Mr Beam Shield User manual

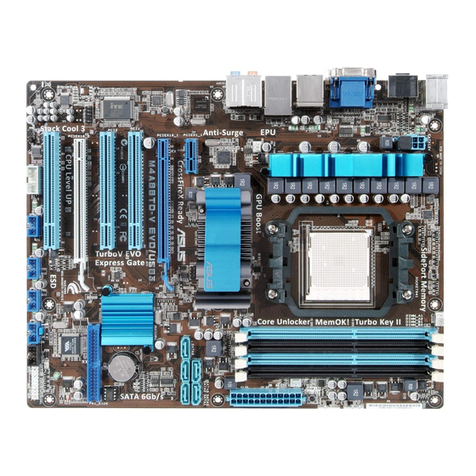

backfront

Mr Beam Shield - Instructions

#01 laser driver

#02 power source

#03 axes & motors

#04 miscellaneous

#05 safety

#06 usage & appendix

#about

What is it?

The Mr Beam Shield was developed within the

Kickstarter project "Mr Beam - a Portable Laser

Cutter and Engraver Kit" (see http://kck.st/1j4BQiz).

Beeing compatible to the grbl firmware (http://

bengler.no/grbl), it combines a laser diode driver with

up to 3 stepper motor drivers on an Arduino Uno

shield. We recommend the usage of our Mr Beam

grbl fork which is already configured to the shields

features. You can find it at https://github.com/

mrbeam .

What can I build with it?

Originally the shield was designed for the Mr Beam

laser cutter kit, but it can be used for every laser

device which uses stepper motors in the mechanics.

Besides laser cutters this can be laser sintering 3D

printers, 3D scanners, laser projectors or other

robots.

Thank you & Have fun!

By purchasing this shield you have supported a piece

of open hardware - thank you!

We enjoyed the development of it and will continue

improving it. We hope you find our work useful and it

will help you to be creative. Whatever you do, take

care about yourself and others. We would love to see

your work in the social networks. Tag it with

#mrbeam to catch our attention.

Have fun!

