5-571.4

10

➀ After the thermostat calls for heat, the power exhauster relay is energized starting the power exhauster motor. Once the motor has reached full speed, the power

exhauster centrifugal switch closes energizing the gas control circuit.

10

START-UP PROCEDURE

Control Operating Sequence

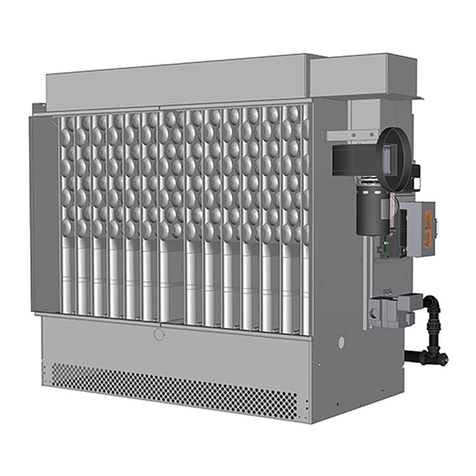

All Modine weatherproof duct furnaces are supplied with

intermittent pilot ignition systems. These systems are offered

with 100% shut-off with continuous retry for operation on

natural gas and 100% shut-off with lockout for units operating

on propane gas. On all systems, both the main burner and pilot

burner are turned off 100% when the thermostat is satisfied.

For natural gas units, the ignition controller is 100% shut-off

with continuous retry. On a call for heat, the system will attempt

to light the pilot for 70 seconds. If the pilot is not sensed for

any reason, the ignition control will wait for approximately six

minutes with the combination gas control closed and no spark.

After six minutes, the cycle will begin again. After three cycles,

some ignition controllers lockout for approximately one hour

before the cycle begins again. This will continue indefinitely until

the pilot flame is sensed or power is interrupted to the system.

For propane gas units, the ignition controller is 100% shut-off

with lockout. On a call for heat, the system will attempt to light

the pilot for 70 seconds. If the pilot is not sensed for any reason,

the ignition control will lockout, the pilot gas valve shut off and

the sparking discontinued. The system will not attempt to relight

until power has been interrupted to the controls and the controls

are reset via the thermostat.

NOTE: Gas Control Options (see page 12) could change the

listed sequence of operation based on their function.

The descriptions given are for the basic duct furnace.

Single-Stage Gas Controls

Utilizes a single-stage combination gas control, an ignition

control, and a single-stage low voltage thermostat.

1. The thermostat calls for heat. For HFP units, see ➀.

2. The pilot valve opens and the spark ignitor sparks in an

attempt to light the pilot. (If the unit was not provided with a

time delay relay, the blower starts at this time.)

3. Once the pilot is lit, the flame sensor proves the pilot and

stops the spark ignitor from sparking.

4. The main gas valve is opened and the main burner is lit to

100% full fire.

5. If the unit was provided with a time delay relay, the blower

starts after 30 to 45 seconds.

6. The unit continues to operate until the thermostat is

satisfied, at which time both the main and pilot valves close

100%. (If the unit was not provided with a time delay relay,

the blower stops at this time.)

7. If the unit was provided with a time delay relay, the blower

stops after 30 to 45 seconds.

Two-Stage Gas Controls

Utilizes a two-stage combination gas control, an ignition control,

and a two-stage low voltage thermostat. The unit fires at 50%

fire on low stage and 100% fire on high stage.

1. The thermostat calls for low stage heat. For HFP units, see ➀.

2. The pilot valve opens and the spark ignitor sparks in an

attempt to light the pilot. (If the unit was not provided with a

time delay relay, the blower starts at this time.)

3. Once the pilot is lit, the flame sensor proves the pilot and

stops the spark ignitor from sparking.

4. The main gas valve is opened and the main burner is lit to

50% fire.

5. If the unit was provided with a time delay relay, the blower

starts after 30 to 45 seconds.

6. If the temperature at the thermostat continues to fall, the

thermostat will call for high stage heat.

7. The main gas valve is opened completely and the main

burner is lit to 100% full fire.

8. The unit continues to operate until the high stage of the

thermostat is satisfied, at which time the main valve closes

to 50% fire.

9. The unit continues to operate until the low stage thermostat

is satisfied, at which time both the main and pilot valves

close 100%. (If the unit was not provided with a time delay

relay, the blower stops at this time.)

10. If the unit was provided with a time delay relay, the blower

stops after 30 to 45 seconds.

Electronic Modulating Gas Controls

Single Furnace

Utilizes an electronic modulating/regulating gas control,

combination gas valve, an ignition control, modulating amplifier,

and either a modulating room thermostat or modulating

duct thermostat with remote temperature set point adjuster.

The thermostat controls can modulate the gas flow between

40% through 100% full fire. When the thermostat is satisfied,

the amplifier cuts power to the combination gas valve which

prevents gas flow to both the main and pilot burners.

When duct sensing is utilized, a room override thermostat can

be added. When calling for heat, the room override thermostat

provides full fire operation until the space temperature is

satisfied. Control is then returned to the duct sensing control.

In this situation, either the duct sensor or the room override

thermostat can call for heat.

1. The thermostat calls for heat. For HFP units, see ➀.

2. The pilot valve opens and the spark ignitor sparks in an

attempt to light the pilot. (If the unit was not provided with a

time delay relay, the blower starts at this time.)

3. Once the pilot is lit, the flame sensor proves the pilot and

stops the spark ignitor from sparking.

4. The main gas valve is opened and the main burner is lit to

100% full fire.

5. If the unit was provided with a time delay relay, the blower

starts after 30 to 45 seconds.

6. The modulating gas valve can be controlled by either

an electronic modulating room or duct thermostat. The

thermostat can modulate the firing rate between 40%

through 100% full fire. The call for heat is created by a

resistance signal (8000 to 12000 ohms) in the thermostat.

The amplifier converts this resistance into a DC voltage (0

to 12 volts DC with 0 volts high fire and 12 volts low fire).

The output voltage is applied to the modulating gas valve to

control the gas flow to the main burner. As the temperature

drops, the voltage drops causing the modulating valve to

open further. If the discharge air temperature increases,

the voltage increases causing the modulating valve to

close allowing less gas flow to the main burner. For further

information regarding the operation of the electronic

modulating system, consult the literature provided with the

unit.

7. The unit continues to operate in this manner until the

thermostat is satisfied, at which time both the main and

pilot valves close 100%. (If the unit was not provided with a

time delay relay, the blower stops at this time.)

8. If the unit was provided with a time delay relay, the blower

stops after 30 to 45 seconds.

IMPORTANT

To prevent premature heat exchanger failure, with all control

systems, a blower starting mechanism must be provided so

that the blower is running or energized within 45 seconds of

the gas control operation.