MIHM-VOGT Tabeo-2/M/Metal-120 Installation instructions

Original Operating Manual

Tabeo Sintering Oven Metal

English

Version 4.0en 10/2018

Friedrich-List-Straße 8

D-76297 Stutensee-Blankenloch

Tel.: +49 (0) 7244 70871-0

Fax: +49 (0) 7244 70871-20

E-Mail: [email protected]

Page 2 Operating Manual Tabeo Sintering Oven Metal Version 4.0en 10/2018

Contents

General information ..................................................................4

Limitation of liability .....................................................................4

Responsibilities of the operator ..................................................................4

Documentation ............................................................................5

Content and structure................................................................................. 5

Labelling scheme for integrated text boxes and references.......................5

Formatting and symbols ..............................................................6

Service address...........................................................................6

Safety..........................................................................................7

Requirements for personnel ........................................................7

Transport, packaging and storage...........................................9

Transport ....................................................................................9

Packaging....................................................................................10

Storage ....................................................................................10

Technical description................................................................11

Function ....................................................................................11

Conformity ...................................................................................12

Certication..................................................................................13

CE Mark ....................................................................................................13

EAC Certication ........................................................................................13

RoHS Conformity .......................................................................................13

Intended use................................................................................14

Potential misuse ..........................................................................14

Sintering with argon.....................................................................14

Technical data............................................................................15

Installation..................................................................................16

Installation location......................................................................16

Installation conditions .................................................................................16

Electrical connection....................................................................17

Local installation.........................................................................................17

Rating plate ................................................................................................18

Connecting the argon supply.......................................................19

Operation....................................................................................20

Operating elements and displays ................................................20

Operating elements ....................................................................................20

Displays ....................................................................................................21

Switching on the sintering oven...................................................21

Initial commissioning................................................................22

10/2018 Version 4.0en Operating Manual Tabeo Sintering Oven Metal Page 3

Placing the supporting stone NEM on the base insulation ..........22

Feeding the sintering oven ..........................................................22

Selecting and loading a heating program....................................24

Starting/stopping a heating program ...........................................24

Removing the sintering dish from the heating oven ....................25

Programming the heating phases................................................25

Programming phase temperatures and holding times.................25

Saving the heating program ........................................................26

Starting a heating program automatically....................................27

Preparing the sintering aid...........................................................28

Recommended lling of the sintering dish.................................................. 28

Basic settings .............................................................................................28

Parameter settings ......................................................................29

Setting the day and the time....................................................................... 30

Switching o the sintering oven...................................................32

RS-232 interface ........................................................................33

Care and maintenance ..............................................................41

Check sealing faces of the sinter bell..........................................41

Faults and error messages.......................................................42

Safety ....................................................................................42

Faults ....................................................................................43

Error messages ...........................................................................44

Decommissioning......................................................................45

Safety ....................................................................................45

Disposal ....................................................................................45

Page 4 Operating Manual Tabeo Sintering Oven Metal Version 4.0en 10/2018

General information

General information

Limitation of liability

The content of this operating manual has been created taking the applicable

laws and standards into account.

The unit has been developed using state-of-the-art technology.

Notice

The manufacturer assumes no liability for damage resulting from:

hDisregard/non-observance of the operating manual

hIntentional misuse

hUse other than as intended

hOperation by untrained personnel

hOperation by lay persons (to carry out maintenance work, etc.)

hTechnical modications to the unit that have not been agreed with the

manufacturer

hUse of replacement parts that have not been approved by the manu-

facturer

Responsibilities of the operator

The unit is used for commercial purposes. The operator of the unit is there-

fore subject to the statutory obligations relating to occupational safety.

In addition to the safety instructions in this operating manual, the regulations

on safety, accident prevention and environmental protection that apply to

the unit's eld of use must be complied with.

In particular, the following apply:

yThe operator must be familiar with the applicable occupational safety

regulations.

yThe operator must ensure that all employees who use the unit have

read and understood this operating manual.

yThe operator must also train personnel at regular intervals and inform

them of the dangers that can arise when using the unit.

yThe operator must provide personnel with the necessary protective

equipment.

yThe operator must have all safety devices checked regularly for oper-

ability and completeness.

General information

10/2018 Version 4.0en Operating Manual Tabeo Sintering Oven Metal Page 5

Documentation

Content and structure

This operating manual is an essential part of this unit. It contains instructions

and information on how to use the unit safely and must be available to all

users throughout the unit's service life. This operating manual is intended for

use by trained operating personnel.