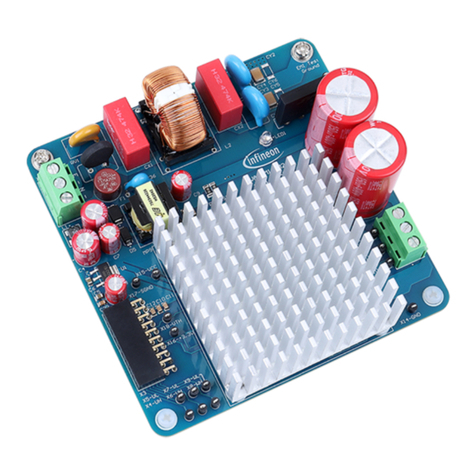

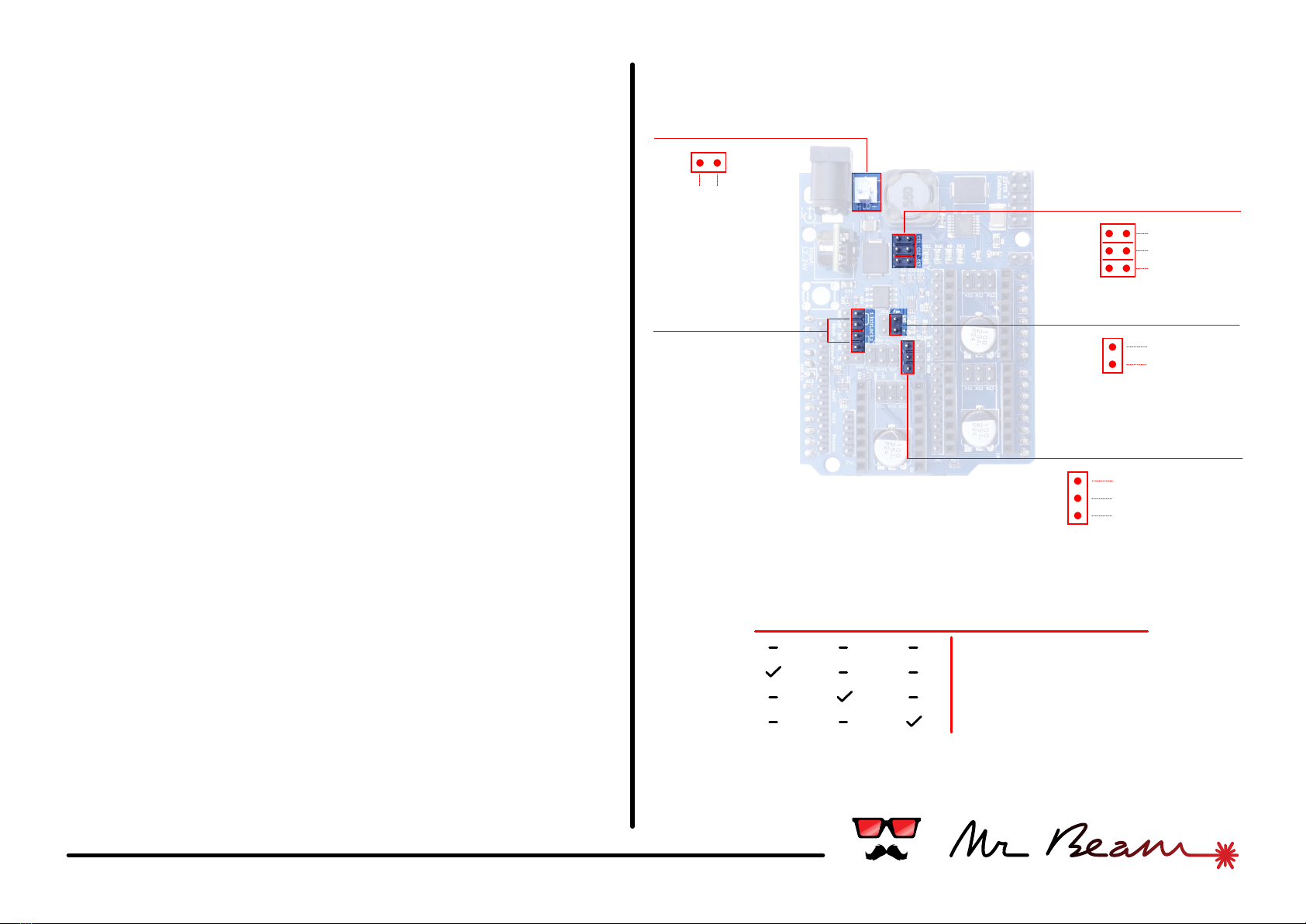

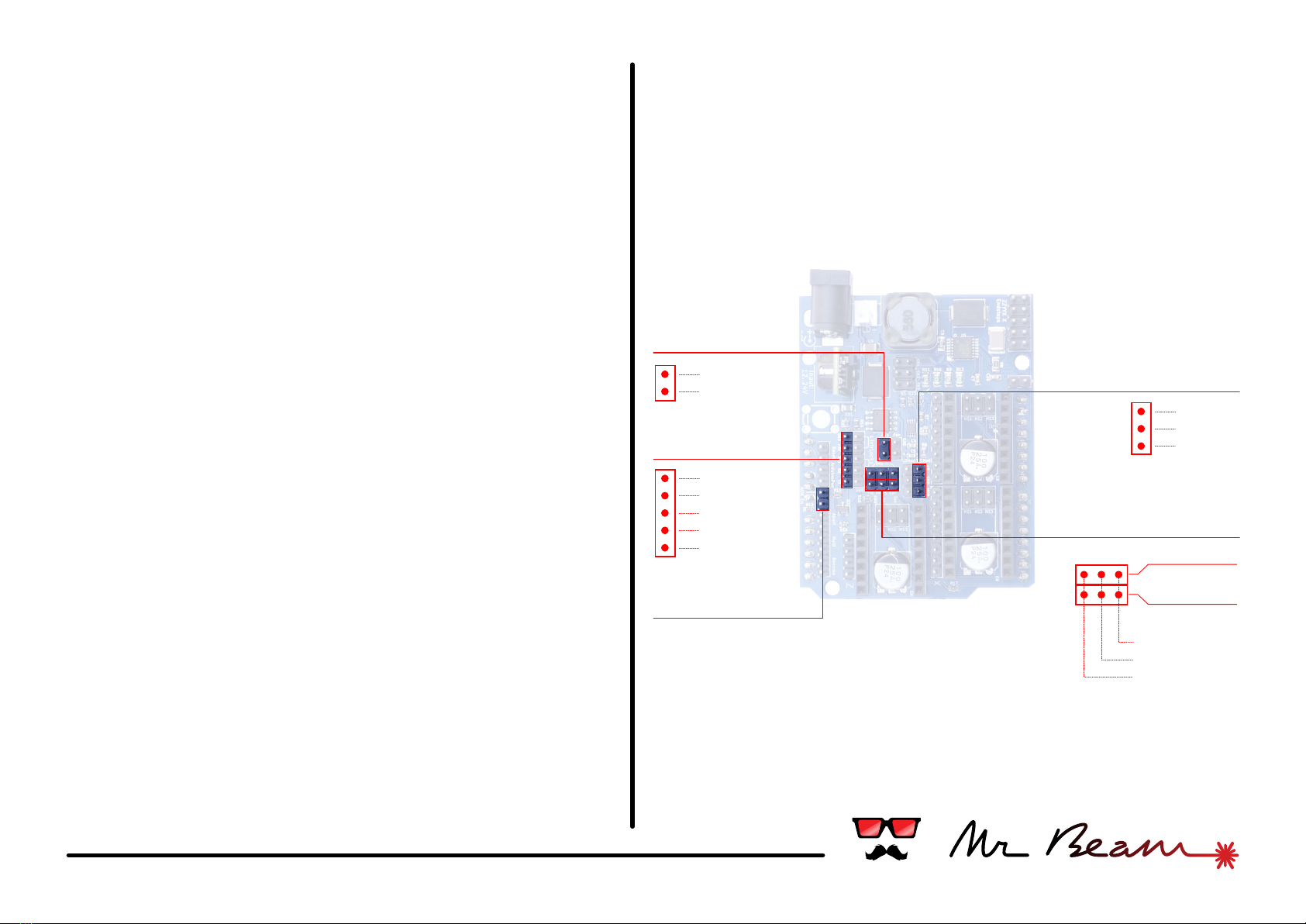

#01 laser driver

Current Selector

2x Interlock

Laser Diode

-

+

Laser diode driver

The Mr Beam Shield features a dimmable and

efficient laser diode driver with a maximum output of

1500mA. The output current has to be set before

connecting a laser diode.

Check the data sheet of your diode for the maximum

current and place the jumper according to the

following table on the right

Setting the current too high may destroy your laser

diode.

Before connecting the laser diode check twice the

polarity of your diode, the cable and the connectors in

between. A false polarity will destroy your diode.

Interlock connectors

The shield provides 2 connectors for interlock

switches or sensors. Both have to be closed for

operating the laser.

Cooling Fan

Connect a cooling fan at this two pins. The voltage

supplied at the + pin equals the input voltage from

your power supply. The fan can be switched with the

commands M08 (on) and M09 (off).

