Metacap D/A User manual

Operating Instructions

METACAP Spray Gun D/A

Operating Instructions

General Information

METACAP Spray Gun D/A

1-2

Version/Edition July 2008

Table of Contents

1

General Information...........................................................................1-3

1.1

Introduction..........................................................................................1-3

1.2

Scope of Supply of the METACAP Spray Gun D/A.............................1-3

2

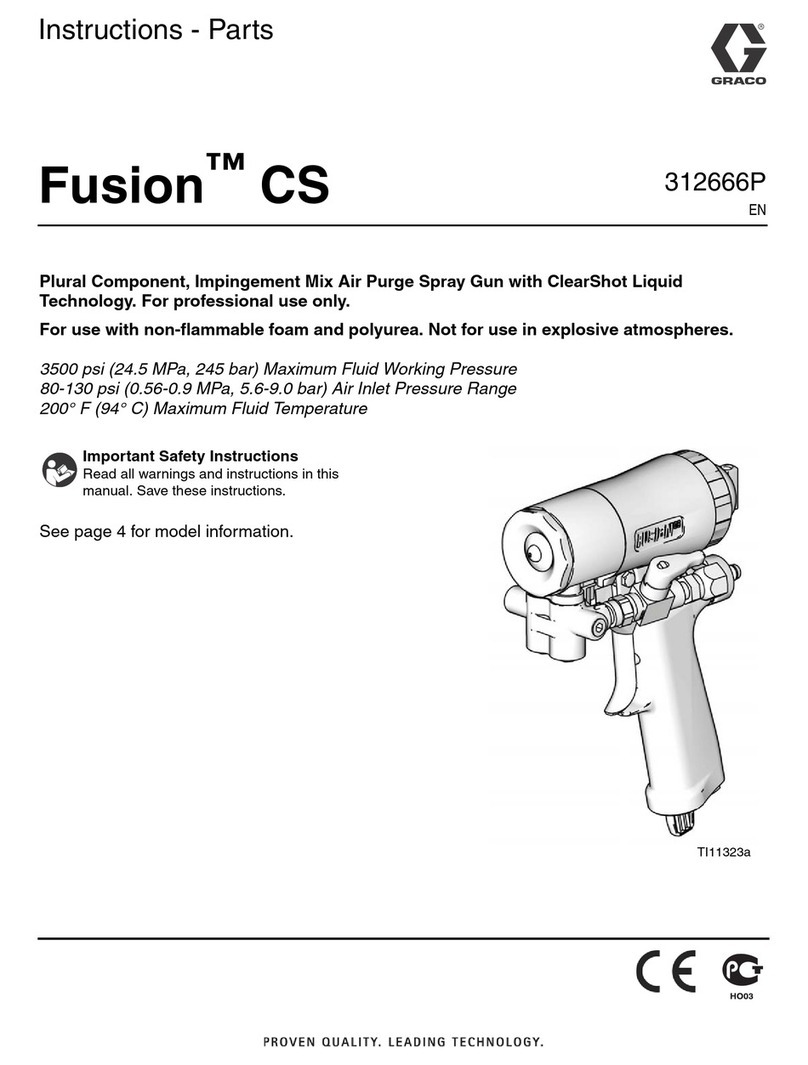

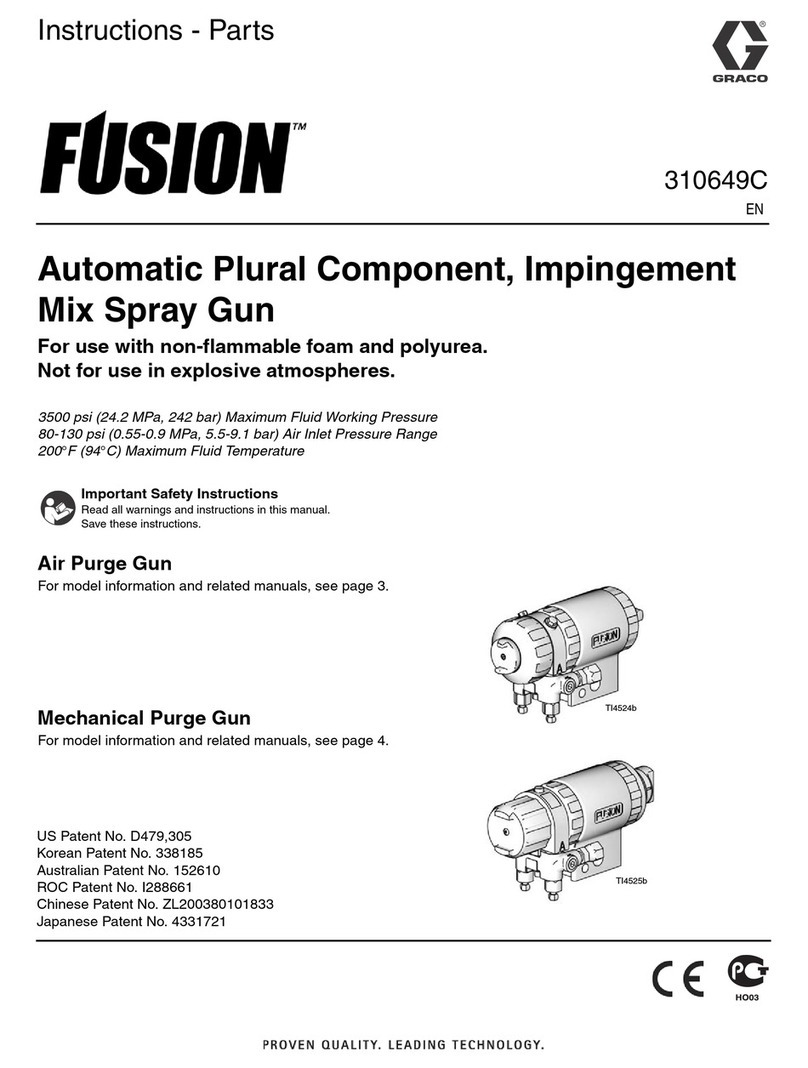

Description of the METACAP Spray Gun D/A.................................2-4

2.1

Technical Data.....................................................................................2-4

