MFC International RS8ER User manual

1

© MFC International 2018

Product Manual

Evacuation Raft

2© MFC International 2018

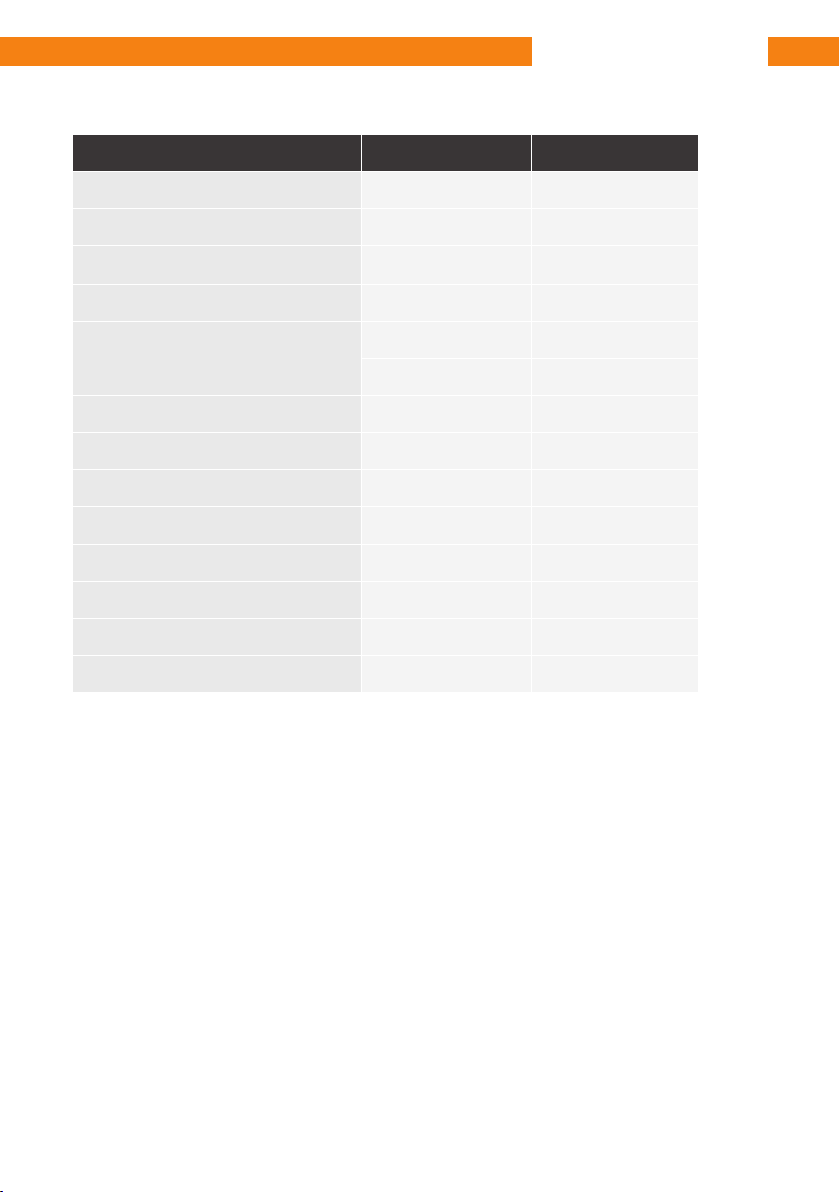

Technical Data / Capacity Parts

Parts List

Materials List

Operational Instructions

Packing

Storage

Maintenance & Test Procedures

Repairs

3

4

5

6

8

8

9

10

WARNING: Carefully read this manual before operating

NOTICE: The manufacturer takes no responsibility for the

consequences of actions not complying with the instructions

given in this manual.

