Mitsubishi MOTORS Lancer Evolution-VIII Instruction manual

LANCER

EVOLUTION VIII

FOREWORD

This manual contains details of the main changes to the ’03

model Lancer Evolution VIII. Since only differences to the

Lancer Evolution VII have been included, lease use this

manual in conjunction with the relevant ages in the material

reviously ublished.

We recommend that work is carried out with careful

reference to this manual, to ensure that servicing is done

correctly and quickly, so that vehicle erformance is

maintained.

This manual is based on the current model (January 2003).

Please bear in mind that as a result of subsequent changes

to vehicle s ecifications, some information may not

corres ond to more recently ublished details.

All the units shown in this manual follow the internationally

recognised SI unit system. Please note that the ractice of

using the old units together with SI units has been dro ed.

(Please note, however, that figures and units s ecified on

various forms may still use the old units)

January 2003

MITSUBISHI MOTOR CORPORATION

CONTENTS

General

Engine

Fuel

Engine Cooling

Intake and E haust

Engine Electrical

Engine and Emission Control

Manual Transmission

Front A le

Rear A le

Engine and Transmission Mounting

Body

E terior

Interior and SRS Airbag

Chassis Electrical

00

11

13

14

15

16

17

22

26

27

32

42

51

52

54

Any o inions, requests, or questions concerning this

manual, should be written on the ‘Servicing Comment Form’

at the end, and sent to us by fax.

Related materials

WARNING REGARDING SERVICING OF VEHICLES FITTED WITH SRS AIR BAGS · SEAT BELTS WITH

PRE-TENSIONERS

Warning

1. Improper servicing or maintenance of any SRS air bag or pretensioner fitted seatbelt component, or

related parts, could cause major injury as a result of the unintentional setting-off (incorrect

deployment) of the SRS air bag or pretensioner fitted seatbelt, or non-operation.

2. When they could be subject to the effects of heat during the painting process, please remove the

SRS-ECU, driver side air bag module, passenger side air bag module, pretensioner fitted seatbelt,

and clock spring, as follows:

• 93°C and above: driver side air bag module, passenger side air bag module, clock spring

• 90°C and above: pretensioner fitted seat belts

3. Service or maintenance of any SRS air bag or pretensioner fitted seatbelt components or related

parts must be performed by an authorised MITSUBISHI dealer.

4. This manual must be consulted (with special reference to Chapter 52B SRS Air Bag) before

any servicing or maintenance is carried out on SRS air bag or pretensioner fitted seatbelt

components or related parts.

Note

Sections titles with an asterisk (*) indicate areas where s ecial attention must be aid to SRS airbags and retensioner fitted

seatbelts.

Title No. Issue date

New model manuals

• Mirage, Lancer

• Mirage, Lancer

• Mirage, Lancer

• Mirage, Lancer

• Lancer

• Mirage, Lancer

• Lancer

• Lancer

• Lancer Sedia

• Lancer Sedia

• Lancer Evolution VII

• Lancer Sedia

• Lancer Sedia

• Lancer Evolution VII

• Lancer Sedia

• Lancer Evolution VII

1036F30

1036F31

1036F32

1036F33

1036F34

1036F35

1036F36

1036F37

1036K30

1036K31

1036K32

1036K33

1036K34

1036K35

1036K36

1036K37

10/1995

1/1996

8/1996

7/1997

1/1998

10/1998

1/1999

12/1999

5/2000

7/2000

1/2001

5/2001

5/2001

1/2002

5/2002

1/2003

Worksho Manuals

• Lancer Sedia

• Lancer Sedia (su lement)

• Lancer Evolution VII (su lement)

• Lancer Sedia (su lement)

• Lancer Sedia (su lement)

• Lancer Evolution VII (su lement)

• Lancer Sedia (su lement)

1036k00

1036K01

1036K02

1036K03

1036K04

1036K05

1036K06

5/2000

7/2000

1/2001

5/2001

10/2001

1/2002

5/2002

Body edition Worksho Manuals

• Mirage, Lancer (su lement)

• Lancer Sedia

• Lancer Sedia (su lement)

• Lancer Evolution VII (su lement)

• Lancer Sedia (su lement)

1036F32

1036K50

1036K51

1036K52

1036K53

8/1996

5/2000

7/2000

5/2001

10/2001

Electrical Wiring Diagrams Worksho Manuals

• Lancer Evolution VIII 1036K77 1/2003

Engine Worksho Manuals

• 4G6 engine

• 4G6 engine (su lement) 1039G46

1039G63 1/2001

1/2003

Transmission Worksho Manual

• W5M51 manual transmission

• W5M51 manual transmission (su lement)

• W6MAA manual transmission

1039M17

1039M22

1039M23

1/2001

1/2003

1/2003

GENERAL - MODEL LINE-UP, APPLIED VEHICLES 00-1

SECTION 00

GENERAL

CONTENTS

Model line-up

Note

[] New model [] Continued model [X] Discontinued model

Applied vehicles

GH-CT9A: CT9A-0200001 ~

Model line-up..............................................1

Applied vehicle numbers ..........................1

Troubleshooting and Inspection ..............2

Model Version ’03 Model Grade Engine Model Transmission Fuel System

GH-CT9A SNDFZ

SYGFZ

SJDFZ

SJGFZ

X

RS

GT-A

RS

GSR

4G63

(2 000 DOHC 16 valve

intercooler turbo)

W5M51 (4WD, 5M/T)

W5A51 [4WD, INVECS-II

S orts mode 5 A/T (with

steering shift switch)

W6MAA (4WD, 6 M/T)

