METHVEN AURAJET User manual

www.methven.com

Technical Specifications:

Operating Pressure:

Min: 100kPa/1bar

Max: 500kPa/5bar*

Optimum: 150kPa/1.5bar - 500kPa/5bar

Operating Temperature:

Hot: Max 70°C*

Cold: Min 5°C

Inlet Connections:

½" BSP

* Regional specific regulations apply.

Please refer to your warranty statement at

www.methven.com

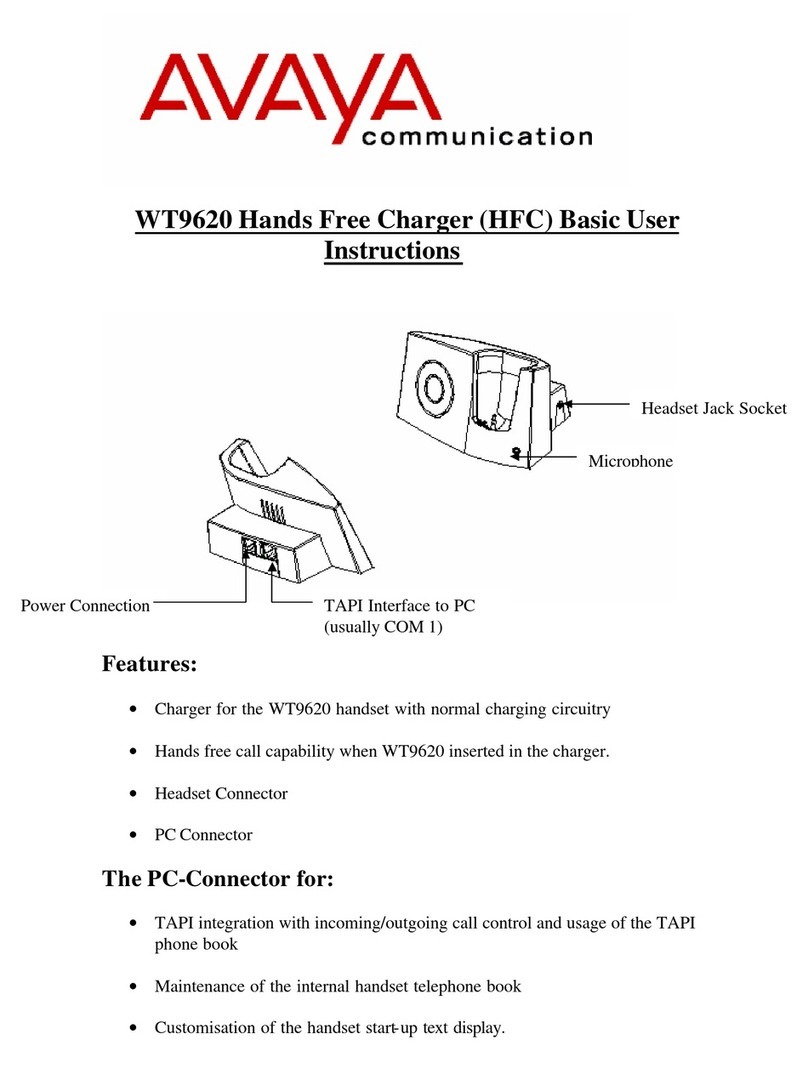

AURAJET™ HANDSET

Installation Guide

Methven warrants this product against manufacturing defects and that it is suitable for use

under the general operating conditions specified in this instruction sheet. However, regional

regulations apply and may affect your warranty. Please refer to www.methven.com or call

customer service for full details.

New Zealand

0800 804 222

Australia

1300 638 483

UK

0800 195 1602

Never use abrasives or abrasive cleaning agents to clean this product. Clean regularly with

contamination free warm soapy water and a damp soft cloth.

A filter washer should be installed in the hose cone on the water outlet and it should be

cleaned periodically.

If shower performance is compromised by the build-up of lime-scale, soak in limescale

remover for up to 10 minutes. Do not use products containing chlorine bleach or

hydrochloric acid as these can damage the shower. Always rinse the shower thoroughly after

cleaning to remove cleaning products that can damage the shower.