CS1 CS2 CS3 Max Output Current

350mA

700mA

1200mA

1500mA

Cooling Fan

-+

Laser intensity

+5v

ground

pwm signal

CS1

CS2

CS3

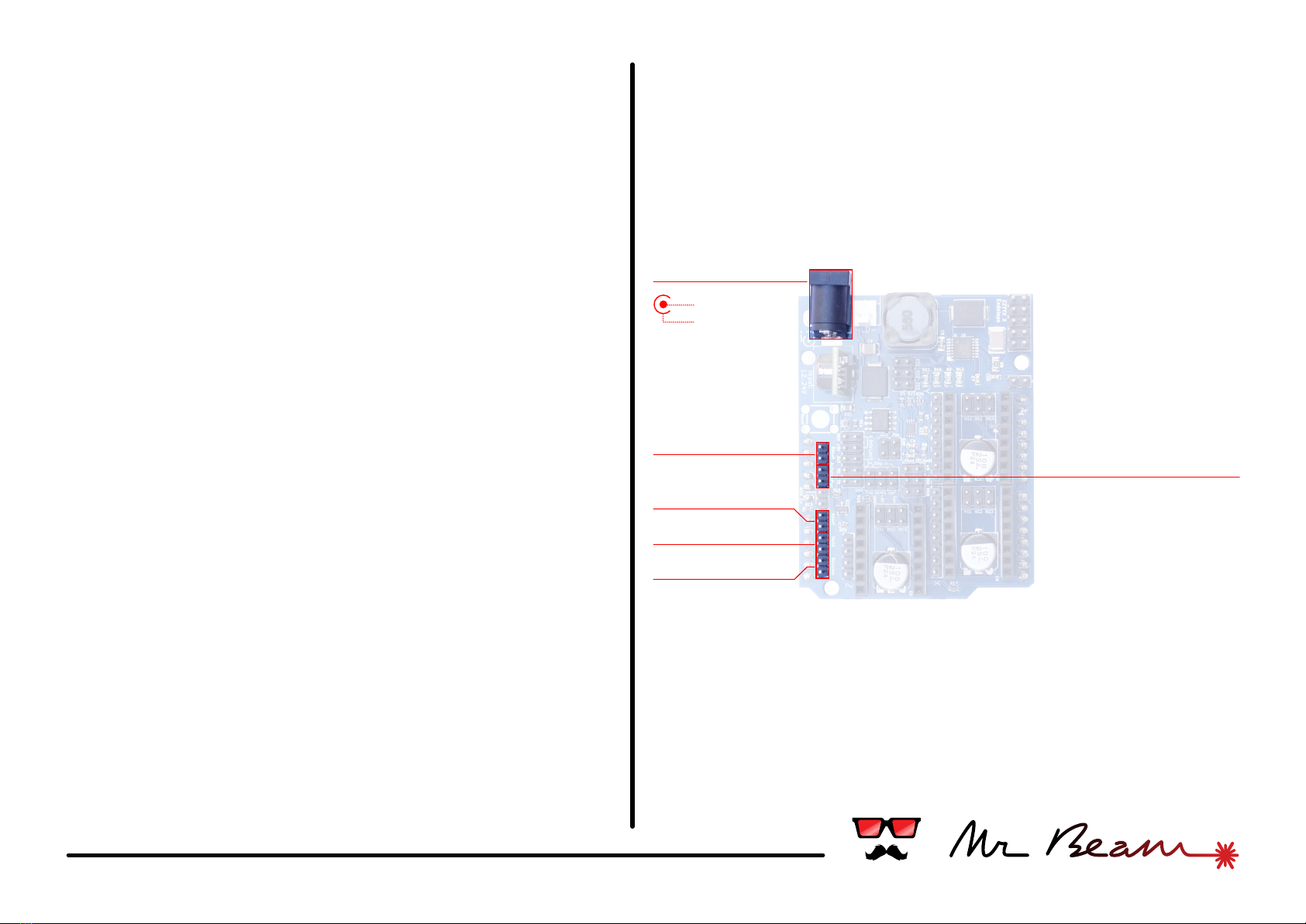

#02 power & control

Power in

Power in

The shield supports a wide input voltage between 12V

and 24V. When using your own power source please

check that the power jack has the correct polarity.

Reset, Cancel, Hold, Resume Buttons

For easy wiring the shield has a dedicated connector

for each control button supported by the GRBL

firmware. Just plug in the button's cables - that's it.

Arduino Power

This little feature powers the Arduino under the

shield with the supply voltage from the power supply

connected to the shield. A voltage converter provides

5V output to the Arduino with a maximum of 1.5A. It is

even enough to power an attached Raspberry via USB

as well.

To enable this feature, place a jumper on the two

pins.