Labelling scheme for integrated text boxes and references

The following safety notices are used in this manual:

$Danger

Indicates an imminent danger that may cause serious physical inju-

ry or death.

$Warning

Indicates a potentially dangerous situation that may cause serious

physical injury or death.

$Caution

Indicates a potentially dangerous situation that may cause minor

physical injury.

Notice

Indicates a potentially harmful situation in which the product or an

object in its vicinity may be damaged.

Notice

Information or tips for easier operation.

Page 6 Operating Manual Tabeo Sintering Oven Metal Version 4.0en 10/2018

General information

Formatting and symbols

$indicates a general safety instruction

;indicates that a requirement must be met

1. indicates a step to be carried out

Âindicates the outcome of carrying out a step

yindicates a list

indicates a button

Service address

Friedrich-List-Straße 8

D-76297 Stutensee-Blankenloch

Tel.: +49 (0) 7244 70871-0

Fax: +49 (0) 7244 70871-20

www.mihm-vogt.de

Safety

10/2018 Version 4.0en Operating Manual Tabeo Sintering Oven Metal Page 7

Safety

The Tabeo sintering oven is a high-temperature oven for commercial use

in dental laboratories and may be used only for sintering sinterable ceram-

ics.

Requirements for personnel

Trained and qualied personnel who know how to use the unit and whose

specialist training, skills, experience and knowledge of the relevant regula-

tions enables them to carry out the tasks assigned to them independently

and recognise and avoid potential hazards.

$Danger

Electricity!

Risk of death from electric shock.

hDo not touch live cables and components with wet hands.

hObserve the accident-prevention regulations when working with elec-

tric current.

hBefore carrying out any installation, maintenance, cleaning or repair

work, disconnect the power supply of the sintering oven (pull out

mains plug) and secure it against being switched back on.

$Danger

Risk of ignition!

Use of inammable and explosive materials near the oven.

hDo not operate the sintering oven near highly inammable sources.

hDo not install the sintering oven on highly inammable supporting

surfaces.

Page 8 Operating Manual Tabeo Sintering Oven Metal Version 4.0en 10/2018

Safety

$Warning

Risk of burns from hot surfaces!

The surfaces of the sintering oven become hot during operation.

These may cause burns if touched.

hDo not touch the housing or the oven door during operation.

hDo not reach into the heating chamber. It may still retain a high level of

residual heat from the previous heating process.

hEnsure that the sintering oven has cooled down before carrying out

maintenance, cleaning and repair work.

hWear heat-resistant safety gloves if it is necessary to carry out work on

hot components.

hUse a suitable and suciently long pair of tongs to place items to be

sintered into the oven and remove sintered items from the oven.

$Caution

Incorrect operation!

No liability is assumed for damage that may be caused by misuse, in-

correct operation, incorrect connections or improper maintenance/repair

work carried out by untrained personnel. All warranty services are also

excluded in such cases.

The unit must not be used if it or the mains cable becomes damaged and

no longer functions correctly.

In this case contact the manufacturer immediately.

For your own safety and to increase the service life of your unit, use only

original replacement parts.

To ensure safe operation of the sintering oven, regional regulations (e.g.

accident-prevention regulations) apply in addition to the instructions in

this operating manual. The former must be made available by the opera-

tor of the unit. The safety notices on the sintering oven must be kept in a

legible condition.

Notice

This operating manual must be read and understood by each user before

working on and with the unit.

The operating manual must be kept for the specied service life of the

sintering oven.

Transport, packaging and storage

10/2018 Version 4.0en Operating Manual Tabeo Sintering Oven Metal Page 9

Transport, packaging and storage

Transport

$Warning

Injury due to the sintering oven falling down!

Slipping/falling when lifting and carrying the sintering oven can lead to

serious injuries.

hOnly carry/hold the sintering oven at the lower edge of the housing

(base).

hAlways have at least two persons carry the sintering oven (max. 30 kg/

person).

$Caution

Risk of injury due to oven weight!

Physical strain/back injuries due to the high inherent weight.

hHave at least two persons carry/move the sintering oven together.

Notice

Transport damage!

To prevent injury to personnel and material damage:

hTransport the unit in an upright position only.

hDo not stack units on top of each other.

hDo not place any other objects on the unit.

hTransport must be as free of shaking and vibrations as possible to

prevent the unit from being damaged.

hMake sure that the unit is secured against slipping and falling during

transport.

hThe goods must be inspected for damage and loss immediately upon

receipt. Defects must be documented by the freight carrier on the

letter of consignment in order to lodge claims. The manufacturer as-

sumes no liability for any damage and loss that is only found subse-

quently.

