MPI KWH124 User manual

MODEL

KWH124™

Instantaneous

Kerosene

Fired

Water

Heater

Owner's

Manual

Thank

youfor

choosing

the

KWH124

InstantaneousKerosene

Fired

WaterHeater.

We

are

sure

that

the

moderndesign

and

outstanding

performance

of

thisunitwill

meetyour

highest

expectations.Pleaseread

this

manual

and

warningscarefully

before

usingyour

KWH124

KeroseneFiredWaterHeater.Pleasebecome

fully

acquainted

with

all

details

ofits

operation

so

that

youcanusethe

KWH124

for

many

years

without

problems

or

malfunctions.Keep

this

manualhandy

for

reference.

4AP\

MONITOR

PRODUCTS

INC

INDEX

1.

SPECIALPRECAUTIONS

2.

SPECIFICATIONS

2

A.

PARTSDESCRIPTION

2

•

APPEARANCE

2

•

CONTROLPANEL

2

•

CONSTRUCTION

2

B.

SPECIFICATIONS

3

C.

DIMENSIONALOUTLINEDRAWING

4

3.

OPERATIONAL

PROCEDURES

5

A.

FUELTYPE

'5

B.

FUEL

SUPPLY

5

C.

PRE-OPERATION

CHECKLIST

• 6

D.

START

UPAND

OPERATION

•

6

E.

UNIT

SHUT

OFF

•

8

F.

FREEZEPREVENTION

• 8

G.

WARNINGS

9

4.

SAFETYDEVICES

10

5.

MAINTENANCECHECKLIST

•

11

6.

REGULARCLEANING

12

7.

TROUBLESHOOTINGGUIDE

13

8.

SCHEMATICDISASSEMBLY

16

The

KWH124

is

designed

for

household

useforthe

purpose

of

supplying

hot

water.

The

unit

should

notbe

used

ona

moving

vehicle

such

asa

boat

or

camper.

Warrantycoverage

for

commercialapplication

could

be

voided

or

limited

to1

year.

1.

SPECIAL

PRECAUTIONS

WARNING

Use

onlycrystalclear

1-K

kerosene.Never

use

gasoline,

white

gas,campfuel

or

other

flammable

liquids.

Useof

suchfuels

can

result

inan

explosion

and

causesevere

injury.

A

damaged

or

malfunctioningpartshould

be

discarded

andbe

replaced

with

a new

genuine

service

part.

All

repairs

should

be

left

to

professionals.

Contact

your

local

authorized

service

dealer.

CAUTION

DO

NOT

STOREflammableliquids

or

materialssuch

as

gasolinenear

the

unit.

Makesure

that

the

flue

is

properly

installed

and

connected.

A

separation

inthe

flue

during

the

operation

ofthe

unit

can

cause

the

release

of

exhaust

gas

into

the

room.

The

consequencescould

be

dangerous.

Turn

off

unit

in

case

ofan

accident

oran

emergency.Stay

calm

anddonot

panic.

Just

turn

offthe

unit.

In

case

ofa

fuel

leak,

exhaust

fumes

in

home,

nohot

water.

Turn

off

unit.

Call

an

authorized

serviceperson.

When

using

a

shower,feel

the

temperature

ofhot

water

with

your

hand

first,

before

movingyourselfunder

thehot

water.

Avoid

theuseof

hardwater.

In

regionswherehard

water

isthe

onlysource,take

advantage

ofa

watersoftener.

This

unit

is

only

for

indoor

use.Avoid

its

exposure

to

rain

or

moisture.

(2.

SPECIFICATIONS")

A.

PARTSDESCRIPTION

•

APPEARANCE

Hot

Water

Outlet

Drain

CONTROL

PANEL

CONSTRUCTION

Coid

WaterIntake

Fan

Motor

Printedcircuit

Board

Hot

Water

Thermistor

ColdWater

Intake

-Filter

-

Control

Panel

Front

Door

Maintenance

Cover

FuelFilter

Connection

Junction

Box

Run

Lamp_______^

Code

LED

Temperature

. —

Adjusting

Knob

Oi

•s

mm

MM

|

LCW

SS3

zsm

1

Eza

UC-J.

asssf

D-

ON<fF

MPI

Power

Lamp

-

Power

Switch

Hot

Water

Outlet

Air

Damper

Mixing

Tank

Burner

Overheat

ProtectorThermo

HeatExchanger

TemperatureFuse

-2-

B.

