MPI KWH124 User manual

Other manuals for KWH124

1

Table of contents

Other MPI Water Heater manuals

Popular Water Heater manuals by other brands

EemaX

EemaX EX240T3 Installation guide and owner's manual

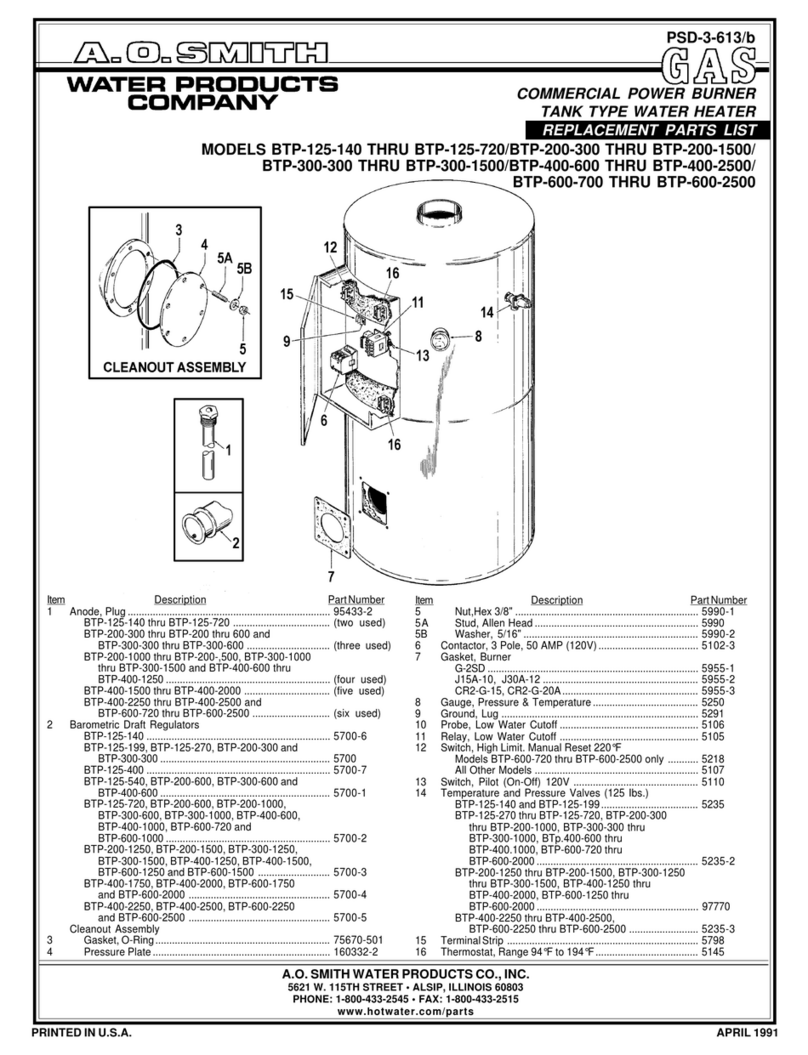

A.O. Smith

A.O. Smith BTP-600-2500 Replacement parts list

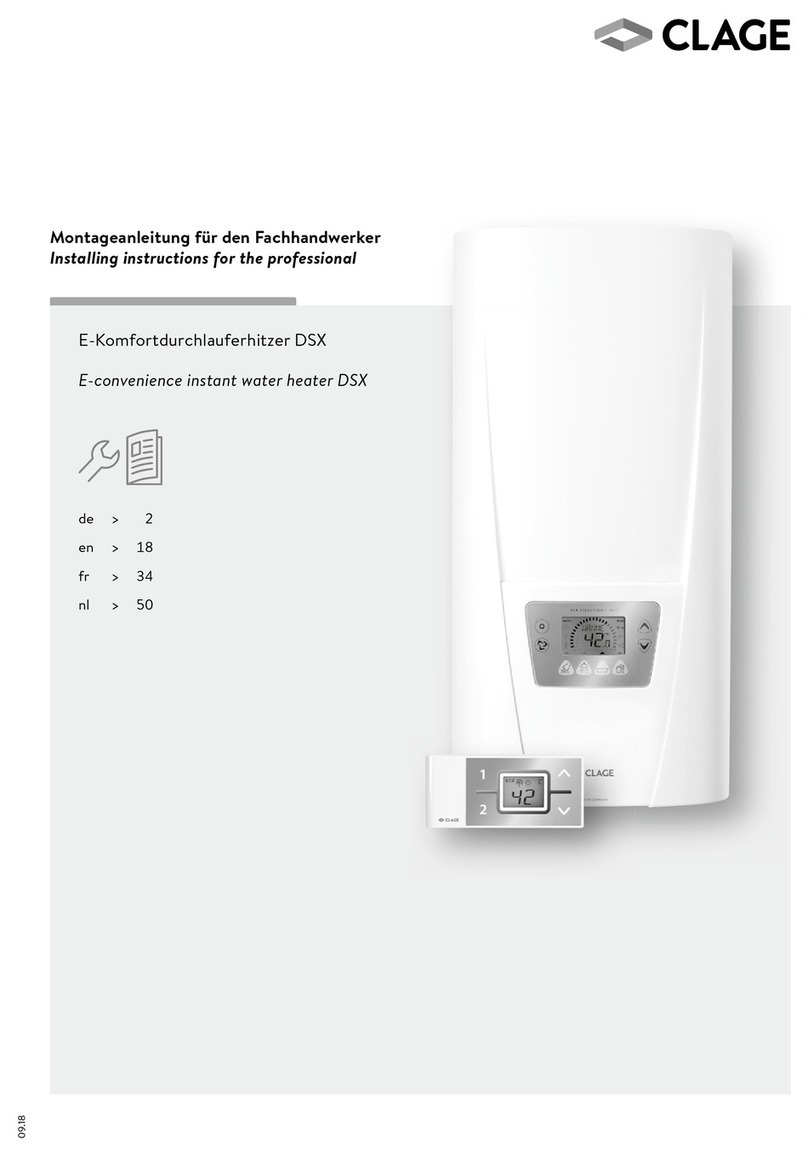

clage

clage DSX Series Installing instructions

STIEBEL ELTRON

STIEBEL ELTRON SBB 200 WP classic Operation and installation

Kospel

Kospel EPO2 manual

US CRAFTMASTER

US CRAFTMASTER 100263116 Installation and operation guide

PREMIER TECH

PREMIER TECH 3P Multitank instruction sheet

A.O. Smith

A.O. Smith Residential Gas Water Heaters instruction manual

A.O. Smith

A.O. Smith DSE-120-24 Description, operation, installation and maintenance manual