Never insert objects into the spray slot or attempt to remove limescale with sharp objects or

abrasives.

•

•

•

•

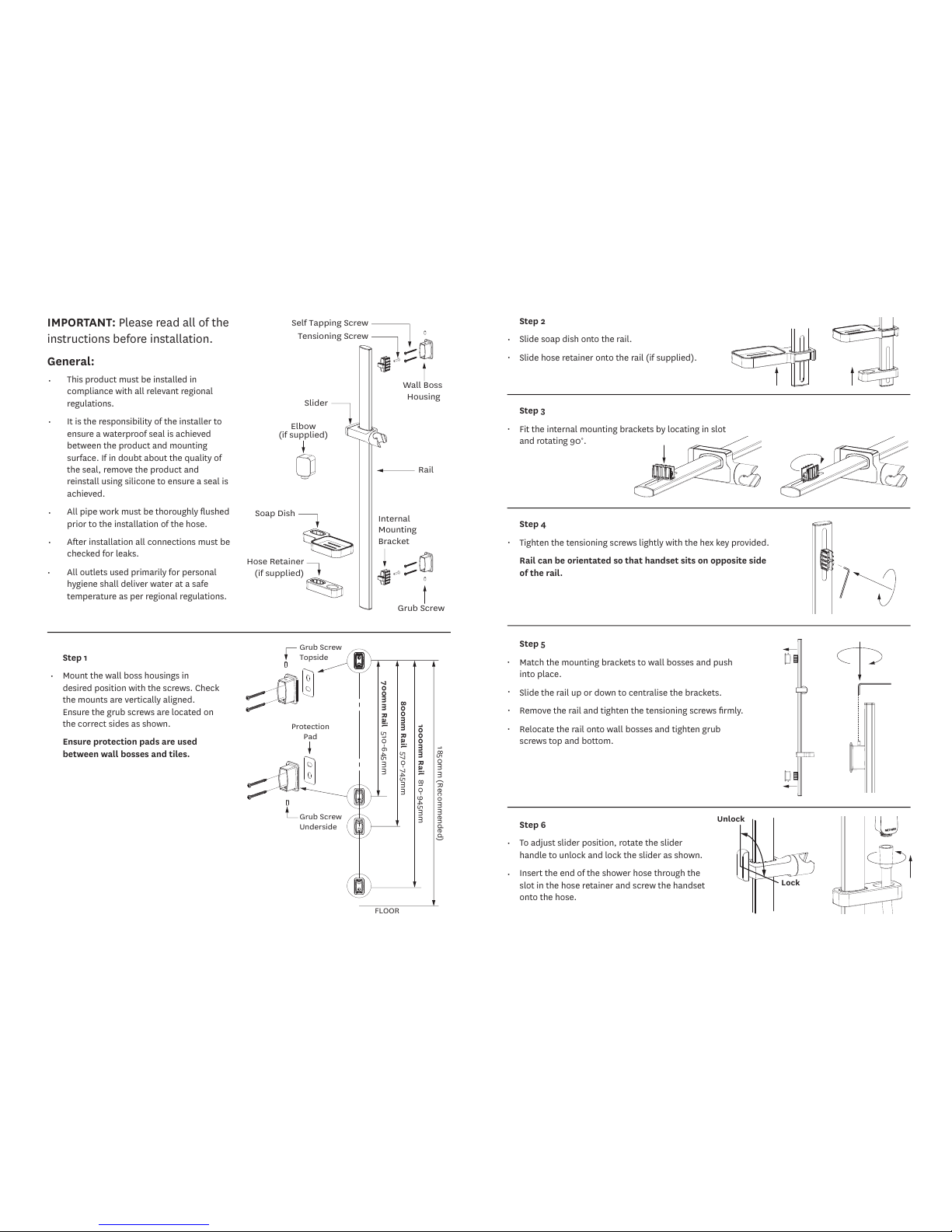

IMPORTANT: Please read all of the instructions before installation.

General:

Methven recommends this product is installed by a licensed plumber in compliance with all

relevant regional regulations.

