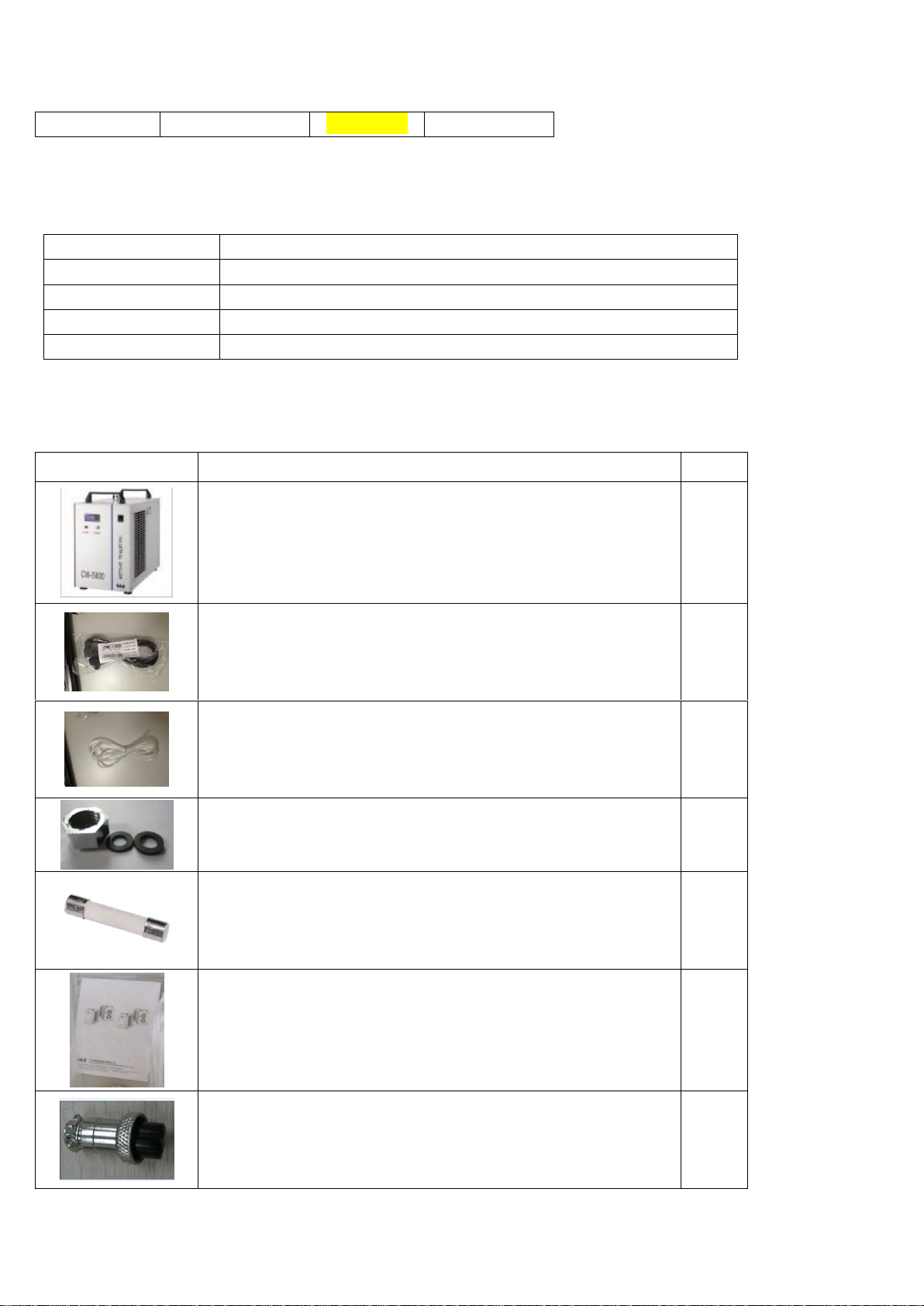

Industrial cooling machine’s installation is very simple, the new machine for the first time using, you can install it as

following steps.