Index

3

© MFC International 2018

Note: all dimensions are accurate to ± 3% and all weights are accurate to ± 5%

RS8ER RS10ER

No. of persons 8 10

Length (cm) 350 400

Width (cm) 190 190

Height (cm) 56 56

Tube Diameter (cm) Front

Rear

23 23

35 35

Floor Thickness (cm) 12 12

Working Pressure 0.2 bar 0.2 bar

Number of Chambers 3 inc. oor 3 inc. oor

Capacity (kg) 820 950

Air Requirements (ltr) 1815 2000

Pack size (cm) 88x50x33 140x50x35

Weight (kg) 35 38

Recommended regulator 8 bar 8 bar

Technical Data

4© MFC International 2018

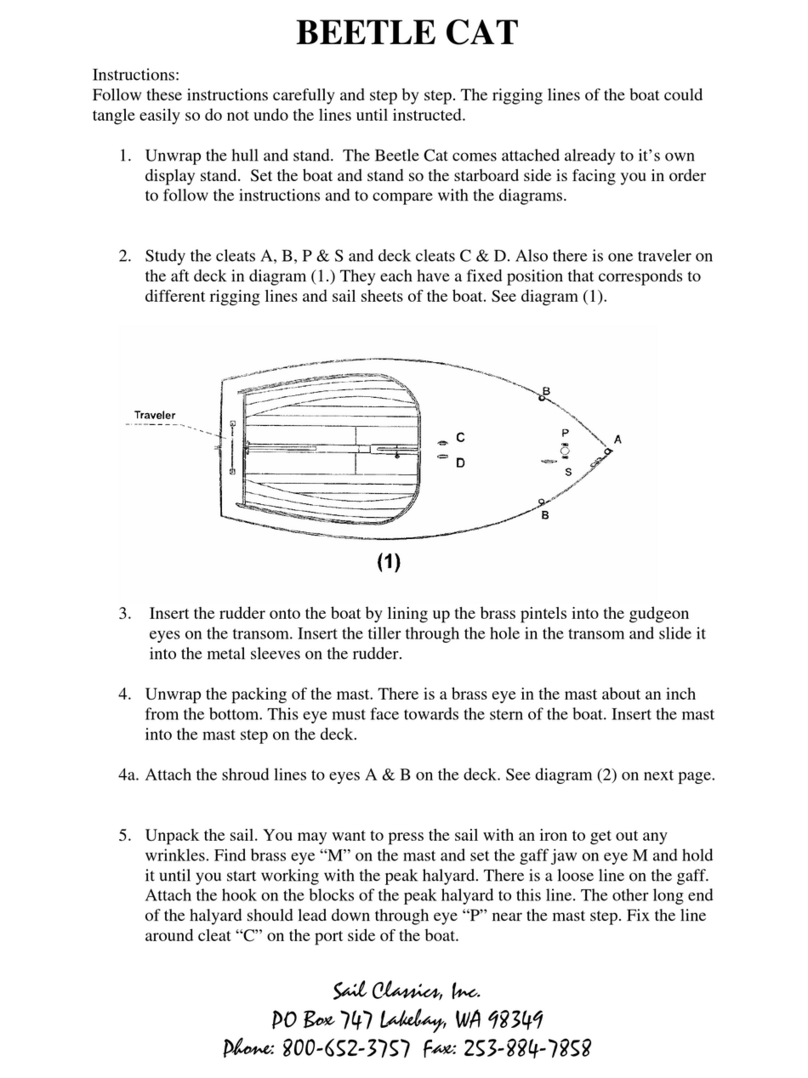

Parts List

91011

16

6

14 713711 4

11 23 15

58

8

2 8

17

14

4

15

5

www.m f csu rvival.com

www.m f csu rvival.com

www.m f csu rvival.com

7

7 7

5

© MFC International 2018

Item Description

1 Buoyancy Tube Hypalon coated polyester - yellow

2Baes Hypalon coated polyester

3Inatable Floor Neoprene- coated drop thread - black

4Inate/Deate Valves Leaeld D7 - Black Acetal

5Relief Valves Leaeld A6 - Black acetal

6Rubstrake Nitrile/PVC - 70mm wide black

7 Carrying Handle Hypalon coated polyester, webbing strap/rubber

handle

8 Lifeline 10mm Diameter 3 strand rope - Black

9Towing Patch Hypalon coated polyester, 316 s/s ‘D’ ring

10 ‘D’ Ring Patch Hypalon coated polyester, 316 s/s ‘D’ ring

11 Reective Strips 50mm Reexite

12 Logo Label White vinyl digitally printed

13 Capacity Label White vinyl digitally printed

14 Inate/Deate Label White vinyl digitally printed

15 Relief valve Label White vinyl digitally printed

16 Stowage Pocket hypalon coated polyester

17 Paddle Retainers Hypalon coated polyester, Webbing strap, velcro

18 Paddles (not shown) Alloy shaft, HDPE blade, T handle

19 Valise (not shown) PVC coated polyester - Orange

20 HP Ination Hose 1.0m Reinforced hose c/w C7 valve adaptor

21 Repair Kit 70ml Neoprene adhesive, Hypalon patches x4

Materials List

6© MFC International 2018

1. Ination

1.1 At deployment point, select best possible at debris-free site.

1.2 Unpack the Raft from its valise and unroll.

1.3 Prepare for Ination:-

a) Fix regulator to cylinder and connect delivery hose to regulator.

