MF&B Restaurant Systems EDGE 1830 User manual

Original Installation

Operation & Service Manual

(2C) Chassis, 2022

US Domestic

Retain This Manual for Future Reference

To Be Service by Authorized & Qualied Personnel Only

MF&B RESTAURANT SYSTEMS, INC.

119 ICMI RD, STE 300, DUNBAR, PA, 15431 USA

(1)888.480.EDGE

(1)724.628.3050

SUPPORT@EDGEOVENS.COM WWW.EDGEOVENS.COM

CD-941-407-3

EDGEEDGE 18301830

EDGEEDGE 2440, 32402440, 3240

EDGEEDGE 2460, 3260, 3260S2460, 3260, 3260S

EDGEEDGE 3860, 4460, 4460S3860, 4460, 4460S

EDGEEDGE 3270, 38703270, 3870

PROUDLY BUILT IN THE USA

MF&B Restaurant Systems, Inc.

119 ICMI RD, STE 300

Dunbar, PA 15431, USA

724.628.3050 (telephone)

724.626.0247 (fax)

www.edgeovens.com

Valued customer,

We thank you for the opportunity to provide you with, what we believe to be, the nest conveyor oven

available on the market today.

Our experience as pizzeria owners has given us the opportunity to improve on the conveyor oven in-

dustry. We imagined a better oven with a better bake, so we built one... for you. Thank you for your trust

and thank you for choosing EDGE ovens. May your business be blessed with success!

Sincerely,

Mark Bielstein,

President, MF&B Restaurant Systems, Inc.

Michael French,

Secretary & Treasurer, MF&B Restaurant Systems, Inc.

Please visit our website for additional information and documentation.

3133776 1312DL6500

Service policy

All service technicians of the EDGE Oven must read this summary and all warnings and cautions in the manual.

Any internal part(s) replacement or assembly and reassembly must be performed by qualied service person-

nel with a good understanding of mechanical, gas and electrical components. If diculties arise in locating a

qualied service person, please contact your EDGE oven distributor or MF&B for assistance in locating qualied

personnel to assist you.

All repairs on products within the warranty period must be PRE-AUTHORIZED by MF&B Restaurant Systems,

Inc., or an approved representative within the designated region. Unauthorized repairs will not be reimbursed.

Modications will void the warranty. Consult the WARRANTY POLICY within the Installation and Operation In-

structions for complete details.

If the product fails to function correctly—or if you need assistance, service, or spare parts—contact MF&B

Restaurant Systems, Inc.

Before contacting MF&B Restaurant Systems, Inc., try to duplicate the problem, and check electrical outlets and

gas supply lines to ensure that they are not causing the problem. When calling, please be prepared to provide:

• Supplier, model number, and serial number of your product.

• Complete description of the problem.

• Complete name, address, and phone number of your facility.

• For out-of-warranty repairs or spare parts orders, a purchase order (or credit card) number.

• For parts orders, the required spare or replacement part numbers.

If your product requires warranty, or non-warranty repair service, please call MF&B Restaurant Systems, Inc.

rst. A representative will assist you troubleshooting the problem and will make every eort to solve it over the

phone, avoiding potential unnecessary expenses and downtime.

In case a service call cannot be avoided, the representative will record all necessary information and may at-

tempt to coordinate the delivery of repair parts with a servicer in your area. Repair parts which are not used and/

or replaced parts should be returned to MF&B Restaurant Systems, Inc.

To aid in quick service and to accommodate the servicer providers needs, ensure the product is accessible and

that there is ample clearance for the product to be disconnected and rotated as needed.

Due to the size of the product and the size of the product parts, a servicer may require assistance with some

handling or maneuvering or this product or product parts. Please use care and correct lifting techniques.

Table of Contents

WARNING AND SAFETY INFORMATION ...............................................................i

SPECIFICATIONS ................................................................................................ 1

Export, Gas Conguration Data........................................................................................................1

North America, Gas Conguration Data ...........................................................................................2

Dimensions.......................................................................................................................................3

