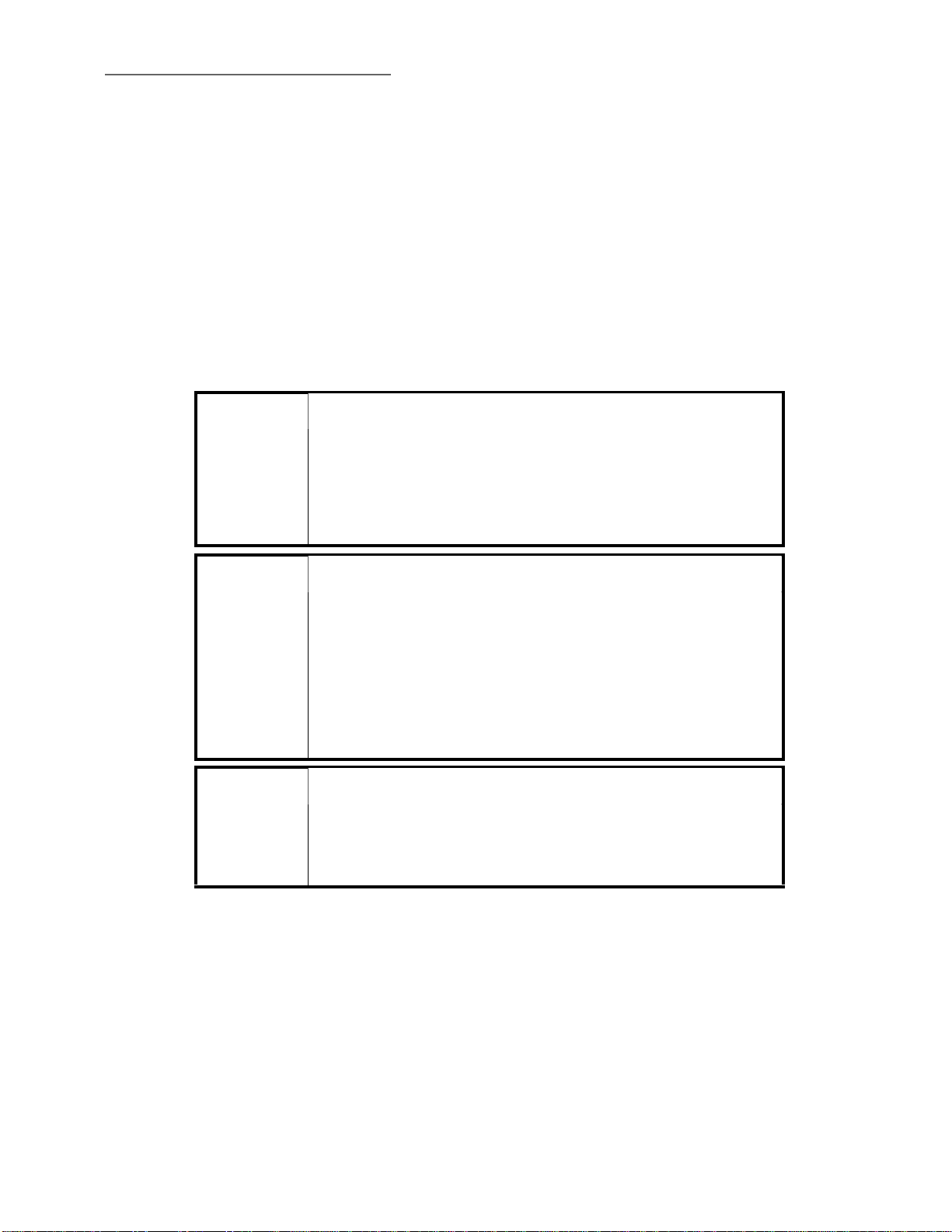

Catalog numbers for Series 835 VQM®Differential Pump Systems

835 VQM Differential Pump System

Product/Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Catalog Number

Differential Pump System, MS Gauge, Total Pressure Gauge, Cross Fitting, 835901- DPS -#(a) # # - #(b)

Roughing Pump, Turbo Pump, Orifice, Power Supply & Cord

Pressure Range: 90 mTorr to 3000 mTorr . . . . . . . . . . . . . . . . . . . Orifice Size 1

Pressure Range: 9 mTorr to 350 mTorr . . . . . . . . . . . . . . . . . . . . . Orifice Size 2

Pressure Range: 1 mTorr to 45 mTorr . . . . . . . . . . . . . . . . . . . . . . Orifice Size 3

Pressure Range: .05 mTorr to 2.2 mTorr . . . . . . . . . . . . . . . . . . . . Orifice Size 4

Pressure Range: .02 mTorr to 1 mTorr . . . . . . . . . . . . . . . . . . . . . Orifice Size 5

No Bypass Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N

Manual Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M

Pneumatic Valve (24 Vdc) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P

Mass Range AMU 1-145 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Mass Range AMU 1-300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power Cord (b) (see below) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . #

(a) = Size of Orifice (1 through 5) - see above.

(b)= Power Cord: -1 = North American 115 VAC & Japan 100 VAC, -2 = North American 240 VAC,

-3 = Universal European 220 VAC, -4 = United Kingdom 240 VAC

835 VQM Controller and Software

NOTE: The following items are required for system operation, but are not

included with the Differential Pump System catalog number listed above.

Controller, Single Gauge, Benchtop Mount, USB 2.0, Power Supply & Cord . . . . . . . . . . 835500-U#- #

Mass Range AMU 1-145 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Mass Range AMU 1-300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power Cord for VQM Controller (b) (see above) . . . . . . . . . . . . . . . . . . . . . . . . . #

Cable - VQM Controller to VQM Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 835300-##M

1 meter (3.28 ft) long . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01

3 meters (9.84 ft) long . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

Cable - VQM Controller to 390 Micro-Ion ATM Module. . . . . . . . . . . . . . . . . . . . . . . . . 802301-##M

1 meter (3.28 ft) long . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01

3 meters (9.84 ft) long . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

10 meters (32.8 ft) long . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CD- 835 VQM Software Suite (Viewer Application Software, LabVIEW VI) . . . . . . . . . . . . . . . 835400

835 VQM Differential Pumping Options / Replacements

KF40 Adapter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801210-K

Isolation Valve Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801700-#-K

Manual Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M

Pneumatic Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P

Orifice Valve Hardware Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801701-#-K

Manual Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M

Pneumatic Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P

Hardware/Bolt Kit - includes 6 flange bolts & washers, 3 plate nuts, & 1 copper gasket . . . 801274-1

Bolt Kit for Orifice when no Gate Valve is used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801207-K

Field Replaceable Filament Assembly Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 830105-Y-K

Field Replaceable Electron Multiplier Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 835110-K

Orifice for Gate Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801211-#(a)

Orifice for when no Gate Valve is used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801212-#(a)

#(a) = Size of Orifice (1 through 5) - see above.

Windows, Windows XP, and Windows 7 are registered trademarks of Microsoft Corporation.

LabVIEW is a registered trademark of National Instruments Corporation.