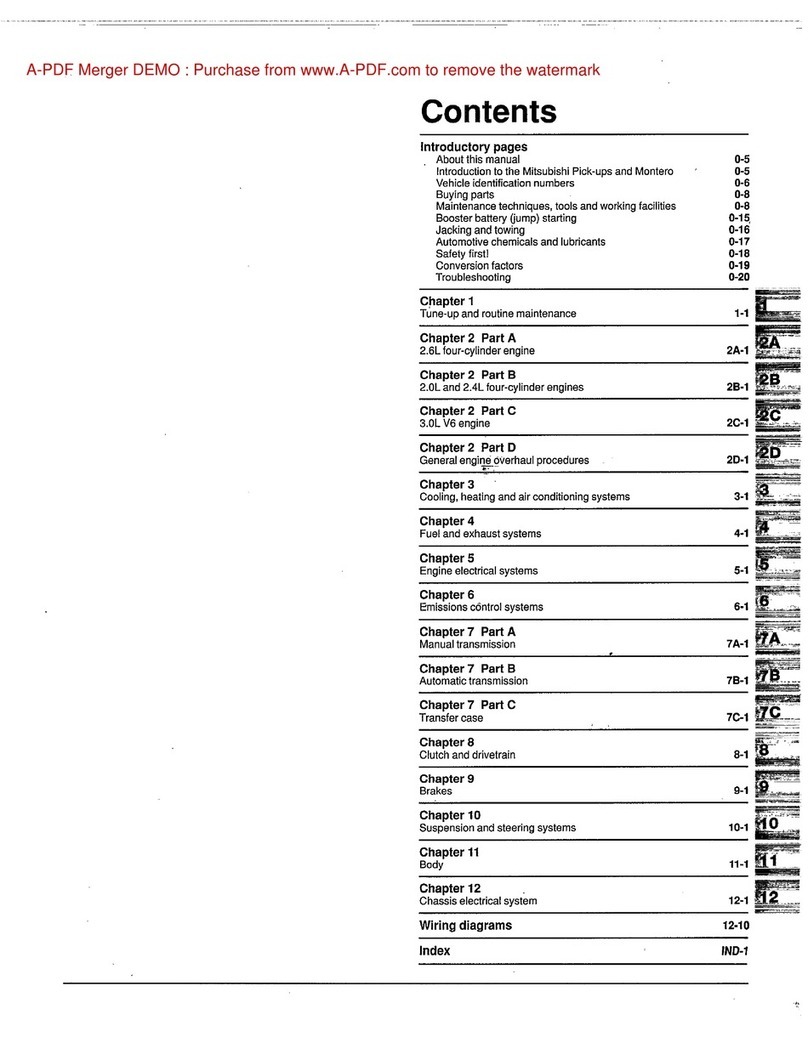

1-2 GENERALINFORMATIONANDMAINTENANCE

Chitton’sTotalCarCaremanualforthe199M10

MitsubishiMirage,GalantandDiamanteis intended

to helpyoulearnmoreabouttheinnerworkingsof

yourvehiclewhilesavingyoumoneyonitsupkeep

andoperation.

Thebeginningofthebookwill likelybereferredto

themost,sincethatiswhereyouwill findinformation

for maintenanceandtune-up.Theothersectionsdeal

withthemorecomplexsystemsofyourvehicle.Oper-

atingsystemsfromenginethroughbrakesarecov-

eredtotheextentthattheaveragedo-it-yourselferbe-

comesmechanicallyinvolved.Thisbookwill not

explainsuchthingsasrebuildingadifferentialforthe

simplereasonthattheexpertiserequiredandthein-

vestmentinspecialtoolsmakethistaskuneconomi-

cal.Itwill, however,giveyoudetailedinstructionsto

helpyouchangeyourownbrakepadsandshoes,re-

placesparkplugs,andperformmanymorejobsthat

cansaveyoumoney,giveyoupersonalsatisfaction

andhelpyouavoidexpensiveproblems.

A secondarypurposeofthisbookis areferencefor

ownerswhowanttounderstandtheirvehicleand/or

theirmechanicsbetter.Inthiscase,notoolsatallare

required.

