STEP 4:

Attach the supplied 1/2"-13 eye bolts to nearby suitable

supports using supplied lockwashers and nuts. Each

eye bolt should be as near to straight line opposite

each other as possible (see Figure 4). Effectively cre-

ating an imaginary line through the junction of the dou-

ble cable link bar center point with the AirBrake® arm.

While 180° is the optimum cable placement, it is allow-

able for the cables to form as small an angle as 90° on

the plane of the AirBrake® arm. Secure the free ends

of the restraining cables to the eyebolts by first insert-

ing one of the supplied thimbles through each eye bolt.

Pass each cable around its associated thimble and se-

cure with three wire rope clips on each cable. See Fig-

ure 5 for proper rope clip installation. Ensure that the

attachment of the cable to the support will not make the

cable more than plus or minus 10° out of level as illus-

trated in Figure 6. Remove as much slack as practical

from each cable. However, cables should NOT be

taught. Apply Loctite 262 (or equivalent) to the threads

of the rope clips and tighten the clips.

Table 1. Torque values for installation bolts.

STEP 5.

After installation of the restraining cables, check by hand

for free rotation of the fan in the normal direction. Then,

again by hand, attempt to rotate the fan in the back-

wards direction and ensure the AirBrake® is working

properly. In the normal rotation direction of the fan, it is

likely that both cables will be very slightly slack. In the

backwards direction one cable should be taught. En-

sure that neither cable may be in contact with any edge

or surface (moving or stationary) which might lead to

fraying and failure of the cable.

STEP 6.

Install all required guards and confirm there is sufficient

clearance for the AirBrake® .

STEP 7.

After all of the necessary guards have been installed,

run the fan at full speed, ensure that the cables are

not overly tight and are positioned properly with all

things working correctly.

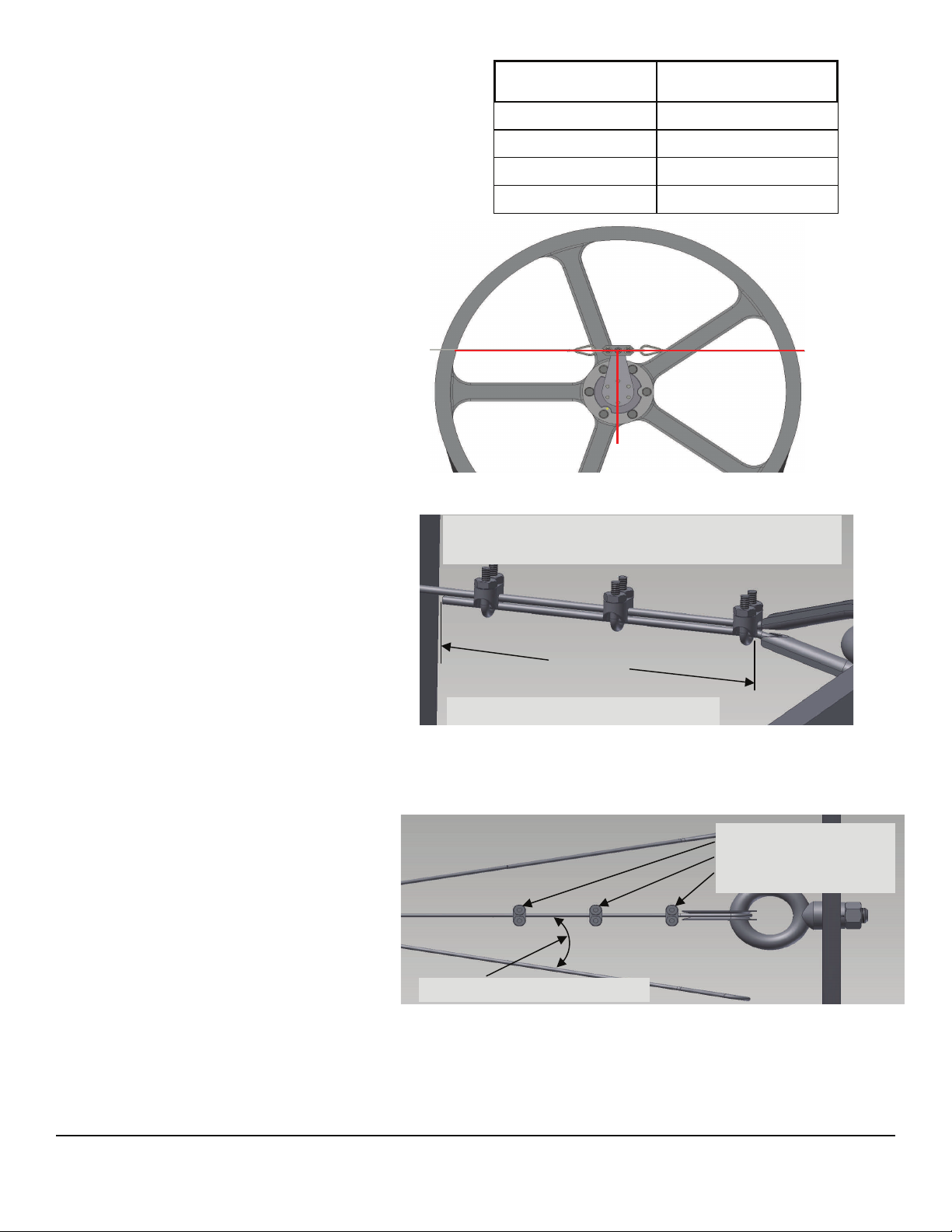

No more than ± 10° out of level

Use the wire rope clips

and apply Loctite to the

threads to secure cable.

