MP3 Solid Air WK25 Series User manual

Brandkleppen manual

P stbus 22756

1100 DG Amsterdam Z.O.

Tel.: +31 (0)20 696 69 95 Fax: +31 (0) 20 691 30 62

mail@s lid-air.nl www.s lid-air.nl

Solid Air

®

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl Brandkleppen manual 06 2013

Brandkleppen manual

WH25

WH45

WK25

WK45

1

1MLWK

25R0G

Via G. La Pira, 9 A-B

Camposampiero

3 5 0 1 2 P D - I t a l y

www.mp3-italia.it

MAINTENANCE AND USE MANUAL

WK25

Rectangular fire damper with low pressure drop

500 Pa

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl Brandkleppen manual 06 2013

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl 06 2013

Brandkleppen manual

WH25

WH45

WK25

WK45

2

1MLWK

25R0G

1. PRODUCT PRESENTATION

The WK25 rectangular fire dampers are installed in ventilation ducts inside walls to stop a fire from spreading.

They have a modular mechanism, entirely outside the walls.

The duct is built in galvanised steel.

The fire damper can be fitted with a simple thermal fuse, or a remote controlled automatic mechanism.

•

Tested in compliance with

EN 1366-2 to 500 Pa.

• Control mechanism entirely outside wall.

•

Easy to install.

•

Maintenance free.

2. RANGE OF DIMENSIONS

Free area (dm²) = [(width – 12) x (height – 37)] / 10 000

with width and height in mm

4

3

2

5

6

1

7

1. Galvanised steel duct.

2. Moveable blade in refractive material.

3. Control mechanism.

4. Connection flanges.

5. I

ntumescent seal.

6. B

lade seal.

7. Thermal fuse.

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl Brandkleppen manual 06 2013

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl 06 2013

Brandkleppen manual

WH25

WH45

WK25

WK45

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl Brandkleppen manual 06 2013

Solid Air®

3

1MLWK

25R0G

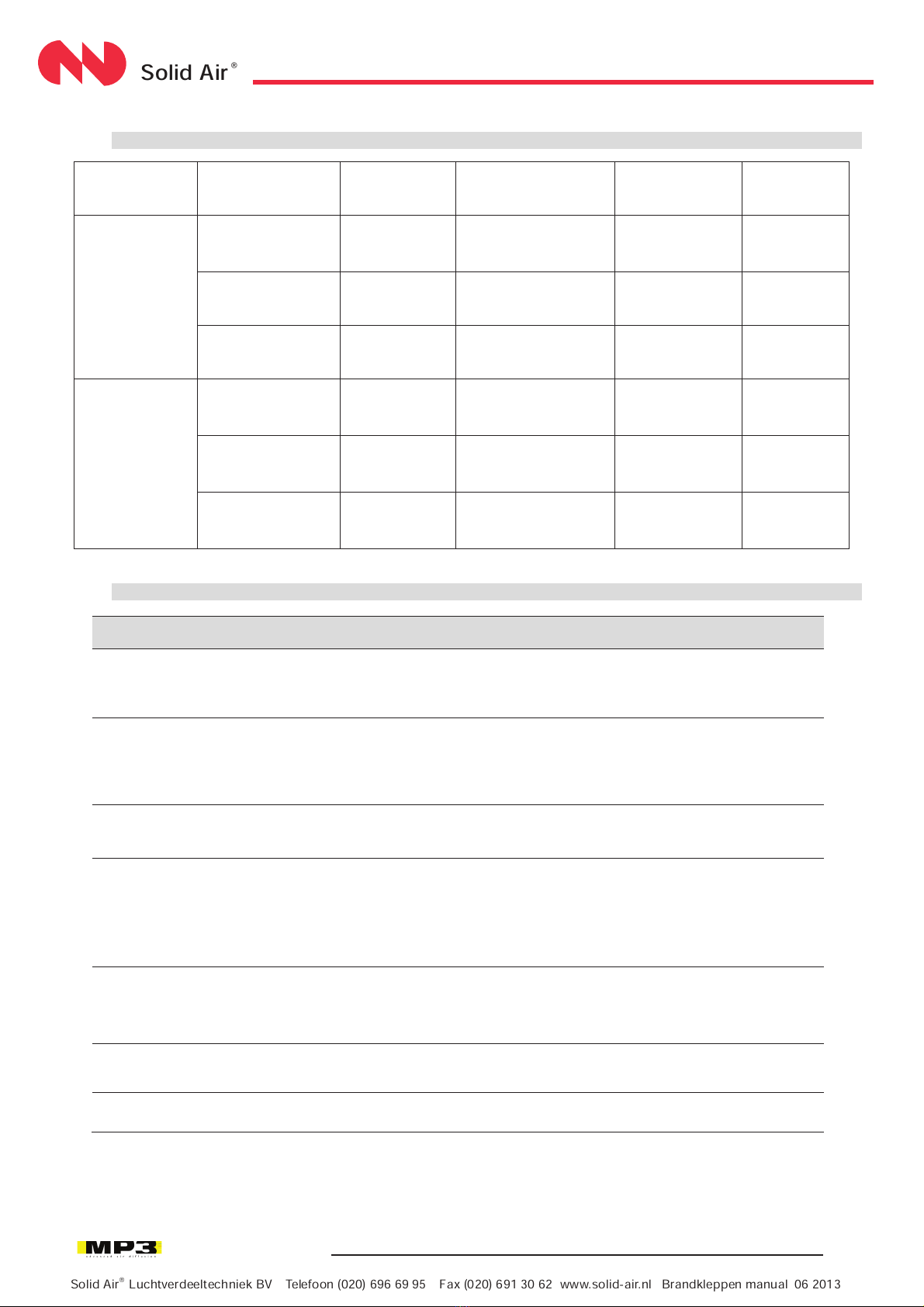

3.