Arduino Power

Reset

Cancel

Hold

Resume

-

+

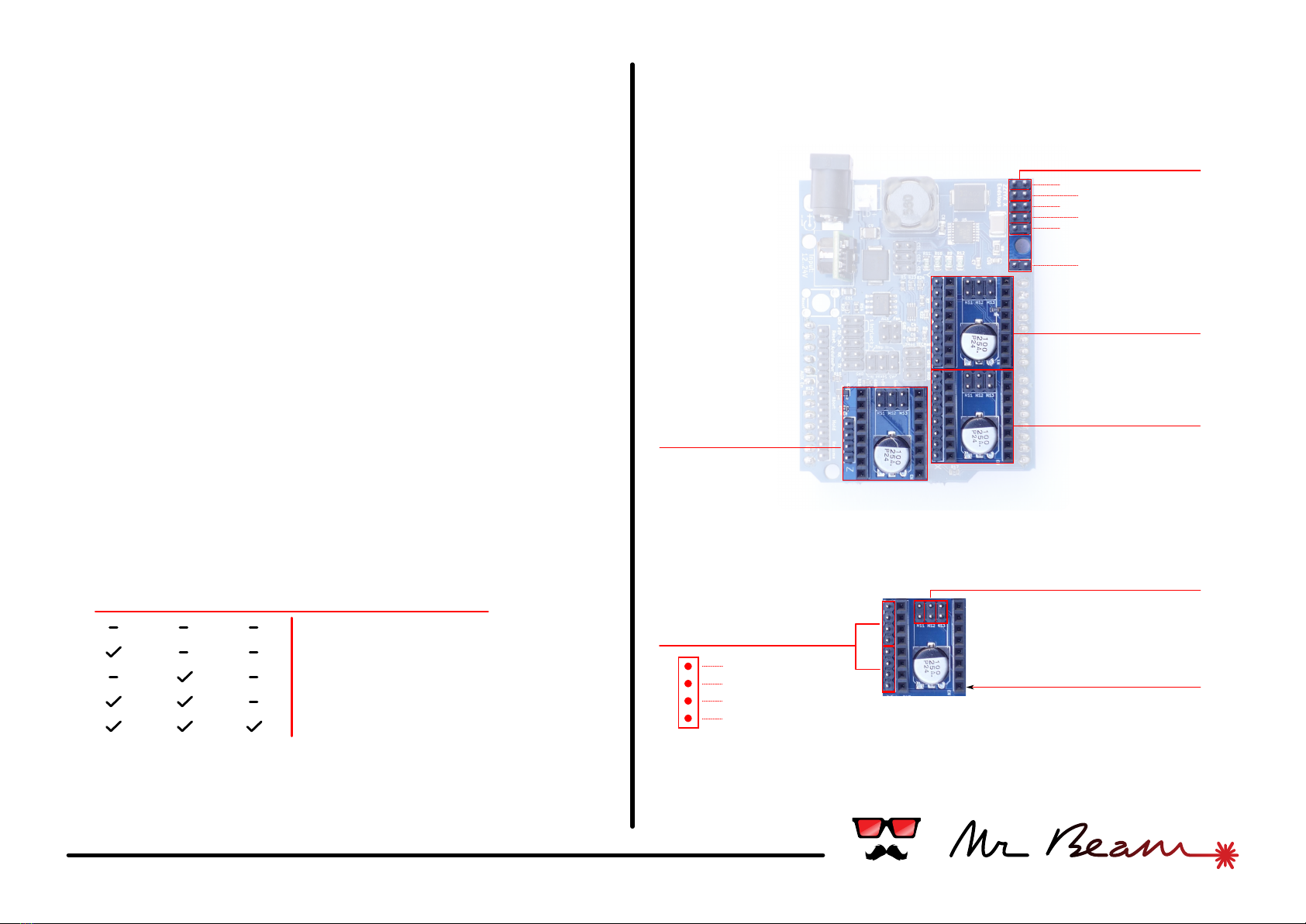

#03 axes & motors

Y-Axis

X-Axis

Z-Axis

Endstops

2x Motor

Micro stepping

Enable pin

Driver socket

Z1

Y1

X1

Z2

Y2

X2

Motor axes:

The Mr Beam Shield can control up to 3 independent

axes. It has 3 sockets compatible with Pololu/

Stepstick stepper drivers like the ones used on many

3D-printers.

While the Z axis has only a single stepper motor, the

other axes have double motor connectors. This allows

to drive two steppers with a single driver and is useful

for a double motor axis like the Y-axis on a Mr Beam

Senior. The connectors are using the reprap-style pin

order (1b, 1a, 2a, 2b). Turning the connector 180°

inverts the motor direction.

Check the orientation of a stepper driver before

plugging it in. The "enable" pin of the driver is

marked on the shield as well.

The 3 jumpers marked with MS1, MS2, MS3 configure

the micro stepping mode of the driver. Depending on

the driver's chipset the modes may differ.

This table shows the settings for the common A4988

chip:

Endstops:

The shield provides 2 endstop connectors for each

axis. Micro switches can be attached directly,

MS1 MS2 MS3 Microstep Resolution

Full step

Half step

Quarter step

Eighth step

Sixteenth step

1b

1a

2a

2b

#04 miscellaneous

A5 Mode

The assignment of the Arduino pin A5 is configurable. It

can be used to switch the power of the AUX connector or

as an additional sensor input.

Place a jumper to enable the AUX power out, leave it open

for using the sensor 2.

AUX

This two pins are an additional switchable power outlet. It

switches directly the input power and can handle a

maximum of 1A.

When using it ensure that the A5 mode jumper is closed.

Serial

The serial rx/tx pins from the Arduino have its own

connector here. The RX/TX pins have 3.3v logic levels, but it

is no problem to use them with 5v as well if the

counterpart is flexible as well. Additionally there are both

voltage levels and ground available as well.