Page 10 Operating Manual Tabeo Sintering Oven Metal Version 4.0en 10/2018

Transport, packaging and storage

Packaging

Notice

The packaging protects the sintering oven against transport damage,

corrosion and other forms of damage. Only remove it shortly before initial

commissioning and store it in dry conditions for later reuse.

Storage

Notice

Temperature damage!

To prevent temperature damage:

hStore the unit only at temperatures between +5 and +40 °C.

hAlways store the unit in dry and dust-free conditions.

hAvoid exposure to direct sunlight.

hAvoid mechanical vibrations.

Technical description

10/2018 Version 4.0en Operating Manual Tabeo Sintering Oven Metal Page 11

Technical description

Function

The Tabeo sintering oven is used to re sinterable ceramics.

The product to be sintered is placed in the sintering dish and set on the

support pins in the combustion chamber. The heat-up process starts after

entering the heating parameters and pressing the Start button.

Once the heating program has ended and the sintering oven has cooled

down, the nished product can be removed from the oven.

Heating chamber

The product is sintered in the heating chamber. This consists of two dier-

ent ceramic insulation layers and is operated using four heating elements

connected in series. The outer insulating layer is designed for temperatures

up to 1200 °C; the inner layer for temperatures up to 1650 °C.

Oven door

The oven door consists of a two-part ceramic door panel. A safety switch

disconnects the heating current as soon as the oven door is opened.

The oven door has an electronic lock and can be opened only if the tem-

perature is below 300 °C.

Oven housing

The oven housing consists of steel plate coated with plastic on both the

inside and the outside and is cooled by a permanent ventilation system.

Program controller

The program controller has a nishing-time setting that can be used to spec-

ify a day and time for the program to nish. The switch-on time is calculated

automatically so that the heating process is stopped at the required time

and the sintered item can be removed.

Operating parameters and heating programs are stored in a non-volatile

memory and are retained even if the power supply fails.

The set target temperature is maintained within an accuracy of ± 1 °C.

A temperature sensor integrated into the heating chamber measures the

temperature of the chamber close to the product.

A thermocouple fail-safe prevents the sintering oven from overheating if the

temperature sensor becomes defective.

Page 12 Operating Manual Tabeo Sintering Oven Metal Version 4.0en 10/2018

Technical description

Conformity

EC Declaration of Conformity according to Machinery Directive 2006/42/EC Annex II

1.A

The manufacturer / distributor

MIHM-VOGT GmbH & Co. KG

Friedrich-List-Str. 8

76297 Stutensee

Tel.: +49 (0) 72 44/7 08 71-0

Fax: +49 (0) 72 44/7 08 71-20

Email: [email protected]

hereby declares that the following

product

Product designation: Tabeo sintering oven

series Make: TABEO-1/M/Zirkon-100

TABEO-1/S/Zirkon-100

TABEO-2/M/Zirkon-120

TABEO-2/S/Zirkon-120

TABEO-2/M/Metal-120

Description:

The Tabeo sintering oven is a high-temperature oven for commercial use in dental laboratories and may

only be used for sintering sinterable ceramics.

corresponds to all relevant regulations of the above directive as well as the further applied directives

(below) – including their amendments applicable at the time of the declaration.

The following EU directives were applied: EMC

2014/30/EU

RoHS 2011/65/EU

The protection objectives of the Low Voltage Directive 2014/35/EU were complied with.

The following harmonised standards were applied:

EN 61010-1:2010 Safety requirements for electrical equipment for measurement,

control and laboratory use – Part 1: General requirements (IEC

61010-1:2010)

EN 61010-2-010:2014 Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 2-010: Particular requirements for laboratory

equipment for the heating of materials (IEC 61010-2-010:2014)

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use – EMC

requirements – Part 1: General requirements (IEC 61326-1:2012)

EN ISO 12100:2010 Safety of machinery – General principles for design –

Risk assessment and risk reduction (ISO 12100:2010)

The following national or international standards (or parts/clauses thereof) and specifications were

applied: –

Name and address of the person who is authorised to compile the technical documents: Gillen, Tobias

Place: Stutensee / Date: 15.09.2016

(Signature) Dietmar Gräbe

Technical description

10/2018 Version 4.0en Operating Manual Tabeo Sintering Oven Metal Page 13

CE Mark

This product bears the CE mark in line with the provisions of Directive

2006/42/EC (Machinery Directive).

