3: General Installation

Before installation please read the following points:

• When placing in position ensure there is adequate access.

• Ensure that the unit is installed on a flat even surface

• Ensue that the table or counter where table top type units are sited can safely support the weight of the unit.

• These units can simply be butted up together to form a food service line.

• Mobile types roll into position and apply the brakes.

• Before installing, it is recommended that the floor is swept clean.

This equipment is designed to be operated by suitably qualified persons. It is the

responsibility of the Supervisor or equivalent to instruct users, provide suitable P.P.E.,

show the mains isolating switch location, and inform users that parts may become hot,

causing injury if touched.

To ensure the satisfactory operation and optimum eciency of this

unit, it is imperative that the ambient room conditions where the units

are being used do not exceed a room temperature of 25°c or exceed

a relative room humidity of 60%. Do not install units where there is high radiated heat,

e.g. direct sunlight, room heaters, or bright spot lights. Do not install units in draughty

conditions where the air movement is greater than 0.2mtr/sec.

(e.g. near doors, windows, air conditioning units or fans]

Should conditions exceed the above, the display units may not maintain food temperatures at the

required levels. E & R Moat cannot accept responsibility for the performance of the units being

used in extreme conditions.

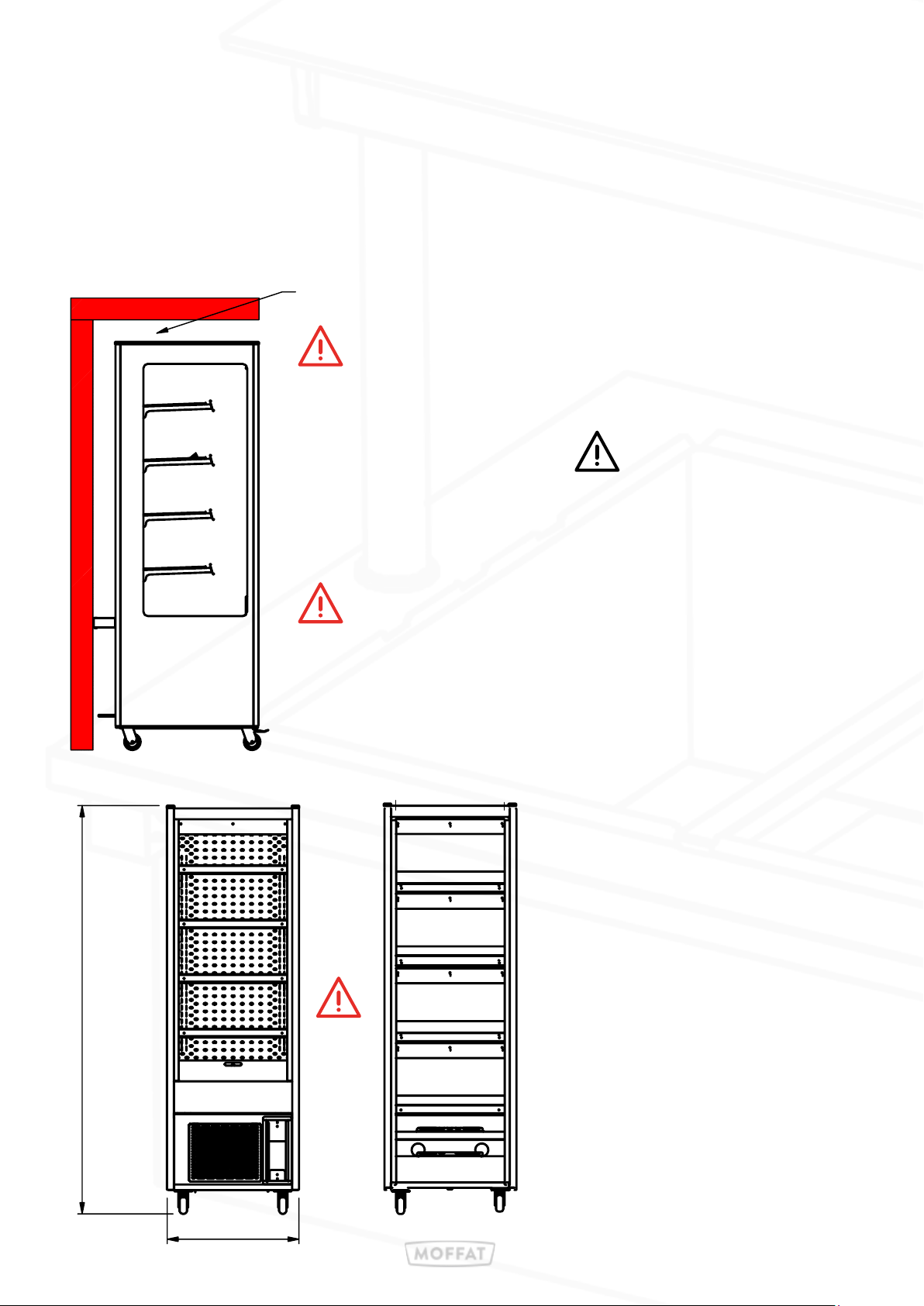

Moving Position.

Prior to moving the unit, it is essential to isolate and disconnect the power cord from the wall socket. This

precautionary measure helps prevent any electrical hazards during the repositioning process. Additionally, it is

important to stow the electrical power cord properly to avoid any potential damage while moving the unit.

Furthermore, it is crucial to note that the units are not designed to pass over ledges or obstacles. Care should be

taken to ensure that the wheels can move freely without any obstructions. It is also important to ensure that the

wheels never come into contact with the power cord, as this can cause damage to the cord and pose a safety risk.

By following these guidelines, the unit can be moved safely and without any unnecessary complications.

5