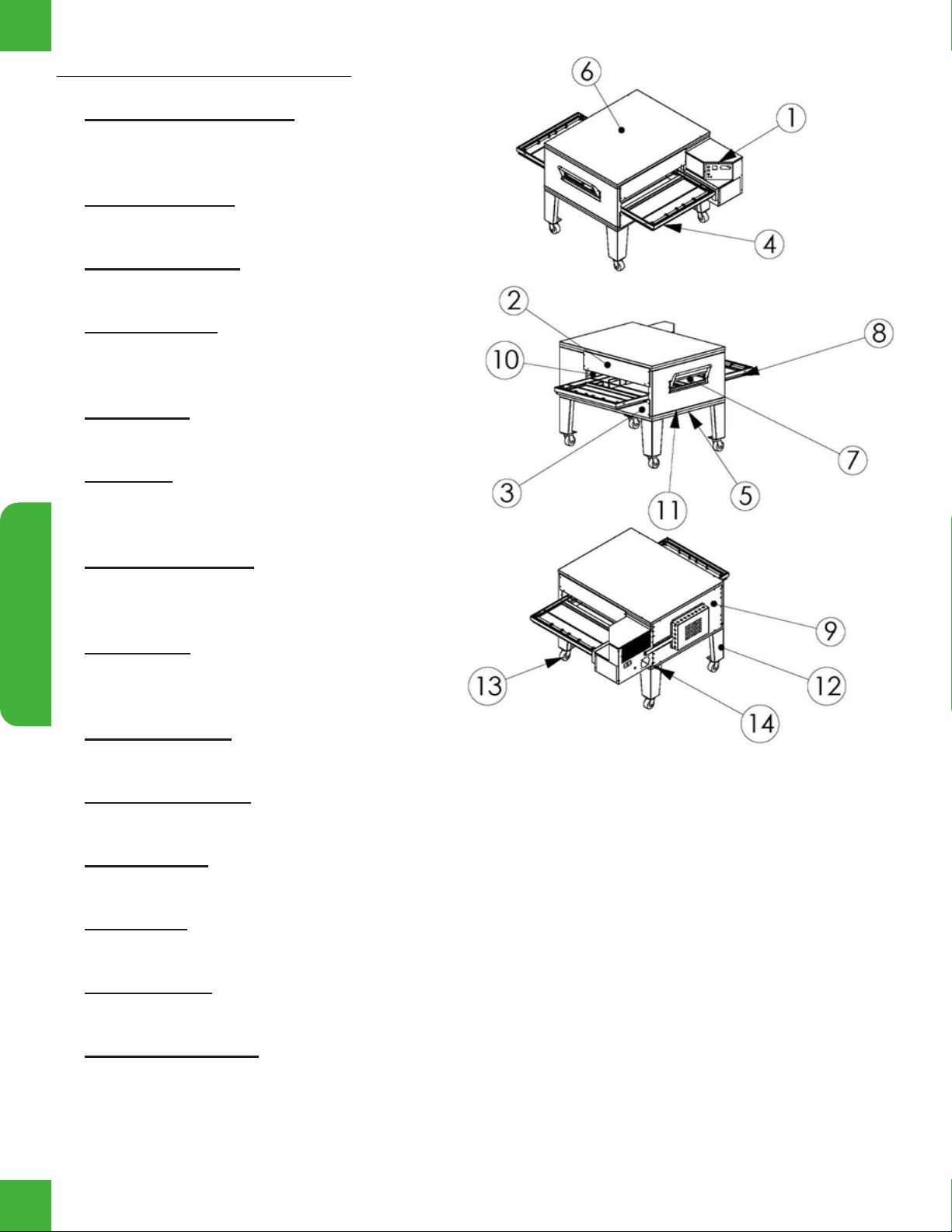

OVEN COMPONENTS.......................................................................................... 4

INSTALLATION INSTRUCTIONS .......................................................................... 5

Foreword ..........................................................................................................................................5

Tools & Equipment Required ............................................................................................................ 6

Stacking Ovens ................................................................................................................................7

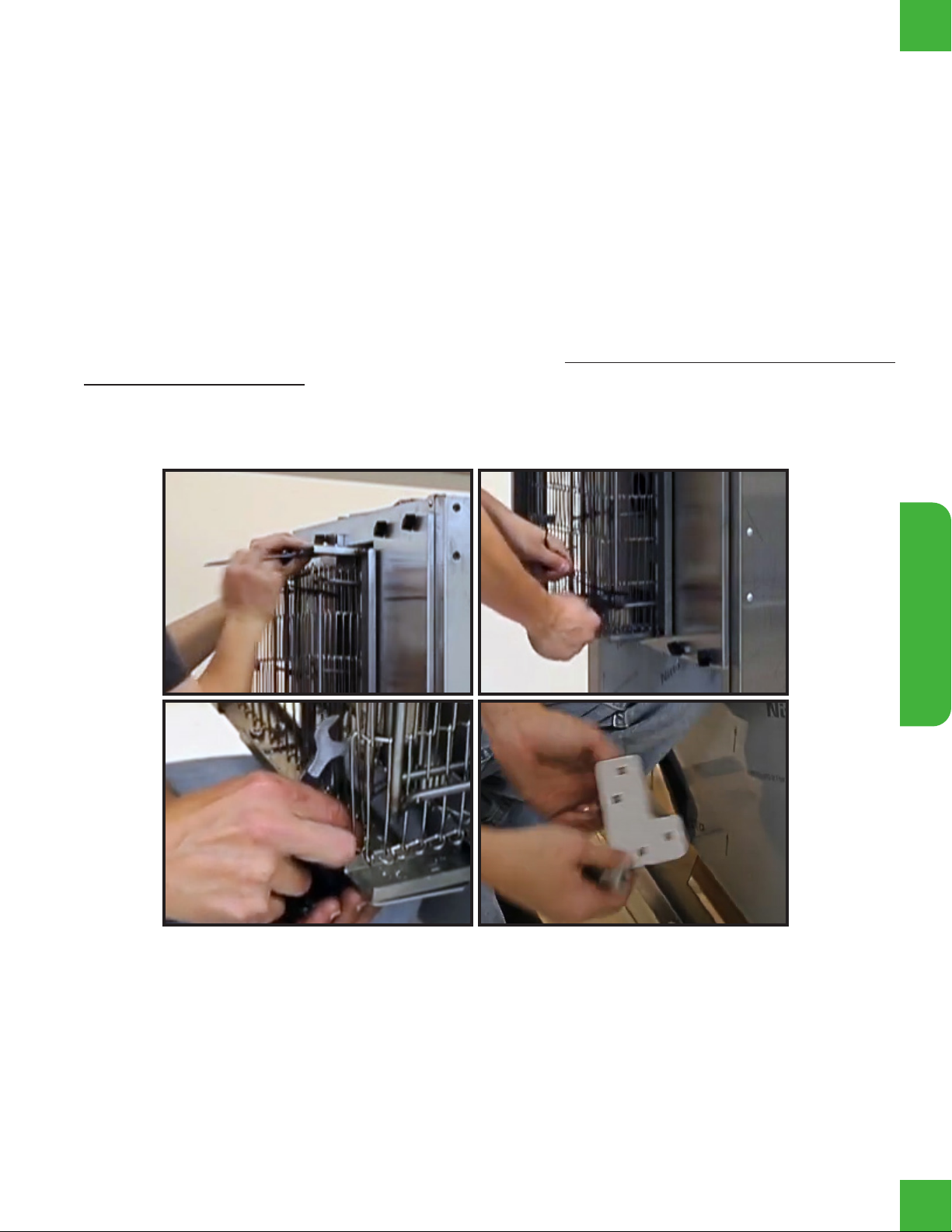

End Plug Removal & Inspection .....................................................................................................12

Conveyor Drive System..................................................................................................................13

Standard Accessories.....................................................................................................................15

Finger Assemblies ..........................................................................................................................16

Collimating Panels..........................................................................................................................17

Restraint Cable...............................................................................................................................18

Final connections............................................................................................................................18

Valve Specications........................................................................................................................19

Manifold Adjustment .......................................................................................................................20