MPI

GENERAL - TROUBLESHOOTING AND INSPECTION

00-2

TROUBLESHOOTING AND INSPECTION

Diagnosis Functions

Reading Diagnosis Code

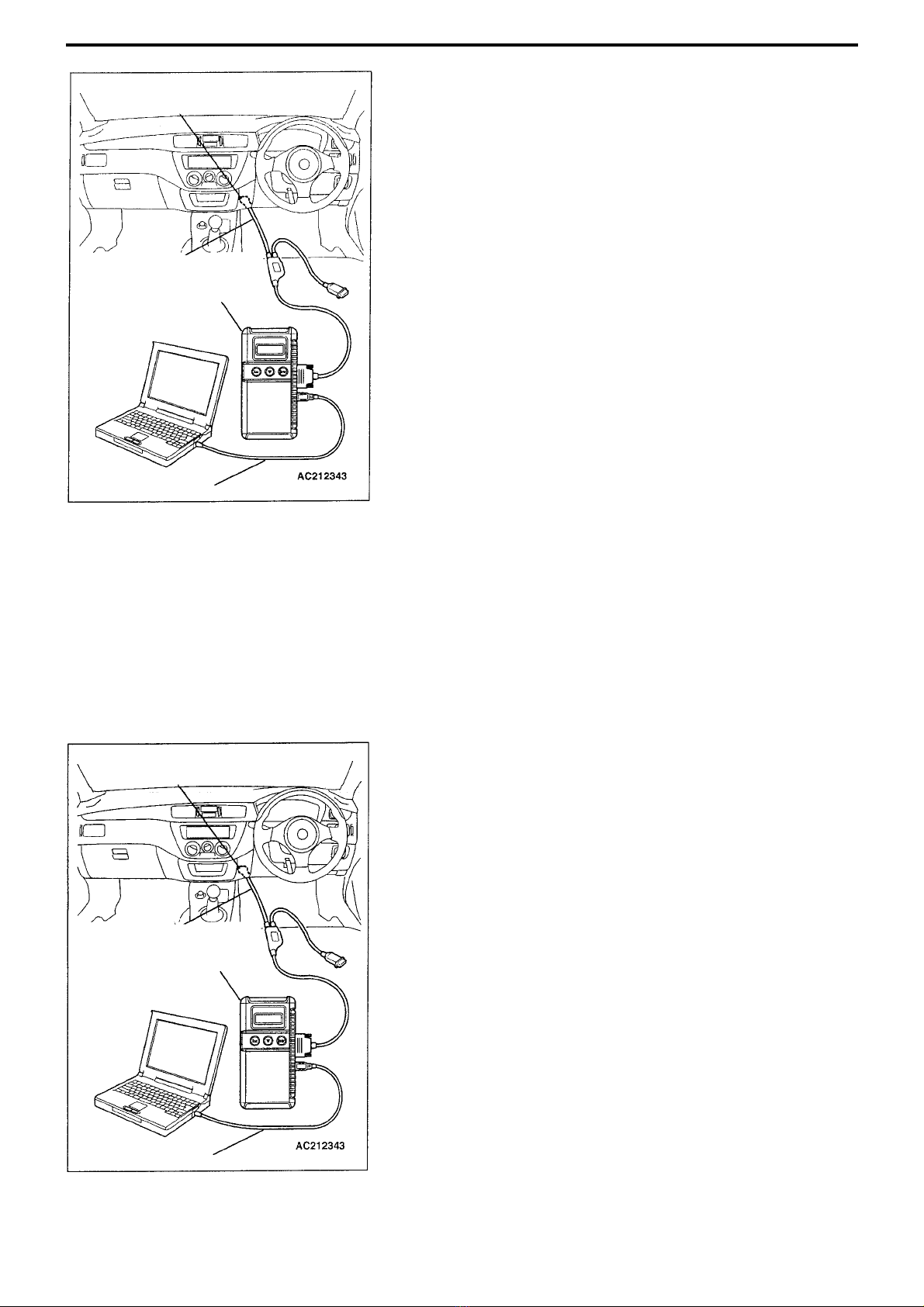

Connect the MUT-III to 16 in diagnosis connector and read diagnosis code

as described below.

NB. Please refer to the User Manual for a detailed ex lanation of how to

use the MUT-III.

(1) Check that the ignition switch is in the LOCK (OFF) osition.

(2) Connect s ecial V.C.I. (MB991824) and PC with s ecial USB cable

(MB991827).

(3) Connect s ecial MUT-III main harness B (MB991911) to V.C.I.

(4) Connect MUT-III main harness B to vehicle diagnosis connector.

(5) Turn V.C.I. ower switch ON.

(6) After switching V.C.I. ON, the green V.C.I. indicator light should come on.

(7) Start u the PC MUT-III system, and turn vehicle switch to the ON

osition.

(8) Read diagnosis code.

(9) When disconnecting, turn ignition switch to LOCK (OFF) osition, and

follow reverse rocedure.

Diagnosis Code Deletion

Connect MUT-III to diagnosis connector in the same way as for ‘Reading

Diagnosis Codes’, then delete diagnosis codes.

MUT-III main harness B

USB cable

Diagnosis connector

MUT-III main harness B

USB cable

Diagnosis connector

V.C.I.

V.C.I.

4G6 ENGINE – GENERAL, SEALANTS, SPECIAL TOOLS 11A-1

SECTION 11A

ENGINE

CONTENTS

4G6 ENGINE

General

The servicing information s ecified below accom anies changes to the 4G63-MPI-T/C engine installed on the new Lancer

Evolution VIII. Other servicing information remains the same.