b) Remove dust cap from inate/deate valve in Inatable oor and

Buoyancy tube. Ensure the central valve diaphragms are closed; i.e. the

internal spindle is raised.(Push and turn to release)

1.4 Connect cylinder to oor, Hold delivery hose tight into ination valve and inate until

relief valve activates. Close cylinder valve. Do not release hose during ination.

1.5 Connect cylinder to inate one half of the buoyancy tube. Hold delivery hose

tight into ination valve and inate until relief valve activates. Close cylinder valve. Do not

release hose during ination. Repeat process to inate remaining half of buoyancy tube.

WARNING: Failure to do this may result in personal injury

1.6 Ensure dust caps are replaced to prevent ingress of dirt and water.

2. Deployment and Use

The following points are operational recommendations established by deploying rescue

equipment at many dierent training and demonstration events. MFC acknowledge

that almost every operational scenario will have dierent hazards and risks, which can only

be properly assessed at, and during, an operational rescue/recovery.

WARNING: During use on water, mud or suspect surfaces, personnel should

wear a ‘lifejacket’ or similar buoyancy aid, and be linked to the evacuation

raft via a safety line. Failure to do this may result in personal injury or death.

2.1 Securing lines- If using the Evacuation Raft on fast owing water use securing lines

to the attached ‘D’ Ring patches on both sides of the bow to manoeuvre and secure the

raft.

CAUTION: The Evacuation Raft must be secured with the bow (raised end) pointing

towards the ow of water to prevent water swamping the craft.

2.2 Towing- The \evacuation Raft may be towed behind a parent craft at a maximum

speed of 5mph. The raft must be towed with a tow line attached to the towing patch on

the bow. The length of the tow line should be adjusted to suit the conditions. The Raft may

also be rigged with a towing bridle for added security.

2.3 Stability - Wherever possible evenly distribute the weight of persons on the

Evacuation Raft (RS8ER: max. 820Kg.) (RS10ER: max. 950Kg.) to avoid instability that

may lead to capsize.

2.4 Boarding – The Evacuation Raft should wherever possible be boarded from the

bow or stern. Rescue personnel should assist less able survivors.

2.5 Lifelines are tted for survivors to hold on to.

Operational Instructions

7

© MFC International 2018

2.6 Survivors should be seated facing each other across the inatable oor holding onto the

lifelines for security. Survivors should initially be seated away from the entry point to

keep the boarding area clear.

WARNING: Survivors should not be seated on the buoyancy tube as they may fall back

into the water and drown.

2.7 Manoeuvring - The Evacuation Raft can be manoeuvred in calm conditions by

two- four persons using paddles. It can also be manoeuvred in shallow water by persons

walking alongside holding the carrying handles.

CAUTION: Avoid contact with sharp or abrasive objects as they may puncture

the fabric causing a loss of buoyancy.

2.8 Carrying handles - The Evacuation Raft should only be carried by the moulded handles

provided (2 each side + bow). Do not use the lifelines.

The Evacuation Raft can in an emergency be used to carry (max). One Debilitated person.

CAUTION: Do not drag the Evacuation Raft, as this may puncture the fabric

causing a loss of buoyancy.

WARNING: The Evacuation Raft is not designed for any type of motorised propulsion.

The tting of any type of motor, or any other modication is not permitted

without prior written approval from MFC International Ltd. Any non-

approved modication will invalidate the warranty and may result in

personal injury or death.

8© MFC International 2018

1. GENERAL

It should be noted that, due to the type of fabrics used in its construction, when the

Evacuation Raft is wet, there may sometimes be visual evidence of minuscule white

bubbles, which form a line of froth at the seams and joints of the unit. This is recognised

within the industry as ‘lateral leakage’, and is simply air that is trapped in the layer of nylon

between the rubber coatings, forcing its way to the nearest available edge of the fabric.

This type of leakage will not aect the performance of any inatable product over the

course of an operational procedure, and can be safely ignored.

However, if there is evidence of large, transparent bubbles, this is clearly evidence of a leak

that must be repaired at the earliest convenience. The following is a recommended regime

for maintenance & test.