After installation all connections must be checked for leaks.

All outlets used primarily for personal hygiene shall deliver water at a safe temperature as per

regional regulations.

It is the responsibility of the installer to ensure a waterproof seal is achieved.

NOTE: Some showers may not provide an effective shower when used with gravity fed heated

water systems or where pressures are less than 150kPa/1.5bar at the outlet. Additionally showers

with flow rates of less than 9L/min may not allow the following to function correctly:

- some instantaneous water heaters

- some tempering valves

- some thermostatic mixing valves

Care and Cleaning:

•

439910 ISSUE B

Methven warrants this product against manufacturing defects and that it is suitable for use

under the general operating conditions specified in this instruction sheet. However, regional

regulations apply and may affect your warranty. Please refer to www.methven.com or call

customer service for full details.

New Zealand

0800 804 222

Australia

1300 638 483

UK

0800 195 1602

www.methven.com

Never use abrasives or abrasive cleaning agents to clean this product. Clean regularly with

contamination free warm soapy water and a damp soft cloth.

Periodically the filter washer should be removed from the end of the shower hose and cleaned.

Care and Cleaning:

439980 ISSUE B

Technical Specifications:

Inlet Connections:

All ½" BSP

* Regional specific regulations apply.

Please refer to your warranty statement at

www.methven.com

EDGE RAIL

Installation Guide

•

Step 1

Wall lining hole should be cut or finished as per

the dimension shown in the diagram on the right.

Cut offthe threaded nipple 13±2mm from the wall

lining and apply thread seal tape to ensure a

good seal.

•

Step 2

Screw the elbow onto the nipple ensuring

that the o-ring is sufficiently compressed to

create a watertight seal.

Ensure that the elbow is oriented vertically

with the outlet oriented downwards.

•

•

Elbow Installation (if supplied):

13±2mm

26mm max

Step 2

Slide soap dish onto the rail.

Slide hose retainer onto the rail (if supplied).

Step 3

Fit the internal mounting brackets by locating in slot

and rotating 90°.

Step 4

Tighten the tensioning screws lightly with the hex key provided.

Rail can be orientated so that handset sits on opposite side

of the rail.

Step 5

Match the mounting brackets to wall bosses and push

into place.

Slide the rail up or down to centralise the brackets.

Remove the rail and tighten the tensioning screws firmly.

Relocate the rail onto wall bosses and tighten grub

screws top and bottom.

•

•

•

•

•

•

•

•

1850mm (Recommended)

1000mm Rail 810-945mm

700mm Rail 510-645mm

800mm Rail 570-745mm

Grub Screw

Underside

Grub Screw

Topside

Protection

Pad

FLOOR

Step 1

Mount the wall boss housings in

desired position with the screws. Check

the mounts are vertically aligned.

Ensure the grub screws are located on

the correct sides as shown.

Ensure protection pads are used

between wall bosses and tiles.

•

Tensioning Screw

Rail

Slider

Grub Screw

Internal

Mounting

Bracket

Elbow

(if supplied)

Soap Dish

Hose Retainer

(if supplied)

Self Tapping Screw

Wall Boss

Housing

Step 6

To adjust slider position, rotate the slider

handle to unlock and lock the slider as shown.

Insert the end of the shower hose through the

slot in the hose retainer and screw the handset

onto the hose.

•

•

Unlock

Lock

This product must be installed in

compliance with all relevant regional

regulations.

It is the responsibility of the installer to

ensure a waterproof seal is achieved

between the product and mounting

surface. If in doubt about the quality of

the seal, remove the product and

reinstall using silicone to ensure a seal is

achieved.

All pipe work must be thoroughly flushed

prior to the installation of the hose.

After installation all connections must be

checked for leaks.

All outlets used primarily for personal

hygiene shall deliver water at a safe

temperature as per regional regulations.

•

•

•

•

IMPORTANT: Please read all of the

instructions before installation.

General:

•

Please retain this document

for future reference.

This product should be fitted

in compliance with Water

Regulations, by a qualified

plumber.