SPECIFICATIONS

Model

KWH124

Type

CombustionType

Air

Intake/Exhaust

Heating

Source

of

Water

Ignition

Fuel

Hot

Water

OUTPUT

FuelConsumption(Max)

Efficiency

Capacity

of

HeatExchanger

MaximumPressureApplied

Minimum

WaterFlow

to

ActivateBurner

Area

of

HeatTransmission

Exterior

Dimensions

Weight

Voltage/Frequency

Rated:

Ampere

(RatedPowerConsumption)

FlueSize(Diameter)

Exhaust

Air

Temperature

PressureVapor

Indoor/Forced

Exhaust

Instantaneous

DirectConnection

to

mainsupply.

HighVoltageDischargeSpark

CrystalClean

1-K

Kerosene

123.000

BTU/H

1.1

GAL/H

86%

X

1.057

OT

(1.0

L)

150PSI

0.45

GAL/MIN

620

in2

35

in(H)

x

11.8in(W)

X

20.9in(D)

88

Ibs

AC

120V/60Hz

Ignition:

1.05A(127W)

Combustion:

1.00A

(HOW)

4

in

482T

Nozzle

Quantity

of

Vapor

Spray

Pattern

Spraying

Angle

TemperatureFuse

Electric

CurrentFuse

SafetyDevices

0.85GPH

Pattern

A

60°

302T

6

A

*Safe

Ignition

*

FlameSensor

*Over

Heat

Protector

*Air

Pressure

Switch

*

SurgeAbsorber

PipeConnection

Water

Intake

Hot

Water

Outlet

Drain

Accessories

(supplied)

Hot

Water

Outlet

(Maximum)

Degree

Rise

3/4NPT

Male

3/4NPT

Male

1/2NPT

Male

Fuel

Filter

Water

Intake

Insulator

Hot

Water

Outlet

Insulator

70F

Rise

210

GAL/H

3.5

GAL/MIN

80F184

3.07

90F

164

2.73

100F

147

2.45

11

OF134

2.23

(Maximum

hot

watersupplied

by

this

unit

is

about

221

GAL/H.)

>KThis

represents

Efficiency

under

laboratory

conditions.

This

efficiency

rating

can

vary

upto4%.

"SINCE

WEARE

CONSTANTLY

IMPROVING

OUR

PRODUCTS,

ALL

SPECIFICATIONS

ARE

SUBJECT

TO

CHANGE

WITHOUT

NOTICE."

-3-

C.

DIMENSIONALOUTLINEDRAWING

(Unit-.Inches)

6.1

3.1

3.1

Hot

Water

Outlet

VentConnector

Cold

Water

Intake

10.6

10.2

Drain

Fuel

FilterConnection

\

1.7

£

'

00

(

I

EEC

11.8

-4-

3.

OPERATIONAL

PROCEDURES)

A.

FUELTYPE:

Use

only

crystal

clear

Type

1-K

Kerosene.

B.

FUEL

SUPPLY

—

Precaution

-

No

water

or

debrisshould

be

allowed

to

enter

the

fuel

tank.

Whenthese

two

are

mixed

with

fuel,imperfectcombustion

can

resulttherebyshortening

the

life

of

the

burner.

1.

Keep

the

tankfilter

cap

tight.

2.

Donot

allow

tank

torun

empty.

If

the

KWH124

is

allowed

to

operate

without

fuel,

air

must

be

purged

inthe

following

manner:

a.

Refill

kerosene

tank.

b.

Allow

30

minutesafterrefilling

to

activate

KWH124.

(This

allowsfuel

to

settle.)

Fuel

purge

screw

c.

Makesuretankvent

is

open.

d.

Open

shut-off

valve

on

fuel

tank.

Loosen

air

purgescrew

at

fuelfilter.

Discharge

airoutofall

channels

through

whichfuelruns.

e.

Fill

the

bowl

ofthe

unit

fuel

filter

with

kerosene.

Fasten

fuelpurgescrewback

in

originalposition.

Handle

O

—Ring

of

fuelpurge

screw

carefully.

A

damaged

0

—Ring

can

cause

fuelleakage

and

render

unit

inoperative.Don'tmisplace

0

—Ring.

f.

Wipe

all

fuelspills

off

thoroughly.

-5-

C.

PRE-OPERATION

CHECKLIST

1.

Water

Leaks

Open

the

valve

andrun

waterthrough

unit

tosee

that

waterrunsproperly

through

heat

exchanger.

No

watershould

be

leakingfrom

it,orany

fittings.

2.