FIRE RESISTANCE IN COMPLIANCE WITH EN 13501-3: 2005 (500 Pa)

INSTALLATION

MATERIAL

CLASSIFICATION

MECHANICAL

ORIENTATION

DIMENSIONS

FIRE

DIRECTION

WALL

(Flush mounted

in wall)

Aerated concrete

Thickness 100 mm

Density 550 kg/m

3

EI 120 S

Horizontal or vertical

blade axis

100X200 to

800X600

Indifferent

Plasterboard type

98/48

EI 60 S

Horizontal or vertical

blade axis

100X200 to

800X600

Indifferent

Carreaux de platre

Gypsum blocks

Thickness 70 mm

EI 90 S

Horizontal or vertical

blade axis

100X200 to

800X600

Indifferent

FLOOR

(Flush-mounted

with floor)

Reinforced concrete

Thickness 150 mm

Density 2200 kg/m

3

EI 180 S

Horizontal blade axis

100X200 to

800X600

Indifferent

Aerated concrete

Thickness 150 mm

Density 650 kg/m

3

EI 120 S Horizontal blade axis 100X200 to

800X600 Indifferent

Aerated concrete

Thickness 100 mm

Density 650 kg/m

3

EI 90 S

Horizontal blade axis

100X200 to

800X600

Indifferent

4. DETAILED TECHNICAL DATA

CONTROL

MECHANISM

WK25B

WK25M

WK25 V/D

Product type

Automatically controlled

fire damper.

Rectangular cross section.

Automatically and remote

controlled fire damper.

Rectangular cross section.

Automatically and remote

controlled fire damper.

Rectangular cross section.

Mandatory

Manual reset by direct

action on the moveable part

after closing when cold.

Manual reset by direct action

on the moveable part after closing

when cold.

Safety position contact (limit switch)

DCU/FCU (S2).

Motorized reset after

closing

when cold

(can be local or

remote).

Safety position contact (limit

switch).

Safety options

Safety and standby

position contacts (S2).

Operating mode

Without external energy.

Without external energy for

power supply input magnet

during stand-by.

With external energy for power

supply interruption magnet

during stand-by.

With external energy.

Control mode

Automatic:

by fuse at

70°C±7°C.

Automatic: by fuse at 70°C ± 7°C.

Remote control: by power supply

input or interruption on the magnet.

Automatic: by fuse at 72°C ± 7°C.

Remote control: by

power supply

interruption.

Installing position

Horizontal or vertical blade

axis.

Horizontal or vertical blade axis.

Horizontal or vertical blade axis

Air circulation

direction

Indifferent.

Indifferent.

Indifferent.

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl Brandkleppen manual 06 2013

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl 06 2013

Brandkleppen manual

WH25

WH45

WK25

WK45

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl Brandkleppen manual 06 2013

Solid Air®

4

1MLWK

25R0G

Certificates:

5. HANDLING AND STORAGE

Since this is safety equipment, the fire damper needs to be stored, handled and installed with care.

Attention:

• Avoid contact with water and exposure to excessive dampness.

• Avoid damage to sealing/gasket during installation. Be careful especially to the external sealing/gasket.

• Avoid deforming the duct during assembly and sealing.

It is best to:

• Unload in a dry area.

• Avoid impacts.

• Do not use the damper as a work table or scaffolding.

• Do not put small dampers into bigger ones.

6. INSTALLATION AND COMMISSIONING

• Installation is possible with the blade axis in horizontal or vertical position.

• The installation must comply with the CE Certificate.

• Never obstruct the blade movement with any object or air ducts.

• The air tightness and fire resistance class is maintained if the damper installation is done in compliance with the

technical specifications.

• Use temperature: 50°C maximum.

The WK25 fire damper is always tested in the frame of standardised supports in compliance with EN 1366-2 : 1999

table 3/4/5'. The results obtained are valid for all similar support frames which have a thickness, density and fire

resistance equal or higher than that of the test.

Example of similar constructions:

aerated concrete wall thickness 100 mm +

density 550 kg/m3 + fire resistance up to 120

minutes

brick walls, reinforced concrete, aerated

concrete wall, etc.+ fire resistance minimum 120

minutes

aerated concrete floor thickness 100 mm +

density 650 kg/m3 + fire resistance up to 90

minutes

parts in concrete, prestressed concrete, etc.

+ fire resistance minimum 90 minutes

flexible wall – metallic uprights +

plasterboard: 100 mm + fire resistance 60

minutes

metallic uprights + plasterboard

+ fire resistance minimum 60 minutes

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl Brandkleppen manual 06 2013

Solid Air®

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl Brandkleppen manual 06 2013

Solid Air®Luchtverdeeltechniek BV Telefoon (020) 696 69 95 Fax (020) 691 30 62 www.solid-air.nl 06 2013

Brandkleppen manual

WH25

WH45

WK25

WK45

This manual suits for next models

4

Table of contents

Popular Fan manuals by other brands

Harbor Breeze

Harbor Breeze RLG52NWZ5L manual

Allen + Roth

Allen + Roth L1405 instruction manual

ViM

ViM KUBAIR F400 ECOWATT Technical manual

HIDRIA

HIDRIA R10R-56LPS-ES50B-04C10 user guide

BLAUBERG Ventilatoren

BLAUBERG Ventilatoren CENTRO-M 100 L user manual

Triangle Engineering

Triangle Engineering HEAT BUSTER SPL Series owner's manual