Use only a clean damp cloth

to maintain the surface finish,

use of abrasive cleaning

materials will invalidate your

guarantee.

Website

www.methven.com

COOLTOUCHWITHEASYFIX

THERMOSTATICBARVALVE

InstallationandMaintenanceGuide

DTCINST274a‐25.09.14

Page 1 Page 6

OPERATING SPECIFICATION

Pressure

Minimum working pressure - 0.3 bar

Recommended working pressure 0.5 - 3 bar

Maximum working pressure - 5 bar

(Pressure above 5 bar must be reduced via a pressure reducer)

In order to assure maximum efficiency of the mixer, the operating pressures

should be balanced.

Water temperature

Inlet hot water supply

IMPORTANT

Maximum 85c

A minimum 10c difference between outlet

Recommended 65c

temperature and hot supply temperature

must be maintained at all times

Inlet cold water supply

10c - 25c

Guarantee

Your product comes with a 5 year guarantee, this includes 2 years parts and labour

followed by a further 3 years parts only, subject to the following:

Proof of purchase will be required.

The guarantee does not cover faults or damage caused by incorrect installation

and/or maintenance, ordinary wear and tear, water composition etc, including:

Supply pipes reversed

Incorrect pressure or temperature

Incorrect use

Foregin bodies and/or scale due to the water composition.

Incorrect cleaning

Cleaning should be carried out using a clean damp cloth, use of abrasive

agents or materials on the product, will invalidate your guarantee.