• The crank angle sensor and O2sensor connector have been changed

• The timing belt front cover is now s lit into 2

Sealants

Note

( ) are original roducts

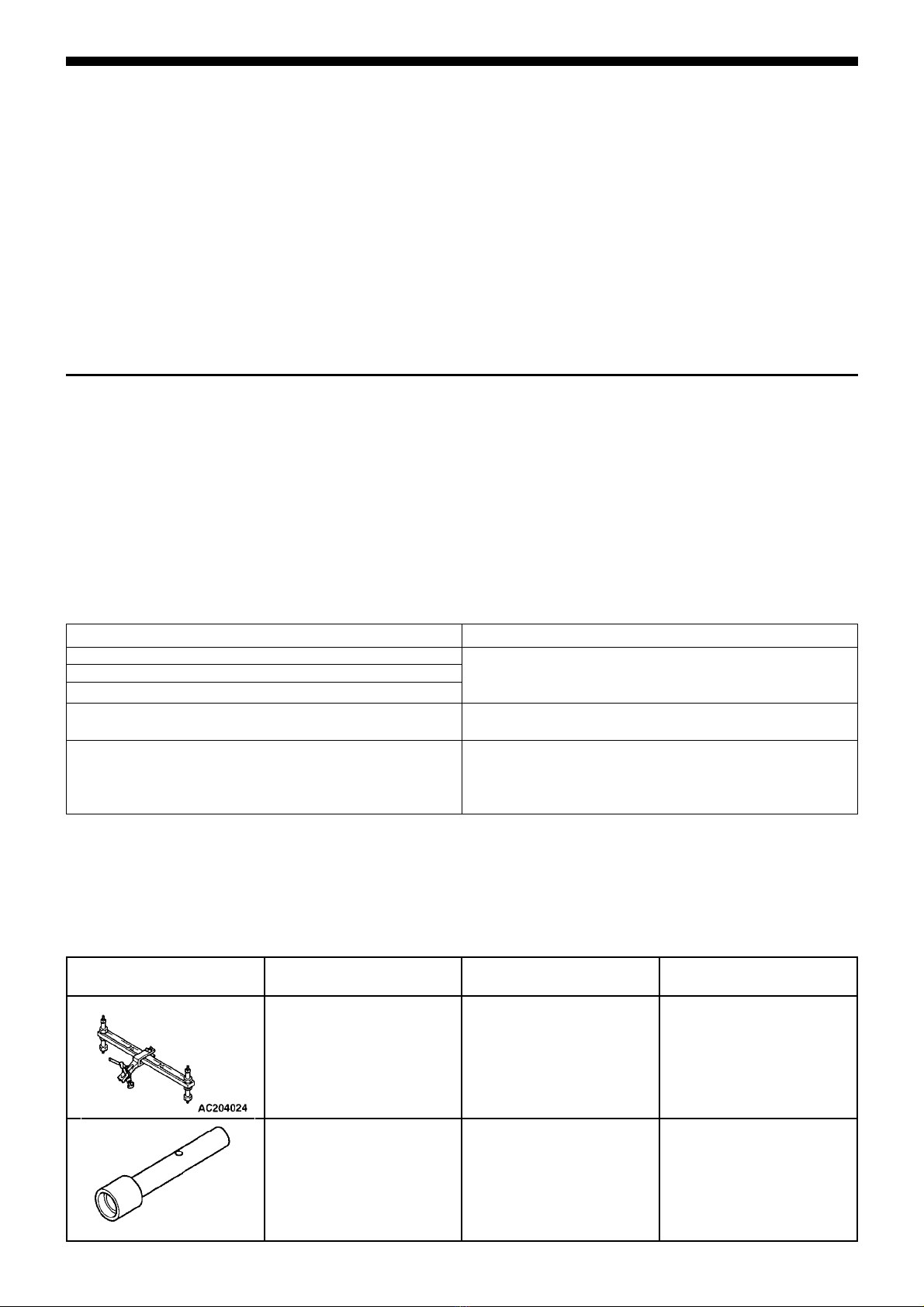

Special Tools

Tool

Number Name Function

MD998772 Valve s ring com ressor Valve s ring com ression

MD998737 Valve stem seal installer Valve seal stem installation

General .......................................................1

Sealants .....................................................1

Special Tools .............................................1

Engine adjustment ....................................2

1. Checking com ression ressure .....................2

Camshaft, valve stem seals .....................2

Timing belt, timing belt B........................11

Location Name

Rocker cover

Rocker cover gasket

Cylinder head

Semi-dry sealant: Three Bond 1207D (MZ100168) (contains

150g)

Camshaft end seal Semi-dry sealant: Three Bond 1211 (MZ100057) (contains

100g)

Camshaft osition sensor su ort Semi-dry sealant: Three Bond 1207F (MZ100191) (contains

150g)

4G6 ENGINE – SPECIAL TOOLS, ENGINE ADJUSTMENT, CAMSHAFT, VALVE STEM SEAL

11A-2

Tool Number Name Function

Camshaft oil seal insertion

ENGINE ADJUSTMENT

1. Checking compression pressure

The crank angle sensor connector osition has been

changed.

CAMSHAFT, VALVE STEM SEAL

Removal and Fitting

Caution

1. When Brembo brake callipers are used, there is concern over paint peeling off, so when doing servicing work,

make sure they are not scratched by other components and tools. Furthermore, if any brake fluid gets onto the

calipers, it should be wiped off immediately.

2. The fitting and removal of parts marked with an * should be carried out for each cylinder.

Jobs to do before removal and after fitting

• Removal and fitting of undercover (refer to Cha ter 51 Front Bum er)

• Checking drive belt tension <only after fitting>

• Draining and filling of coolant

• Removal and fitting of air duct

• Removal and fitting of air i e C (refer to Cha ter 15 Intercooler)

• Removal and fitting of timing belt (refer to P.11A-12)

