Mier DA-500 User manual

THE ORIGINAL VEHICLE DETECTION SYSTEM!

DA-500 INSTALLATION MANUAL

THE BASICS

1A sensor(s) detect(s) a vehicle entering a monitored

area

2 A control panel receives a signal from the sensor

and triggers an alert-whistle inside the control panel

3 Add a remote chime in the front room to alert those

on the rst oor

4 Add another chime in the basement to alert those

downstairs

5 Add a third chime in an upstairs bedroom to alert

those upstairs

6 Add a wireless or hard-wired timer controlled light

kit to turn on outdoor lights, indoor overhead lights,

and/or lamps to warn strangers or welcome friends

7 Attach video surveillance to record activity and

display the driveway on a monitor inside

8 Add a portable chime to alert those in the backyard

pool, garden or deck

9 Activate signs, gates or other equipment

MORE OPTIONS

TABLE OF CONTENTS

Page Content

Cover Page

1 Table of contents

2 Introduction to the DA-500 and Accessories

3-4 Installation Guide

5 Operation Instructions

6-7 Schematics for using the DA-500 to control other alarms and chimes

7 DA-500ContentsandSpecications

8 DA-655 Installation

9 Technical Support and Warranty Information

10 Troubleshooting Guide

1

Model DA-500 General Information

Drive-Alerts are perfect for use in residential driveways, on farms, at drive-up

windows, in remote locations, and to protect valuable assets and equipment

such as tractors or constuction vehicles. The Drive-Alert will detect a vehicle

approaching, or whenever a vehicle or metal equipment is moved.

The Drive-Alert detects any metal which contains iron. It will not detect copper

or aluminum.

The Drive-Alert’s method of operation is to sense the change in the magnetic

eld around it. This eld is always present, and is disrupted when a metal

object moves through it.

The key element in the Drive-Alert installation is to locate the sensor/probe in

the area where you wish to detect this change. The usual installation is near

the entrance of a driveway, but located far enough away from roads or streets

so as not to detect trafc. Moving ferrous (iron) metal trips the sensor. Larger

metal objects are detected easier than smaller. Faster moving metal objects

are detected easier than slower. Metal moving nearer the probe is detected

easier than metal moving farther away. These are the three factors which

determine the system’s range of detection. Therefore, trucks traveling 65 mph

can be detected up to 50 feet; cars moving 4 mph up to 8 feet; and a walking

person with steel toe shoes up to 1 foot.

The Control Panel houses the electronics which allows the Drive-Alert to

function. It also contains an annunciator, and the terminal strip permits the

attachment of the probe as well as accessories or other devices.

Longer lengths of cable are available. Simply order a DA-500CP (control pan-

el only) and a DA-051-___ where you ll in the blanks for the amount of cable

needed in 50’ increments. Ex: DA-051-250 is a sensor with 250’ of cable.

A Hard-Wired DA-655 Chime with Volume is the most popular accessory for

the DA-500, and is HIGHLY recommended for all business, drive-up win-

dow, and high-trafc areas where a DA-500 is used. The chime is far more

pleasant than the standard whistle inside the DA-500 Control Panel, and the

volume control makes it far more versatile.

A DA-505 Hard-Wired Timer Control unit is available. It is housed in a sepa-

rate box and is attached by wires to the terminal strip on the Master Control

Panel. This Timer Control turns on lights, usually outside lights, for an adjust-

able period when a vehicle is detected.

The Hard-Wired DA-052V allows you to add additional alert whistles to the

DA-500.

Wireless chimes are available with the DA-066 Chime Transmitter. This

transmitter easily hooks up to the contacts on a DA-500 and triggers DA-068

Plug-in chimes and DA-070 Battery-powered Portable Chimes.

Wireless light control is available with the DA-606LK with timer control.

