ERC FAILURE CODES

The oven may stop operating but not give an F code on the display immediately.

F codes are stored in nonvolatile eeprom memory until the same fault occurs twice

consecutively. After that, the F code will be displayed. F codes can be recalled by press-

ing together 3, 1 and 0. While F codes are displayed, pressing 8and 6together will

clear them. A fault must exist continuously for 5 minutes before an F code is recorded

(F2 and F8 are 1 minute or sooner). Press Cancel/ Off to exit failure code mode.

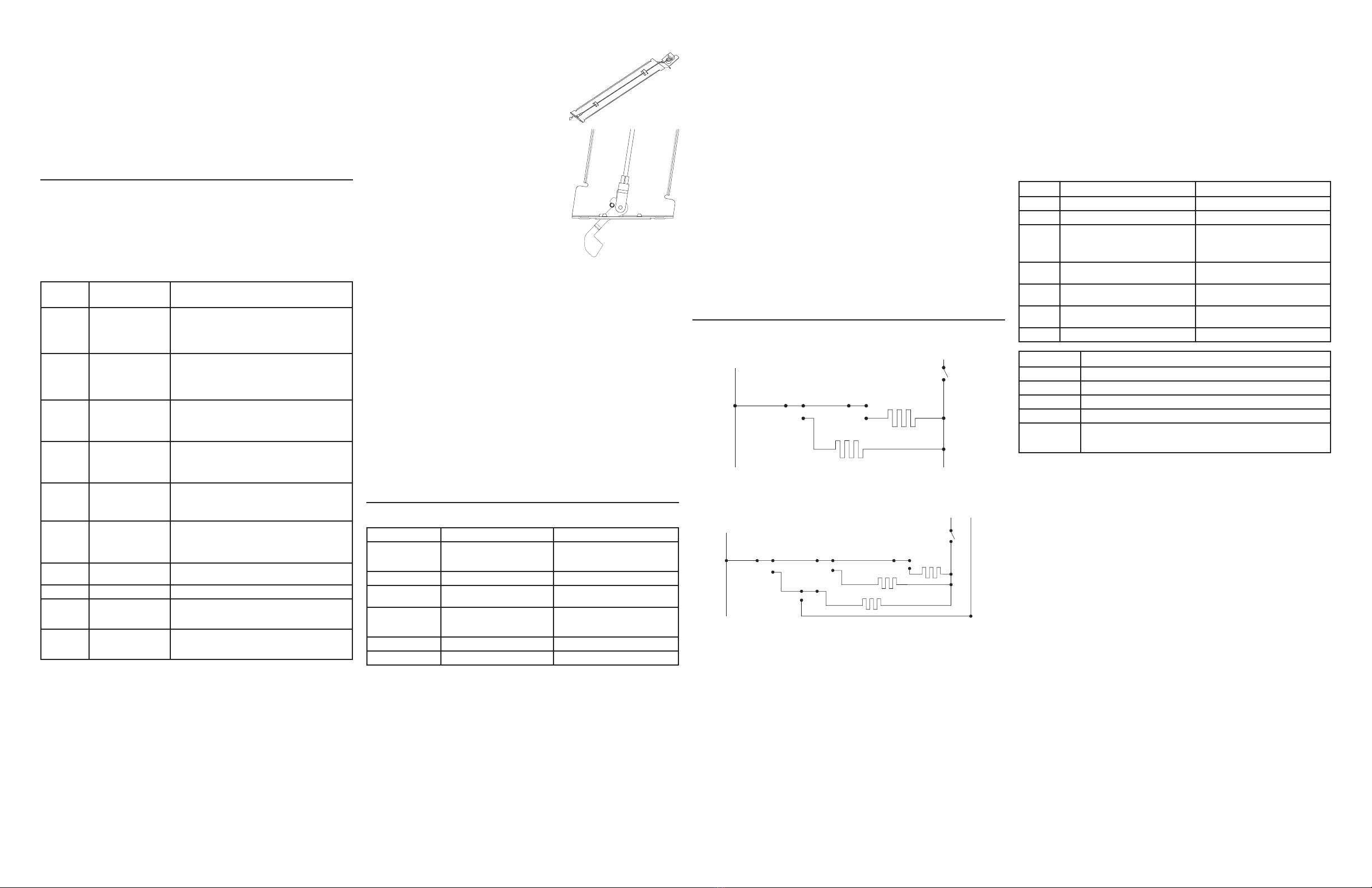

MOTORIZED DOOR LOCK

The motorized door lock assembly is located above the

oven. The assembly consists of

a lock motor cam and switch assembly,

lock hook, mounting plate and heat barrier.

