2

TABLE OF CONTENTS

Dear User,............................................................................................................................... 3

1. Overview ............................................................................................................................ 3

1.1. Safety Instructions........................................................................................................... 3

1.2. Warranty Terms and Conditions .................................................................................... 5

1.3. Fuel.................................................................................................................................. 6

1.3.1. Burning Other Fuels ..................................................................................................... 7

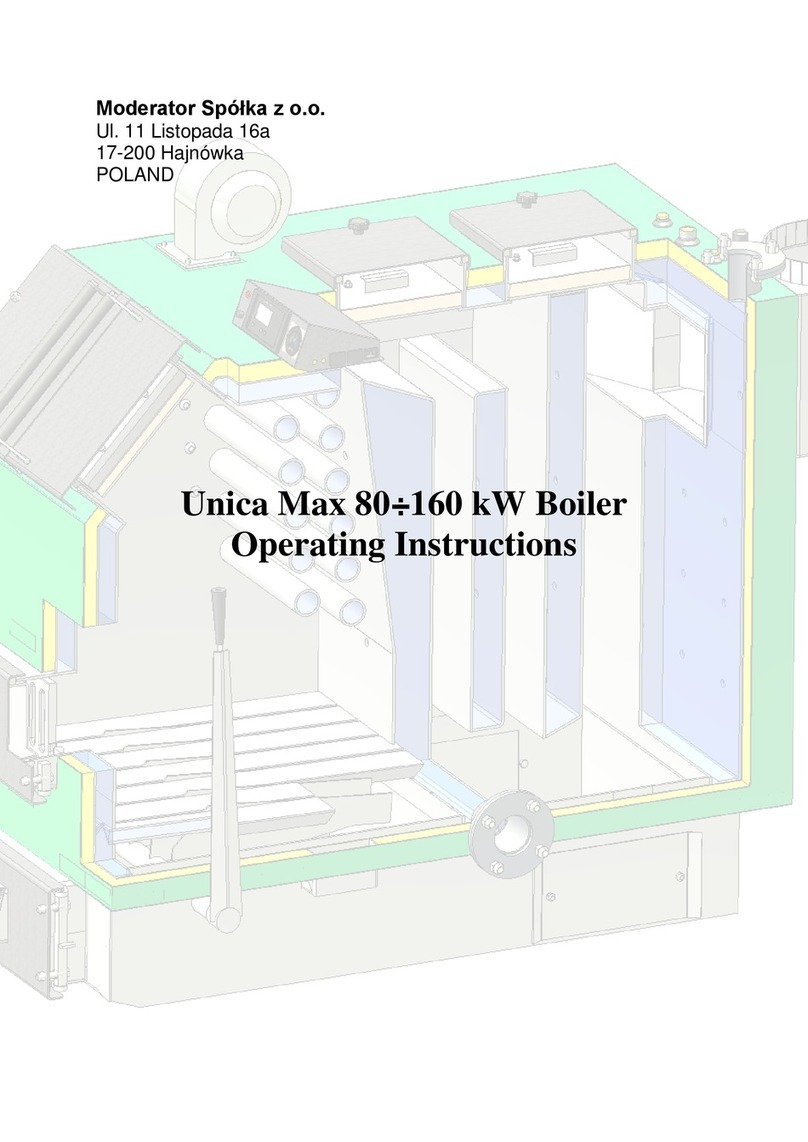

1.4. Technical Description ..................................................................................................... 7

1.5. Equipment ....................................................................................................................... 8

2. Installation.......................................................................................................................... 8

2.1. General parameters.......................................................................................................... 8

2.2. Boiler Room .................................................................................................................. 11

2.3. Boiler Installation.......................................................................................................... 11

2.4. Connecting to the Chimney........................................................................................... 11

2.5. Boiler connection to the central heating system............................................................ 12

2.6 Connecting the boiler to electric installation.................................................................. 13

2.7. Protection of the Installation ......................................................................................... 19

2.7.1. Open systems.............................................................................................................. 19

2.7.2. Closed Systems .......................................................................................................... 20

2.7.3. Thermal protection ..................................................................................................... 22

3. Boiler operation................................................................................................................ 23

3.1. Controller – description, operation, servicing............................................................... 23

3.2. Igniting .......................................................................................................................... 25

3.3. Burning.......................................................................................................................... 25

3.4. Boiler and Chimney Cleaning ....................................................................................... 26

3.5. Planned shutdown of the boiler..................................................................................... 28

3.6. Emergency Shutdown of the Boiler .............................................................................. 28

4. Boiler Troubleshooting .................................................................................................... 29

4.1. Maintenance and overhauls........................................................................................... 29

5. Safe operation conditions ................................................................................................. 29

6. Disposal............................................................................................................................ 31

7. Connecting the boiler to automatic feeders...................................................................... 31

7.1. The boiler may be used with Automatic Biomass Burning Feeders “Smok” ŻL and

GC ........................................................................................................................................ 31

7.2. Boilers intended for pellets burners .............................................................................. 32

8. Boiler specifications......................................................................................................... 33

Due to on-going research & development work, the manufacturer

reserves the right to make boiler design and documentation

changes. Consequently certain elements of the boiler, as presented

on photographs or drawings in these instructions may differ from

elements as in delivered unit.