The DA-500 includes a

Control Panel, Sensor, and 100 feet

of direct burial cable

DA-505 Timer Control

DA-655 Chime with Volume

DA-052V Remote Whistle

DA-066 Wireless Transmitter for

wireless chimes pictured with a

Wireless DA-068 Chime and a

Wireless DA-070 Chime

DA-606LK Wireless Light Kit

DA-051-___ Probe with longer

lengths of cable

2

INSTALLATION page 1 of 2

The Control Panel is generally located in a closet, utility room, or garage. If the only noisemaker used (remotes are

available) is the one contained within the control panel, the panel must be located where users can easily hear the

“whistle.” The control panel is not suitable for outdoor installation.Also, 120 volt AC power must be available. The ease

of routing the three-wire cable from the sensing probe should be considered when deciding the location of the panel. The

control panel is usually attached to the wall with screws.

Improper installation is the No. 1 reason for system malfunction. Please use caution when installing the sensing probe to

assure a properly operating Drive-Alert.

The probe’s sensor is a coil of wire wrapped around an iron rod. Its resistance is 700-1100 ohms. The red and black wires

connect to the coil. It is encapsulated in epoxy to protect it from physical damage and moisture.

DO NOT CUT OR NICK THE CABLE JACKET!

If moisture enters, false alarms will be the result!

Mier HIGHLY recommends burying the cable within 1/2-inch PVC pipe for added protection to the cable.

The cable is made with an extra thick outer cover. There is a foil wrapper surrounding the red and black wires. There is

a silver (bare) wire in the foil. False alarms will occur if moisture gets into the foil wrapper. Nicks in the outer cover and

improper splices allow moisture to enter the cable. As moisture enters the cable, the resistance decreases. Resistance

between the red or black wire to the shield wire must be innite. (Use meter with ability to read resistance above 20 million

megaohms).

The ideal installation is without any splices. The use of cable other than that which is designed for the Drive-Alert is

undesirable. Improper splices and unsuitable cable are major causes of false alarms. If splicing is unavoidable, splice the

cable using a 3M SLiC-TM SPLICE KIT, or equivalent. The splice kit is available from Mier Products.

The sensing probe does not know if it is in or out of the ground, but it must remain absolutely motionless. Most probes are

buried 6 inches deep and parallel to the driveway. Be sure to protect it from physical damage.

The cable is made for direct burial in the ground. Do whatever is necessary to protect it from physical damage to the outer

cover, such as using 1/2-inch PVC pipe.

The probe responds to changes in the magnetic eld around it. The signal produced by the coil is a few micro volts for a

fraction of a second. The probe and cable must not be within 20 feet of electric wires because they have changing mag-

netic elds of their own. Never bury the sensor in the same trench with other electrical wires, including telephone wires

and wires for lights, bells, etc.

You may wish to place a sensing probe atop the ground in the general area of where you wish to bury it, and connect the

cable to the control panel. This will allow you to TEST the system in application BEFORE nal installation. It would be

acceptable to leave the sensing probe and cable above the ground for a couple of days, but make certain it is not

damaged during this period. This method should not be used permanently. See OPERATIONS INSTRUCTIONS for

adjustments which may be necessary.

The burial of the probe is ideal in the center of the area being monitored, but often is not practical. If a new driveway is

being put in, the sensing probe could be buried a minimum of 12-24 inches deep. In case you wish to place the sensor in

the center of the drive, the cable and sensing probe could be placed in a 1 1/2 inch piece of PVC to provide protection.

The cable should also be protected whenever vehicles move over it.

The usual installation of the sensing probe is parallel to an already existing driveway. In this case, the probe can be buried

6 inches deep, and the cable simply placed below the grass line. However, if vehicles are going to travel directly over the

probe and cable, they should be buried deeper.

The sensing probe may be placed up to 5,000 feet from the Control Panel. Up to 4 sensing probes can be attached to one

panel, but each additional probe reduces every probe’s ability to detect. The Drive-Alert will not know which sensing probe

detects a vehicle.

3

INSTALLATION page 2 of 2

When more than 1 probe is used, connect the red and black wires in series. Connect

the silver wires in parallel. The red wire from one cable is soldered to a black wire from

another cable. The remaining red wire & black wire are attached to the Drive-Alert

terminals. All silver wires are attached to the Drive-Alert.

Keep the probe, cable, and control panel at least 8 feet away from heavy power lines,

power panels, motors, arcing or sparking machinery, and radio transmitters. In some

cases, moving the panel and/or cable a few feet can solve interference problems.