andrews

andrews RSC 150 Installation and operation manual

Maxwell

Maxwell MS-C2PSU Series Installation and instruction manual

Rinnai

Rinnai TRW02i installation manual

Force 10

Force 10 Electric Water Heater owner's manual

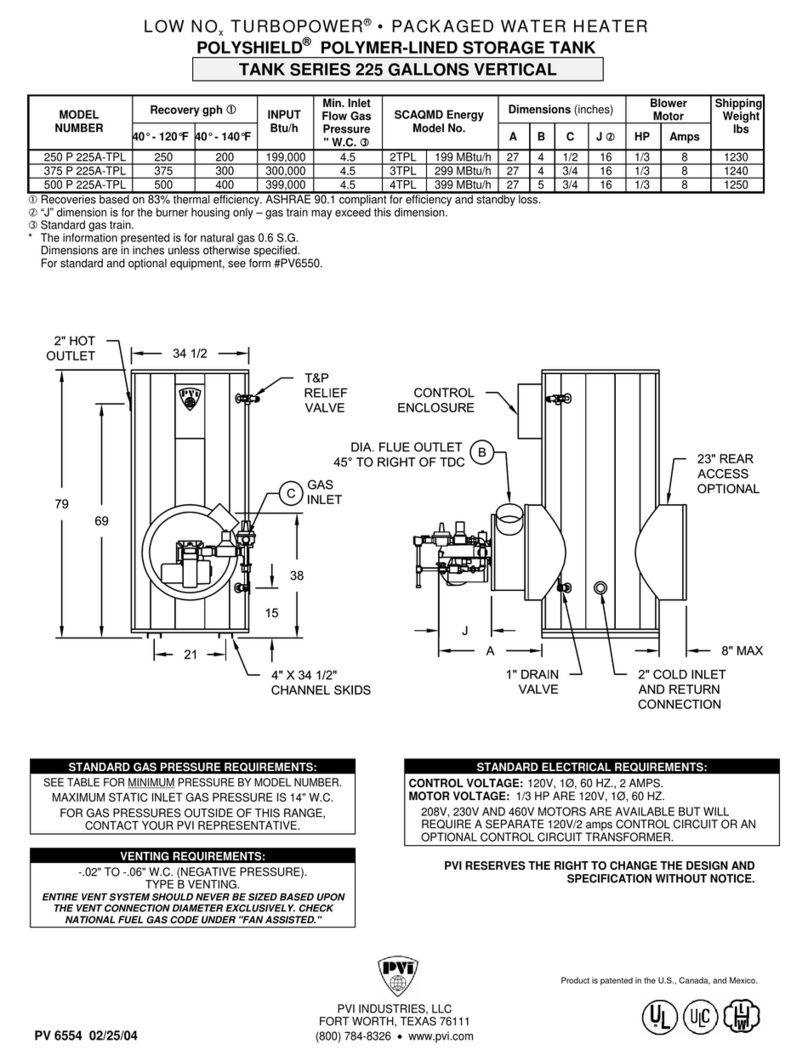

PVI Industries

PVI Industries 250P225A-TPL Specifications

STIEBEL ELTRON

STIEBEL ELTRON DEM 6 Operation and installation instructions

Whirlpool

Whirlpool FLAME LOCK 315420-000 Installation and use manual

Ariston

Ariston NEXT EVO X OUTDOOR Series user manual

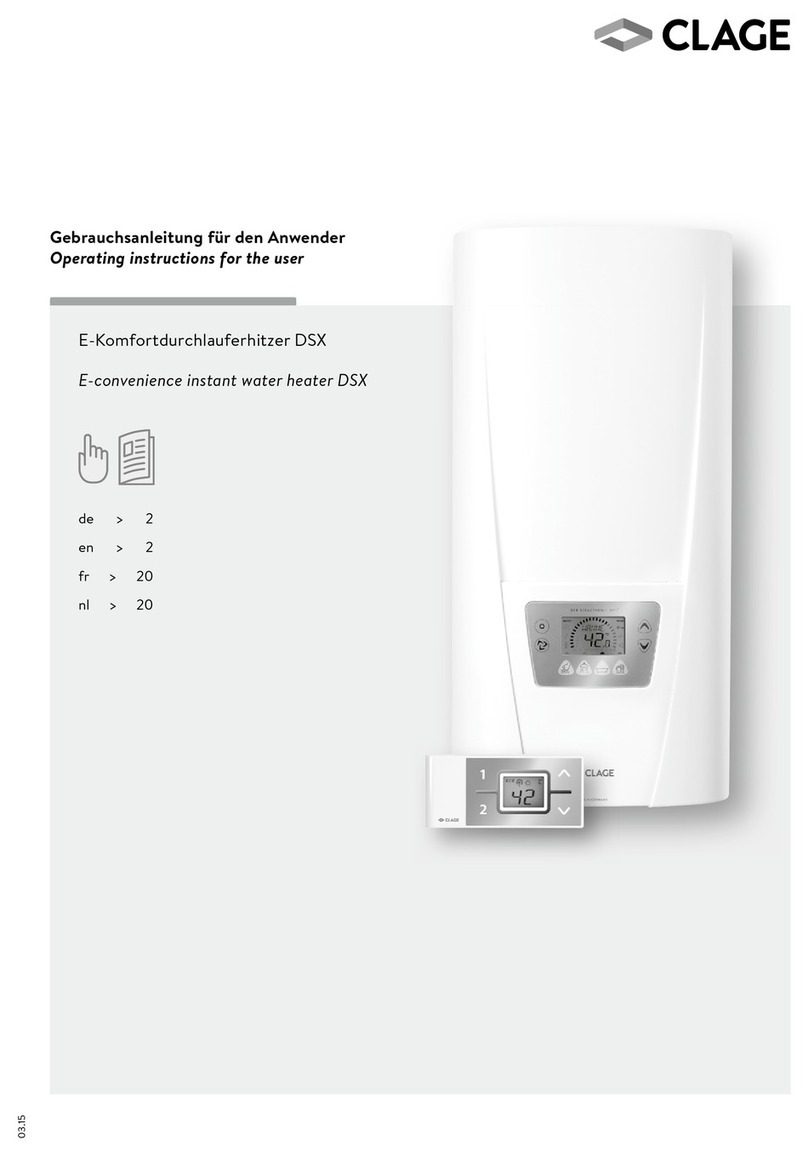

clage

clage DSX Operating instructions for the user