Motorized Door Lock Operation

The lock motor is energized when the control

is set for the Clean and Clean Time is selected. The K12

(upper) or K905 (lower) relay contact will close and com-

plete the circuit that supplies

the voltage to the lock motor.

NOTE: To enable proper operation of the door lock, ensure that the door jamb switch

is closed.

NOTE: Display of Control will flash “LOCK” if the door switch is in the open position

(door open).

• The words “LOCK” will flash on and off in the display while the lock motor is in

motion. When the door is locked, the word “LOCK” remain illuminated in the display.

• CAM – The cam on the motor performs two functions:

1. Positions the lock hook in the door to prevent opening during clean operation.

2. Operates the lock switches which tell the control if the door is unlocked or locked

and ready for clean operation.

NOTE: The door lock switch will be open when the latch is locking. Once locked, the

door switch will be closed.

SPECIAL FUNCTIONS

The control has a section that can be entered to change how the control will work.

To enter this section, press and hold the Bake and Broil pads for 3 (three) seconds

and “UP OFFSEt” appears in the display. Scroll through options using the 3(up) and 8

(down) number pads. Select and confirm options using the 0number pad; cancel with

the 6number pad.

• Sabbath Mode – “SAbbAth” - Enables or disables Sabbath Mode.

• Clock Display – “Cloc diSP” - Turns clock on or off.

• Clock Configuration– “Cloc cFg” - Configures clock to 12- or 24-hour time.

• Auto Recipe – “Auto rEciPE” - Turns auto convection conversion on or off.

• Degree Unit – “dEg Unit” - Configures temperature to Celsius or Fahrenheit.

• 12-hour Shutoff – “12H ShutoFF” - Enables or disables 12-hour shutoff.

• End Tone – “End tonE” - Sets end tone to single or continuous beep.

• Sound – “Sound” - Adjusts volume level to low “Lo”, medium “Reg”, or high “Hi”.

• Lower Oven Offset – “Lo OFFSEt” - Adjusts temperature up or down by up to 35º F

for lower oven.

• Upper Oven Offset – “UP OFFSEt” - Adjusts temperature up or down by up to 35º F

for upper oven.

The controls may be locked out by pressing the Lock Control pad for 3 seconds;

display will show “Loc On”. It may be unlocked by pressing the Lock Control pad for 3

seconds again; display will show “Loc Off”.

• If a button is pressed while the control is locked, “Loc On” will show in the display.

• The Cancel/Off pad will always work, regardless of whether the control is locked.

Failure

Code

Meaning Correction

F2.0, F2.1 Upper Oven temperature

inside oven cavity as

measured by sensor

over 650°F unlatched or

915°F latched.

a) Welded relay contacts

b) Airflow to rear of unit

c) High resistance in oven sensor leads/ connectors

(especially at sensor in rear)

F2.2, F2.3 Lower Oven temperature

inside oven cavity as

measured by sensor

over 650°F unlatched or

915°F latched.

a) Welded relay contacts

b) Airflow to rear of unit c) High resistance in oven sensor

leads/ connectors (especially at sensor in rear)

F3.0 Shorted Upper oven

sensor (under 950 ohms)

a) Disconnect power. Disconnect sensor harness from

control. Measure sensor resistance (white leads) to be -1080

ohms at room temperature with 2 ohms per degree change.

b) Separate sensor from harness to determine fault.

F3.1 Open Upper oven sensor

(over 2900 ohms)

a) Disconnect power. Disconnect sensor harness from

control. Measure sensor resistance (white leads) to be -1080

ohms at room temperature with 2 ohms per degree change.

b) Look for damaged harness terminals if not a bad sensor.

F3.2 Shorted Lower oven

sensor (under 950 ohms)

a) Disconnect power. Disconnect sensor harness from

control. Measure sensor resistance (white leads) to be -1080

ohms at room temperature with 2 ohms per degree change.

b) Separate sensor from harness to determine fault.

F3.3 Open Lower oven sensor

(over 2900 ohms)

a) Disconnect power. Disconnect sensor harness from

control. Measure sensor resistance (white leads) to be -1080

ohms at room temperature with 2 ohms per degree change.

b) Look for damaged harness terminals if not a bad sensor.

F7.0, F7.2,

F7.3

Shorted key matrix. OFF

key or Stuck Key

Replace control.

F8.0, F8.1 EEPROM data shift failure If repeated, replace control.

