Foundation

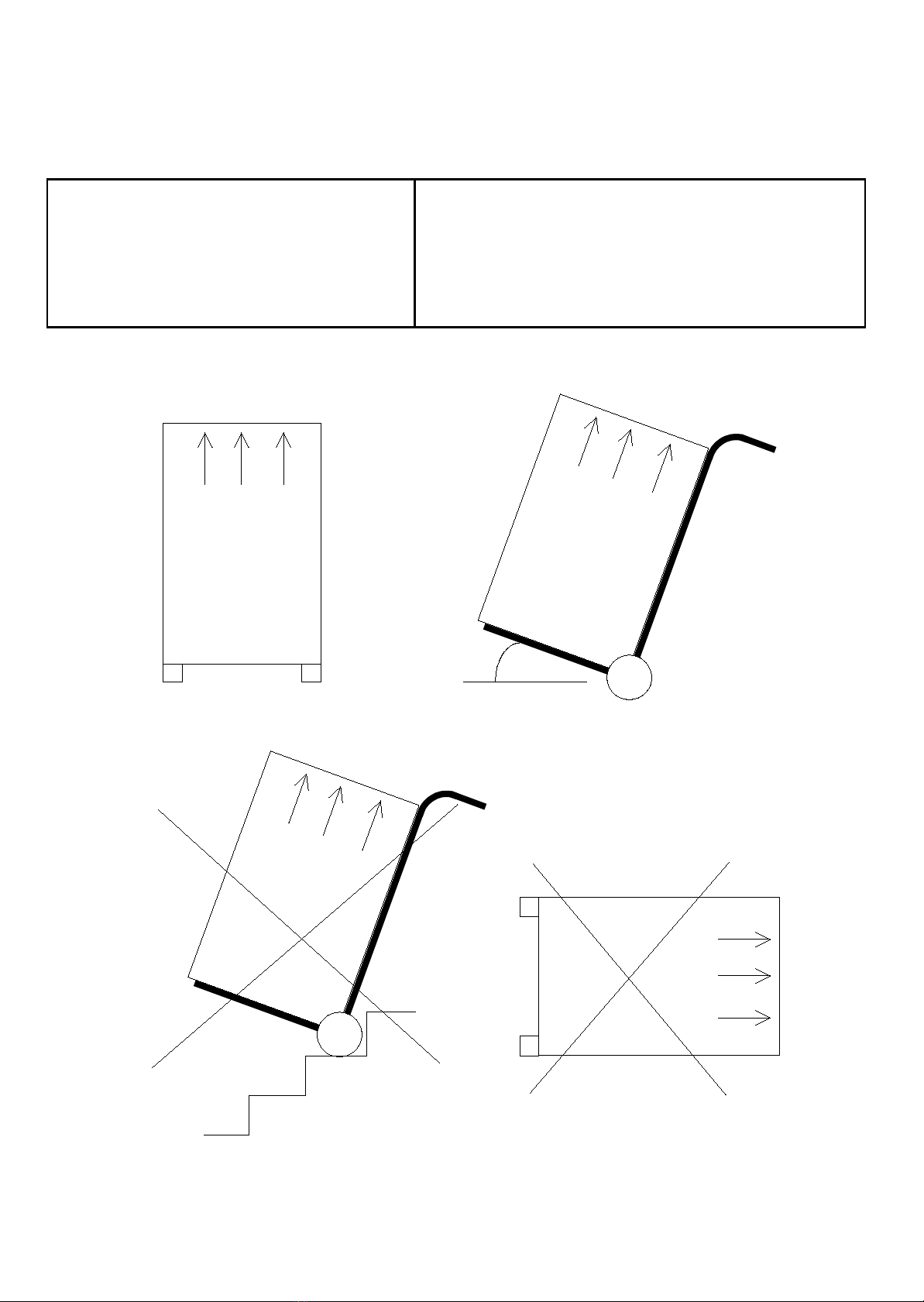

Site Installation

Installation

Structure-borne noise

Vibrations

Clearances

1. The condenser air is blown out vertically or horizontally.

2. Do not install the device close to heat sources. Heated air intake must be

avoided.

3. The condenser fans are rated for ZERO external static pressure. The fan

do not have the capacity to push air through ducting, which means that

NO DUCTS OR MUFFLERS may be used on the inlet ot outlet of the

chillers.