Fuel

Leaks

Make

sure

that

there

isno

fuelleakingfromfueltank,filters,

valves

or

from

anyofthe

piping

connections.

3.

Location

Makesureproperclearances

are

kept

around

unit

and

there

is

nothing

flammablenearby.

Keep

a

distance

from

walls

of

combustiblematerial.

From

left

side

7 in

(180

mm)

From

right

side

19in

(505

mm)

Fromback

of

heater

8 in

(205

mm)

From

Heater

to

closetdoor

29in

(735

mm)

Flue

pipe

to

combustiblesurface,vertically

9 in

(229

mm)

Flue

pipe

to

combustible

surface,

horizontally

9 in

(229

mm)

4.

Flue

Connection

All

flueconnections

must

beair

tight

and

sealed

so

that

no

fumes

can

leak

into

the

room.

5.

Unit

Wiring

The

powersupply

is

properly

connected

and

grounded

to

unit.

D.

START

UPAND

OPERATION

1.

Readying

Safety

Device

For

Action

Press

and

turn

off

"Power"switch.

The

"Power"

light

goes

off.

Press

"Power"

switch

again,thus

turning

iton.

Thisprocedurereadiessafetydevices

for

actionwhennecessary.

2.

Starting

Unit

With

the

"Power"

switch

inthe

"ON"

position,

"Power"

lamp

should

beon.

Open

hot

waterfaucet

and

unit

will

igniteautomatically.

(While

burner

has

flames,

run

lampstays

on.)

Should

run

light

go

off,

a

code

"4"may

blink

signaling

airin

fuel

supply

line.

Refer

to

installationManual"TestRun"

-6-

Adjustment

ofHot

WaterTemperatures

a.

Thermostat

has

been

setat

factory

to

about

104T.

(LOW)

b.

Slide"HotWaterTemperatureAdjuster"

knob

up

toward

"High"

to

raise

watertemperature.

Slide

knobdowntoward"Low"

to

reduce

the

temperature.

c.

When

adjusting

hot

watertemperature

with

hot-coldwater

mixing

valve,

control

the

amount

of

coldwaterfrommain

without

changing

the

amount

ofhot

waterbeingsupplied.

>£Knob

at

position

"High"

provides

hot

water

ata

temper-

ature

around

167T.

Knob

at

position"MED"provides

hot

water

ata

tempe-

raturearound

130'F.

Knob

at

position"Lowprovides

hot

water

ata

temper-

aturearound

104'F.

WARNING

•KHiimiaa

HIGH

r

LOW

MED.

^

Hightemperaturesettingincreases

the

risk

of

SCALD

injury.

^Households

with

smallchildren

or

invalids

may

require

a

120'F

or

lowerthermostat

setting

(to

preventaccidentalcontact

with

"HOT"water.)

NOTE

^Seasonal

change

in

temperature

of

waterfrommainresults

in

different

hot

water

temperatures

supplied.

Usehot

watersupply

tapto

control

hot

water

temperature,

or

readjustthermostat

setting.

7

G.

WARNINGS

|

Burns

Don'ttouch

the

flue.

The

flue

reaches

a

hightemperature.Protectyourselffrompotentialburns.

•

Water

For

Drinking

The

quality

of

waterfrom

unit

may

changedepending

on

waterbeingsuppliedfrommain,

and

deterioration

of

piping

material,scale,etc.

Never

use

water

that

has

remainedstagnant

in

heatexchanger

and

pipes

for

longperiod

as

drinking

water.Turnwater

onfora

couple

of

minutesbeforedrinking.

•

SHOWER:

Feel

temperature

ofhot

water

with

yourhandbeforeenteringshowerstall.

•

KEEPDRAINVALVESHUTWHILE

UNIT

IS

OPERATING

Openingdrain

valve

while

unit

isin

operationresults

ina

"boiling

no

water"situation,

and

may

result

ina

blowntemperaturefuse.

•

LIGHTNING

Lightning

may

cause

a

temporarypowersurge,which

may

damagesomeelectronicparts.

Where

there

is

thunderstorm

activity,

install

a

surgeprotector

in

power

circuit.

•

WHEN

UNIT

WILL

NOTBE

USED

FORAN

EXTENDED

TIME

TAKE

THE

FOLLOWINGMEASURES:

1.

Closefuelsupply

valve

at

fueltank.

2.

Turn

"Power"switchoff.

3.

Purgewaterfrom

unit

(See

instructions

on

Page

8.)

-9-

(5.