crank angle sensor

connector

MD998713 Camshaft

Oil seal

Installer

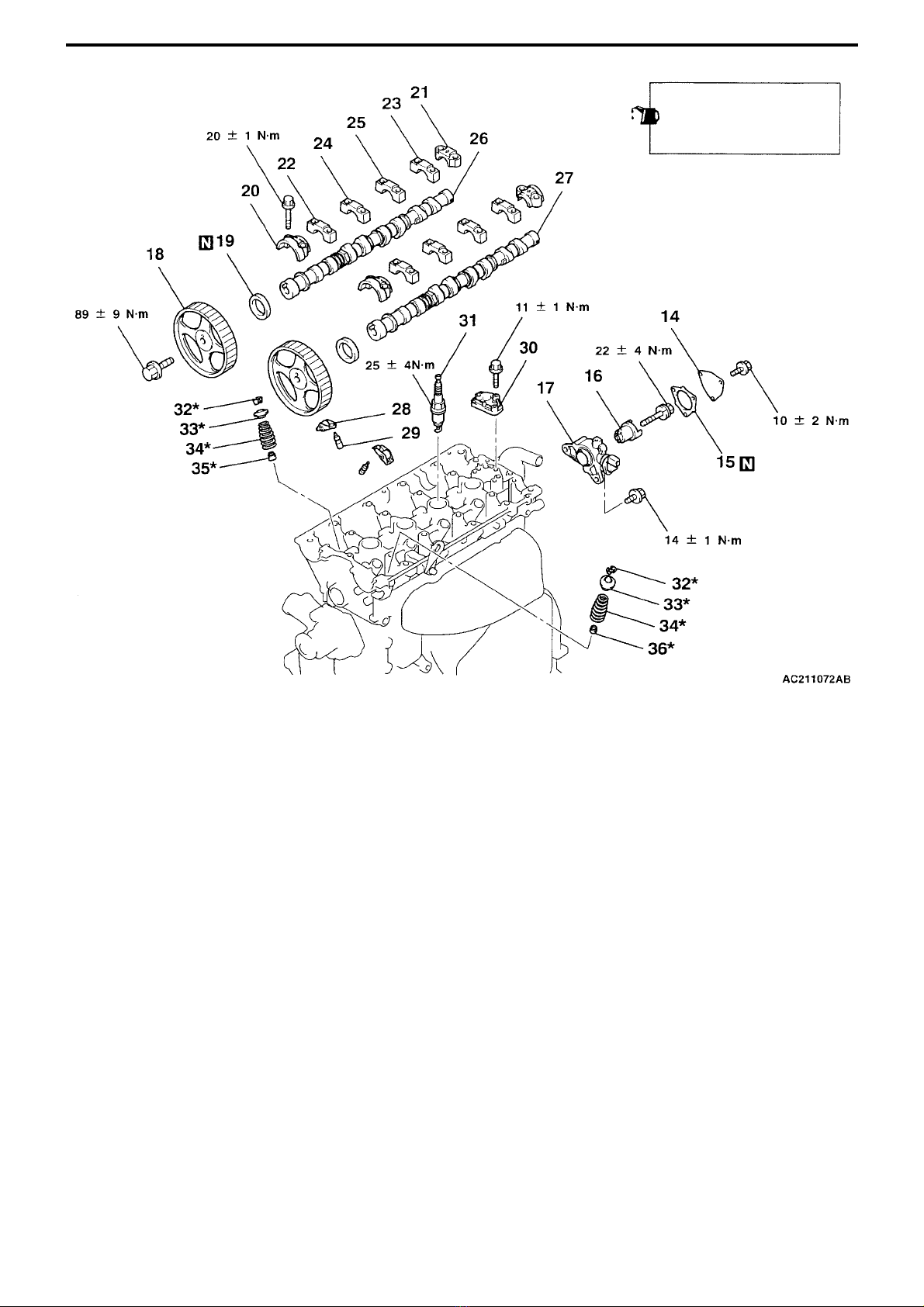

4G6 ENGINE- CAMSHAFT , VALVE STEM SEAL 11A-3

Removal rocedure

1. Breather hose

• Air bag ASSY

(refer to Cha ter 15-2 Secondary Air Control

System)

2. Centre cover

• Ignition coil

(refer to Cha ter 16 Ignition

Equi ment)

3. O2sensor connector

4. Crank angle sensor connector

5. Connecting the control harness

6. PCV hose

7. Radiator u er hose

8. Camshaft osition sensor connector

9. Connecting earth cable

10. Rocker cover ASSY

11. Camshaft end seal

12. S ark lug hole gasket

13. Rocker cover gasket

A N

M

L

K

14. Camshaft osition sensor

su ort cover

15. Camshaft osition sensor

su ort cover gasket

16. Camshaft osition sensing

cylinder

17. Camshaft osition sensor

su ort

18. Camshaft s rocket

19. Camshaft oil seal

20. Camshaft bearing ca front

21. Camshaft bearing ca rear

22. Camshaft bearing ca No.2

23. Camshaft bearing ca No.5

24. Camshaft bearing ca No.3

25. Camshaft bearing ca No.4

26. Inlet camshaft

27. Exhaust camshaft

28. Rocker arm

29. Lash adjuster

30. Oil delivery body

31. S ark lug

32. Valve s ring retainer lock

33. Valve s ring retainer

34. Valve s ring

35. Inlet valve stem seal

36. Exhaust valve stem seal

When assembling, a ly

engine oil to all sliding

arts

J

I

B H

G

F

F

F

F

F

F

E

E

D

C C

B

A

A

4G6 ENGINE – CAMSHAFT, VALVE STEM SEAL

11A-4

4G6 ENGINE- CAMSHAFT , VALVE STEM SEAL 11A-5

Lubricant and seal application locations

<View of rocker cover lower surface>

Semi-dry sealant: Three Bond 1207D

<View from A>

Semi-dry sealant: Three

Bond 1207D

Engine oil

(Li art)