Beforeremovinganybolts,readthroughtheentire

procedure.Thiswill giveyoutheoverallviewofwhat

toolsandsupplieswill berequired.Thereis nothing

morefrustratingthanhavingtowalktothebusstop

onMondaymorningbecauseyouwereshortonebolt

onSundayafternoon.Soreadaheadandplanahead.

Eachoperationshouldbeapproachedlogicallyand

allproceduresthoroughlyunderstoodbeforeattempt-

inganywork.

Allsectionscontainadjustments,maintenance,re-

movalandinstallationprocedures,andinsomecases,

repairoroverhaulprocedures.Whenrepairisnotcon-

sideredpractical,wetellyouhowtoremovethepart

andthenhowto installthenewor rebuiltreplacement.

Inthisway,youatleastsavelaborcosts.“Backyard”

repairofsomecomponentsisjustnotpractical.

Manyproceduresinthisbookrequireyouto “label

anddisconnect.. ” agroupoflines,hosesorwires.

Don’tbelulledintothinkingyoucanrememberwhere

everythinggoes-you won’t.Ifyouhookupvacuum

orfuellinesincorrectly,thevehiclemayrunpoorly,if

atall.Ifyouhookupelectricalwiringincorrectly,you

mayinstantlylearnaveryexpensivelesson.

Youdon’tneedto knowtheofficialorengineering

nameforeachhoseorline.A pieceofmaskingtape

onthehoseandapieceonitsfittingwill allowyouto

assignyourownlabelsuchastheletterA orashort

name.As longasyourememberyourowncode,the

linescanbereconnectedbymatchingsimilarletters

ornames.Dorememberthattapewill dissolvein

gasolrneorotherfluids;if acomponentisto be

washedorcleaned,useanothermethodof identifica-

tion.A permanentfelt-tippedmarkerorametalscribe

canbeveryhandyfor markingmetalparts.Remove

anytapeor paperlabelsafterassembly.

It’snecessarytomentionthedifferencebetween

maintenanceandrepair Maintenanceincludesrou-

tineinspections,adjustments,andreplacementof

partswhichshowsignsof normalwear Maintenance

compensatesforwearordeterioration.Repairimplies

thatsomethinghasbrokenor is notworking.A need

forrepairis oftencausedbylackofmaintenance.Ex-

ample,drainingandrefillingtheautomatictransaxle

fluidis maintenancerecommendedbythemanufac-

tureratspecificmileageintervals.Failuretodothis

canshortenthelifeofthetransmission/transaxle,re-

quiringveryexpensiverepairs.Whilenomaintenance

programcanpreventitemsfrombreakingorwearing

out,ageneralrulecanbestated:MAINTENANCEIS

CHEAPERTHANREPAIR.

Twobasicmechanrc’srulesshouldbementioned

here.First,whenevertheleftsideofthevehicleoren-

gineis referredto,it ismeanttospecifythedrivers

side.Conversely,therightsideofthevehiclemeans

thepassengersside.Second,screwsandboltsare

removedbyturningcounterclockwise,andtightened

byturningclockwrseunlessspecificallynoted.

Safetyisalwaysthemostimportantrule.Con-

stantlybeawareofthedangersinvolvedinworking

onanautomobileandtaketheproperprecautions.

SeetheinformatroninthissectionregardingSER-

VICINGYOURVEHICLESAFELYandtheSAFETY

NOTICEontheacknowledgmentpage.

Payattentiontotheinstructionsprovided.There

are3 commonmistakesinmechanicalwork:

1. Incorrectorderofassembly,disassemblyor

adjustment.Whentakingsomethingapartorputting

ittogether,performingstepsinthewrongorderusu-

allyjustcostsyouextratime;however,it CANbreak

something.Readtheentireprocedurebeforebegin-

ningdisassembly.Performeverythingintheorderin

whichtheinstructionssayyoushould,evenifyou

can’timmedratelyseeareasonfor it.Whenyou’re

takingapartsomethingthatisveryintricate,you

mightwantto drawapictureof howit lookswhenas-

sembledatonepointinordertomakesureyouget

everythingbackin itsproperposition.Wewill supply

explodedviewswheneverpossible.Whenmaking

adjustments,performthemintheproperorder.One

adjustmentpossiblywill affectanother.