Sensor Input

Though the analog Arduino pins A4 and A5 are not used in

standard GRBL firmware, the shield is ready for future

developments and provides own connectors for them. In

combination with a +5v and ground pin for each, it is easy

to plug in common sensors.

When using the sensor 2 ensure that the A5 mode jumper

is open.

TEC Signal

Another thing for future development. Currently not

supported.

TEC Signal

Serial

AUX

A5 Mode

Sensor Input

+5v

ground

signal

sense

+5v

ground

Sensor 1

Sensor 2

-

+

ground

+5v

+3.3v

rx

tx

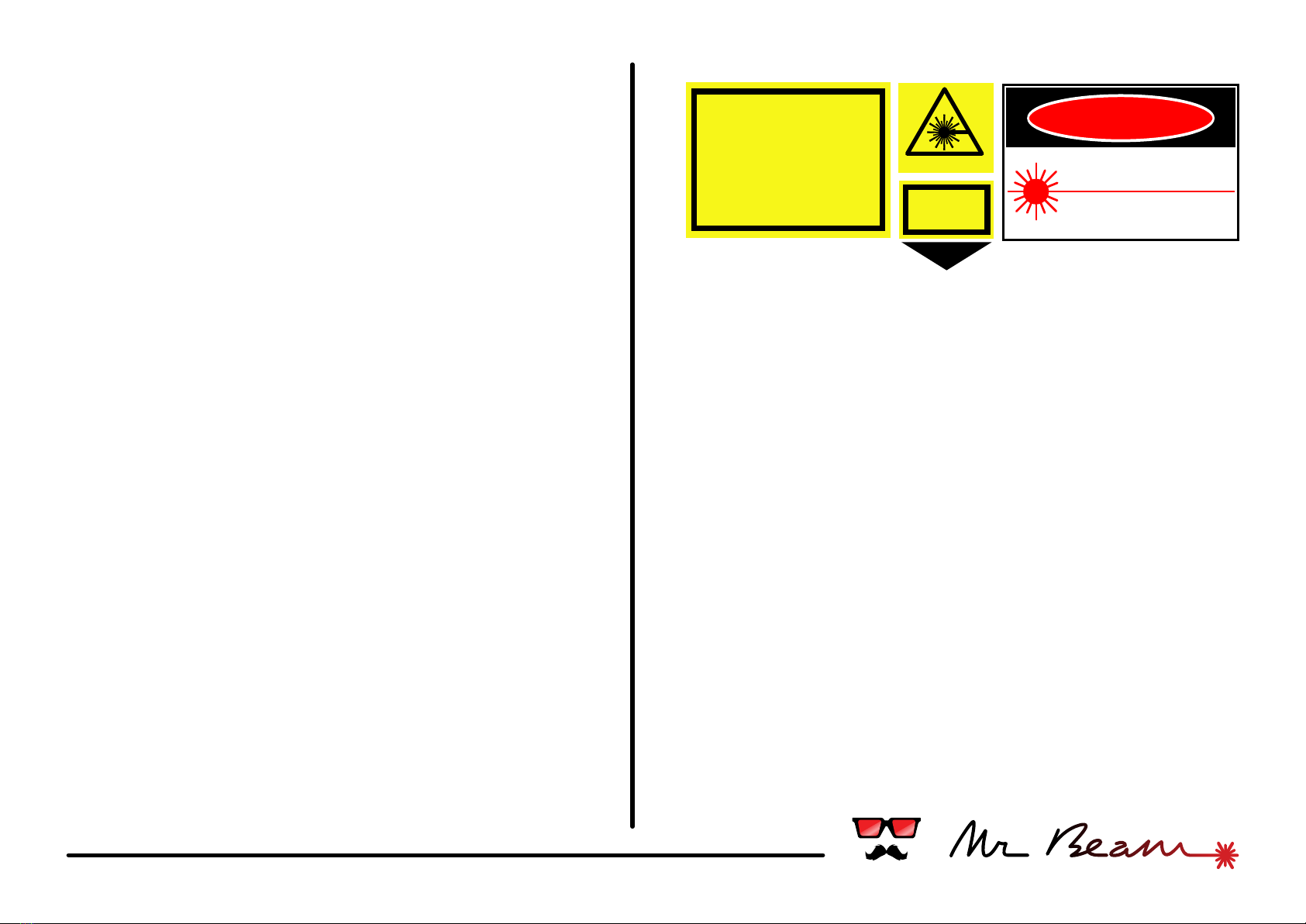

#05 safety

Laser Classification

IEC 60825 classiefies laser products into different

categories depending on light emitted, wavelength and eye

safety. Classes for typical laser diodes are given below.