Air shutter .......................................................................................................................................20

First Firing / Test Firing ...................................................................................................................20

Warranty Activation.........................................................................................................................21

OVEN VENTILATION ......................................................................................... 21

Ventilation Requirements................................................................................................................21

Fire Suppression ............................................................................................................................21

DECOMMISSIONING AND DISPOSAL................................................................ 21

OVEN OPERATION ............................................................................................ 22

Oven Start-Up.................................................................................................................................22

Oven Shutdown ..............................................................................................................................22

Basics .............................................................................................................................................22

Menu System..................................................................................................................................23

Advanced Operation.......................................................................................................................24

PREVENTATIVE MAINTENANCE........................................................................ 27

SERVICE OPERATION....................................................................................... 32

SERVICE TOOLS & MATERIAL.......................................................................... 33

SEQUENCE OF OPERATION ............................................................................. 34

EDGE G2, Control Module Pinout ..................................................................... 36

WIRING DIAGRAM............................................................................................. 37

PART IDENTIFICATION...................................................................................... 38

GAS CONVERSION ........................................................................................... 39

Removing the Gas Train ................................................................................................................. 39

Replacing the Main Orice .............................................................................................................39

Replacing the Pilot Orice ..............................................................................................................40

Replacing the Gas Valve ................................................................................................................40

Installing the Gas Train ................................................................................................................... 40

Adjustment Air Shutter....................................................................................................................41

Gas Type Markings.........................................................................................................................41

TROUBLESHOOTING ........................................................................................ 42

Basics First .....................................................................................................................................42

G2 ‘DIAGNOSTIC’ Lamp ................................................................................................................43

G2 Control System Messages........................................................................................................44

PART FAILURE VERIFICATION.......................................................................... 47

Controls and assemblies ................................................................................................................47

TYPE-J THERMOCOUPLE CHART..................................................................... 50

Thermocouple Worksheet ..............................................................................................................51

PART LIST......................................................................................................... 52

EDGE Original Installation, Operation and Service Manual i

PREFACE

PREFACE

WARNING AND SAFETY INFORMATION

WARNING

Do not store or use gasoline, cleaning solvents, or any other material that may emit am-

mable vapors near this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service, or maintenance can result in prop-

erty damage, injury, or death. Read this entire manual and ensure that you thoroughly

understand all instructions before installing, operating, or servicing this equipment.

WARNING

Keep the appliance free and clear of combustibles. Do not use aerosols within the area

of the operating appliance.

WARNING

Do not obstruct the ow of combustion or ventilation air to and from the oven. There

should never be any obstructions on or around the oven that could hamper the ow of

combustion or ventilation air to or from the oven. Any changes to the area where the

oven is installed must not aect the combustion or ventilation air to and from the oven.

IMPORTANT

Retain all shipping materials until you are certain that the oven has not been damaged

(either externally or internally) during shipment. Thoroughly inspect the oven on receipt

for both external and internal damage. It is solely the customer’s responsibility to report

any shipping damage to the freight company.

NOTICE

Oven installation, including electrical and gas connections, oven placement, and venti-

lation must comply with all applicable national and local codes. National and local codes

supersede the recommendations, requirements, and guidelines contained in the manual.

NOTICE

The purchaser of this equipment is required to prominently post instructions to be fol-

lowed should the user smell gas. This information shall be obtained from the local gas

supplier.

NOTICE

Installing any part(s) not provided by the Edge oven OEM shall void the warranty and

release the OEM from any and all liabilities.

EDGE Original Installation, Operation and Service Manual

ii

PREFACE

PREFACE

NOTICE

The oven electrical wiring diagram is located inside the control compartment.

IMPORTANT

US CUSTOMERS

Oven installation must comply with local codes or, if local codes do not exist, with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54.

This appliance must be electrically grounded in accordance with local codes, or if local

codes do not exist, with the National Electrical Code, ANSI/NFPA 70.

IMPORTANT

CANADIAN CUSTOMERS

Oven installation must comply with local codes or, if local codes do not exist, gas oven

installation must comply with the Natural Gas Installation Code, CAN/CGA-B149.1, or

the Propane Gas Installation Code, CAN/CSA-B149-2, as applicable.

This appliance must be electrically isolated in accordance with local codes, or if local

codes do not exist, with the Canadian Electrical Code, CSA C22.2.

IMPORTANT

EXPORT CUSTOMERS

Oven installation must comply with local codes. This appliance must be electrically

grounded in accordance with local codes.

NOTE

This appliance and its individual manual shuto valves must be disconnected from the

gas supply piping system during any pressure testing of gas supply piping at pressures

exceeding 1/2 psi (3.5 KPa).

WARNING

Always check for leaks after making any gas supply piping connections or performing

any service on the oven.

NOTE

The installer of this oven must contact local building and re ocials concerning inspec-

tions and installation requirements of this oven and its ventilation system.

NOTE

Appliance is NOT to be cleaned with jets of water. End plugs and oven back are not to

be submerged.

EDGE Original Installation, Operation and Service Manual iii

PREFACE

PREFACE

IMPORTANT

NORTH AMERICA CUSTOMERS

OVENS EQUIPPED WITH CASTERS:

1. When this appliance is installed with casters, it must be installed with the casters sup-

plied, a connector complying with ANSI Z21.69 (CSA 6.16), a quick-disconnect device

complying with ANSI Z21.41 (CSA 6.9), and a mechanism to limit movement of the

appliance without straining the connector or its associated piping system.

2. Adequate means must be provided to limit movement of the appliance without de-

pending on the connector, quick-disconnect device, or associated piping to limit ap-

pliance movement.

3. The restraining device must be attached to the mounting eye located on the left side

of the oven base assembly.

IMPORTANT

EXPORT CUSTOMERS

OVENS EQUIPPED WITH CASTERS:

1. When this appliance is installed with casters, it must be installed with the casters

supplied, a quick-disconnect device, and a mechanism to limit movement of the ap-

pliance without straining the connector or its associated piping system.

2. Adequate means must be provided to limit movement of the appliance without de-

pending on the connector, quick-disconnect device, or associated piping to limit ap-

pliance movement.