Rocker

Cover

Cylinder

head

Semi-dry sealant: Three Bond 1211

Semi-dry sealant: Three Bond 1207F

Ø 3mm

<View of cylinder head u er surface>

Semi-dry sealant: Three Bond 1207D

4G6 ENGINE – CAMSHAFT, VALVE STEM SEAL

11A-6

MAIN POINTS REGARDING REMOVAL

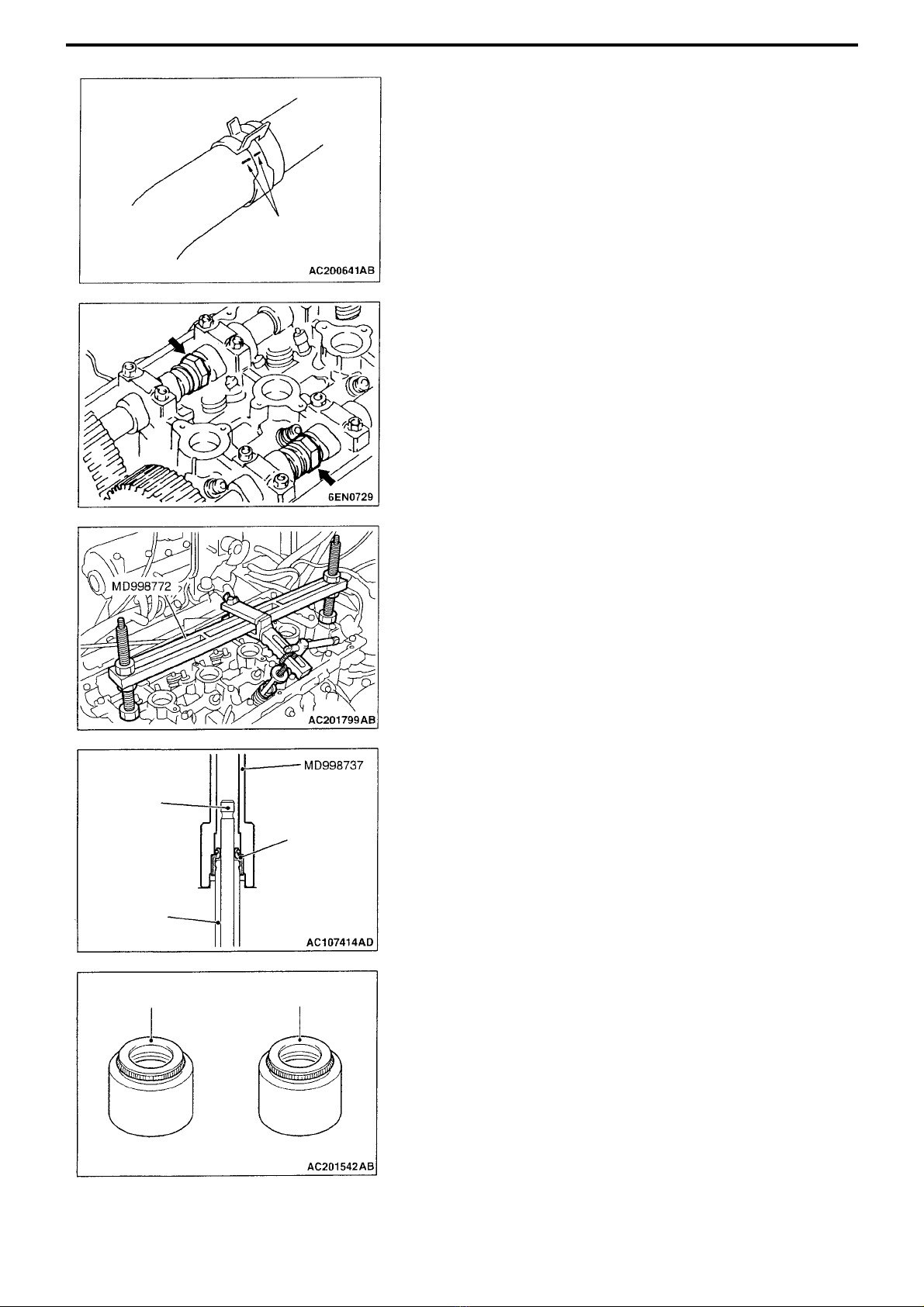

ADETACHING RADIATOR UPPER HOSE

Align the matching marks on radiator u er hose and hose clam , then

detach radiator u er hose.

BREMOVING CAMSHAFT SPROCKETS

Hold camshaft hexagonal art with a wrench, loosen mounting bolt, and

remove camshaft s rocket.

CREMOVING VALVE SPRING RETAINER LOCK

Com ress valve s ring using the s ecial valve s ring com ressor tool

(MD998772), and remove valve s ring retainer lock.

CAUTION

When removing the valve spring retainer lock, all cylinder pistons

should be in the top dead centre position. If pistons are not in the

top dead centre position, valves could fall into the cylinders.

ASSEMBLY - MAIN POINTS

AFitting e haust valve stem seals/inlet valve stem seals

1. A ly a small quantity of engine oil to valve stem seals

2. Place the valve stem into the guides, then insert a new valve stem

seal into the valve guide using the s ecial valve stem seal installer

(MD998737).

CAUTION

(1) Valve stem seals cannot be re-used.

(2) If valve stem seals are not fitted correctly, it could lead to oil

leaking down, so the special valve stem seal installer tool

(MD998737) should be used for fitting.

Note

Check the colours on the rubber arts to identify inlet valve stem seals

and exhaust valve stem seals.

Matching marks

Valve

Valve guide

Valve stem

seal

Colour of main

body: grey Colour of main body:

