6Genuine OEM Parts 1.800.233.4823 www.morganolsonparts.com

Side Door Removal:

1. Remove the an rale clips.

2. Remove the 4 fasteners and the door handles (inner and outer).

3. Using a socket wrench, remove the bolts fastening the door and hanger assembly.

4. To simplify door removal, remove the grab handle located forward of the door.

*Fold side view mirror back.

5. Holding the top of the door in posion, pull out on the boom front corner of the door

unl it clears the body of the truck. Then lt the top of the door down and out and re-

move the door.

6. The upper track is mounted to the header channel. Remove the nuts, and the track.

Reinstall by reversing the removal sequence.

Weather Seal Removal:

1. The forward and rear weather seals are installed simply by sliding into a mated part. To

remove simply pull straight out from the top of the door or door frame. Install by feeding

into the mated part and sliding into place.

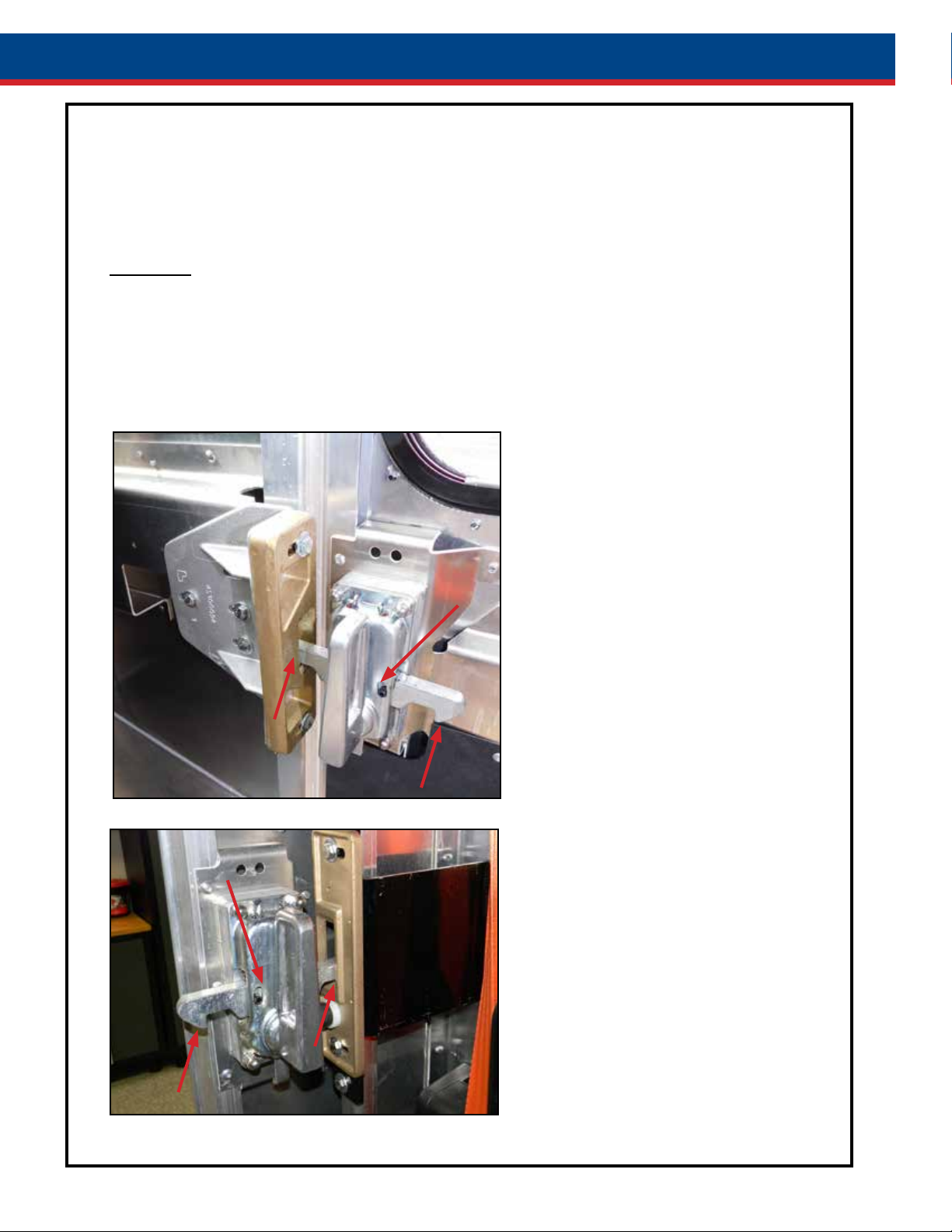

Handle Mechanism Removal:

1. To remove the door handles simply remove the 4 mounng screws. Pay special aenon

to spacer locaons. You can then remove the inside and outside handles. Remember

when installing the handles, posion of the spacers idencal to the way they were at

removal.

Wear Strip (Lower) Removal:

1. Remove side door.

2. Remove exisng rivets.

3. Replace wear strip and rivet in place.