3. The restraining device must be attached to the mounting eye located on the left side

of the oven base assembly.

WARNING

To prevent damage to the oven and personal injury or death, the voltage, phase and

grounding of the electrical supply must be inspected and veried prior to energizing.

WARNING

NORTH AMERICA CUSTOMERS

This appliance is equipped with a three-prong (grounding) plug and must be connected

to a properly grounded three-prong receptacle. This is to protect you from a possible

shock hazard.

DO NOT remove the grounding prong from this plug or use any form of adapter to plug

the appliance into a standard two-prong receptacle.

Use only the cord set supplied by the oven OEM, or a direct replacement cord set pur-

chased from the oven OEM. Other cord sets may present a re and/or electric shock

hazard.

EDGE Original Installation, Operation and Service Manual

iv

PREFACE

PREFACE

General cautions

!

WARNING Indicates conditions that could lead to injury or death.

!

CAUTION Indicates conditions that could damage equipment or property.

CAUTION Indicates conditions that may result in a burn injury.

General Warnings

Warnings indicate conditions or practices that could lead to injury or death.

Warnings related to the operating environment

!

WARNING To avoid a possible explosion, do not service the product in an atmosphere where explo-

sive gases or fuel vapors are present. Verify all gas valves are in the OFF position and that enough ventilation is

present to evacuate any unburnt gases.

Warnings related to electric shock

!

WARNING Electricity can seriously injure or kill. Disconnect the power cord for the electrical outlet

or lock out the service disconnect before servicing this equipment. Always ensure an earth ground is correctly

connected to the equipment. When troubleshooting live electrical circuits, use care and best practices to ensure

an electrical pathway is not completed through the body.

Warnings related to hot surfaces

WARNING Seriously injuries may occur from contact to hot surfaces. Allow adequate cooling time

of the appliance prior to service or maintenance. In situations where handling of the appliance or its parts is

unavoidable, use thermal protective gloves to protect the hands, wear long shirts and pants to protect arms and

legs. Do not attempt to “test” the temperature of surfaces by touch.

General Cautions

Cautions indicate conditions or practices that could damage the equipment or other correctly.

!

CAUTION To prevent possible damage, do not use sharp or hard objects on interface screen, use

only ngertips.

!

CAUTION Mobile RF communications equipment and high frequency LED lighting may aect the

performance of this equipment as dictated by FCC regulations.

!

CAUTION The power cord must be disconnected from the AC power before cleaning, maintaining,

servicing, or transporting.

!

CAUTION The gas supply line must be disconnected from the oven before cleaning, maintaining,

servicing, or transporting.

!

CAUTION There are NO parts of the oven that are designed to withstand impacts. Damage will re-

sult.

EDGE Original Installation, Operation and Service Manual v

PREFACE

PREFACE

Electrostatic discharge (ESD)

!

CAUTION Electrostatic discharge (ESD) can damage or destroy electronic components. Handle stat-

ic-sensitive components using safe practices.

!

CAUTION Assume that all electrical and electronic components of the appliance are static sensitive.

Electrostatic discharge is a sudden current owing from a charged object to another object or to ground. Elec-

trostatic charges can accumulate on common items such as foam drinking cups, cellophane tape, synthetic

clothing, untreated foam packaging material, and untreated plastic bags and work folders, to name only a few.

Electronic components and assemblies, if not correctly protected against ESD, can be permanently damaged or

destroyed when near or in contact with electrostatic charged objects. When you handle components or assem-

blies that are not in protective bags and you are not sure whether they are static-sensitive, assume that they are

static-sensitive and handle them accordingly.

• Always use techniques to protect personnel and equipment from electrostatic discharge. ESD Wrist or Heel

strap (recommended for appliance and personal safety)

• Remove static-sensitive components and assemblies from their static-shielding bags only when you are sta-

tionary and prepared to immediately install the component.

• Remove / install static-sensitive components and assemblies only with appliance power disconnected.

• Insert and seal static-sensitive components and assemblies into their original static-shielding bags.

• Always test your ESD strap before beginning any disassembly or assembly procedures.