2.2

Identification.........................................................................................2-4

3

Use ......................................................................................................3-5

3.1

Intended Use .......................................................................................3-5

3.2

Incorrect Use .......................................................................................3-5

4

Warranty .............................................................................................4-6

5

General Safety Instructions..............................................................5-7

5.1

Risk of Fire and Explosions.................................................................5-7

5.2

Personal Protection .............................................................................5-8

5.3

Noise Level..........................................................................................5-9

5.4

Instruction of the Personnel.................................................................5-9

6

Description, Structure and Functioning........................................6-10

6.1

Description.........................................................................................6-10

6.2

Structure of the METACAP Spray Gun D/A ......................................6-11

6.3

Spare Parts List for the METACAP Spray Gun D/A..........................6-12

6.4

Functioning ........................................................................................6-13

7

Initial Operation ...............................................................................7-14

8

Operating Instructions ....................................................................8-15

8.1

Default Settings .................................................................................8-15

8.2

Spray Process ...................................................................................8-18

9

Maintenance and Care.....................................................................9-19

9.1

Cleaning.............................................................................................9-19

9.2

Maintenance and Repair....................................................................9-22

9.2.1

Safety Instructions .............................................................................9-22

9.2.2

Check/Replacement of Silencer Ring................................................9-22

9.2.3

Replacement of Nozzle & AKKORD Needle, Adjustment of Initial Air

Input Settings.....................................................................................9-22

9.2.4

(Dis-)Assembly of Nozzle Holder , Replacement of Sealing Ring.....9-24

9.2.5

Air Converter Adjustment...................................................................9-26

10

Troubleshooting Table – METACAP Spray Gun D/A .................10-28

11

Cleaning and Disposal..................................................................11-30

11.1

Cleaning...........................................................................................11-30

11.2

Disposal...........................................................................................11-31

12

ATEX ...............................................................................................12-31

13

EC-Declaration of Conformity ......................................................13-32

Operating Instructions

General Information

METACAP Spray Gun D/A

Version/Edition July 2008

1-3

1 General Information

1.1 Introduction

It is indispensable for the user of this METACAP Spray Gun D/A to carefully

read the complete contents of this operating manual before using the spray

gun to ensure a safe and correct operation. This operating manual includes

important information concerning the safe and economical use of this spray

gun.

Therefore, always keep this operating manual accessible!

Failure to observe the instructions of this operating manual will render the

manufacturer free of any legal liabilities!

1.2 Scope of Supply of the METACAP Spray Gun D/A

1 METACAP Spray Gun D/A Item no. 101115

1 cleaning brush, short (see 9.1 Cleaning, page 9-19) Item no. 30078

1 cleaning brush, long (see 9.1 Cleaning, page 9-19)

Item no. 30077

1 needle cleaning brush (see 9.1 Cleaning, page 9-19)

(only for the AKKORD type) Item no. 30083

1 mounting bolt for nozzle holder

(see 9.2.4 (Dis-)Assembly of Nozzle Holder , page 9-24) Item no. 30084

The above mentioned item numbers refer to the spare parts available by

Metacap upon request.

Operating Instructions

Description of the METACAP Spray Gun D/A

METACAP Spray Gun D/A

2-4

Version/Edition July 2008

2 Description of the METACAP Spray Gun D/A

The METACAP Spray Gun D/A was developed for the combined use with

conveying equipment and circulation systems for coating materials and with

METACAP bottom cup sets.

2.1 Technical Data

Hose couplings Air supply 1/4" outside thread with plug-in nipple

for quick connect coupling NW7, 2 equipped.

Material supply 3/8" outside thread

Maximum working

pressure Air supply PI 10bar max.

Material pressure 8bar max.

Weight 680g without cup,

Bottom cup set 0.5L - 305g

Bottom cup set 1.0L - 370g

Accessories Bottom cup sets for 0.5 and 1.0 L

item no. 101115A and 101115B

Recommended air

pressure 3 – 6 bar for at least 300 L/min of efficient air

supply

The compressed air must be dry and oil-free.

Minimum inner section of the feed pipe: 9mm

Material pressure The material pressure depends on the coating

material and can be adjusted on the paint delivery

unit (maximum: 8 bar).

When using bottom cup sets, the material

pressure results from the spraying pressure.

2.2 Identification

Note:

The identification was effected according to DIN EN 1953 "Atomising and

Spraying Equipment for Coating Materials– Safety Requirements", section

7.2 "Identification".

The serial number of the spray gun is recorded on the left side of the spray

gun handle, the maximum air pressure and the maximum pressure for the

coating material are indicated on the right side of the spray gun handle.

Operating Instructions

Use

METACAP Spray Gun D/A

Version/Edition July 2008

3-5

3 Use

3.1 Intended Use

The METACAP Spray Gun is exclusively intended for:

—

the spraying of coating materials (paint, lacquer, stripping agent, oil,

fatty matters and similar substances).

—

the combined use with conveying equipment and circulation systems for

coating materials and with METACAP Bottom Cup Sets.

—

Use only conductive tubing. (more information see 5.1 Risk of Fire and

Explosions)

3.2 Incorrect Use

—

Never point the spray beam and/or air jet at living things.

There is a risk of injury.

—

Never exceed the admissible working pressures of the coating device /

of the spray gun.

—

Use accessories or spare parts supplied or recommended by the

manufacturer only.

—

Before effecting any maintenance work or cleaning procedures, always

switch off the air and the material supply. Actuate the spray gun to

reduce the pressure of the coating device.