greenish grey colour

Inlet side Exhaust side

4G6 ENGINE- CAMSHAFT , VALVE STEM SEAL 11A-7

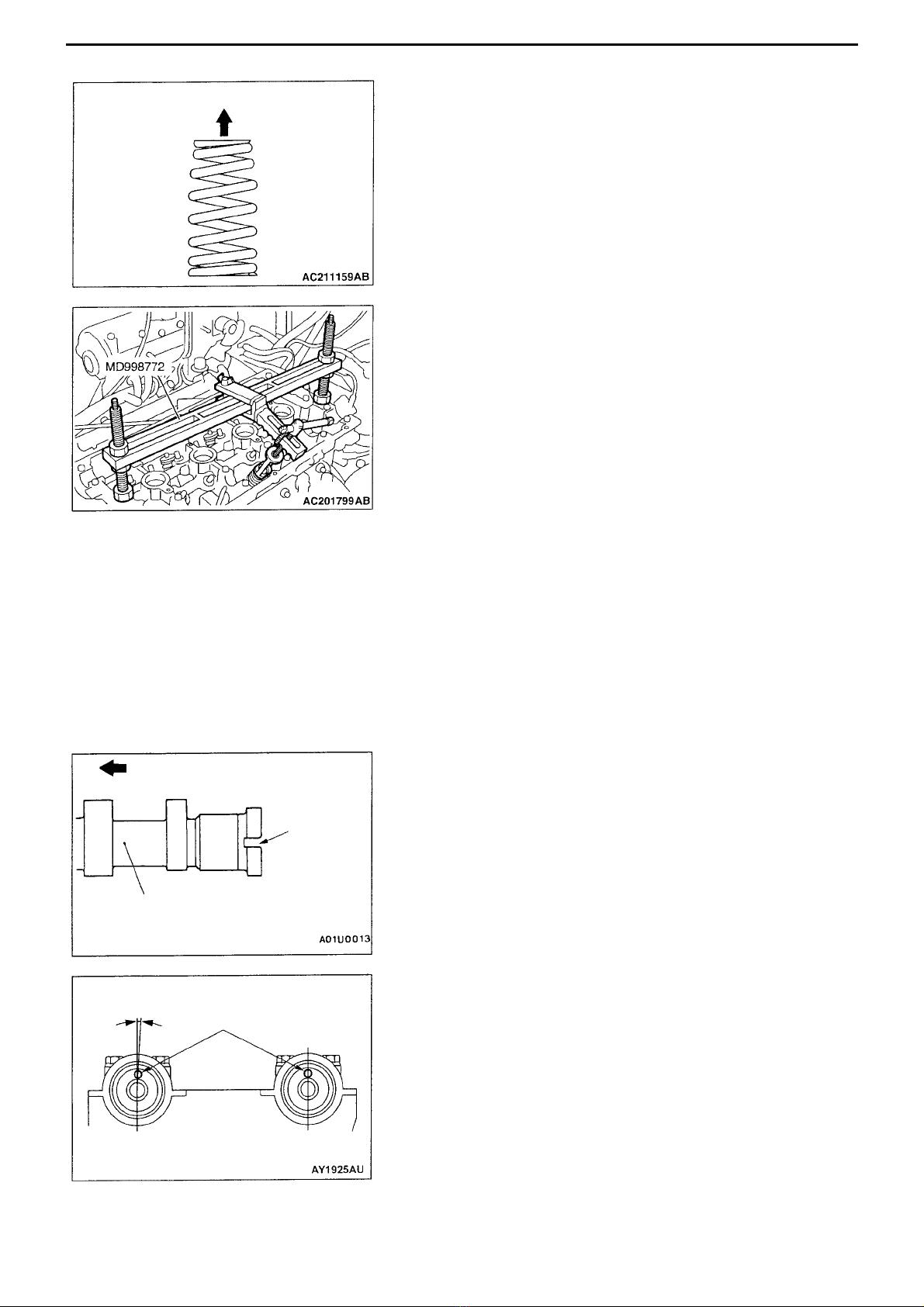

B FITTING VALVE SPRING

Fit so that the valve s ring small radius end is on the rocker arm side.

CFITTING VALVE SPRING RETAINER LOCK

Com ress the valve s ring using the same valve s ring com ressor tool

(MD998772) as the one used for removal and fit the valve s ring retainer

lock.

D FITTING LASH ADJUSTER

CAUTION

When re-using lash adjuster, without fail wash and check before fitting.

(Refer to Engine Worksho Manual)

EFITTING EXHAUST CAMSHAFT / INLET CAMSHAFT

1. Remove any sealant adhering to the cylinder head.

2. A ly engine oil to camshaft cams and journals.

3. Fit camshaft to cylinder head.

CAUTION

Do not get intake and e haust sides the wrong way round.

The e haust camshaft has a slit on the rear end.

F FITTING CAMSHAFT BEARING CAP No.4/ FITTING

CAMSHAFT BEARING CAP No.3/ FITTING CAMSHAFT BEARING

CAP No.5/ FITTING CAMSHAFT BEARING CAP No.2/ FITTING

CAMSHAFT BEARING CAP REAR/ FITTING CAMSHAFT

BEARING CAP FRONT

1. Set the camshaft dowel ins in the osition shown in the diagram.

Rocker arm side

Engine front direction

Slit

Exhaust camshaft

A rox. 3° Dowel ins

Intake side Exhaust side

4G6 ENGINE – CAMSHAFT, VALVE STEM SEAL

11A-8

2. The camshaft bearing ca s No.2~5 are the same sha e, so check the

identification marks before fitting in the direction shown in the diagram,

in order to avoid getting bearing ca number, and intake and exhaust

sides, mixed u .

Identification marks (stam ed on front and on bearing ca s No.2~5)

I: Intake side

E: Exhaust side

3. A ly sealant to the 6 ositions indicated in the diagram on the u er

surface of the cylinder head.

Semi-dry sealant: Three Bond 1207D

4. Fit camshaft bearing ca s so that front marks are in the direction

indicated.

5. Check the identification marks on the camshaft bearing ca fronts, so

that, as with bearing ca s No.2~5, there are no mistakes over intake

and exhaust sides.

6. Gradually tighten the bearing ca mounting bolts, 2~3 turns at a time, to

the s ecified torque.

Tightening torque: 20 ± 1 N·M

7. Check that the rocker arm is fitted correctly.

NB. Wi e away any traces of sealant squeezed out.

GFITTING CAMSHAFT OIL SEAL

1. A ly engine oil around the entire circumference of the oil seal li .

2. Insert oil seal using the s ecial camshaft oil seal installer tool

(MD998713), as shown in the diagram.

HAs when removing, hold the camshaft hexagonal art with a

wrench, then tighten the mounting bolts to the torque s ecified.

Tightening torque: 89 ± 9 N·M

Engine forward

direction

Bearing ca

No.2

Intake side

Exhaust side

marks

Engine forward direction

Engine forward

direction Front mark

4G6 ENGINE – CAMSHAFT, VALVE STEM SEAL 11A-9

IFITTING CAMSHAFT POSITION SENSOR SUPPORT

1. Remove any sealant on the camshaft osition sensor su ort.

2. A ly sealant to the camshaft osition sensor su ort flange, as

shown in the diagram, then fit to the cylinder head.

Semi-dry sealant: Three Bond 1207F

3. Tighten camshaft osition sensor su ort mounting bolts to the

torque s ecified.

Tightening torque: 14 ± 1 N·M

JFITTING CAMSHAFT POSITION SENSING CYLINDER

1. Set the exhaust camshaft dowel in in the osition shown in the

diagram (No.1 cylinder com ression to dead centre)

Note

It will turn slightly in a counter-clockwise direction, under ressure

from the exhaust valve s ring.

2. As shown in the diagram, fit the camshaft osition sensing cylinder

vain (small), so that it is a roximately 45° relative to the exhaust

camshaft dowel in.

3. Tighten the camshaft osition sensing cylinder mounting bolts to the

torque s ecified.

Tightening torque: 22 ± 4 N·M

KFITTING ROCKER COVER GASKET

1. Remove any sealant on the rocker cover gasket.

2. A ly sealant to 4 locations on the rocker cover lower surface, as

shown in the diagram.

Semi-dry sealant: Three Bond 1207D

3. Fit the rocker cover gasket to the rocker cover.

Vain (small)

A rox. 45° Dowel in

Vain (large)

4G6 ENGINE – CAMSHAFT, VALVE STEM SEAL

11A-10

LFITTING CAMSHAFT END SEALS

A ly sealant to the locations on the camshaft end seal, as shown in the

diagram, then fit to the cylinder head.