EDGE Original Installation, Operation and Service Manual 1

SPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONS

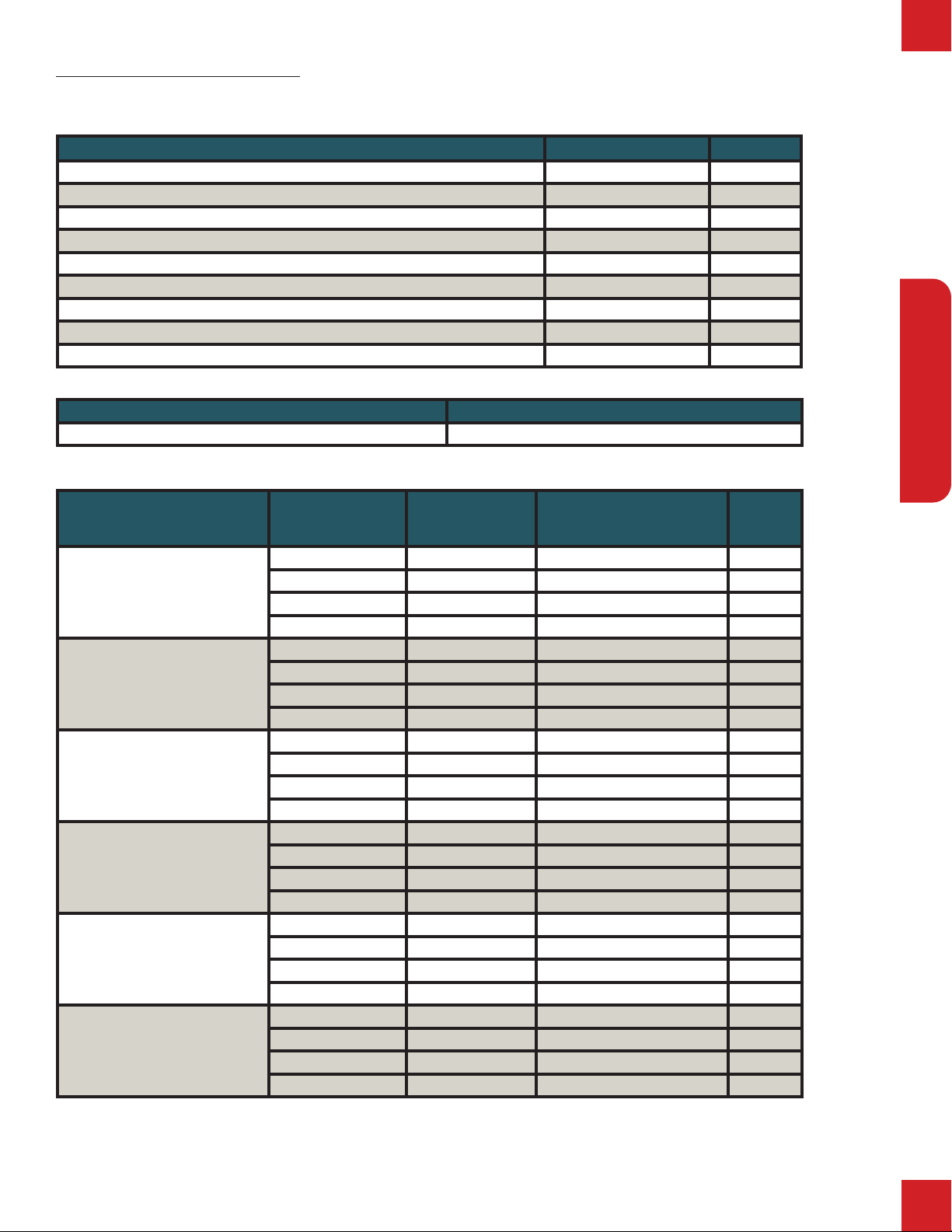

Export, Gas Conguration Data

Desnaon Country (Export)Supply Pressure (mbar) Category

AT-CH-CY-CZ-DK-EE-ES-FI-FR-GB-GR-HR-HU-IE-IT-LT-LU-LV-NO-PT-RO-SE-SI-SK-TR 20 2H

DE-PL-RO 20 2E

RO-NL 25 2L

BE-FR 20; 25 2E+

BE-CY-ES-FR-GB-GR-HU-IE-PT 30; 28-30 3B

DE-FI-NL-RO 30 3P

BE-CH-CZ-ES-FR-GB-GR-IE-IT-LT-NL-PL-PT-SI-SK 37 3P

AT-BE-CH-CY-CZ-DE-DK-EE-FI-GB-GR-HU-IT-LT-NL-NO-PL-RO-SE-SI-SK-TR 30 3B/P

BE-CH-CY-CZ-ES-FR-GB-GR-IE-IT-LT-PT-SI-SK-TR 28; 30/37 3+

Model “B”: BASO BGF378 valve

Electrical Supply Breaker / Circuit Required (per oven)

230VAC / 50Hz / 1Ph / 700W 16A

Model

Heang Category Orice

Manifold

High-Fire / Low-Fire

Shutter

(Air)

Opening

EDGE-1830

Gross Net kW/Hr

19.05 17.0

I2H / I2E 0.1405 in. 11.2 mbar #2

I2L / I2E+ 0.089 in. 17.4 mbar #2

I3P / I3+ 0.089 in. 24.9 mbar #3

I3B / I3B/P 0.089 in. 18.7 mbar #3

EDGE-2440

Gross Net kW/Hr

23.45 21.5

I2H / I2E 0.154 in. 11.2 mbar #2

I2L / I2E+ 0.1015 in. 17.4 mbar #2

I3P / I3+ 0.1015 in. 24.9 mbar #3

I3B / I3B/P 0.1015 in. 18.7 mbar #3

EDGE-3240

Gross Net kW/Hr

36.63 33.6

I2H / I2E 0.191 in. 11.2 mbar #2

I2L / I2E+ 0.120 in. 17.4 mbar #2

I3P / I3+ 0.120 in. 24.9 mbar #3

I3B / I3B/P 0.120 in. 18.7 mbar #3

EDGE-2460

EDGE-3260

Gross Net kW/Hr

43.96 40.3

I2H / I2E 0.209 in. 11.2 mbar #2

I2L / I2E+ 0.136 in. 17.4 mbar #2

I3P / I3+ 0.136 in. 24.9 mbar #3

I3B / I3B/P 0.136 in. 18.7 mbar #3

EDGE-3860

Gross Net kW/Hr

43.96 40.3

I2H / I2E 0.209 in. 11.2 mbar #2

I2L / I2E+ 0.136 in. 17.4 mbar #2

I3P / I3+ 0.136 in. 24.9 mbar #3

I3B / I3B/P 0.136 in. 18.7 mbar #3

EDGE-4460

EDGE-3270

EDGE-3870

Gross Net kW/Hr

54.22 48.4

I2H / I2E 0.2323 in. 11.2 mbar #3

I2L / I2E+ 0.154 in. 17.4 mbar #3

I3B / I3B/P 0.154 in. 24.9 mbar #3

I3B / I3B/P 0.154 in. 18.7 mbar #3

EDGE Original Installation, Operation and Service Manual

2

SPECIFICATIONS

SPECIFICATIONS

North America, Gas Conguration Data

Model

Heang Gas Type Supply Pressure Orice

Manifold

High-Fire / Low-Fire

Shuer (Air)