CAUTION

CE mark with connected products!

Products that are connected to this product must also bear the CE mark.

These products must be test in accordance with the respective standards.

We declare conformity for sintering oven Tabeo Metal based on the follow-

ing standards:

ySafety: EN 61010-1:2010 and EN 61010-2-010:2014

yEMC: EN 61326-1:2013

yRisk assessment and risk reduction EN ISO 12100:2010

The Eurasian Economic Community Conformity Mark

Certicate number ЕАЭС N RU Д-DE.АД75.В.02156

RoHS Conformity

This symbol indicates that this product does not contain any poisonous or

dangerous substances and can be recycled after disposal, and should not

be thoughtlessly discarded.

Page 14 Operating Manual Tabeo Sintering Oven Metal Version 4.0en 10/2018

Technical description

Intended use

The Tabeo sintering oven is a high-temperature oven for commercial ap-

plication in dental laboratories and may be used only for sintering sinterable

chromium cobalt using original spare parts.

At a total output >1kW, no limit values for the harmonics apply.

The protection of persons can no longer be ensured and no liability can

be assumed for damage that is caused by misuse, incorrect operation,

incorrect connections or improper maintenance/repair work carried out

by untrained personnel. All warranty services are also excluded in such

cases.

The use of spare and wearing parts that have not been procured from the

manufacturer will render the approval and guarantee of the sintering oven

null and void.

Potential misuse

yOperation by untrained and insuciently qualied personnel.

yUse of products that have not been approved by the manufacturer.

yUse of replacement parts that have not been approved by the manu-

facturer.

yAny use not in accordance with the declaration of conformity.

yTechnical modications to and conversions of the unit that have not

been approved by the manufacturer.

Sintering with argon

The sintering of NEM is possible only in an oxygen-reduced atmosphere.

This is attained by using argon. Argon is an inert gas in a compressed gas

bottle. Always use argon bottles with a pressure gauge as well as a pressure

reducer. The purity of the argon must be at least 4.6= 99.996 % vol. During

the sintering process the argon ow is 1 l/min.

The lling level of the compressed gas can be determined at the pressure

gauge. A new argon compressed gas bottle is lled with 200 bar.

A 50 litre compressed gas bottle of argon with a lling pressure of 200 bar

contains approx. 10,000 litres of argon.

At a ow of 1 l/min, the consumption per sintering process is approx. 270

litres.

With a 50 litre compressed gas bottle, approx. 35 NEM sintering processes

are possible.