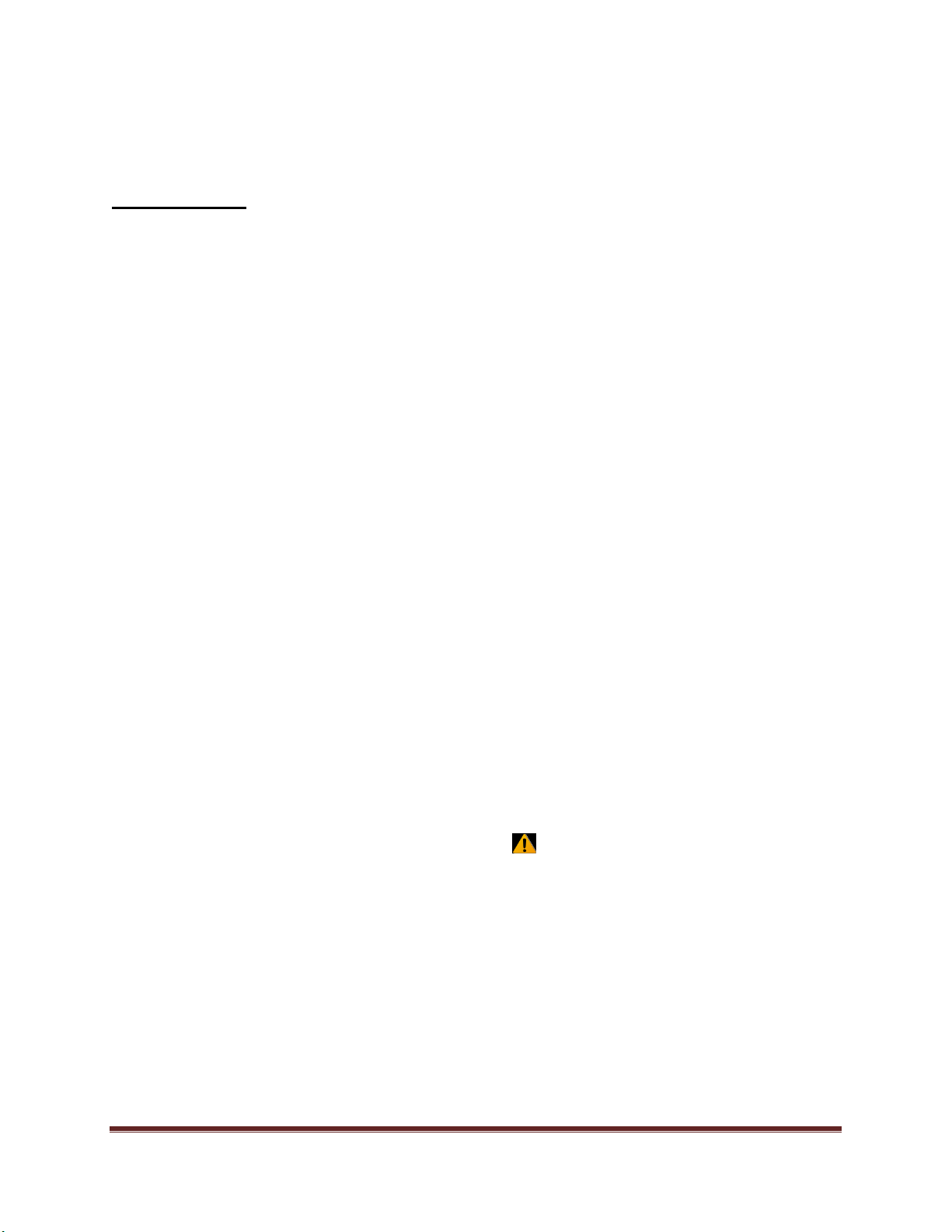

4. No air short-circuit is permitted, i.e. the heated discharge air from the

condenser fans must never be drawn back into the condenser inlet. This

will occur if the chiller is too close to a wall, or a low ceiling or other

obstructions.

5. In the case of shaft or trench mounting, contact the manufacturer for

advice on the installation site.

It ispossible thatnoise or vibration may betransmitted through the ground,

or building structure. If this occurs, it may benecessary toinstall a vibration

elimination device. The construction specifications ofthe

customer/engineering contractor regarding structure transmitted noise or

vibration must be observed.

May betransmitted through the chilled water piping. This can beavoided by

the use of flexible piping connections.