Moore Fans

TMC 878 REV H (Jun 2018)

Live End

Figure 5. Proper installation of wire rope clips.

Figure 6. Restraining cable angle tolerance.

Dead End

Turnback

Position saddle side of the clip on the live end and the

u-bolt side of clip on the dead end

Allow 4.75 in (120.65mm) of turnback

Live End

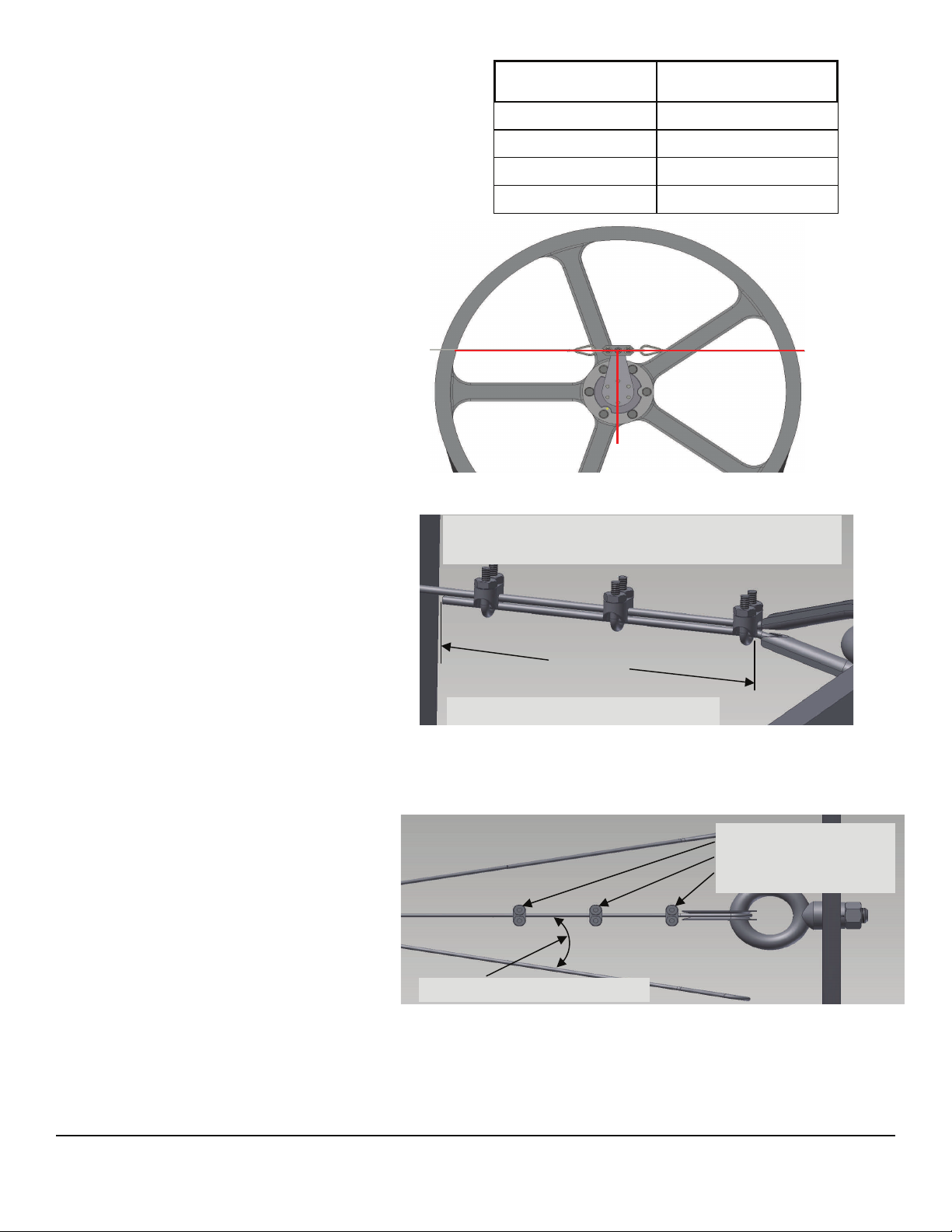

QD Bushing Size Torque

E 60 ft-lbs (8.3 kg-m)

F 75 ft-lbs (10.4 kg-m)

J 135 ft-lbs (18.7 kg-m)

SF 50 ft-lbs (6.9 kg-m)

800 S. Missouri Ave

Marceline, MO 64658

Phone: 660-376-3575

Fax: 660-376-2909

www.moorefans.com

Figure 4.