—

Never use the METACAP Spray Gun D/A in combination with airless

pumps or with pumps for air-supported airless.

—

Do not atomize acids, caustic solutions, removers and similar

substances.

—

Do not use non-conductive tubing.

Operating Instructions

Warranty

METACAP Spray Gun D/A

4-6

Version/Edition July 2008

4 Warranty

The warranty period for the METACAP Spray Gun D/A is 24 months. This

period will start from the date of purchase.

It is not possible to make any warranty claims:

—

regarding wear parts like gaskets, silencers, nozzles, needles or similar

parts.

—

if the user does not observe the instructions of this operating manual.

—

if the user modifies the METACAP Spray Gun D/A without prior

authorization of the manufacturer.

—

if other than original spare parts are used.

—

if the user tries to eliminate warranty deficiencies on his own without

prior written consent of the manufacturer.

The manufacturer must be informed in writing about any warranty claims

immediately after the occurrence of the deficiency. Then, the METACAP

Spray Gun D/A will have to be sent to the manufacturer to check the

warranty claim.

We are of course available for any maintenance or repair work which might

become necessary.

METACAP reserve the right to carry out all modifications which might be

required for an improved functioning of the METACAP Spray Gun D/A.

Operating Instructions

General Safety Instructions

METACAP Spray Gun D/A

Version/Edition July 2008

5-7

5 General Safety Instructions

5.1 Risk of Fire and Explosions

Caution!

Solvents and coating materials may represent a potential risk of fire and

explosions.

—

All dangerous zones must be equipped with an efficient ventilation or

suction system to avoid a potentially dangerous accumulation of

inflammable vapors.

Please observe the respective rules for prevention of accidents

"Processing of Coating Materials".

—

Open fires and smoking are not allowed within the working areas for

spraying and mixing.

—

Appropriate fire extinction devices must be available within the working

areas.

—

When using spray guns or when working with coating materials in

general, all legal and official instructions will have to be observed and all

requirements of the employer's liability insurance associations regarding

the protection against fire and explosions must be met.

Caution!

Solvents basing on halogenated hydrocarbon, like trichloroethane and

methylene chloride 1,1,1, for example, may cause chemical reactions in

combination with aluminum and galvanized or hot galvanized components

and will therefore represent a potential risk of explosion.

Please carefully read all labels, safety data sheets and technical data sheets

regarding the materials you want to use.

The METACAP Spray Gun D/A is originally not designed to be used with

halogenated hydrocarbon. The manufacturer is, however, in the position to

modify it accordingly on request. Moreover, the user has to ensure that all

other components of the coating device are suitable for the above mentioned

materials.

Attention!

Never use devices to spray materials containing solvents which are not

authorized accordingly by their manufacturers.

Operating Instructions

General Safety Instructions

METACAP Spray Gun D/A

5-8

Version/Edition July 2008

Caution!

It is possible that static electricity may be produced during the spraying

procedure.

In case of high flow rates, it might be possible that an electrostatic spark is

generated by friction. This spark may then ignite certain types of solvents

and coating materials. To avoid fire and explosions, a continuous grounding

of the spray system and of the object to be sprayed should be ensured.

Make also sure that the compressed air plant is grounded so that eventual

charges can be discharged by the tubing. Use only conductive tubing

(resistance > 10

3

Ω/m and < 10

6

Ω/m according to the German Employers'

Liability Insurance Association guideline 132). Use our anti-static air hoses,

e.g. 10m item no. 30051, or sold by the meter item no. 300531 as

compressed air supply line. For spreaders METASET 2 – 10 L or bigger,

use our conductive twin-hoses, e.g. 5m item no.30058 or for METASET 3 –

2 Liter our conductive twin-hoses for combination, e.g. 1.5m item no.30073.

5.2 Personal Protection

Toxic vapors:

When spraying coating materials, dangerous vapors or clouds (aerosols),

which are detrimental to your health, can escape. Please carefully read all

labels and safety instructions and observe all indicated instructions and

recommendations.

In case of doubt, please ask the material supplier.

—

Please use respiratory equipment when spraying. The respiratory

equipment used must be suitable for the material in use and adapted to

the degree of the gas concentration (when spraying paint, please use

respiratory equipment independent of the ambient atmosphere or

equipment with filter combination A1/A2-P2.

—

Always wear safety goggles during all spraying and cleaning

procedures.

—

When using certain coating materials and solvents, it is indispensable to

wear protective gloves during all spraying, cleaning or maintenance

procedures.

—

Ensure a sufficient protection of your skin during all spraying and

cleaning procedures. Either wear appropriate protective clothes or use

suitable protective skin ointments. We recommend expendable suits

and/or our liquid gloves called METACLEAN or similar products.

Operating Instructions

General Safety Instructions

METACAP Spray Gun D/A

Version/Edition July 2008

5-9

5.3 Noise Level

The continuous noise level within the highest performance range of these

spray guns may exceed 85 db(A) depending on the adjusted supply air

pressure and on the nozzle cap settings. The noise levels are measured by

using impulse noise meters under normal operating conditions of the spray

gun.

In case of a continuous noise level of more than 85 db(A), it is

recommended to wear an appropriate ear protection (see the respective

rules for prevention of accidents).

Please contact the manufacturer for more detailed information on the noise

levels.

5.4 Instruction of the Personnel

The personnel has to be made familiar with the correct use and with the

necessary maintenance procedures regarding the METACAP Spray Gun

D/A. The general instructions and the safety instructions of this operating

manual as well as the operating instructions of the coating materials to be

used should be thoroughly read and understood before using the spray gun.

Operating Instructions

Description, Structure and Functioning

METACAP Spray Gun D/A

6-10

Version/Edition July 2008

6 Description, Structure and Functioning

6.1 Description

The METACAP Spray Gun is a low pressure device.