2. QUARTERLY

2.1. Check control equipment as per relevant manual.

2.2. Inate Evacuation Raft to working pressure.

2.3. Check audible relief valve operation.

2.4. Whilst ination system is charged, check connections and valves using brush and soapy

water.

2.5. When relief valve has operated, and the unit is at working pressure; it can be left to stand

for a length of time that would be comparable to an operational situation (e.g. 2 to 3

hours.)

2.6. After this time, the Evacuation Raft should still be rm.

2.7. If the Evacuation Raft has become soft, the air-loss should be located by applying a

soapy-water solution.

2.8. Any signicant leaks (See 1 above) should be marked and repaired using the repair kit

provided.

RECOMMENDATIONS

1. Rescue crafts should undergo an annual test carried out by the manufacturer, or people

certied by MFC International. If in doubt contact the service department.

Maintenance & Test Procedures

9

© MFC International 2018

1. On return to base the Evacuation Raft should be unpacked, inated and left to dry.

2. When the Raft is completely dry it should be checked for wear or damage. If none is found

it should be repacked in the valise.

3. If any damage is found it should be repaired immediately in accordance with the Repair

instructions.

4. Where possible the packed Evacuation Raft should be stored on the oor or suitable

shelving, ensuring no damage can be caused by it’s proximity to other items of equipment.

1. After every use, especially on mudats, the Evacuation Raft should be hosed down in its

inated state, to remove as much debris as possible.

2. Allow the Evacuation Raft to become as dry as possible before packing.

3. Lay the Raft on a clean, debris free area.

4. Deate the Evacuation Raft. This is achieved by depressing the central spindle in all the

inate/deate valves, (push and turn to lock open).

5. Roll the Raft from both ends to expel as much air as possible. Close inate/deate valves

and replace dust caps.

CAUTION: To prevent possible damage, do not walk on the deating Raft to expel

the air.

6. Un-roll the Raft to its full length once again. Fold each side of the buoyancy tube /inatable

oor to the centre of the inatable oor. (use carrying valise for guide to pack width.)

7. Roll the Raft from the front, taking care to maintain the width of the roll.

8. Lay the valise on the ground as an ‘open box’ and place Evacuation Raft into the valise.

Close valise and secure straps.

Packing

Storage

10

© MFC International 2018

As a general rule, punctures and other damage will need to be assessed in two

categories: a) that which is repairable at the base, or b) serious damage that will need to

be repaired by MFC International.

a) Repairs that are manageable at the base workshops will be minor punctures

to any area of the Evacuation Raft. These can normally be repaired by the

application of a small repair patch.

b) Repairs that should be carried out by MFC will be the more serious kind,

such as damaged valves, badly torn fabric (either on the side-walls or the at

surfaces) and the replacement of damaged ttings.

Parts List

If in doubt as to the extent of the damage and the level of repairs necessary, please

contact :-

MFC International

Naval Yard

Tonypandy

Rhondda Cynon Ta

CF40 1JS

T. +44 (0) 1443 433 075

F. +44 (0) 1443 420 448

www.mfc-international.com

A Respirex International Limited Group Company

11

© MFC International 2018

MFC International

Naval Yard

Tonypandy

Rhondda Cynon Ta

CF40 1JS

T. +44 (0) 1443 433 075

F. +44 (0) 1443 420 448

www.mfc-international.com

A Respirex International Limited Group Company SA-MA64-02

This manual suits for next models

1

Table of contents

Other MFC International Boat manuals

Popular Boat manuals by other brands

Heritage Kayaks

Heritage Kayaks Kayak owner's manual

Sea Eagle Boats

Sea Eagle Boats FoldCat 375FC Instruction & owner's manual

AREBOS

AREBOS AR-HE-SUP320SB manual

Trophy

Trophy 1703 Owner's manual supplement

Sprint Boats

Sprint Boats 1997 Manta Ray owner's manual

Tayana

Tayana VANCOUVER 42 Operation and maintenance manual

Sail Classics

Sail Classics BEETLE CAT instructions

Sea Ray

Sea Ray 480 Sedan Bridge Owner's manual supplement

Alpacka Raft

Alpacka Raft Alpacka Series owner's manual

Cumberland

Cumberland Treasure VI Operation manual

Highfield

Highfield Ocean Master 350 owner's manual

Boston Whaler

Boston Whaler 320 Vantage owner's manual