DTCINST274a‐25.09.14

Page 5 Page 2

Maintenance Installation

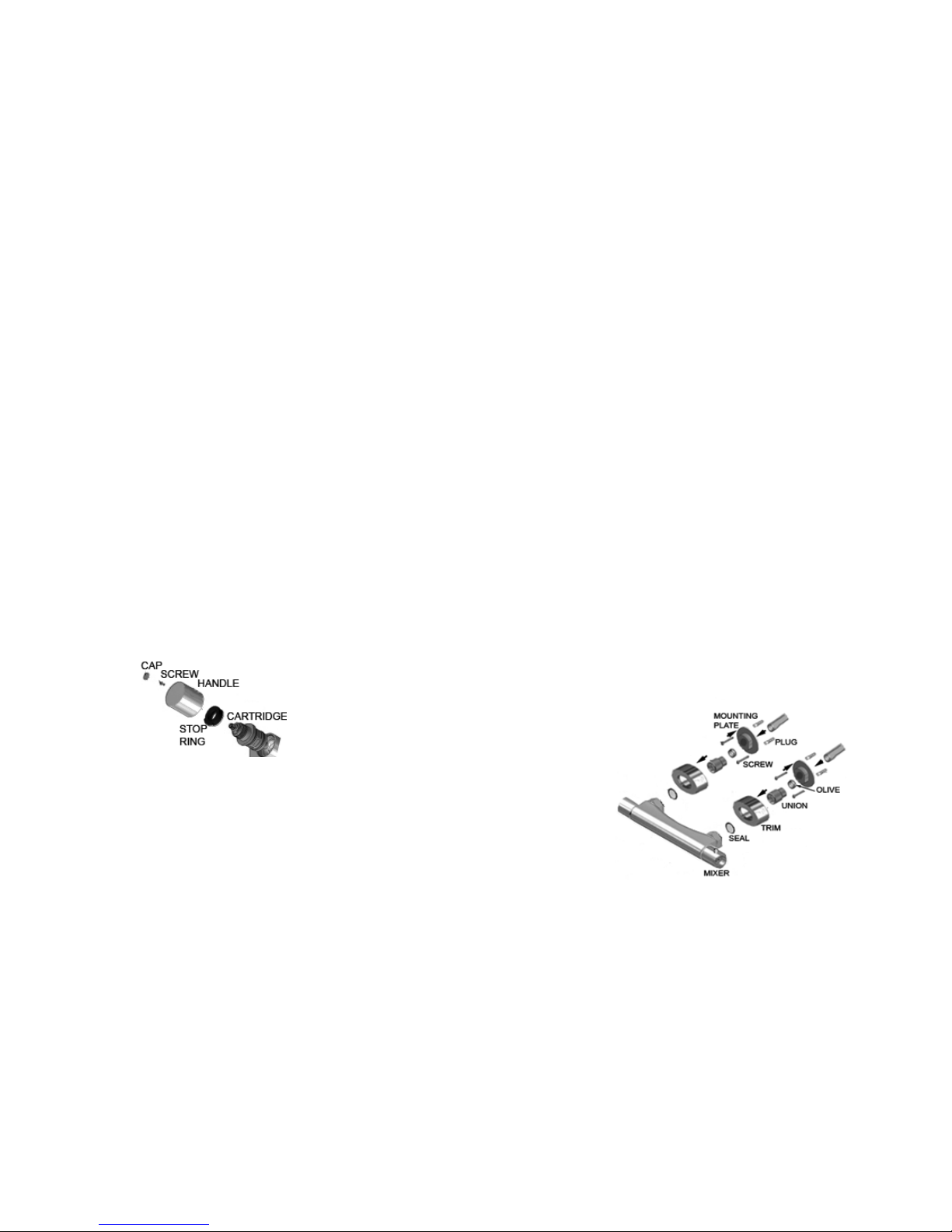

To replace the thermostatic cartridge; (See diagram)

Turn off water supply

Remove the handle cap , followed by the screw

Inside the handle, remove the screw Prepare the supply pipes at 150mm centres, allowing approx 22mm of pipe to exposed

Pull handle from mixer from the finished wall.

Take note of the stop ring position for re-assembly after maintenance The pipework must be flushed prior to installation.

Remove the cartridge from the mixer body. After flushing the pipework, install the mixer as a standard exposed fitting, with the outlet

Clean or replace the cartridge as necessary, then replace, ensuring components are located facing downwards.

correctly to give correct maximum set temprature. The hot supply pipe must be connected to the hot inlet of the mixer, indicated by the red dot.

If re-calibration is required follow instruction in "operation and setting" Place the mounting plate over the pipe end and mark drill holes, ensuring no pipes or

Once water supply is turned on check for leaks. wires are affected.

Once holes are marked remove and drill holes, then fit wall plugs,

Next place the mounting plate over pipe end and locate over drill holes, secure using

screws provided.

Place olive over pipe end and then fit threaded union, tighten using a two spanners one

on the flats of the union the other on the flat of the mounting plate.

Tighten until fully secured, to create a compression fitting seal.

Once secured, screw the trim onto the threaded union and screw up to finished wall

(if required sealant can be used)

Place seals into mixer inlets and connect

mixer to union and secure using a spanner

(take care not to damage product finish)

Once all connections

have been made

turn on water supply to

check for leaks,

ensuring the valve is

in the OFF position

DTCINST274a‐25.09.14

Page 3 Page 4

OPERATION & SETTING Maintenance

To control the temperature of the shower, turn the left handle for more hot To replace the flow control valve:

or cold water, in the direction indicated by the marking. Turn off water supply

Remove handle by forcing off handle cap

To control the flow of water turn the handle to regulate the flow of water from the Inside the handle, remove the screw

shower in the direction shown on the mixer. Pull handle from valve.

Take note of stop ring positioning for re-fit

The product also has override buttons, the flow control allows for Pull off stop ring.

reduced flow, to activate full flow, press the button and continue Remove valve from mixer, using a spanner unscrew the nut

to turn the handle then unscrew the valve, taking care not to damage the pipe work

The temperature control allows for a temperature stop position Clean or replace valve as necessary.

this can be exceeded by pressing the button and continuing to Replace all components, turn on water supply and check for leaks.

turn the handle

If on installation the temperature is not to your requirement, this can be re-calibrated.

Turn temperature handle to fully hot.

Remove the handle cap , followed by the screw

Pull handle from valve.

Turn the spindle on the thermostat until the desired temperature is reached.

(Always maintain the 10c difference between supply and mixed)

Once the temperature is reached, replace the handle so that the stop is in the maximum

position, replace screw and handle cap.

Re-calibration should only be carried out when absolutely necessary

DTCINST274a‐25.09.14

Table of contents