The spray material is atomized with low pressure while at the same time

being encapsulated by a large volume of air; this air jacket presses the

atomized spray material against the surface to be processed and prevents

clouds of atomized spray material from escaping. This process is, however,

only efficient within a distance of max. 20 cm for a wide spray beam and of

approx. 30 cm for a circular spray beam. Please keep these distances during

the spraying procedures and always guide the spray gun in such a way that

the spray beam will vertically hit the surface. Otherwise, clouds of atomized

spray material will escape.

The nozzle and needle are made of stainless special steel and therefore

ensure a high durability. Both components are appropriate for various

coating materials.

This spray gun is equipped with the standard METACAP-AKKORD nozzle

set. This nozzle set is continuously adjustable according to nozzle sizes

between 0.5 and 3.6 mm. Thus, different coating materials can be processed

using only one nozzle set avoiding the annoying nozzle change and the

purchase of further nozzle sets. Furthermore, the AKKORD needle is a pipe

through which an additional atomizing airflow is brought to the coating

material to improve the spraying process.

Apart from the AKKORD nozzle set and nozzle cap, also nozzle sets with

fixed nozzle diameters and standard nozzle caps can be installed in the

spray gun.

For special applications, there are of course nozzle sets with fixed diameters

available upon request.

Important note:

The standard type of this spray gun can only be used to a certain degree in

case of highly corrosive or abrasive coating materials.

If the spray gun is charged with such materials, an increased need of

maintenance and cleaning and of spare parts will be the consequence.

If you are in doubt concerning the possible use of any kind of material with

this spray gun, please contact the manufacturer and exactly indicate the

material to be used and/or send us a sample.

Special designs concerning the whole material guiding system made of

special steel are of course possible. A list of the materials used for the

manufacturing of this spray gun is available upon request.

If necessary, please also check the other components of your coating

device, if they are suitable for the above mentioned coating materials.