F9.0, F9.1,

F9.4

Upper door latch

changed state

unexpectedly

Check upper door latch assembly & welded relay

F9.2, F9.3,

F9.5

Lower door latch

changed state

unexpectedly

Check lower door latch assembly & welded relay

SH. 2 of 4 31-17195-2

CONVECTION FAN

Symptom Possibility Correction

No fan operation Open winding as indicated by ohm

check red to grey and blue to grey

(approx. 60 ohms each)

Replace motor.

Fan loud Loose shaft nut Tighten shaft nut. Do not bend blade.

Fan loud Convect cover screws or cavity

screws loose

Tighten. Use larger screw if stripped.

No fan operation Check voltage CCW to N – should

read 120VAC in Convection Bake.

• If no voltages, replace ERC.

• If voltages OK, check harness or

winding resistance.

No fan operation Shaft or blade rubbing on oven liner Loosen screws/readjust position/tighten.

No fan operation Jamb switch NO to C is open Replace jamb switch or check harness.

NOTES:

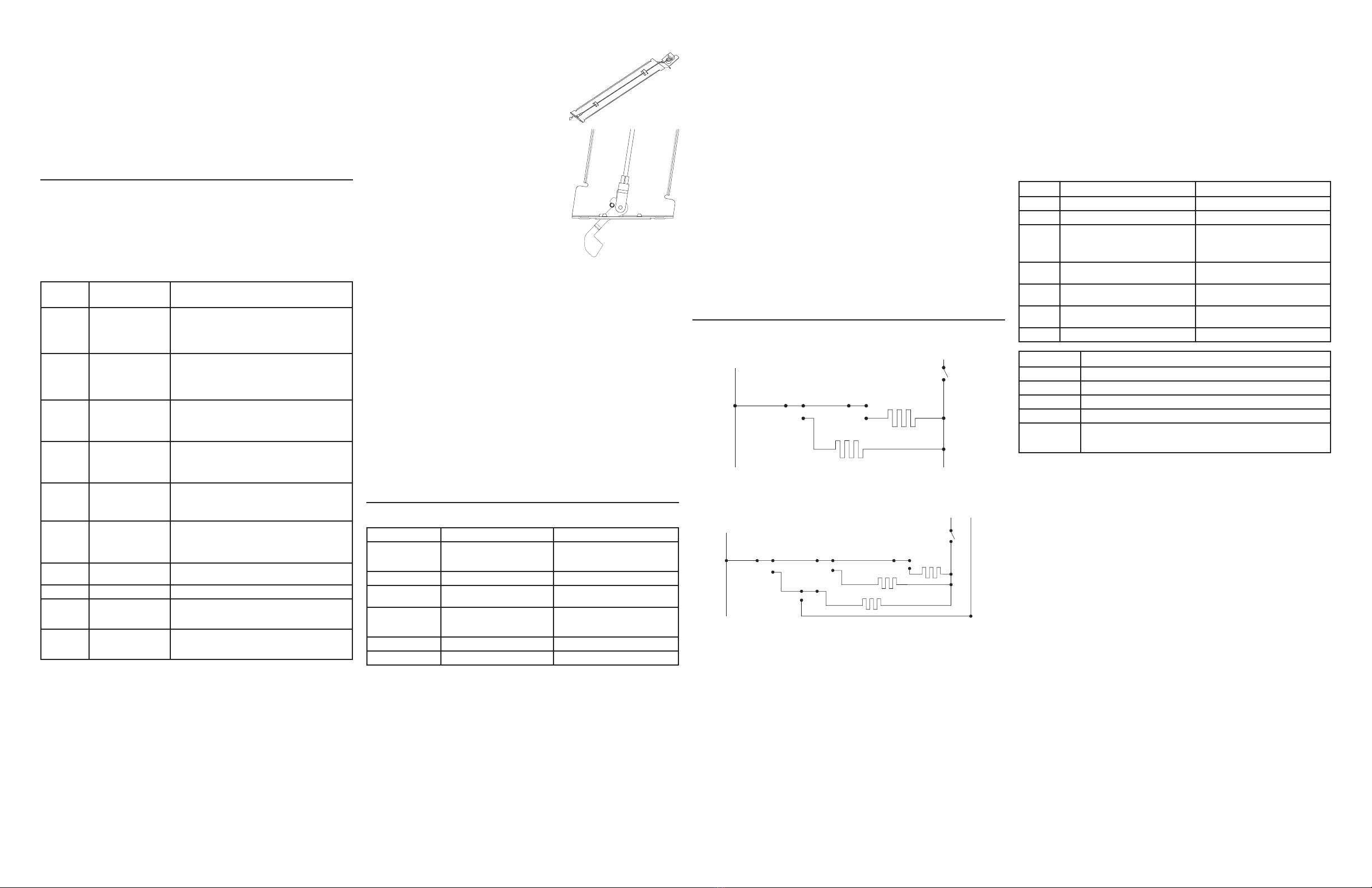

• QUARTER TOP HEAT – There is an additional relay which connects the L1 side of Broil

to neutral instead of L1, therefore applying 120V to the broil element during select

modes or portions of modes. Quarter top heat is on with the bake element during the

following cycles: Bake preheat & steady state, Convection bake preheat and steady

state, Convection roast preheat and steady state and Self Clean stage 2.