Must bemaintained for servicing and ventilation purposes. All removable

side panels must be available service.

*See CLEARANCE REQUIREMENTS section under MOTIVAIR INSTALLATION

ENGINEERING BULLETIN

CHILLER INSTALLATION

All chillers must be mounted ona solid, horizontal surface,suitable for the

weight of the chiller.* Note the chiller weight is incresed byfillingwith

glycol/water mixture.

Observe all local regulations.

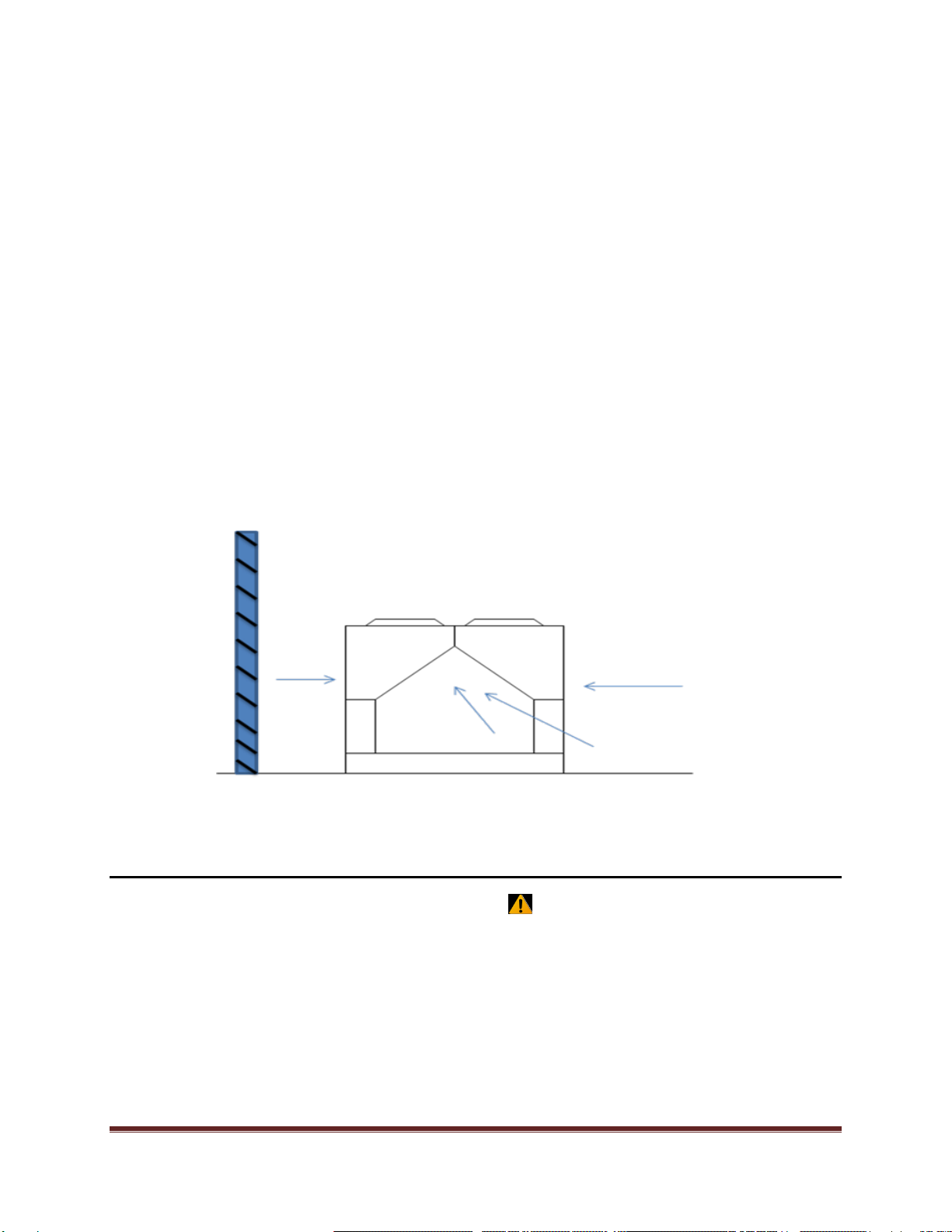

Compliance with the following basic rules for the erection ofdevices with

radial fans will ensure problem-free operation andthe rated refrigeration

capacity.

Basic rules: