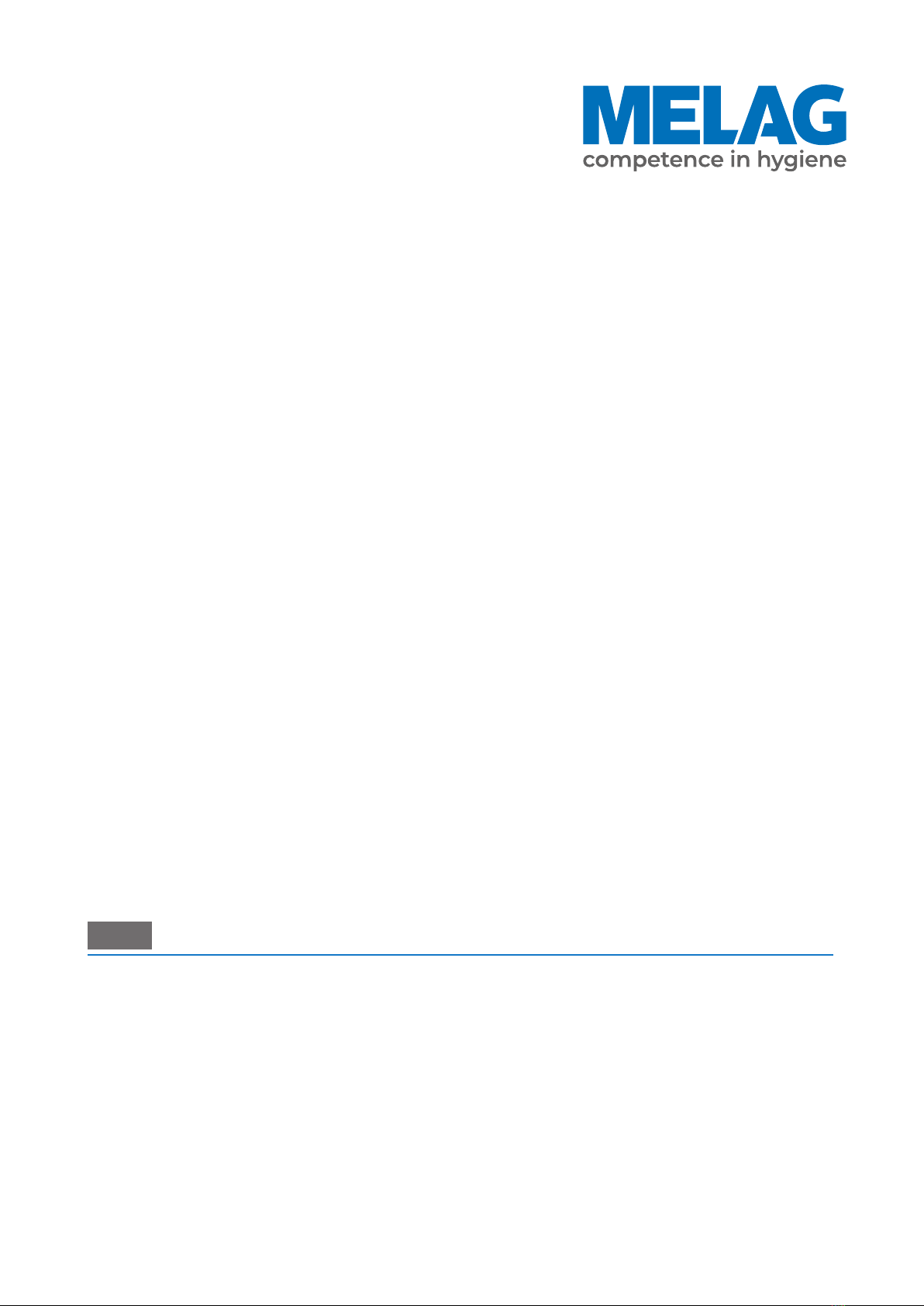

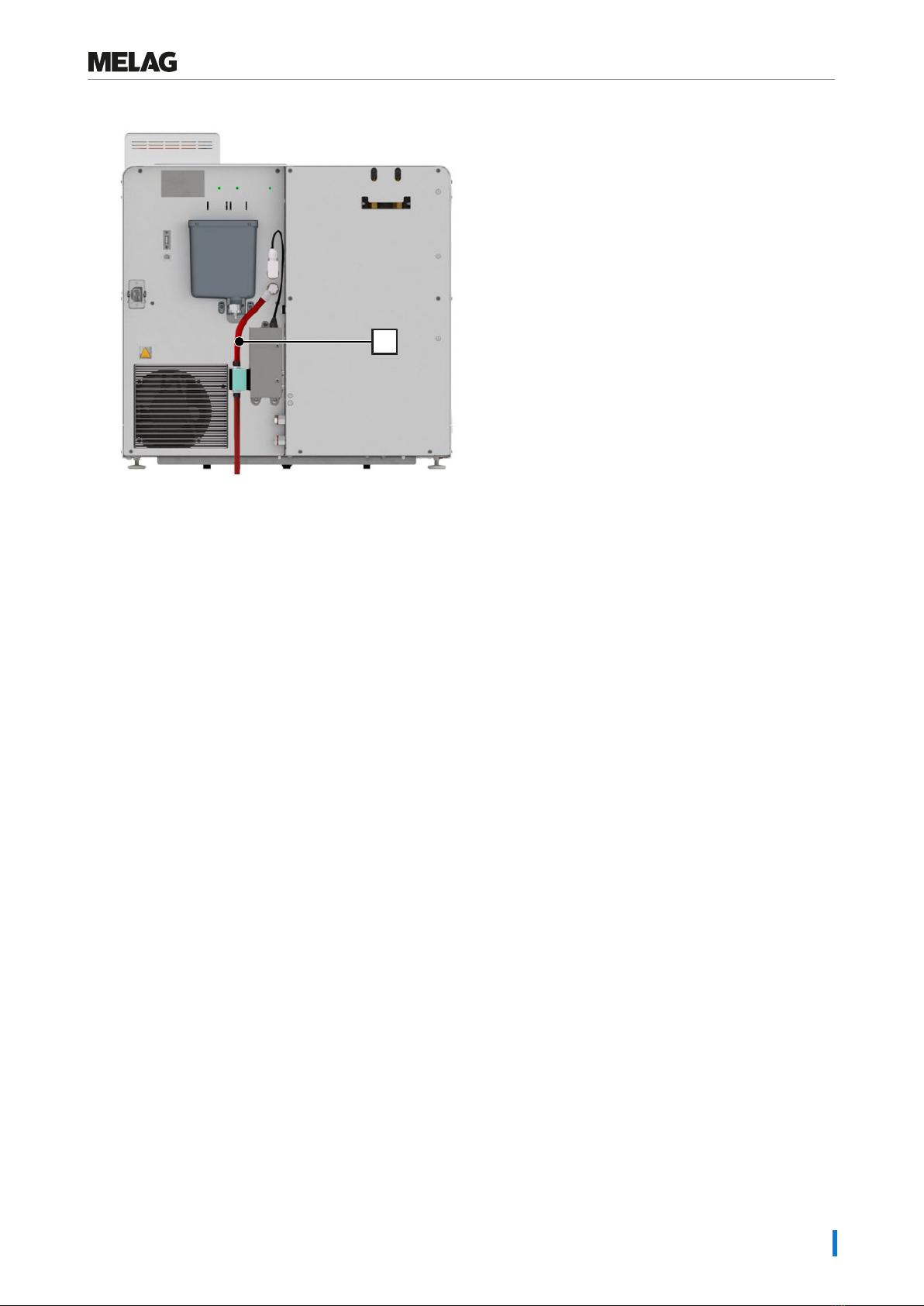

6 Mains cable connection (safety clip)

7 Overflow funnel

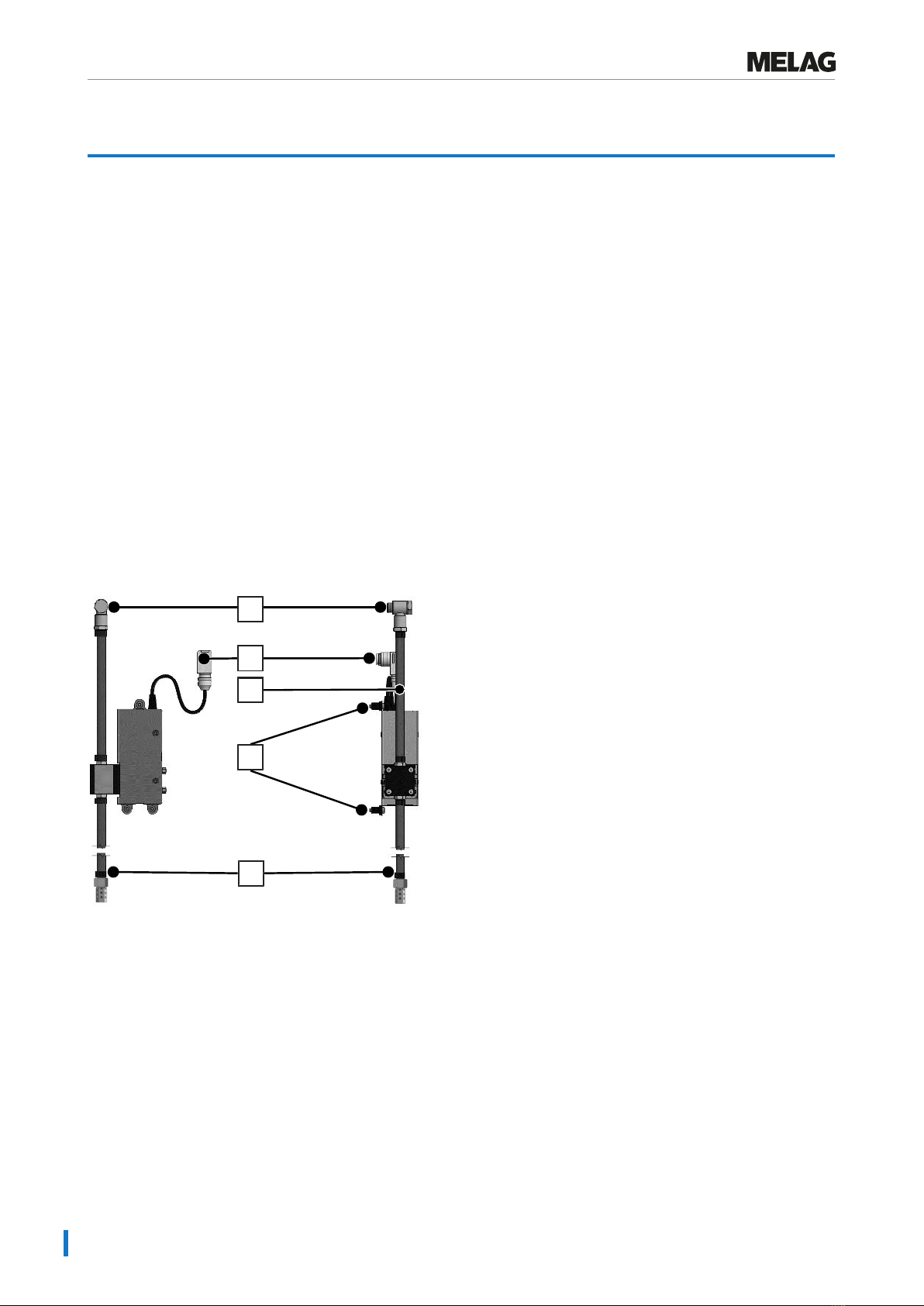

8 Rear device cover (left)

9 Electrical connection of filling pump

(cover plug)

10 Feed water connection of the filling

pump

11 Mounting holes of the filling pump

12 Feed water connection, water treatment

unit

The following must be fulfilled or present:

ü

2x open-end spanner (AF17)

ü

Torx key (TX20)

WARNING

Danger of electric shock from live components

nBefore opening the unit, switch off at the power switch, and remove the plug.

nDetermine the absence of voltage at all poles.