Semi-dry sealant: Three Bond 1211

MFITTING ROCKER COVER ASSY

1. A ly sealant to the 6 locations on the rocker cover gasket, as shown

in the diagram.

Semi-dry sealant: Three Bond 1207D

2. Fit the rocker cover ASSY to the cylinder head.

NCONNECTING RADIATOR UPPER HOSE

1. Insert radiator u er hose as far as the rotrusion on the water outlet

fitting.

2. Align the radiator u er hose and hose clam matching marks to fit the

radiator u er hose.

Cylinder head

Engine forward direction

Protrusion

Water outlet

fitting Matching mark

4G6 ENGINE – TIMING BELT, TIMING BELT B 11A-11

TIMING BELT and TIMING BELT B

Removal and Fitting

Caution

When Brembo brake callipers are used, there is concern over paint peeling off, so when doing servicing work, make

sure they are not scratched by other components and tools. Furthermore, if any brake fluid gets onto the calipers, it

should be wiped off immediately.

Jobs to do before removal and after fitting

• Removal and fitting of undercover (refer to Cha ter 51 Front Bum er)

• Removal and fitting of LH side cover

• Checking drive belt tension <only after fitting>

• Removal and fitting of crank shaft ulley

• Removal and fitting cross member bar

• Removal and fitting of front exhaust i e

Removal procedure

1. Timing belt front u er cover

2. Water um ulley

3. Idler ulley

4. Drive belt auto-tensioner

5. Timing belt front lower cover

• Timing belt tension adjustment

6. Timing belt

7. Tensioner ulley

8. Connecting earth cable

9. Auto-tensioner

10. Idler ulley

G

A F

E

D

4G6 ENGINE – TIMING BELT, TIMING BELT B

11A-12

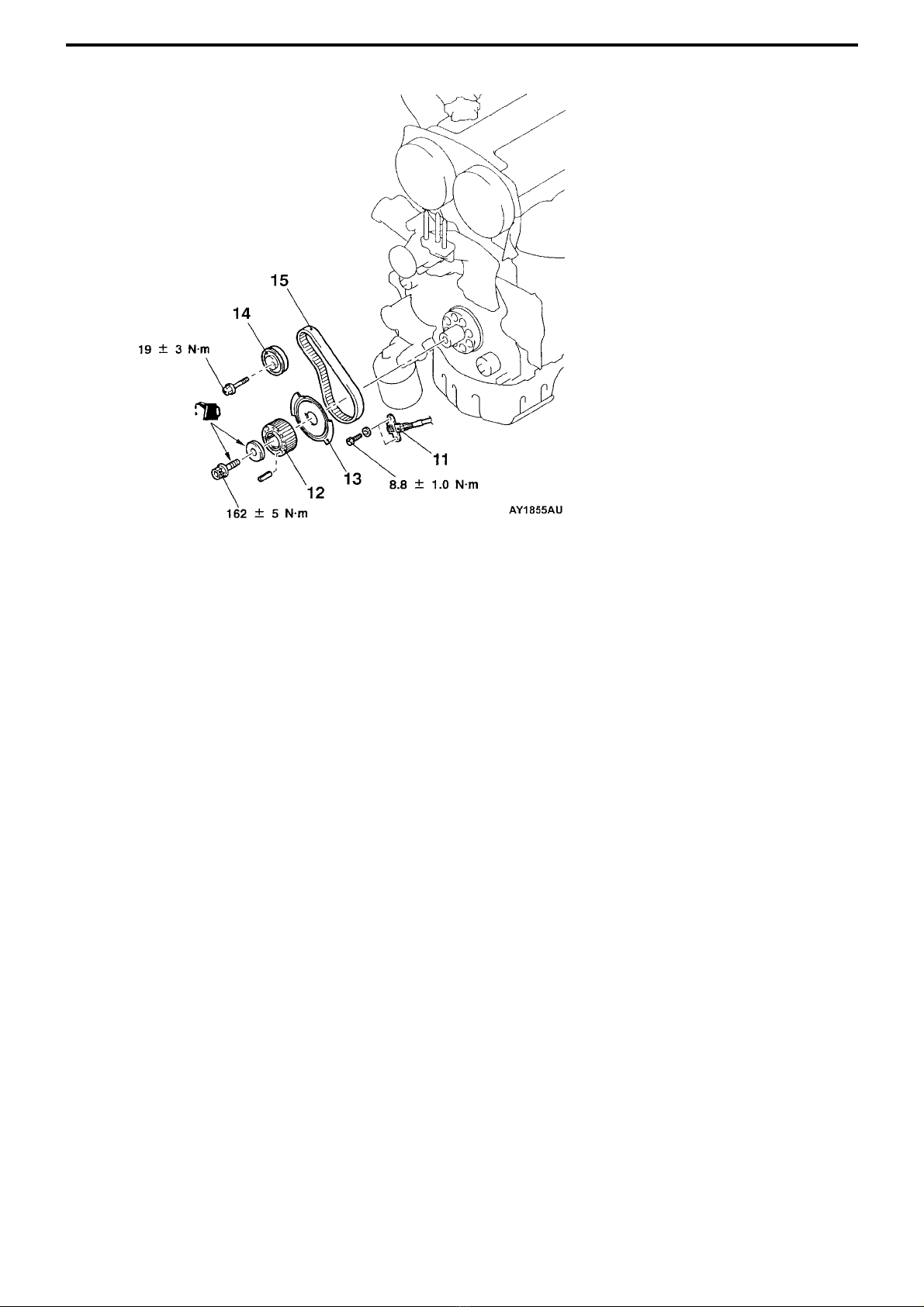

11. Crank angle sensor

12. Crank shaft s rocket

13. Crank shaft sensing blade

• Timing belt B tension adjustment

14. Timing belt B tensioner

15. Timing belt B

B C

C

B

A

C A

Note

Carry out removal and fitting in accordance with existing

instructions

(Engine oil)

MPI (Multipoint Injection)

SECTION 13A

13A-1

CONTENTS

General..................................................................... 2

Special tools ............................................................3

Troubleshooting ......................................................5

Injectors ...................................................................100

Engine control registers and relays.......................102

MPI - GENERAL

13A-2

General

The following changes have been made to vehicles fitted with the 4G63-DOHC-T/C engine. Otherwise the system remains the

same.