2. Overtorquing(orundertorquing).Whileit is

morecommonforovertorquingtocausedamage,

undertorquingmayallowafastenertovibrateloose

causingseriousdamage.Especiallywhendealing

withaluminumparts,payattentiontotorquespecifi-

cationsandutilizeatorquewrenchinassembly.Ifa

torquefigureis notavailable,rememberthatifyou

areusingtherighttooltoperformthejob,youwill

probablynothavetostrainyourselftogetafastener

tightenough.Thepitchofmostthreadsis soslight

thatthetensionyouputonthewrenchwill bemulti-

pliedmanytimesinactualforceonwhatyouare

tightening.A goodexampleofhowcriticaltorqueis

canbeseeninthecaseofsparkpluginstallation,es-

peciallywhereyouareputtingtheplugintoanalu-

minumcylinderhead.Toolittletorquecanfailto

crushthegasket,causingleakageofcombustion

gasesandconsequentoverheatingoftheplugand

engineparts.Toomuchtorquecandamagethe

threadsordistorttheplug,changingthesparkgap.

Therearemanycommercialproductsavailablefor

ensuringthatfastenerswon’tcomeloose,evenifthey

arenottorquedjustright(averycommonbrandis

Loctite? Ifyou’reworried

about

gettingsomething

togethertightenoughto hold,butlooseenoughto

avoidmechanicaldamageduringassembly,oneof

theseproductsmightoffersubstantialinsurance.Be-

forechoosingathreadlockingcompound,readthe

labelonthepackageandmakesuretheproductis

compatiblewiththematerials,fluids,etc.involved.

3. Crossthreading.Thisoccurswhenapartsuch

asaboltisscrewedintoanutorcastingatthewrong

angleandforced.Crossthreadingismorelikelyto

occurifaccessisdifficult.Ithelpstocleanandlubri-

catefasteners,thentostartthreadingthebolt,spark

plug,etc.withyourfingers Ifyouencounterresis-

tance,unscrewthepartandstartoveragainatadif-

ferentangleuntilit canbeinsertedandturnedseveral

timeswithoutmucheffort.Keepinmindthatmany

parts,especiallysparkplugs,havetaperedthreads,

sothatgentleturningwill automaticallybringthepart

you’rethreadingtotheproperangle.Don’tputa

wrenchonthepartuntilits beentightenedacouple

ofturnsbyhand.Ifyousuddenlyencounterresis-

tance,andtheparthasnotseatedfully,don’tforceit.

Pullit backoutto makesureit’scleanandthreading

properly.

Besuretotakeyourtimeandbepatient,andal-

waysplanahead.Allowyourselfampletimeto per-

formrepairsandmaintenanceYoumayfindmain-

tainingyourcarasatisfyingandenjoyable

experience.

b SeeFigures1 thru15

Naturally,withoutthepropertoolsandequipment

it is impossibleto properlyserviceyourvehicle.It

wouldalsobevirtuallyimpossible

to

catalogevery

toolthatyouwouldneedto performall oftheopera-

tions inthisbook.Ofcourse,Itwouldbeunwisefor

theamateurto rushoutandbuyanexpensivesetof

toolsonthetheorythathe/shemayneedoneor more

ofthematsometime,

Thebestapproachisto proceedslowly,gathering savingswill

be

faroutweighedbyfrustrationand

agoodqualitysetofthosetoolsthatareusedmost mangledknuckles.

frequentlyDon’tbemisledbythelowcostofbargain Beginaccumulatingthosetoolsthatareusedmost

tools.It isfarbetterto spenda littlemorefor better frequently:thoseassociatedwithroutinemaintenance

quality.Forgedwrenches,6 or12-pointsocketsand andtune-up.Inadditiontothenormalassortmentof

finetoothratchetsarebyfarpreferabletotheirless screwdriversandpliers,youshouldhavethefollow-

expensivecounterparts.Asanygoodmechaniccan ingtools:

tellyou,therearefewworseexperiencesthantrying

l

Wrenches/socketsandcombinationopen

toworkonavehiclewithbadtools.Yourmonetary end/boxendwrenchesinsizesfrom%-% in.or