• BAKE/TIME BAKE – The bake, broil and convection elements cycle during preheat

with one element on at a time. The convection fan also operates while preheating

and will turn off once the set temperature is reached. Once the bake preheat

temperature is reached, the bake and broil elements cycle for the balance of the

bake operation with one element on at a time.

• CLEAN – The broil element is on only during the first 30 minutes or until the sensor

reaches 750°F. During the balance of the clean cycle, the oven will cycle between

the bake and broil units.

• STEAM CLEAN – Bake unit turns on continuously for 3 minutes at the start of the

cycle. The bake element turn off after 3 minutes and no additional heat is generated

for the balance of the cycle.

• See schematic for wattage values

L1

ACK

K908

BROIL

BROIL

BAKE

K907

QTH

K909

BAKE

K910

CONV

CONV

RED

DLB

K915

L1

ACK

RED

K7

DLB

K3

UPPER BROIL

K18

UPPER BAKE UPPER BAKE

UPPER BROIL

KEY PANEL TEST

1. Touch each pad on the Key Panel.

2. If the Key Panel is functioning properly, the following should occur:

• Bake, Broil, Convection Bake, Convection Roast, Warm Self Clean, and Timer

Modes – An audible tone sounds and the display shows the mode of the operation

selected.

• Cancel/Off, Cook Time and Delay Time – An audible tone sounds and the display

shows the time of day.

• Number pads can only be used after another function has been selected.

• Oven Light - Oven light turns on. Audible tone. Relay click.

Troubleshooting Door Lock

If the door will not lock, check that the door jamb switches work. If lights are good,

then when the doors are both closed the lights should turn off. If lock icon flashes,

indicating the oven is trying to lock the door, check for voltage at the lock motor

(on the rear of the cavity). If 120V is present, turn off power, disconnect harness and

check the lock motor for resistance using ohmmeter. Lock motor should be around

3400Ω. If not, replace lock motor.

Upper Oven

Lower Oven

SERVICE MODE

Power must be cycled within 2 hours before user can enter Service Mode. To enter

Service Mode press and hold the 1 & 5 pads for 2 seconds. Entering into service mode

will turn off all other active modes. When the Service Mode is entered, the word “tESt”

will appear in the time display. If a key is pressed while another load is already on, the

control will turn off the first load and then activate the new load. Note that for the Self

Clean and Self/Steam Clean keys, the control will ignore additional Self and Self/Steam

Clean key presses and not keep track of state for every time the corresponding key is

pressed. The Door Lock will only seek the opposite state when the key is pressed while

in a known state. DLB will always be energized while in Service Mode. All keys will play

the “Touch” tune upon press. Each key press will turn on the associated load. Each

load will turn off when one of the following conditions is met: the same key is pressed

again; another key has been pressed; or 15 seconds has passed after the key has

been released. The loads and associated keys for the control are listed below:

Key Action - Upper Action - Lower

Bake Energize Bake; “Bake” illuminated Energize Bake; “Bake” illuminated

Broil Energize Broil; “Broil” illuminated Energize Broil; “Broil” illuminated

Self Clean Cycle Door Locks positions; “Door” and Lock

icons flash (1/2 second ON 1/2 second OFF)

during transition, ON solid when locked, OFF

when unlocked

Cycle Door Locks positions; “Door” and Lock

icons flash (1/2 second ON 1/2 second OFF)

during transition, ON solid when locked, OFF

when unlocked

Convection

Bake

No Action Energize Convection Bake, Convection Fan

Enable; “Conv” and “Bake” illuminated

Cook Time Read and show Upper oven sensor value

(in degrees F)

Read and show Lower oven sensor value

(in degrees F)

Warm No Action Energize Broil; “Warm” (rightmost Warm

icon) illuminated

Cancel/Off Reset the control Reset the control

Key Action

1

Energize Convection Fan (turn fan)

3Display control Application version

4Display control Parametric version

Oven Light Energize Oven Light relay(s)

Timer On/Off Light up all LED segments. It is normal for some LED segments to turn off after some

time. For example, if the door is unlocked,

the lock LEDs will not stay on the full 10 seconds