MAINTENANCE

CHECK

LIST

)

Flammables

or

Dust

Keep

thetopand

vicinity

of

unit,

clean.

Keep

flammables

and

dangerousitemsawayfrom

unit.

Fuel

Leakage,Spills,Stains

Makesure

all

fuelconnections

are

tight

andarenot

leaking.

Any

spills

or

stains

by

unit

indicate

a

leak

and

must

be

corrected.

Fuel

PipesReplacement

Check

fuelpipes

at

leastonce

a

year

for

distortions

and/or

cracks.Contactauthorized

servicedealer

for

replacement

of

defectivepipes.

Water

in

Fuel

Tank

Water

and

dust

can

easily

go

into

fuel

tank.

After

accumulating

inthe

tank,

they

may

flow

into

burner

and

cause

imperfectcombustion.Check

if

there

isany

water

inthe

tank

at

least

every

6

months

by

checking

the

fuel

filter

canister

at

tank.Have

any

water

removed

byan

authorizedserviceperson.

Flue

andIts

Vicinity

Periodically,makesure

that

there

areno

flammablesaround

and

above

flue,

sure

flue

is

properlyinstalled

and

maintained.

Also,

make

Cleaning

Heat

Exchanger

Drainwater

from

heatexchanger

at

leastonce

a

year.

l.Shut

watersupplyvalve

at

main.

2.

Open

hot

watersupplyfaucet.

3.

Opendrain

valve

at

heatexchanger.Also,open

inlet

waterfilter

and

pressure

release

valve.

Then,drainwater

from

heatexchanger.

Cleaning

Inlet

Water

Filter

Checkonceevery

three

months

and

removedebris

gathered

inthe

inlet

water

filter.

l.Shut

watersupplyvalve

at

main.

2.

Open

hot

water

supply

faucet.

3.

Opendrainvalve

at

heatexchanger.

Then,remove

inlet

water

filter

and

wash

and

clean

it.

Cold

waterintake

Inlet

Water

Filter

CAUTION

If

lime

has

accumulated,remove

it

with

a

commercialcompound

for

dissolving

lime.

Checkwater

softening

equipment

if

lime

is

found

inthe

filter.

-11-

7.

TROUBLE

SHOOTING

GUIDE

)

|

Use

the

followingchart

for

detection

and

correction

of

problems

and

their

causes.

Contact

yourlocaldealer

for

problemsbeyondyour

control.

(1)

Power

lamp

does

notgoon.

^

Power

is

disconnected.

%

A

power

failure.

^

TemperatureFuse

has

beenactivated.

Reset

circuitbreaker

or

safety

fuse.

Unit

operation

is

suspended

until

power

is

restored.

Overheat

situation.Contactyourlocaldealer.

J

(2)

Unit

does

not

start.

^•^ruwt;

lamp

UMJ

%

Temperatureadjustment

issettoo

low.

%•

Water

inlet

filter

is

clogged.

^

Watersupplyvalve

at

Main

isnot

open.

V

Set

temperatureAjusterhigher.

Remove

and

clean

the

filter.

OpenWaterSupply

Valve

at

Main.

(3)

Unit

stops

during

use.

^

Powerconnection

is

loose.

:£A

temporarypowerfailure.

^Temperature

Fuse

has

beenactivated.

-

Reset

CircuitBraker.

Retighten

connection.

Unit

operation

will

resume

shortly.

Call

yourlocaldealer.

fPnwf*i*

lirnn

nn^

—

%

Hot

WaterTemperatureAdjustment

is

seton

"LOW"side.

:£

Water

and/or

debris

go

into

Fuel.

Filter/Fuel

supplypipe.

sfcAir

remains

in

FuelSupplypipe.

Set

TemperatureAdjustmentHigher.

Clean,

or

replace.

Purge

air

fromFuelSupplyPipe.

(4)

Excessive

noise

develops

while

operating.

%.

Water

and/or

debris

has

goneinto

Fuel.

Filter/Fuel

supplypipe.

^Air

remains

in

Fuel

Supplypipe.

>fc

Flue

has

clogged.

JjiOil

(light

oil)

other

than

Kerosene

is

used.

:fc

Insufficient

air

intake

for

combustion.

Clean,

or

replace.

Purge

air

from

FuelSupplyPipe.

Dismantle

and

clean.

Clean

and

replace

with

cleankerosene.

Contactyourlocaldealer.

-13-

(5)

Waterdoes

not

flowfrom

hot

wateroutlet.

Water

supply

valve

at

Main

isnot

open.