1. Remove the safety clip from the mains cable connection (Pos. 6).

2. Pull the waste water hose off the overflow funnel (Pos. 7).

3. Dismantle the left side of the rear device cover (Pos. 8) by unscrewing the six screws (TX20).

4. Remove the cover plugs of the mounting holes (Pos. 11) from the dismantled device cover.

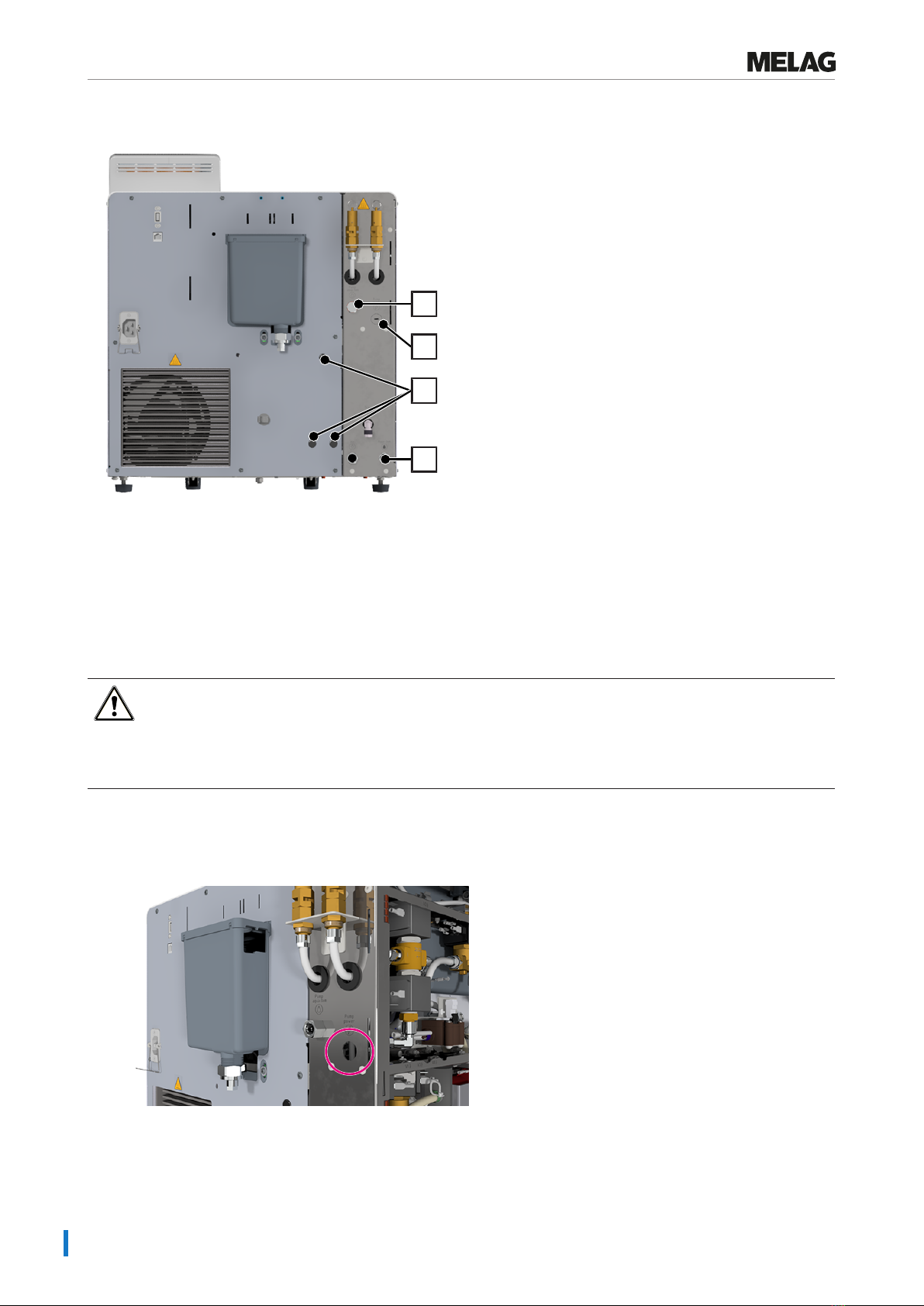

5. Remove the cover plug from the electrical connection of the filling pump (Pos. 9).

6. Remove the ring nut from the wiring harness supplied for the filling pump.

7. Insert the connection socket from the wiring harness of the filling pump from the inside through the opening of the

electrical connection of the filling pump (Pos.9).

PLEASE NOTE: The detent at the opening of the connection socket determines the alignment.

8. Hand-tighten the ring nut of the wiring harness.