• The engine ECU has been changed

• An immobiliser system has been fitted

• A lated metal delivery i e has been ado ted

• Fuel um relay mounting osition has been changed

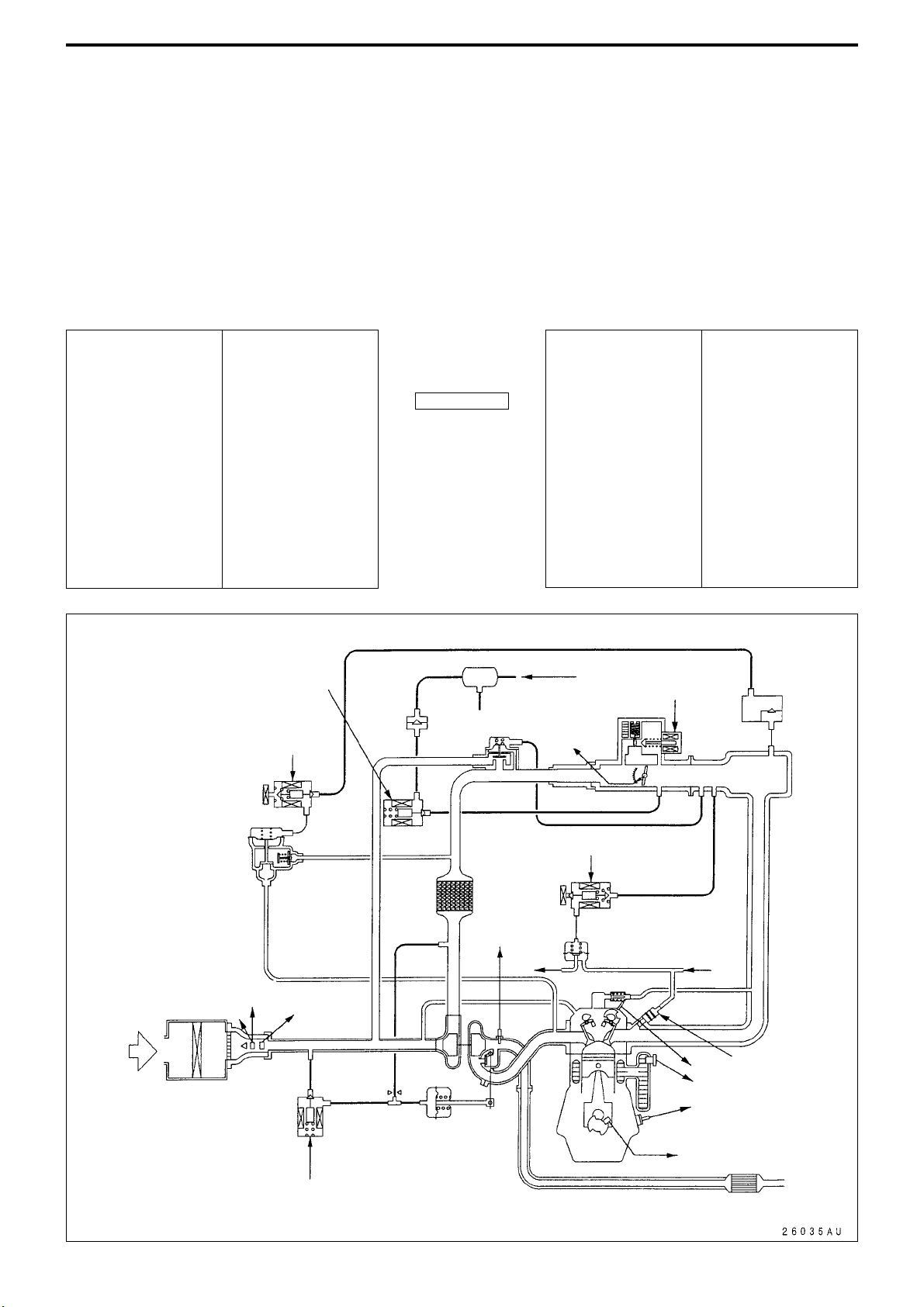

MPI SYSTEM DIAGRAM

Canister

✩2. ISC servo Vacuum

tank

By- ass

valve

Check

valve

✩5. Purge control

solenoid valve

✩6. Secondary air control

solenoid valve

Secondary air valve ✩3. Fuel ressure control solenoid valve

★1. O2

sensor Fuel

ressure

regulator

From

fuel

um

Intake

★2. Air flow sensor

★7. Barometric ressure sensor ★3. Intake

air tem .

sensor

✩4. Waste gate solenoid valve

Waste gate

actuator

Catalytic converter

★6. Crank angle sensor

★8. Water tem . sensor

✩1. Injector

From fuel tank

★4. Throttle

osition

sensor

Engine ECU

★1. O2 sensor

★2. Air flow sensor

★3. Intake air tem .

sensor

★4. Throttle osition

sensor

★5. Cam osition

sensor

★6. Crank angle

sensor

★7. Barometric

ressure sensor

★8. Water tem .

sensor

★9. Knock sensor

• Power su ly

• Ignition switch IG

• Ignition switch ST

• Vehicle s eed

sensor

• A/C switch

• A/C load signal

• Power steering

fluid ressure switch

• Alternator FR signal

• Intercooler water

s ray switch (auto)

• Intercooler water

s ray switch (manual)

✩1. Injector

✩2. ISC servo

✩3. Fuel ressure

control solenoid valve

✩4. Waste gate

solenoid valve

✩5. Purge control

solenoid valve

✩6. Secondary air

control solenoid valve

• Engine control relay

• Fuel um relay 2,3

• A/C relay

• Ignition coil

• Fan controller

• Condenser fan Relay

(HI)

• Condenser fan relay

(LO)

• Engine warning light

• Diagnosis out ut

• Alternator G terminal

• Intercooler water

s ray relay

• Intercooler water

s ray lam

• Tachometer

➩➩

★5. Cam osition sensor

★9. Knock sensor

To fuel

tank

Other manuals for Lancer Evolution-VIII

1

Table of contents