Class 2, 2M / US Class IIa, II

Caution, normally visible laser light less than 1.0mW.

Considered eye safe, normal exposure to this type of beam

will not cause permanent damage to the retina

Class 3R / US Class IIIa

Danger, visible laser light between 1.0mW and 5.0mW.

Considered eye safe with caution. Focusing of this light into

the eye could cause some damage.

Class 3B / US Class IIIb

Danger, infrared (IR) and high power visible lasers <

500mW. Considered dangerous to the retina if directly

esposed.

Class 4 / US Class IV

Danger, laser output power greater than 500mW. Class 4

lasers are capable of causing injury to both the eye and

skin and will also present a fire hazard if sufficiently high

output powers are used.

You are responsible for the correct classification of your

device. Additionally you have to put all safety labels on it

according to your local regulations. Some examples of

such labels are shown on the right.

Check your local regulations for chosing the right ones.

LASER RADIATION

LASER RADIATION

AVOID EYE OR SKIN EXPOSURE TO

DIRECT OR SCATTERED

RADIATION

CLASS 4 LASER PRODUCT

Max Power: 1000mW

Wavelength: 400-695nm

Classified according IEC 60825-1

2007

LASER

APERTURE

Safety Glasses

Laser light is very intense. The natural winking reflex is not

able to protect your eye. Always protect your eyes with

appropriate safety glasses when operating a laser.

Appropriate laser safety glasses need to block the laser's

wavelength sufficiently. Sunglasses or just dark glasses

are not able to do that. In addition to safety glasses you

should consider to build a safety housing around your laser

device.

Be Responsible

Always take care about yourself and others. Operate lasers

with maximum attention at any time.

Respect Local Laws and Regulations

Almost every country has its own laws and regulations for

operating a laser. You are fully responsible to respect and

act in compliance with these.

LASER RADIATION

AVOID EYE OR SKIN EXPOSURE

TO DIRECT OR SCATTERED RADIATION

DIODE LASER

1000mW MAX at 445 nm

CLASS IV LASER PRODUCT

DANGER

#06 usage & appendix

Usage

The shield was designed to be used with the popular grbl firmware. We

recommend our own fork at https://github.com/mrbeam which is

preconfigured to the shield's pin layout and features.

Flashing GRBL

Checkout https://github.com/grbl/grbl/wiki/Flashing-Grbl-to-an-

Arduino for detailed multiplatform instructions how to flash the

firmware on your Arduino.

Use the precompiled grbl.hex from https://github.com/mrbeam

G-Code

In addition to the standard G-code supported by grbl (see http://

www.shapeoko.com/wiki/index.php/G-Code#G-

code_supported_by_Grbl) the Mr Beam version has reused some

commands for controlling the laser intensity.

Replace # with appropriate parameter values in the examples below.

Laser Control

M03 S### : switch laser to intensity. Intensity is number between 0 and

255. If the laser was switched off before it will be switched on.

M05 : switch laser off.

Fan Control

M08 : switch cooling fan on.

M09: switch cooling fan off.

Movement

$H : do a homing cycle

G21 : switch to mm units

G90 : switch to absolute coordinates

G92 X0 Y0 Z0 : set coordinate origin

G0 X# Y# : rapid positioning move

G1 X# Y# : move to given position with the current feedrate

F### : set feedrate

Additional Information Resources

The internet is full of information about laser technology and safety.

Some (but not all) information resources are listed below:

Safe usage of lasers

http://en.wikipedia.org/wiki/Laser_safety

Safety glasses

http://www.thorlabs.com

http://www.noirlaser.com

http://www.lasersafetyindustries.com

and many more.

Laser cutting

http://atxhackerspace.org/wiki/Laser_Cutter_Materials

GRBL / G-Code

http://bengler.no/grbl

http://en.wikipedia.org/wiki/G-code

Accessories

http://www.pololu.com/category/120/stepper-motor-drivers

http://www.watterott.com/en/Interfaces/Motor-Controllers/Stepper

https://www.lasertack.com/

http://www.insaneware.de/

https://sites.google.com/site/dtrlpf/

http://odicforce.com/

Table of contents