Opening

EDGE-1830

65k Btu/Hr

Natural 6”w.c. ~ 8”w.c. 0.1405 in. 4.5 inW.C. 1

Natural 6”w.c. ~ 8”w.c. 0.1405 in. 4.5 inW.C. #2

Propane 11”w.c. ~ 13”w.c. 0.0935 in. 10 inW.C. 1

Propane 11”w.c. ~ 13”w.c. 0.0935 in. 10 inW.C. #3

EDGE-2440

80k Btu/Hr

Natural 6”w.c. ~ 8”w.c. 0.154 in. 4.5 inW.C. 1.5

Natural 6”w.c. ~ 8”w.c. 0.154 in. 4.5 inW.C. #2

Propane 11”w.c. ~ 13”w.c. 0.1015 in. 10 inW.C. 1

Propane 11”w.c. ~ 13”w.c. 0.1015 in. 10 inW.C. #3

EDGE-3240

125k Btu/Hr

Natural 6”w.c. ~ 8”w.c. 0.191 in. 4.5 inW.C. 1.5

Natural 6”w.c. ~ 8”w.c. 0.191 in. 4.5 inW.C. #2

Propane 11”w.c. ~ 13”w.c. 0.120 in. 10 inW.C. 1

Propane 11”w.c. ~ 13”w.c. 0.120 in. 10 inW.C. #3

EDGE-3860

150k Btu/Hr

Natural 6”w.c. ~ 8”w.c. 0.209 in. 4.5 inW.C. 1.5

Natural 6”w.c. ~ 8”w.c. 0.209 in. 4.5 inW.C. #2

Propane 11”w.c. ~ 13”w.c. 0.136 in. 10 inW.C. 1

Propane 11”w.c. ~ 13”w.c. 0.136 in. 10 inW.C. #3

EDGE-2460

EDGE-3260

150k Btu/Hr

Natural 6”w.c. ~ 8”w.c. 0.209 in. 4.5 inW.C. 1.5

Natural 6”w.c. ~ 8”w.c. 0.209 in. 4.5 inW.C. #2

Propane 11”w.c. ~ 13”w.c. 0.136 in. 10 inW.C. 1

Propane 11”w.c. ~ 13”w.c. 0.136 in. 10 inW.C. #3

EDGE-4460

EDGE-3270

EDGE-3870

185k Btu/Hr

Natural 6”w.c. ~ 8”w.c. 0.2323 in. 4.5 inW.C. 1.5

Natural 6”w.c. ~ 8”w.c. 0.2323 in. 4.5 inW.C. #2

Propane 11”w.c. ~ 13”w.c. 0.154 in. 10 inW.C. 2

Propane 11”w.c. ~ 13”w.c. 0.154 in. 10 inW.C. #3

Electrical Supply Breaker / Circuit Required (per oven)

120VAC / 60Hz / 1Ph / 5.5A ~ 9.5A 20A (If GFCI protecon is required, use only panel breakers)

EDGE Original Installation, Operation and Service Manual 3

SPECIFICATIONS

SPECIFICATIONS

Dimensions

When installed as: Measurements are in inch unless otherwise noted

Detail Sin-

gle

Dou-

ble Triple EDGE

1830

EDGE

2440

EDGE

3240

EDGE

2460

EDGE

3260

EDGE

3860

EDGE

4460

EDGE

3270

EDGE

3870

A Chamber (W) 19.8 25.5 33.5 25.5 33.5 39.5 45.5 33.5 39.5

*Chamber (L) 30.3 40.0 58.5 68.5

*Chamber w/plugs (L) 31.3 41.0 59.5 69.5

B Window (D) 3.9

C Conveyor (L) 65.5 75.3 93.8 93.8 103.8

D Oven (D) 44.1 50.6 58.6 50.6 58.6 64.1 70.1 58.6 64.1

G Window (L) 20.0 35.0

H Cont. Cab. (L) 17.8

J Chamber (H) 3.5

K Motor (D) 5.3 3.8

Weight per packaged

oven

342 lbs ~

538 lbs

614 lbs ~

810 lbs

718 lbs ~

914 lbs

776 lbs ~

972 lbs

869 lbs ~

1000 lbs

899 lbs ~

1097 lbs

948 lbs ~

1170 lbs

978 lbs ~

1198 lbs

1070 lbs ~

1290 lbs

E Floor-Oven (H) 44.0 64.1 68.5

F Floor-Conveyor (H) t56.3

m52.0 36.0

b31.5 15.5

L Leg/Caster (H) 21.5 5.8

EDGE Original Installation, Operation and Service Manual

4

INSTALLATION

INSTALLATION

OVEN COMPONENTS

1. Control Can Assembly: Houses the operat-

ing controls for the oven and the natural gas

control devices and burner.

2. End Plug, Upper: Closes o the top half of the

bake chamber, above the conveyor belt.

3. End Plug, Lower: Closes o the bottom half

of the bake chamber, below the conveyor belt.

4. Conveyor Belt: Runs horizontally through the

bake chamber; carrying the product through

the oven.

5. Oven Base: Supports and insulates the bot-

tom of the oven.

6. Oven Lid: Mounts to the top of the oven, n-

ishes o the oven stack and covers the oven

insulation.

7. Half-Bake Window: Opens to allow the prod-

uct to be placed halfway through oven (half

bake time).

8. Crumb Pan: Located under both the entrance

and exit of the conveyor belt, catches debris

that falls through the conveyor belt.

9. Back Assembly: Closes o the back of the

bake chamber.

10. Plenum Assembly: Houses the hot air blower motor and fan, and thermocouples to monitor hot air

temperature.

11. Oven Bottom: Mounts to the top of the oven base, seals o the stack and covers the oven insula-

tion.

12. Oven Legs: Used with single- and double-stack congurations to raise / lower oven to convenient

working heights.

13. Oven Casters: Used on all oven congurations to allow moving the oven for installation and ser-

vicing.

14. Restraining Device: Secures the oven base to the wall to avoid damage to gas and electrical con-

nections.

EDGE Original Installation, Operation and Service Manual 5

INSTALLATION

INSTALLATION

INSTALLATION INSTRUCTIONS

IMPORTANT REQUIREMENTS

Oven installation must comply with local codes or, if local codes do not exist, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 -OR- Natural Gas Installation Code, CAN/CGA-B149.1, or

the Propane Gas Installation Code, CAN/CSA-B149-2, as applicable.

This appliance must be electrically grounded in accordance with local codes, or if local codes

do not exist, with the National Electrical Code, ANSI/NFPA 70. OR with the Canadian Electrical

Code, CSA C22.2.