Operating Instructions

Description, Structure and Functioning

METACAP Spray Gun D/A

Version/Edition July 2008

6-11

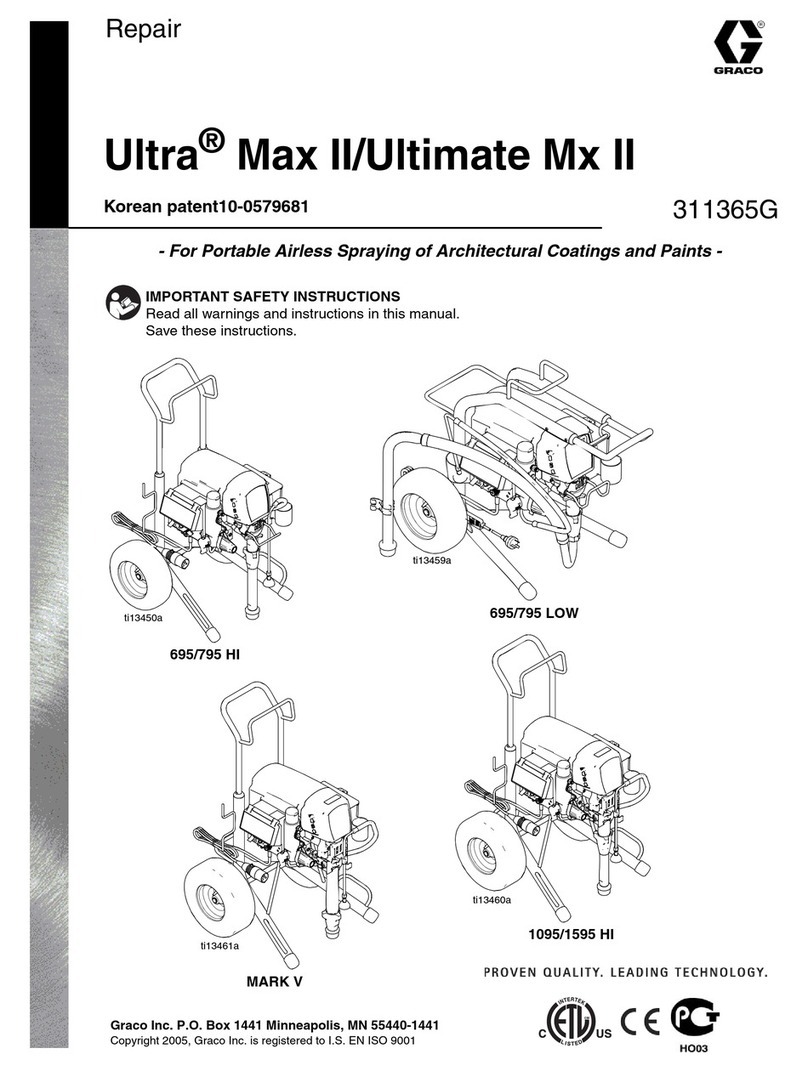

6.2 Structure of the METACAP Spray Gun D/A

Figure 1: Structure of the METACAP Spray Gun D/A

Operating Instructions

Description, Structure and Functioning

METACAP Spray Gun D/A

6-12

Version/Edition July 2008

6.3 Spare Parts List for the METACAP Spray Gun D/A

Pos. Item No. Designation Quantity

1 10266 Nozzle cap adjusting ring 1

2 10252 AKKORD nozzle cap 1

3 10265 Nozzle cap diaphragm, complete 1

4 10251 AKKORD nozzle 1

5 10224 Blocking screw 1

6 10221 Sealing ring 1

7 10218 Nozzle holder 1

8 10211 Gun body 1

10 10248 Needle guide ring 1

11 10247 Guiding spring 1

12 10249 AKKORD needle 1

13 10245 AKKORD needle adjusting screw 1

14 102138 Counternut 1

15 10261 Pressure spring 1

17 10213 Control device 1

18 10212 Articulated axle 1

19 10281 Venturi air converter, complete 1

20 10279 Annular gasket for air converter 1

21 10273 Valve block 1

22 10272 Valve spring 1

23 10270 Valve needle 1

24 10269 Valve support 1

25 10267 Basic body of venturi air converter

1

26 10268 Air supply nozzle 1

27 10271 Valve underpart 1

27-A 10277 O-ring for valve underpart 1

28 10228 Air hose pipe connection piece

Inner Thread M4 1

28-A 10231 Screw plug for

10228 DIN 84 M4x6 VA 1

29 10230 Thread connection piece for paint

3/8" 1

31 10238 Fastening screw for trigger handle 2

33 10236 Trigger handle 1

36 102137 Pressure spring sleeve 1

37 1021391 O-ring for the material fine

adjustment device PTFE 1

38 102136 Knurled nut 1

39 102135 Material fine adjustment device,

complete 1

45 10214 Pressure guide screw 1

46 10215 Guide pin 1

47 10250 AKKORD needle, complete 1

49 10282 Locking screw for air converter 1

50 10274 silencer ring 1

51 10276 O-ring for silencer ring 1

52 30031 Plug-in nipple for quick connect

coupling 1/4" Inner Thread 1

Operating Instructions

Description, Structure and Functioning

METACAP Spray Gun D/A

Version/Edition July 2008

6-13

6.4 Functioning

Note:

The position numbers refer to figure 1, see chapter 6.2 Structure of the

METACAP Spray Gun D/A, page 6-11.

The METACAP Spray Gun D/A generates the necessary low pressure and

the required high air volume from the compressed air produced by the

compressor and from the ambient air.

The air supply nozzle (1/26) supplies the compressed air into the spray gun,

where it is reduced to approx. 0.3 bar to considerably increase the

compressor-driven air volume with a Venturi nozzle (Bernoulli system),

which is located within the Venturi air converter body (1/25) to take in the

ambient air via suction holes. This air now flows through the completely

hollow interior space of the spray gun body (1/8) up to the nozzle cap (1/2),

where, depending on the respective adjustment of the nozzle cap with

regard to the nozzle (1/4), the actual spraying pressure (approx. 0.3 - 0.5

bar) is built up which ensures the spraying of the coating material.

When using bottom cup sets, a part of this air volume will be pressed into

the cupcup via the air tube connection piece (1/28) and ensures the paint

transport to the nozzle.

It is also possible to operate these spray guns using turbines. For such an

operation, it is necessary to dismount the air converter (1/19), which

prepares the compressed air for low pressure according to the process

described above, and to replace it by corresponding blower adapters

(available upon request).

The coating material is transported via the thread connection piece for paint

(1/29) into the nozzle holder (1/7) and then reaches the nozzle (1/4), which

adds the coating material to the atomizing airflow. The AKKORD needle

(1/12) opens and closes the nozzle.

The generated coating material cloud will be encapsulated by an outside air

jacket, which is produced by the special geometry of the nozzle and of the

nozzle cap, and will then be guided to the work piece. Thus, this system is

able to considerably reduce clouds of atomized spray material from

escaping.

Operating Instructions

Initial Operation

METACAP Spray Gun D/A

7-14

Version/Edition July 2008

7 Initial Operation

Note:

The position numbers refer to the figure 1, see chapter 6.2 Structure of the

METACAP Spray Gun D/A, page 6-11.

Important note:

To ensure that no residual matters have a negative effect on the spray

results, use an appropriate solvent to thoroughly rinse the METACAP Spray

Gun D/A before initial operation.

Attention!

Before using the METACAP Spray Gun D/A for the first time, carefully and

thoroughly read the complete content of this operating manual to avoid

possible dangers and damages caused by an incorrect use of your spray

gun.

The same applies to new staff members who have to work for the first time

with a METACAP Spray Gun D/A that has already been in use.

Since the handling and operation of the METACAP Spray Gun D/A are

different compared to other spray gun types, it is recommended to practice

the manipulation and adjustment of this spray gun using water before using

any coating materials.

The same applies to new staff members who have to work for the first time

with a METACAP Spray Gun D/A that has already been in use.

—

Ensure the air supply by mounting the quick connect coupling NW 7,2 of

your compressed air tube on the plug-in nipple (1/52) of your spray gun

until it locks and latches audibly and perceptibly. If you are not sure, pull

the air hose to check the firm connection.

—

Establish the coating material supply by connecting your material tube

with a union nut (3/8") and the threaded connection piece for paint

(1/29), then use an appropriate wrench to tighten the nut.

If you are using bottom cup sets, please install these cups according to the

corresponding mounting instructions belonging to the scope of supply of

your cup set.

Operating Instructions

Operating Instructions

METACAP Spray Gun D/A

Version/Edition July 2008

8-15

8 Operating Instructions

Note:

The position numbers refer to the figure 1, see chapter 6.2 Structure of the

METACAP Spray Gun D/A, page 6-11.

—

Mix, condition and filter the coating material to be sprayed according to

the instructions of the manufacturer.

—

Fill the material container with the coating material taking into account

the maximum filling height indicated by the manufacturer.

The maximum filling height for the bottom cups is approx. 10 mm below

the cup shoulder.

8.1 Default Settings

1. Turn the knurled screw (1/38) carefully clockwise to the limit stop to

close the paint supply. Please be careful, if you use too much force, you

may damage the AKKORD needle (1/12) and the nozzle (1/4).

2. Tighten the nozzle cap (1/2) by means of the nozzle cap adjusting ring

(1/1) and then loosen the connection by a half up to a full turn.

The horns of the nozzle cap should be in a horizontal position.

3. Set the compressed air and material hose pipes under pressure. Closely

watch all pipes and connections and pay attention to potential leaks.

Attention!

When using cup sets, it is not required to set the material supply under

pressure. This will be effected automatically by starting the spraying process

by means of the spraying pressure let off by the spray gun. When the spray

process is finished, the cup will de-aerate automatically via the air supply

hose pipes.