Open

WaterSupply

Valve

at

Main.

(6)Hot

Watertemperature

istoo

low.

>(c

Temperatureadjustment

issettoo

low.

:fc

Hot

Water

is

being

used

beyond

capa-

city.

%

Water

and/or

debris

getin

FuelFilter-

/Fuel

supplypipe.

Set

TemperatrueAdjustment

higher.

Partially

close

theHot

Water

outlet.

Clean,

or

replace.

(7)Hot

Watertemperature

istoo

hot.

Set

TemperatureAdjustment

isseton

high.

Set

Temperature

Adjustment

lower.

(8)

Unitgoesinto

the

state

of

code

"4"

occasionally.

(Unit

is

shut

off.)

Water

and/or

debris

get

into

Fuel

Filter/Fuel

supplypipe.

Air

remains

in

FuelSupplypipe.

Clean,

or

replace.

Purge

air

from

FuelSupplyPipe.

Refer

to

page

5.

The

following

are

conditionsthat

are

normal

or

easilyremedied

:

§

OPENING

HOT

WATER

SUPPLY

VALVE

A

SMALLAMOUNTWON'TSTARTUNIT

:

The

burner

of

this

unit

cannot

be

ignited

unless

minimum

water

flow

about

0.45

G/min

is

maintained.

Open

up

faucetwider.

§

HOT

WATERTEMPERATURES

CAN

VARYWITHMULTIPLEFAUCETSOPEN

:

When

hot

water

is

used

from

twoor

morefaucetssimultaneously,

the

amount

and

temperature

ofhot

waterfrom

each

faucetcouldvarydepending

on

pipingscheme

andhow

much

eachvalve

is

opened.Thistendencycould

be

enhancedwhenshower

and

another

faucet

areputto

servicesimultaneously.

§

HOT

WATERAPEARSOPAQUE

:

Hot

water

might

lookwhite

and

opaqueduring

initial

outflow,

because

air

mixes

with

water

in

heater,

and

underpressure

is

released

to

atmospherewhenfaucet

is

opened.

When

this

happens,

airand

watercome

outinthe

form

of

bubbles,

looking

white.

There

is

no

harm

in

thisprocess,

andhot

waterwillsoon

turn

transparent.

|

SOUND

OF

FAN

MOTORSTILLAUDIBLEAFTER

UNIT

IS

TURNED

OFF

:

Fan

motorcontinues

torunfor

about

150

secondsafter

unit

is

turned

offin

order

to

drive

exhaust

gasoutof

combustionchamber.

-14-

•

BURNEROPERATES

IN

REPETITIVE

RUN/STOP

CYCLE

:

This

is

normal

if

flow

is

low.

This

unit

is

beingcontrolled

by

micro-processor

to

maintainsteady

outlet

temperature.

•

WHITEVAPORRISING

FROM

FLUE

(IN

WINTER)

Vapor

in

exhaust

gas

could

turn

into

droplets

in

winter,

which

may

come

out

from

flue

in

the

form

of

white

vapor.

•

UNIT

OCCASIONALLYDISPLAYS

AN

ERROR

CODE

"4"

AFTERREFILLINGFUEL

TANK

:

Error

code

"4"may

startblinking,

a

sign

ofair

being

in

fuelsupplypipeafter

filling

a

emptyfueltank.

Follow

the

procedureprovided

on

page

5 forair

purge.Then,

setthehot

watersupply

temperature

adjustment

onthe

control

panel

on

"High".

Fullyopen

the

watersupply

valve,

and

press

"Power"switchonceagain.Allowunit

torunfor

10

to

15

minutesafter

it

moves

into

"ContinuousOperation"mode

to

makesure

that

there

isnoair

remaining

in

pipe.

Donot

allowfueltank

to

becomeempty.

•

ONLYLUKEWARMWATER

IS

SUPPLIED

INTHE

BEGINNING

:

This

can

happenespecially

in

winter

or

when

the

unit

that

has

been

installed

with

a

long

hot

watersupply

piping

arrangement.Whenstandingwater

in

pipe

is

purged,

the

temperature

ofhot

water

will

become

constant.

DETECTION

OF

TROUBLES

BY

READINGCODEINDICATOR

:

1.

Code

indicators

on

controlpanel

can

tell

wheretrouble

is.

2.

If

service

of

yourlocal

dealer

is

needed,provideinformation

on

code

signs.

(

CODESIGNS

)

"

4

"

Burnerdoes

not

ignite.

Flamesstalloccasionally.

Cdshasa

brokenwire.