When this appliance is installed with casters, it must be installed with the casters supplied, a

connector complying with ANSI Z21.69 / CAN/CGA-6.16, a quick-disconnect device complying

with ANSI Z21.41, and a mechanism to limit movement of the appliance without straining the

connector or its associated piping system. This quick-disconnect device must not exceed 1.5

meters in length.

The gas supply tubing or hose shall comply with the national requirements in force and shall be

periodically examined and replaced as necessary.

This appliance and its individual manual shuto valves must be disconnected from the gas

supply piping system during any pressure testing of gas supply piping at pressures exceeding

1/2 psi (3.5 kPa).

The installer of this oven must contact local building and re ocials concerning inspections

and installation requirements of this oven and its ventilation system.

Unless otherwise stated, parts protected by the manufacturer or the authorized agent shall not

be adjusted by the installer.

In the event this appliance is to be converted to a gas type other than which it was originally ad-

justed for, contact manufacturer or authorized agent for the appropriate conversion kit (correct

orice & valve, correct appliance decal, and instructions)

Foreword

Gas must be present at the installation site at the time of the planned installation. If this is not possi-

ble, arrangements must be made with the installer or a comparable service provider to complete the

requirements of the Installation Checklist and First Firing inspection. This may incur additional cost to

you.

The utility connections to the oven MUST match the specications detailed for the oven(s) installation.

Ovens which are not installed on casters and ovens which are not plumbed using a exible gas hose

are immobile. These conditions will violate the terms of your warranty.

Extraction systems must meet the minimum requirements specied in this manual AND local code. The

oven control system must not be subjected to high heat. If the operating space is uncomfort-

able to work in, the extraction is insufcient for the oven. Heat will deteriorate control and

drive components, resulting in premature failure. Great care has been taken to equip your EDGE oven

with the highest quality of components and thermal protection abilities.

A preventative maintenance guide is provided in this manual. Please utilize it to keep your new oven(s)

operating at the best level.

EDGE Original Installation, Operation and Service Manual

6

INSTALLATION

INSTALLATION

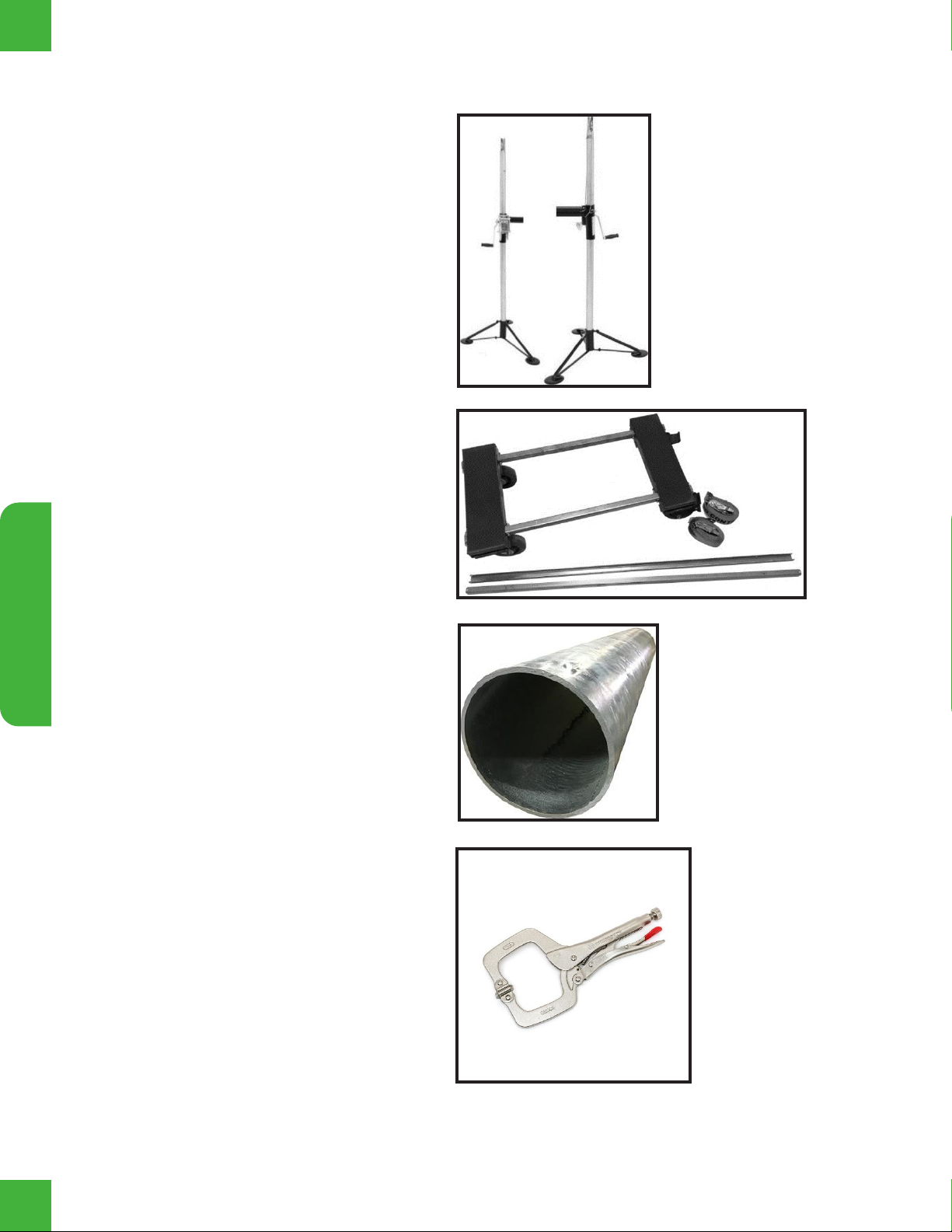

Tools & Equipment Required

LIFTING SYSTEM

(2) EDGE Lifting Jacks, PN: IE-9001,

Genie Lift or similar lifting system

(1) EDGE installation cart, PN: IE-9201,

4-wheel cart, pallet jack, or similar.

(1) 10ft, SCH40 steel pipe, 3” O.D. or

2.5” I.D. (Sourced locally)

(2) Clamps or locking pliers, when not

using EDGE Lifting Jacks IE-9001.