The material pressure streams out of spray gun and is also de-aerated here,

so hold the spray gun in a vertical and steady position. In cases where this

is not possible, hold the trigger handle (1/33) at action point to ensure a

continuous initial air input.

The air supply pipes are under pressure and a material return flow into the

spray gun is therefore not possible.

Do not put down, knock over or shake spray guns with filled cups, otherwise

coating materials or solvents may be transported into the spray gun via the

air supply hose pipes.

4. Now, carry out a trial spray operation. Take a piece of cardboard, of

sheet metal or the like.

—

Keep the spray gun in a vertical position with a distance of approx. 20

cm to the work piece surface and pull the trigger handle (1/33) until

the limit stop. In this state, there should not be any visible coating

material since the AKKORD needle is still not able to lift off the

nozzle due to the tightened knurled screw (1/38). Now, turn the

knurled screw counterclockwise in a careful and gradual manner and

thus open the material supply.

Operating Instructions

Operating Instructions

METACAP Spray Gun D/A

8-16

Version/Edition July 2008

—

Turn the screw as long as the required coating material quantity

becomes visible.

5. Now move the spray gun to and fro in front of the work piece and ensure

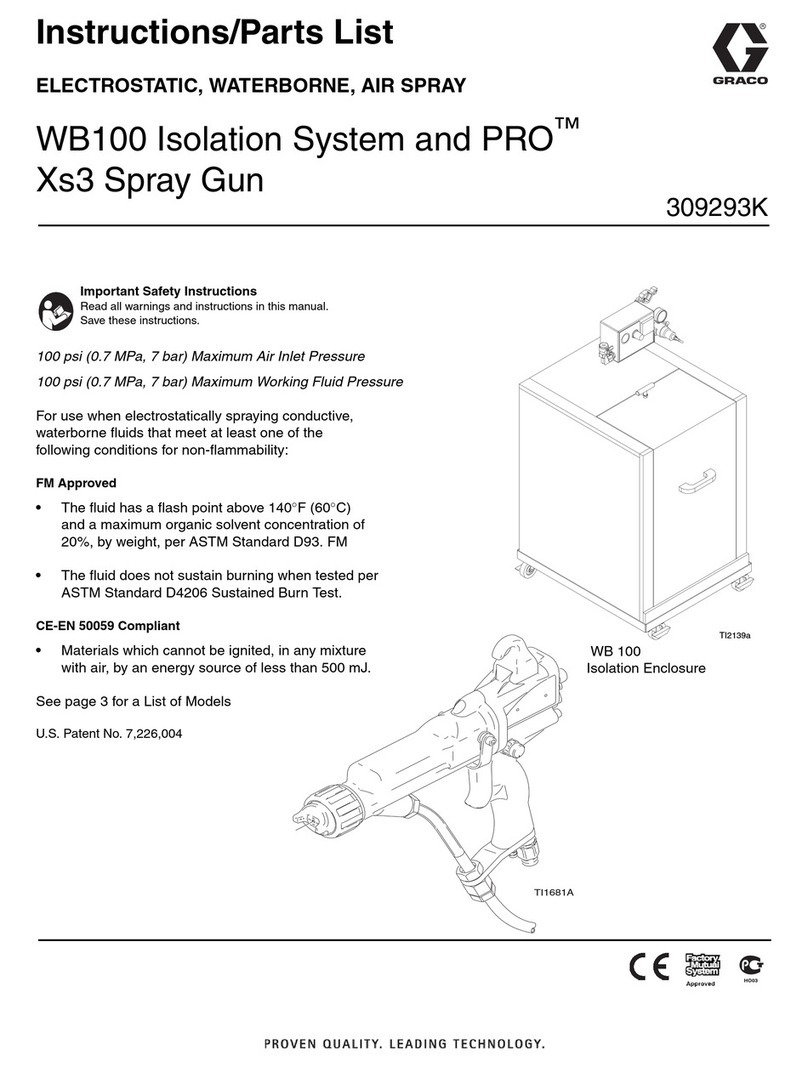

a vertical spray beam, if possible (see figure 2).

Figure 2: Guiding of the METACAP Spray Gun D/A

Attention!

Intensive waving will cause the air jacket will become unstable, allowing

clouds of atomized spray material to escape.

6. Now, adjust the required spray beam, as described below:

—

Necessary adjustments to modify the spray beam

—

The shape (circular or wide) of the spray beam will be directly

adjusted on the nozzle cap (1/2). The nozzle cap is spring-mounted

and engages automatically in the corresponding positions.

—

To adjust the shape of the spray beam, engage the nozzle cap in the

required position by means of the horns.

—

The horns are horizontal to the gun axis: vertical wide spray beam.

—

The horns are vertical to the gun axis: horizontal wide spray beam.

—

The horns are transversal to the gun axis: circular spray beam.