A. Open the package to check if the machine is intact and all the necessary accessories are completed.

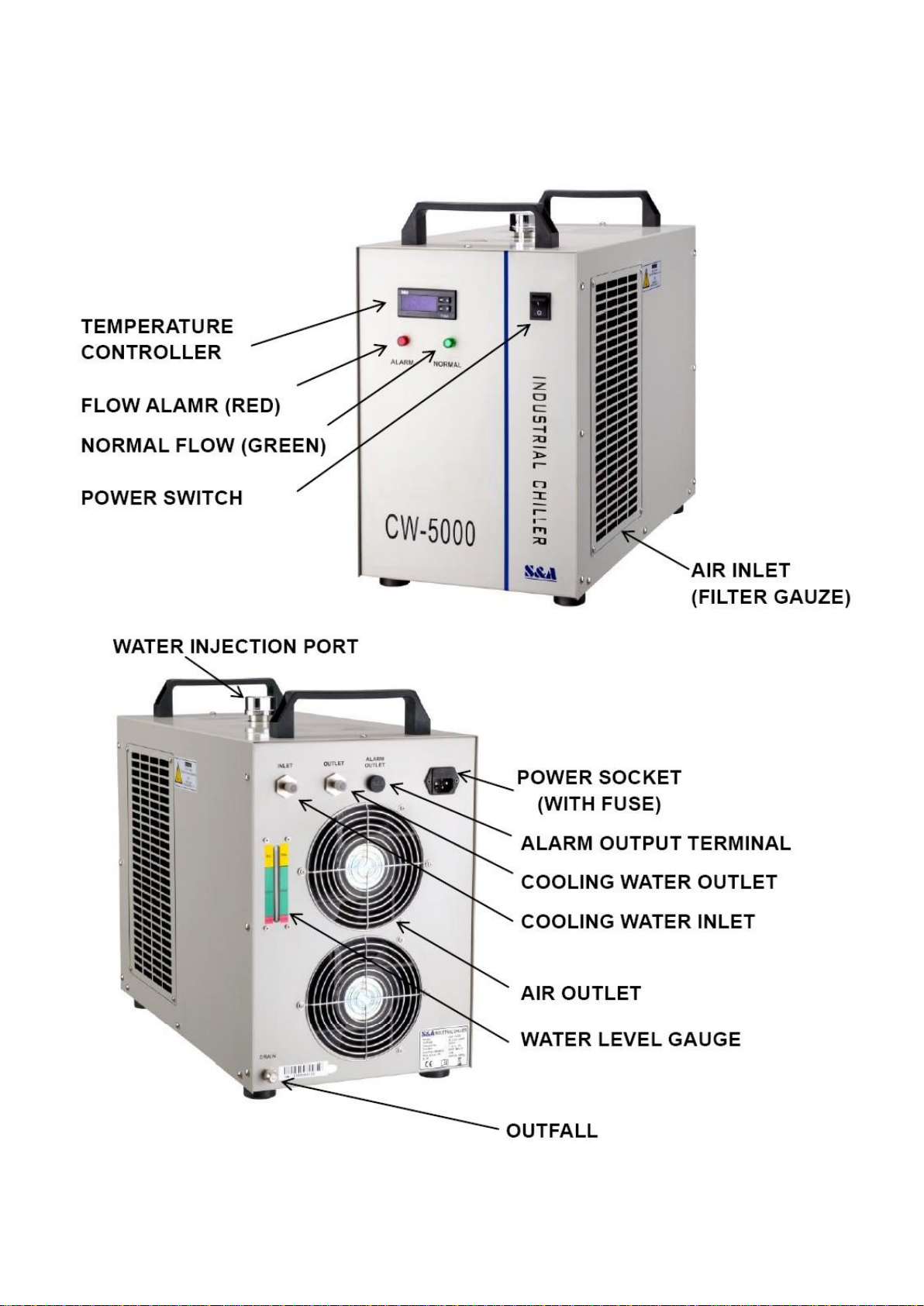

B. Open the injection port to feed cooling water.

Observing the water level gauge and adding water slowly, be careful not to have the water overflowed! For the cooling

of carbon steel equipment, the water should be added an appropriate amount of anti - corrosion agentia. Working in cold

north area, it’s better to use noncorrosive antifreeze fluid.

C. According to system conditions, please connect the water inlet and outlet pipe well.

D. Plug in power, turn on the power switch. (Do not start up without water in the water tank!)

(1) Power switch turned on, the circulation pump of the chiller starts working. The first time of operating may cause more

bubbles in the pipe leading to a flow alarming occasionally, but running for a few minutes later, it will go back to normal.

(2) After the first boot, you must immediately check whether the water pipe leaks.

(3) Power switched on, if the water temperature is below the set figure, it is normal that fans and other components of the

machine do not work. The temperature controller will automatically control the working conditions of the compressor,

magnetic valve, fans and other parts based on the set controlling parameters.

(4) As it takes a longer time to start the compressor and other components, according to different conditions, the time is

range from seconds to minutes, so do not turn off the power and again on frequently.

E. Check the water level in the water tank.

The first startup of the new chiller empties the air in the water pipe, leading a slight water level decline, but in order to keep

the water level in the green area, it’s allowed to add adequate water again. Please observe and record the current water level,

and inspect it again after the chiller running for a period of time, if the water level drops obviously, please re-inspect the

water pipeline leakage.

F. Adjust parameters of temperature controller.

CW-5000 series use an intelligent thermostat. Normally users do not need to adjust it. If it is really necessary, please refer to

“Operating status and parameters adjustment.”