EDGE Original Installation, Operation and Service Manual 7

INSTALLATION

INSTALLATION

HAND TOOLS

(1) #2 Phillips Screwdriver

(1) Ratchet and short extension

(1) 5/16” Socket or nut driver

(1) 7/16” wrench

(1) 9/16” Socket

(1) 3/8” Socket or wrench *oven back

(1) Tin snips for cutting banding

(1) Adjustable wrench (Crescent) *as needed

Stacking Ovens

1. Unpackage BOTTOM oven, retaining all attached documents and DO NOT cut any banding at this

point, the oven must remain attached to the cart or pallet. Inspect the oven for concealed shipping

damage before continuing.

2. Use dolly or cart to move the oven to the installation location, allow enough room for the oven to be

lifted, rotated, and stacked.

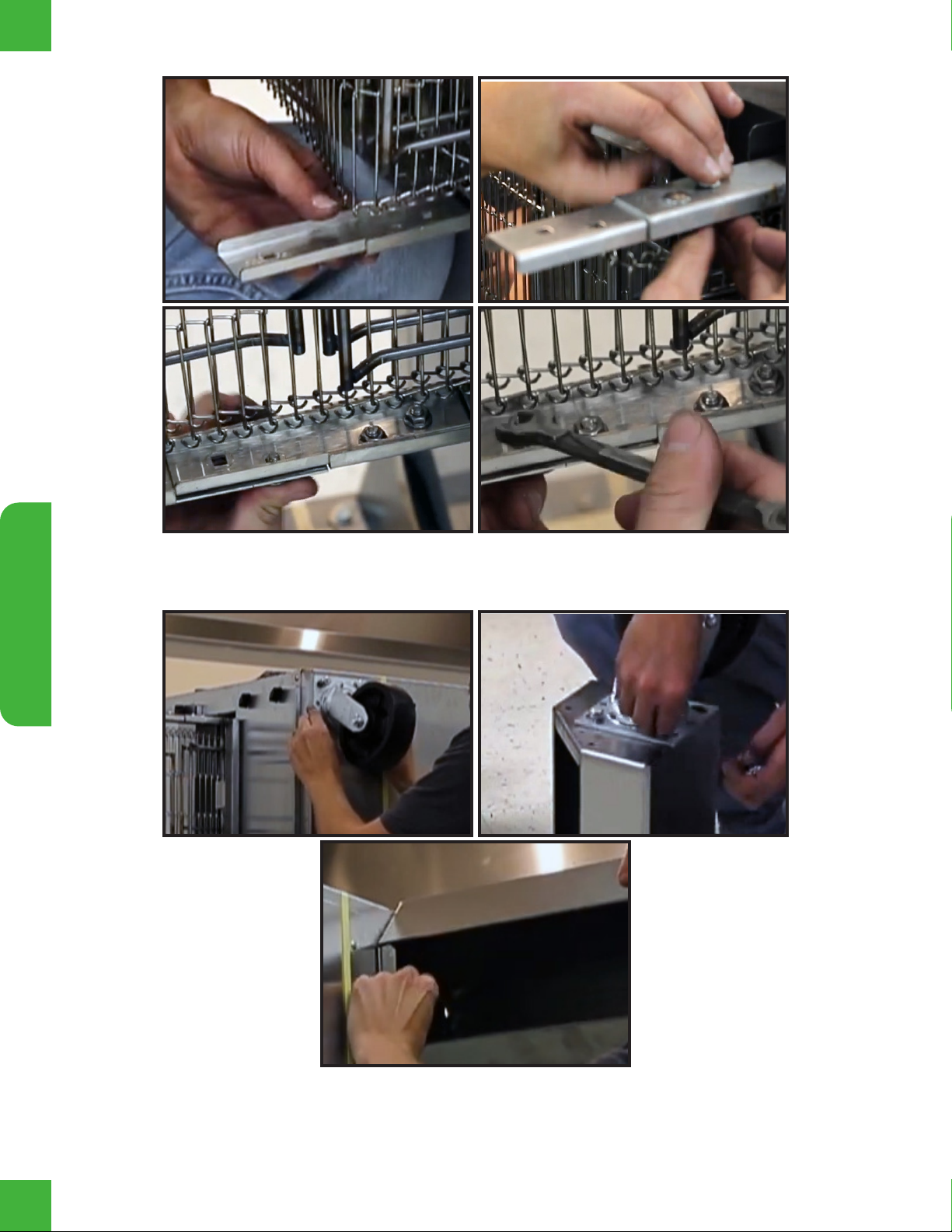

3. Remove the “L” brackets from the belt frame. Retain the hardware, as it is needed for reassembly.

EDGE Original Installation, Operation and Service Manual

8

INSTALLATION

INSTALLATION

4. Install the supplied belt frame hinge using the previously removed hardware.

5. For Triple Stacked ovens, the casters are to be fastened directly to the bottom oven base. Single

and Double Stacked ovens, the casters are to be attached to the supplied legs, which will then be

attached to the bottom oven base.

EDGE Original Installation, Operation and Service Manual 9

INSTALLATION

INSTALLATION

6. Remove the fasteners from the pallet shipping bracket.

7. With the belt now straight and assembled and the oven released from the pallet, pass the 3” O.D.

Schedule 80 pipe through the lifting plates and the oven body.

8. Using your Genie Lifts and at least 2 people, begin lifting the oven, rotating it until you clear the oor

surface. Banding straps may be removed once the oven is lowered to the ground.

EDGE Original Installation, Operation and Service Manual

10

INSTALLATION

INSTALLATION

9. Stacking ovens in a Double or Triple Stack requires enough room for the base oven to be moved

clear of your work area. Simply repeat the process for each additional oven, continuing the lift until

each additional oven clears the height of the oven stack.

10. With a helper maintaining control of the suspended oven, remove the 2 fasteners from each of the

pallet shipping brackets. DO NOT DISCARD THE FASTENERS. Once each bracket is removed,

install the fasteners back into the screw holes of the oven they were removed from. There should be

5 fasteners in each side of the oven back.

This manual suits for next models

10

Table of contents