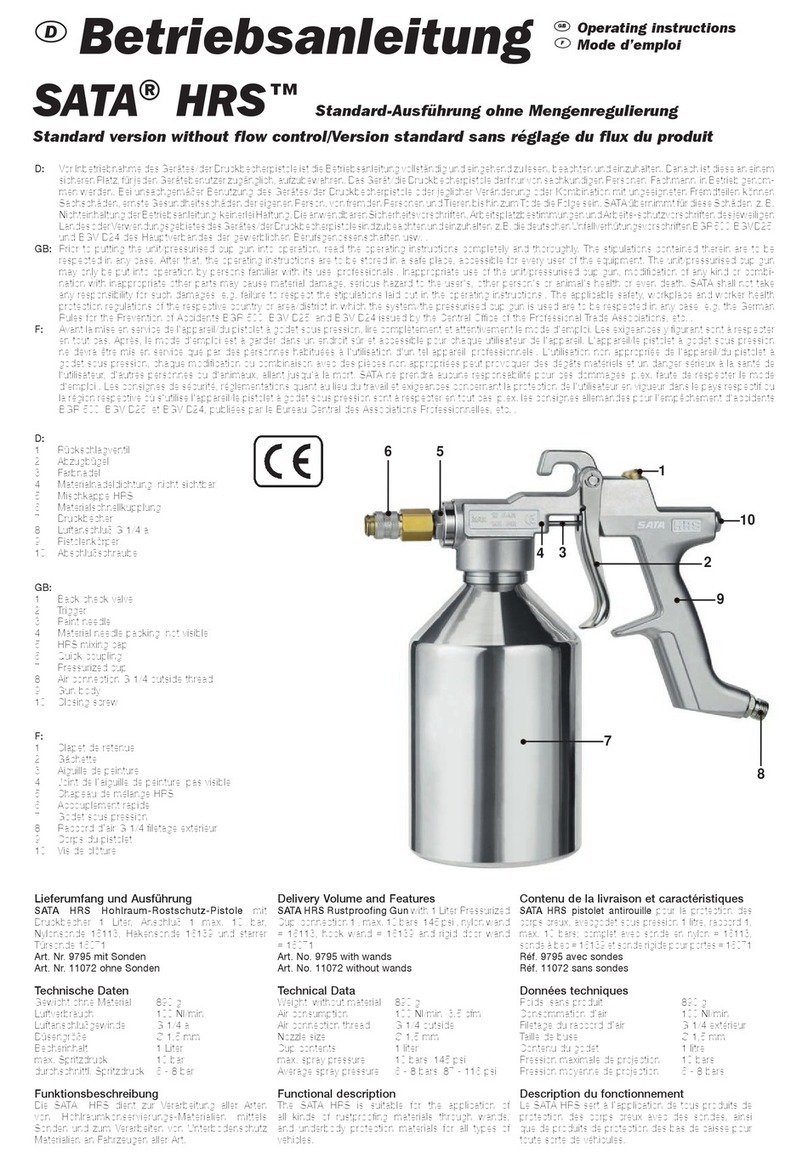

See figure 3.

Operating Instructions

Operating Instructions

METACAP Spray Gun D/A

Version/Edition July 2008

8-17

Figure 3: Spray Beam Shape Adjustment

7. Adjust the width of the spray beam by using the nozzle cap adjusting

ring (1/1) to modify the distance between the nozzle cap (1/2) and the

nozzle (1/4).

—

turn clockwise – wide spray beam

—

turn counterclockwise – narrow spray beam

Attention!

Never tighten the nozzle cap adjusting ring too firmly.

If you tighten the nozzle cap adjusting ring too firmly, the nozzle cap is

directly positioned on the nozzle. Thus, the atomizing airflow is blocked and

the horn air becomes so strong that the air jacket cannot be produced.

The consequence will be a sputtering spray gun producing unwanted

clouds, see figure 4.

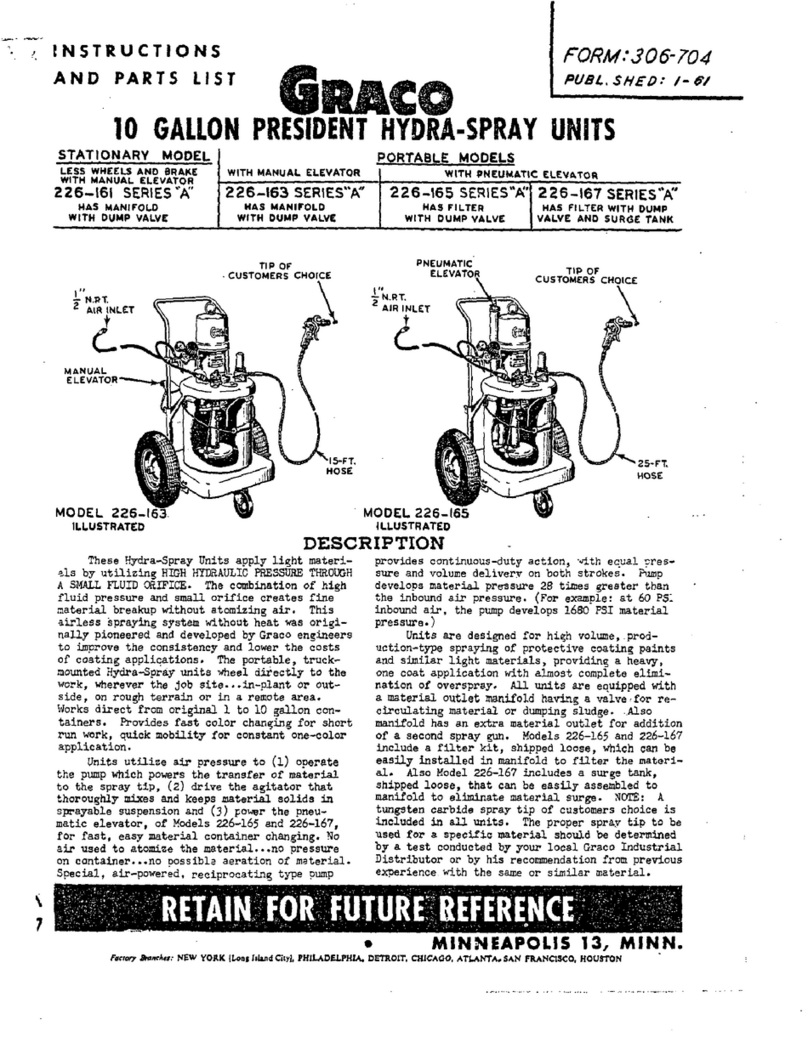

Figure 4: Adjustment of the Spray Beam Width

Description of the position according to figure 4:

1 narrow spray beam: larger

droplets 3 wide spray beam: smaller droplets

2a spray beam, narrow 2b spray beam, wide

Operating Instructions

Operating Instructions

METACAP Spray Gun D/A

8-18

Version/Edition July 2008

An infinite number of variants are possible between the indicated settings 1,

2, and 3.

The quantity of coating material coming out of the spray gun can be adjusted

by turning the knurled screw (1/38).

—

counterclockwise: more material

—

clockwise: less material

Attention!

Please, take into account that you always adjust the material quantity

simultaneously when modifying the width or shape of the spray beam.

Always adjust the spray beam only as wide as required to avoid a nuisance

or possible danger caused by coating material splashes.

Depending on the coating material used, spray beam widths of about 5 mm

up to 200 mm are adjustable.

8.2 Spray Process

The required spray beam has been correctly adjusted by spraying a test

object. This process might not be necessary in case of trained operators.

Such experienced users may adjust the spray beam directly on the work

piece.

—

Always keep the spray gun vertical to the work piece surface. If you

move or incline the spray gun in a bow shaped way, the coating material

will be irregularly applied. The spraying distance should not exceed

approx. 200 mm.

—

Spray all edges first. Let approx. 50% of each applied spray beam

overlap. Actuate the trigger handle (1/33) only shortly before reaching

the edge of the surface to be sprayed. Move your spray gun with

continuous velocity over the surface and then release the trigger handle.

Repeat all these steps for the application of the following spray beam in

the counter direction.

Attention!

If there are any holes, grids, or the like within the work piece, place a plate

behind these orifices allowing the air jacket to build up for catching misled

coating material overspray.

Avoid an unintentional spraying of coating material by switching off the air

and material pressure and by releasing the residual pressure when the spray

gun is not used.

Operating Instructions

Maintenance and Care

METACAP Spray Gun D/A

Version/Edition July 2008

9-19

9 Maintenance and Care

9.1 Cleaning

Note:

The position numbers refer to the figure 1, see chapter 6.2 Structure of the

METACAP Spray Gun D/A, page 6-11.

1. Switch off the air and material supply and release the residual pressure.

2. Remove the residual coating material from the conveyor according to

the instructions of the manufacturer. Refill the coating material residues

into the container or evacuate them professionally.

3. Clean the conveyor according to the instructions of the manufacturer.

—

When using METACAP Bottom Cup Sets, clean the cup (acc. to the

structural drawing of the bottom cup sets 1/78 and 1//81) by means of

a brush. Dismount the gasket sheet (see structural drawing of bottom

cup set 1/77) by pulling it out of the holding device (see structural

drawing of bottom cup set 1/79). Clean both the gasket sheet and the

holding device by means of a brush.

—

Fill in the corresponding solvent (filling height: half-full).

4. Adjust the nozzle cap (1/2) to circular spray beam, then use the nozzle

cap adjusting ring to tighten it, so that there is no remaining annular gap

between the nozzle cap and the nozzle.

5. Now spray with the solvent suitable for the coating material to be used.

Never spray directly in the ambient area, because this will cause

needless dangers through the release of solvents.

—

Always use the METACAP SRG spray gun cleaning device or the

injection orifice of a spray gun cleaning device. Repeat this

procedure until the spray gun is clean. The number of the rinsing

cycles depends on the coating material and on the corresponding

type of solvent.

6. Switch off the air and material supply and release the residual pressure.

7. Now, clean the outside of the spray gun by means of a cleaning cloth, if

necessary.

Operating Instructions

Maintenance and Care

METACAP Spray Gun D/A

9-20

Version/Edition July 2008

8. Unscrew the nozzle cap adjusting ring and remove the nozzle cap (1/2)

and the nozzle cap diaphragm (1/3) from the spray gun. Clean these

component parts by means of an appropriate solvent. If the drilled holes

of the nozzle cap are clogged, clean them by means of a tooth pick. Do

not use a wire, a drill or similar objects which may damage the nozzle

cap. Such damages may lead to incorrect spraying results.

—

Now, the spray gun is clean enough to start working with a new

coating material.

—

If the work is interrupted for a longer period of time (e.g. at the end of

the working shift), the following operations will have to be carried out:

—

Unscrew the knurled screw (1/38) counterclockwise and remove it.

—

Unscrew the pressure spring sleeve (1/36) counterclockwise and

remove it.

9. Pull the complete AKKORD needle (1/47) carefully backwards out of the

spray gun. Push the AKKORD needle guide ring and guiding spring

(1/10 and 1/11) forward down from the AKKORD needle. Do not loosen

the adjustment screw of the AKKORD needle (1/13) and the counternut

(1/14), as they ensure the initial air input settings of the spray gun which

should not be altered.

—

Clean the outside of the AKKORD needle with a solvent and the

inner part of the flare needle by means of the brass wire brush

belonging to the scope of supply of your spray gun. Push this brush

completely through the needle before you pull it back, otherwise the

brass wires will wedge with the needle and it will not be possible any

longer to remove the brush without damaging the flare needle.

10. Remount the AKKORD needle guide ring and the guiding spring on the

AKKORD needle.

—

Slightly lubricate a length of approx. 10 mm of the AKKORD needle

situated approx. 30 cm behind the tip by means of a non-corrosive, non-

hardening lubricant (for example: Molycote LongTerm W2 or Vaseline)

and then put it aside.

11. Unscrew the nozzle (1/4) counterclockwise by means of a deep offset

wrench, a wrench or a nut (wrench size: 13 mm) and remove it from the

nozzle holder (1/7). Do not use an open-jawed wrench or tongs for

mounting or dismounting the nozzle, because these types of tools may

damage the nozzle or the spray gun body. It is possible that such

damages completely destroy the spray gun. If there are still coating

material residues within the nozzle, clean the nozzle by means of a

solvent. To clean the inside, use the short cleaning brush belonging to

the scope of supply of your spray gun. Afterwards, clean the nozzle and

put it aside as well.

Table of contents