(Refer

to

page

5)

"

5

"

Faulty

flames

or

shortcircuitedCds.

"

6

"

A

brokenwire

on

detectionwater

thermistor.

11

7

"

Hot

watersupply

high

limit

was

activated.

(PCS

malfunction).

Thermistor

has

electrical

short.

"

8

"

Hot

watersupply

high

limit

shut

offwas

activated.

(194°F

—

Thermooverheat

protector)

"

9

"

Hot

watertemperatureadjustment

control

has

malfunctioned.

"

E

"

Communications

circuit

in

trouble.

"

H

"

Main

PCBhas

problem

"

P

"

Fan

motor

has

problem

and

fails

to

turn.

(might

be

caused

by

extremewindycondition)

Forallofthe

above,

please

contactyour

local

dealer.

-15-

MONITOR

KWH124

SERVICE

PARTS

LIST

ITEM

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

PART

No,

7001

7002

7003

7004

7005

7006

7007

7008

7009

7010

7011

7012

7013

7014

7015

7016

7017

7018

7019

7020

7021

7022

7023

7024

7025

7026

7027

7028

7029

7030

7031

7032

7033

7034

DESCRIPTION

Fuel

Pump

Ass'y

Air

DamperSolenoid

Ignitor

Transformer

PhotoSensor(Cds)

Combustion

Blower

Ass'y

BurnerAss'y

Burner

Base

Burner

Head

Ring

Air

Pressure

Switch

Fuel

Filter

Nozzle

Ignition

RodSet

(Right

and

left)

HeatExchangerAss'y

(W/lnsulated

Wrap,Gasket)

Water

Inlet

connector

Filter

WaterGovernor

Inlet

Pipe

Set

FlowSensor

Flow

Sensor

Bracket

Mixing

Tank

Water

Outlet

Connector

Hot

Water

Thermistor

Set

Printed

Circuit

Board

ControlPanelAss'y

ControlPanel

Circuit

Board

Thermo

Overheat

Protector

Over

TemperatureFuse

Set

MainFuse

6A

PowerTransformer

Terminal

Block

PCS

SpacerClip

FuelPipe

Fuel

Filter

Mounting

Bracket

Silencer

Ass'y

(W/Gasket)

ITEM

No.

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

PART

No.

7035

7036

7037

7038

7039

7040

7041

7042

7043

7044

7045

7046

7047

7048

7049

7050

7051

7101

7102

7103

7104

7105

7106

7107

7108

7109

7110.

7111

7201

7202

7203

7204

7205

DESCRIPTION

Exhaust

Stack

Ass'y

Base

Exterior

Cover

(Right

side)

Access

cover

Electric

Outlet

Cover

Exterior

Cover

(left

side)

Drain

Cover

Front

Cover

Top

Cover

Front

Cover

Screws/Collar

Air-Pressure

Sensor

Front

Cover

Bracket

PCB

MountingBracket

Burner

RetainingBracket

Ass'y

Water

InletInsulation

Set

Junction

Box

Drain

Retainer

Heat

Exchanger

Insulated

Wrap

Heat

Exchanger

Base

Gasket

Exhaust

Stack

Gasket

Fan

Motor

Gasket

Flange

Gasket

Burner

HeatGasket

Water

Inlet

Gasket

Water

Outlet

Gasket

Water

Governor

Gasket

Damper

Cushion

Exhaust

Stack

Outlet

Insulator

0-Ring(Thermistor

P64C)

0-Ring

(Water

FilterP10A

1A)

0-Ring

(Multiple

UseP144C)

O-Ring

(Flow

Sensor

Inlet

PI

8

4C)

0-Ring

(Water

Governor

P22A

1A)

-17-

KWH124

LIMITED

WARRANTY

MONITORPRODUCTS,INC.warrantseach

KWH124

InstantaneousWaterHeaterSystemsold

byit

tobe

freefromdefects

in

material

and

workm-

anship,

undernormal

useand

service,

forone

year

after

the

date

of

original

retail

purchase,

in

a

singlefamilydwelling,subject

tothe

term

and

conditions

stated

below.

An

extended

warrantyperiod

of48

month

is

provided

for

combustion

chamber

and

heatexchanger.

The

remainder

ofthe

unit

is

subject

tothe12

months

warranty

as

providedherein.

Ifthe

KWH124

is

installed

in

otherthan

a

single

familydwelling,

this

warranty

is

limited

toONE

year

fromdate

of

installation.

1.

