1.3.1 Installing, mounting of the boiler manipulation, operation, using, control and

†

maintenance of the boilers are forbidden if it is not in

Safety and economic operation of the boiler requests

†accordance with rules and directions of this instruction

a technical project made by authorized heating or manual. It is forbidden mainly to disconnect any of

civil engineer for whole heating system. safety units or elements in the boiler!!!

Mounting of the boiler could be carried out only by

†If the guarantee list is not filling fully, it is not valid

†

authorized company or persons.

On the boiler and 100mm before the boiler there is

†If you take the boiler from the colder

not allowed a placement of things from flammable environment to the warmer one (for

materials. example if the outside temperature is

The boiler mounted on the wall is not able to be

†below 0° C or 0° C and you want to mount

moved or placed to another place. it inside), please wait approximately 2

hours.

Boiler connection is allowed only with nut with flat

†

ring sealing. 1.3.3 Operation of the boiler

It is necessary to put heating water inlet with a filter

†The boiler has to be controlled and used only according

and shut off valves. †

to advices and instructions stated in this instruction

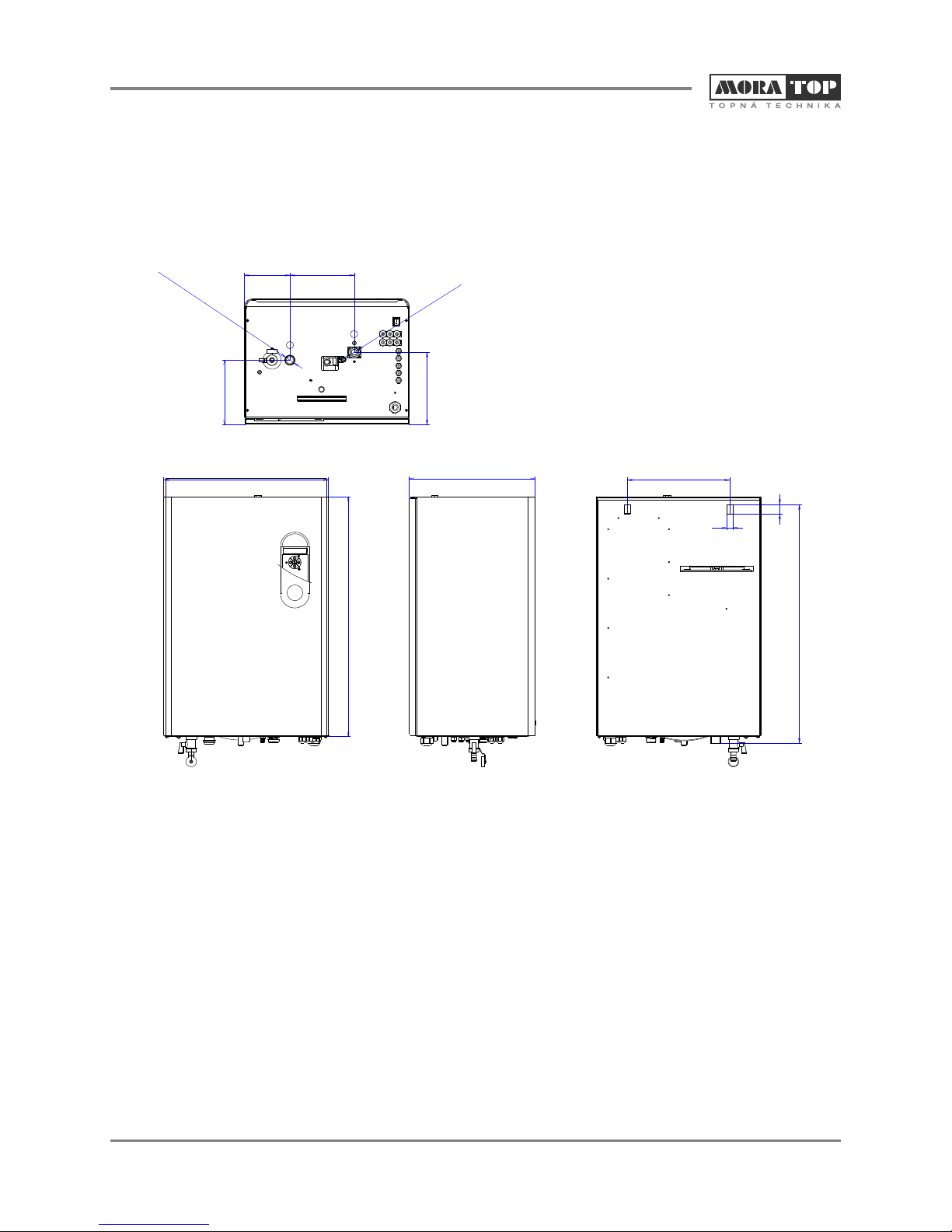

It is necessary to leave a free space on both side

†manual, only by adult person who was posted in

walls of the boiler 100 mm and minimally 400mm maintenance of the boiler. Putting the boiler into

from the top for after sales service. In case that you operation will made by authorized service person

will not observe this request for free space you have during the heating test.

to pay dismantling and mounting the boiler back to Any manipulation, operation, using and maintenance of

the wall and to heating system, it is not a repair paid †

the boiler, which is not in accordance with instructions

in guarantee period! and advices stated in this instruction manual, is

1.3.2 inadmissible. The producer is not responsible for

Putting the boiler into operation has to be carried out

†damages caused by wrong using and maintenance of

only by authorized professional company or service the boiler.

person that has a valid agreement signed with the The producer recommends periodical service controls

†

producer. The list of these companies is enclosed. of the boiler 1x per year before heating season. The

The company or person who will put the boiler into

†service control could be done only by a professional

operation has an obligation to assure repairs of authorized service company or person. The list of

breakdowns or defects in guarantee period. In case that service control steps recommend to be controlled

this company doesn't exist anymore, the guarantee before heating season you will find in the chapter

repair will be assured by any company from the list “maintenance”.

closed to you. The producer allows only room thermostat connection,

†

By putting the boiler into operation the authorized

†if the room thermostat has with potentional-free outlet

person is obligated to: connection. The authorized service person is

†control connections of the boiler to electric supply responsible during putting the boiler into operation to

network and to heating system fill and sign guarantee card.

†control tightness of the boiler If you find any breakdown or any defect on an electrical

†

†control all functions of the boiler part of the boiler, please, don´t repair it by yourself,

†inform the user about boiler operation, its control and disconnect the boiler from the electric supply network

maintenance and ask for after sales service person.

inform the user about safety dimensions from sides of

†It is not allowed to use the boiler Electra-Comfort for

†

the boiler from flammable walls and its protection another purposes than is stated in this instruction

according to ČSN 061008 and ČSN 730823. manual.

To fulfil requests for boiler safety and economic

†

operation it is necessary to observe below mentioned 1.3.4

conditions:

for boiler mounting and installing the user has to get the

†Fire instructions:

permission from the company who is a distributor of Disconnect the boiler from the electric

†

electricity in your region, control the input of the boiler if supply network and take out it out of its

it is in accordance with the input stated in the operation according to possibilities.

permission Extinguish fire using pulverized or

for mounting of the boiler it is necessary to have an

†snows extinguish appliance flammable

authorized technical project for heating system and for and explosive materials

connection of electric boiler Don't stock any flammable and explosive

†

the boiler is able to be mounted only in an environment

†things closed to the boiler (for example

according to its determination and according to the paper, colours, chemicals etc.)

project

Putting into operation

Safety

ELECTRA COMFORT 4