Technical data

10/2018 Version 4.0en Operating Manual Tabeo Sintering Oven Metal Page 15

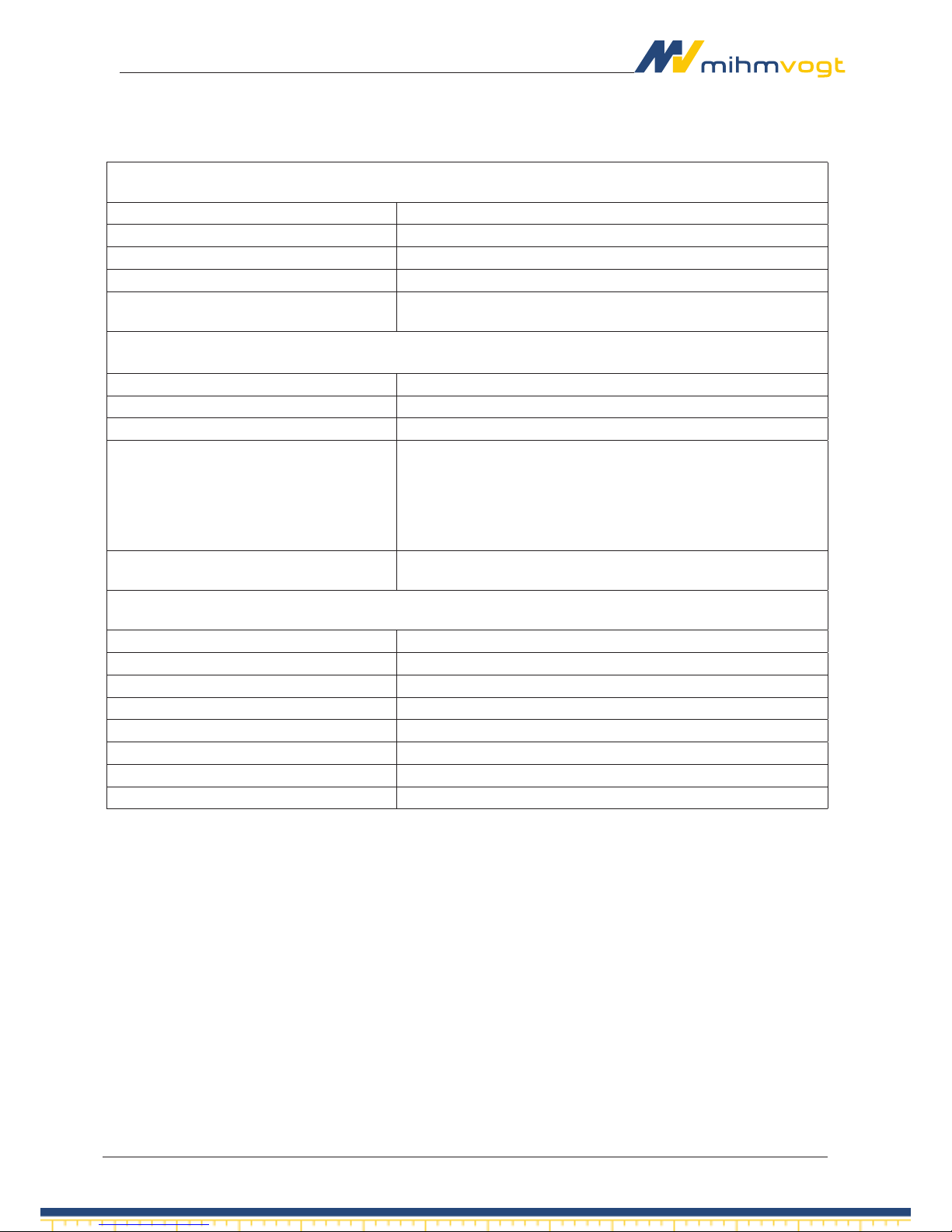

Technical data

Dimensions (W x D x H) 480 x 680 x 460 mm

Combustion chamber volume 1 dish Ø 85 x 40 mm or 1 dish Ø 109 x 35 mm

Max. temperature 1400 °C

Weight 78 kg

Minimum clearance around the sintering

oven

50 mm

Connected electrical load

Voltage supply 200 - 240 V

Frequency 50/60 Hz

Max. power consumption 1600 W

Protection

Device end

Customer end

12 AT

Connection to a separate electrical circuit with a 16-A circuit

breaker, type K or type Z (other types of circuit breaker depend-

ing on the country of use)

Protection class IP 20 (protection against the ingress of foreign bodies, but not

against the ingress of water)

Operating conditions

Installation area Indoors only (in dry rooms)

Temperature range +5 to +40 °C

Relative air humidity Up to 31 °C: 80%

Maximum air humidity Up to 40 °C: 50% No condensation

Height Max. 2000 m

Pollution degree 2

Optimal pressure range of argon supply 6-7 bar

Maximum pressure range of argon supply 10 bar

Page 16 Operating Manual Tabeo Sintering Oven Metal Version 4.0en 10/2018

Installation

Installation

Installation location

The Tabeo sintering oven is designed as a table-top unit. To ensure stabili-

ty, we recommend a level surface of at least:

y60 cm x 60 cm that can support a load of up to 80 kg

Installation conditions

►Always install the sintering oven in dry rooms that are as dust-free as

possible and make sure that liquids cannot penetrate the unit.

► Highly inammable and combustible gases and liquids must not be

stored in the installation rooms.

► Do not place any combustible and inammable objects near the sin-

tering oven.

► Keep a distance of 50 mm around the sintering oven for sucient

cooling.

$Caution

Tipping loads!

Supporting surface with an insucient load-bearing capacity.

hWhen installing the sintering oven, make sure that the supporting sur-

face has a sucient load-bearing capacity.

$Caution

Risk of injury due to oven weight!

Physical strain/back injuries due to the high inherent weight.

hHave at least two people carry/move the sintering oven together. (max.

30 kg load bearing capacity/person).

$Caution

Risk of overheating!

In the event of overheating, the electronic system will switch the heater

o.

hMake sure that the air vents remain clear on all sides.

Installation

10/2018 Version 4.0en Operating Manual Tabeo Sintering Oven Metal Page 17

1. Align the supporting surface horizontally.

Lift and carry the sintering oven only at the unit base.