WARRANTOR:

Thiswarranty

is

granted

by

MONITOR

PRODUCTS,INC.,P.O.

Box

3408,

Princeton,

New

Jersey

08543.

2.

PARTIES

TO

WHOM

WARRANTY

IS

EXTENDED:

Thiswarranty

shall

be

extendedonly

tothe

originalretailpurcaser.

3.

PARTSCOVERD:

All

products

and

parts

manu-

factured

byorfor

MONITOR

PRODUCTS,

INC.,

except

as

provided

for

herein.Replacementparts

are

warranted

only

forthe

balance

ofthe

origin-

al

warrantyperiod.

4.

PARTS

NOT

COVERD:

The

followingparts

are

not

coverd

by

this

warranty:

fuelfilters,venting

apparatus,

oil

lines,fuses

and

waterpipes.

5.

REMEDY:

if,

within

the

applicablewarranty

period,

any

product

or

partincluded

in

this

warranty

proves

tobe

defective

in

material

and/or

workmanship,

then

MONITOR

PRODUCTS,

INC.,

shallrepair

or

replace,

atits

option,

the

defective

product

or

part.

Service

atthe

point

of

installation

(not

including

dealertravel

time)

will

be

provided

atno

charge

tothe

customer,

but

must

be

performed

bya

MONITOR

PRODUCTS,

INC.,

dealer

authorized

to

sell

and

service

the

KWH124

InstantaneousWaterHeatersystem.

6.

PROCEDURE

FOR

OBTAININGPERFORMANCE

UNDER

THISWARRANTY

: In

order

to

obtain

performance

ofthe

obligationsunder

this

warra-

nty,

the

originalpurchasermustpromptly

(inno

event

later

than

thirty

(30)

days

afterdiscovery

of

the

defect)

notify

the

localMONITORPRO-

DUCTS,

INC.dealerauthorized

to

sell

and

service

the

KWH124

Instantaneous

WaterHeatersyste-

m.

Service

will

be

providedduringnormal

business

hours

within

a

reasonable

timeafter

the

dealer

has

been

notified

ofthe

need

for

service.

If

youare

unable

to

locate

a

localMONITOR

PRODUCTS,

INC.dealerauthorized

to

sell

and

service

the

KWH124

Instantaneous

WaterHeater

System,

call

or

write

to:

SERVICE

DEPARTMENT,

MONITOR

PRODUCTS,INC.,P.O.

BOX

3408,

PRINCETON,

NEW

JERSEY

08543,

908-329-0900.

Any

claimmadeunder

this

warrantymust

be

accompanied

by

proof

of

originalpurchasedate

sales

invoice

or

cancelledcheck

showing

serial

number

is

satisfactoryevidence.

7.

SOLEREMEDY

: The

remedy

and

liability

forany

breach

of

warranty,

express

or

implied

set

forth

above

isthe

sole

and

exclusiveremedy

andthe

limit

of

liability

forany

suchbreach.

8.

EXCLUSIONS

:

Thiswarrantydoes

not

extend

to

any

defect

duetothe

negligence

of

others,failure

to

install,

operate

or

maintain

the

waterheater

in

accordance

with

the

installation,

operation

• and

maintenanceinstructionsfurnished

with

each

new

waterheater,unreasonableuse,accidents,alterat-

ions,ordinarywear

and

tear,

theuseof

unauthori-

zed

or

non-standarizedparts,

accessories

ortheuse

ofany

fuel

other

than

good

quality

kerosene,such

as

Type

1-K

grade.Thiswarrantywill

not

apply

to

partssubject

to

misuse,abuse,neglect,alteration,

accidents,

excessivetemperature,excessivepress-

ure,

lime

or

sedimentaccumulation,corrosive

atmosphere,noise,odor,

rusty

water,

or

installed

outside

ofthe

United

States,

oron

which

the

serial

numbershavebeenaltered.

9.

IMPLIED

WARRANTIES

: All

implied

warranties,

if

any,arising,understate

lawin

connection

with

the

sales

by

MONITORPRODUCTS,INC.

ofanynew

heater

are

limited

in

duration

tothe

duration

of

this

written

warranty.There

areno

warranties,

express

or

implied,

of

merchantability,fitness

fora

particularpurpose

or

otherwisewhichextend

beyond

this

warranty

MONITOR

PRODUCTS,

INC/

shall

notbe

responsible

forany

incidental

or

consequential

damages.Whether

asa

result

of

breach

of

warranty,

negligence,

strict

liability

in

tort

or

otherwise.