FIGURE 1 illustrates the contacts on the bottom of the DA-500 Control Panel, with the

sensor correctly attached.

FIGURE 1

The sensing probe is a 1” x 12”

cylinder containing a sealed

sensor. Be cautious when

handling the sensor and

particularly careful to not nick

the cable attached to it.

Bury the probe at least 6” deep.

A typical installation is the probe

6 inches deep parallel to drive,

which will allow the probe to

“sense” 12’ across the driveway.

The ideal installation allows you

to extend your detection

range by installing the sensor

under the center of drive.

12’

12’

12’

RED WIRE

BLACK

SENSOR

SHEILD WIRE

4

Other manuals for DA-500

1

Table of contents

Popular Car Alarm manuals by other brands

Ultra Start

Ultra Start 650 Series owner's manual

Audiovox

Audiovox Prestige Platinum+ APS-511C owner's manual

Sparkrite

Sparkrite SRA8 Guide

Federal Signal Corporation

Federal Signal Corporation Pathfinder Siren Series Installation and maintenance manual

Falcon

Falcon Predator XL3 Installer manual

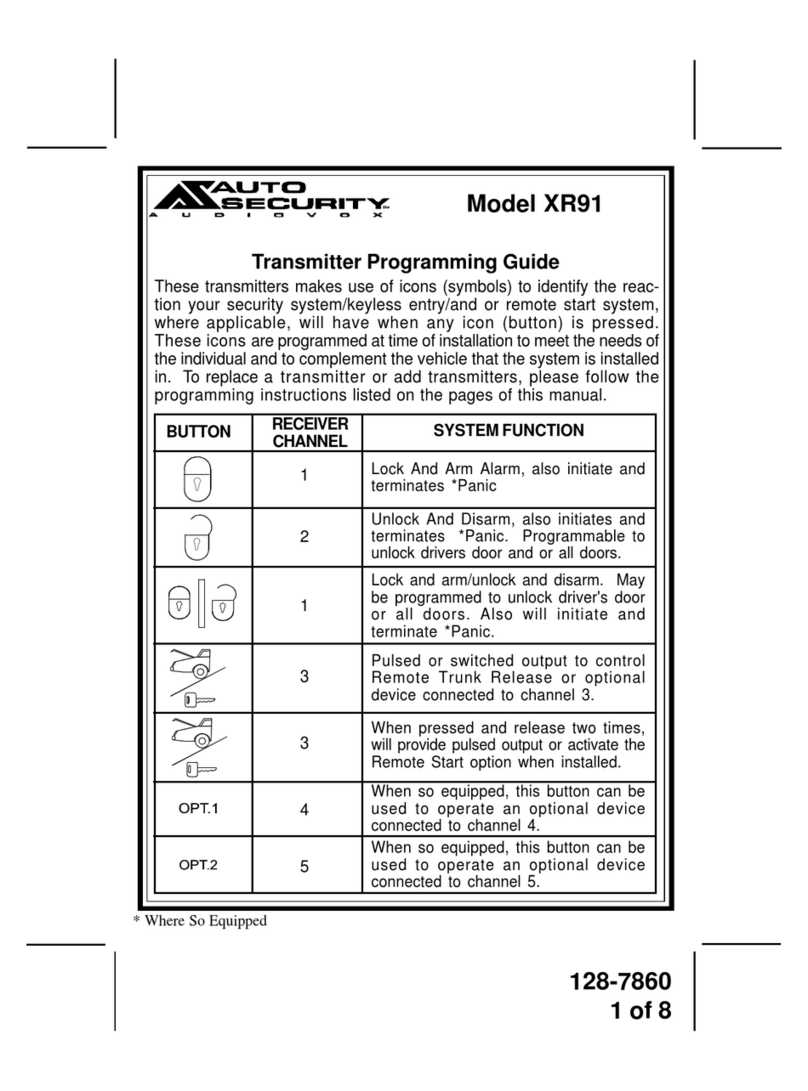

Audiovox

Audiovox Auto Security XR91 Programming guide