2. Place the sintering oven on the supporting surface.

$Make sure the surface is non-slip.

Electrical connection

Local installation

$Warning

Release of pollutants!

Pollutants can be inhaled when the insulating materials are handled.

hWear personal protective equipment (respiratory protection) during

disposal.

;The sintering oven requires its own electrical circuit.

;The building's electrical circuit must have a type-K or type-Z circuit

breaker with a rated current of at least 16 A (other types of circuit

breaker depending on the country of use).

;An additional residual-current circuit breaker (designed for 30 mA

tripping current) must be installed.

;To ensure electrically safe operation, the sintering oven requires a

protective earth conductor connected to the power socket.

;When selecting the installation location, ensure that the accompany-

ing mains cable is 2.0 m long. Extending the cable is not permitted.

The supply voltage must be within the rated voltage range of 200 -

240 V (see „Technische Daten“ on page 12).

$Danger

Electricity!

Risk of death from electric shock.

hDo not touch live cables and components with wet hands.

hObserve the accident-prevention regulations when working with elec-

tric current.

hOnly connect the unit to a voltage supply that matches the specica-

tions on the rating plate.

Page 18 Operating Manual Tabeo Sintering Oven Metal Version 4.0en 10/2018

Installation

Rating plate

220-240V 50/60Hz 2700W

Tabeo-2/M/Metal-120

S/N: 00000

Manufactured in Germany 2016

Mihm-Vogt GmbH & Co.KG

Friedrich-List-Str.8

D-76297 Stutensee-Blankenloch

REF 00000000

10

1

8

23

9

5

11

7

6

200-240V 1600W 4

Abb. 1: Rating plate (example)

1 Machine type/designation 7 QR code

2 Operating voltage 8 Serial number

3 Mains frequency 9 Year of manufacture

4 Output 10 Manufacturer's details

5 CE mark 11 RoHS mark

6 Reference number Mihm-Vogt

Installation

10/2018 Version 4.0en Operating Manual Tabeo Sintering Oven Metal Page 19

Connecting the argon supply

$Danger

Danger due to escaping gas!

Potential risk of explosion or re as well as suocation.

hDuring all work on the Tabeo-2/M/Metal-120, the argon and voltage

supply must be shut o (pull out mains plug) and the gas bottle must

be closed.

hWhen working with argon, observe the national safety regulations

TRGS526 (Chapter 5.2.11 “Compressed gas bottles and ttings”).

1. Close the connecting hose (included in the delivery) at the sintering

oven (A) and the argon supply (gas bottle).

Abb. 2: Argon connection Tabeo Metal (illustrative example)

2. Set the outlet pressure of the gas bottle to 6-7 bar (optimal pressure!).

Maximum pressure: 10 bar!

Notice

If the outlet pressure of the gas bottle is higher or lower than 6-7 bar, too

much/too little argon will enter the sintering dish and the sintering process

will fail!

3. Check the gas lines and connected couplings for leaks and a secure

t.

ÂIn the event of a malfunction the volume of an argon bottle is su-

cient to ood the entire room.

A ventilation in the oor area is recommended (argon is heavier than

air and settles on the oor).

4. Protect the ducts and shafts against penetration by gas.

Page 20 Operating Manual Tabeo Sintering Oven Metal Version 4.0en 10/2018

Operation

Operation

Operating elements and displays

The microprocessor-controlled program controller enables a wide range of

heating curves to be run through with high precision. The unit is operated via

a membrane keyboard and menus displayed on a 7-segment screen.

The program controller has the following operating elements:

1

2

348

7

56

1 Function display 5 Program phase

2 Week day/Time 6 Current program

3 Door opener 7 Navigation buttons

4 Start/Stop 8 Main on/o switch

Operating elements

Function

Mains switch; lights up when switched on (at bottom switch position)

Changes the display mode, activate/deactivates the nishing time function

Increases the value

Decreases the value

Activates programming mode

Starts/stops the program

Activates the door opener

This manual suits for next models

5

Table of contents

Other MIHM-VOGT Oven manuals

Popular Oven manuals by other brands

Bosch

Bosch HBN 43M 550 A Installing and operating instructions

Samsung

Samsung NV75A657 Series User & installation manual

Electrolux

Electrolux B4401-5 user manual

Frigidaire

Frigidaire FEB500CEBI parts catalog

Hotpoint Ariston

Hotpoint Ariston CP 87SEA /HA S operating instructions

Siemens

Siemens HB 58 6B Series instruction manual