NOTE:

Some

states

do not

allow

(A)

limitations

on

how

long

an

implied warranty lasts

:

or

(B)

the

exclusion

or

limitation

of

incidental

or

consequential damages,

so the

above

limitations

or

exclusions

may not

apply

to

you.

10.

NO

VARIATION

OF

TERMS

: The

parties

intend

that

this

warranty

bethe

exclusive

and

final

expression

of

their

agreement.

No

person

hasthe

authority

to

orally,

in

writing

or

in

any

other

way

vary

the

terms,conditions

or

exclusions,

of

this

warranty

orto

make

any

express

warrantiesother

than

thosecontainedherein.

11.

LEGAL

RIGHTS

:

Thiswarrantygives

you

specific

legal

rights

andyoumay

alsohave

other

rights

whichvaryfromstate

to

state.

MONITOR

PRODUCTS,INC.

P.O.

BOX

3408

PRINCETON,

NJ.

08543

PART

NO.

7213

PRINTED

IN

JAPAN

COPYRIGHT

©1990

MONITORPRODUCTS,INC.,

Other manuals for KWH124

1

Table of contents

Other MPI Water Heater manuals

Popular Water Heater manuals by other brands

Ariston Thermo

Ariston Thermo S/SGA X 50 Installation and maintenance instructions

Kampa

Kampa Geyser Installation and operating manual

Lochinvar

Lochinvar CHP-WI-04 Installation and service manual

A.O. Smith

A.O. Smith GPVL-50 Service handbook

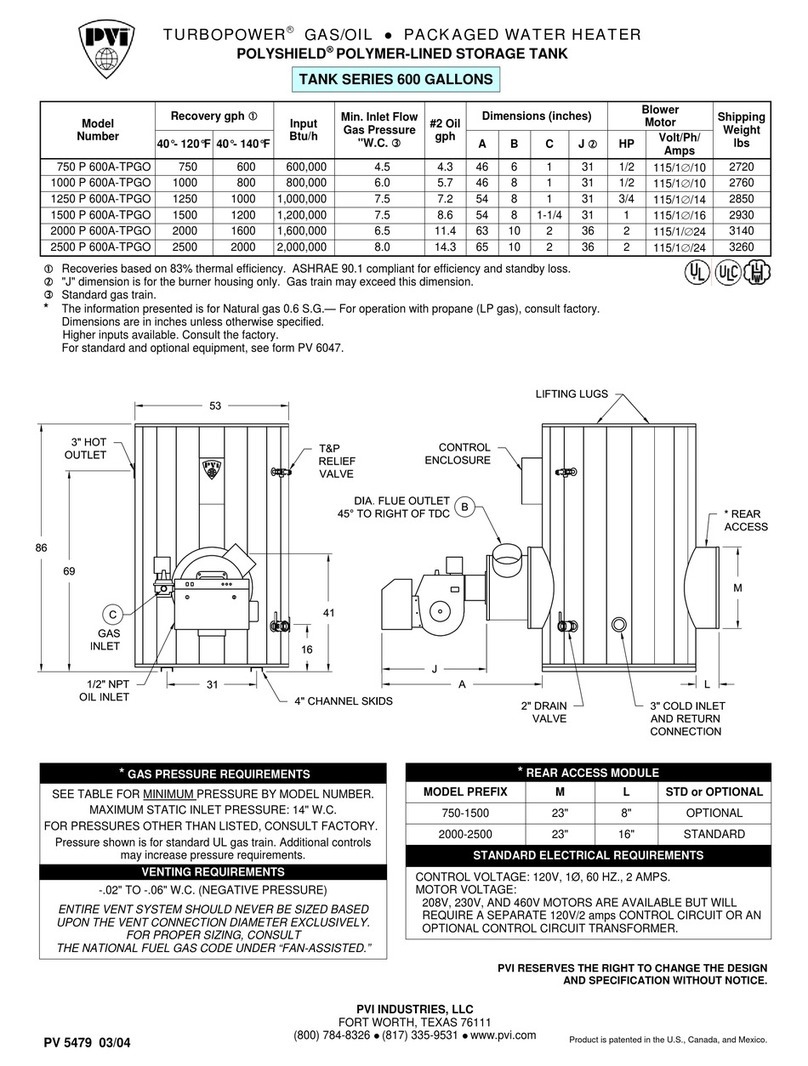

PVI Industries

PVI Industries 1000P600A-TPGO Specification sheet

Rheem

Rheem Marathon CMR50245 Specification sheet