MTD 137-496A User manual

Other MTD Lawn Mower manuals

MTD

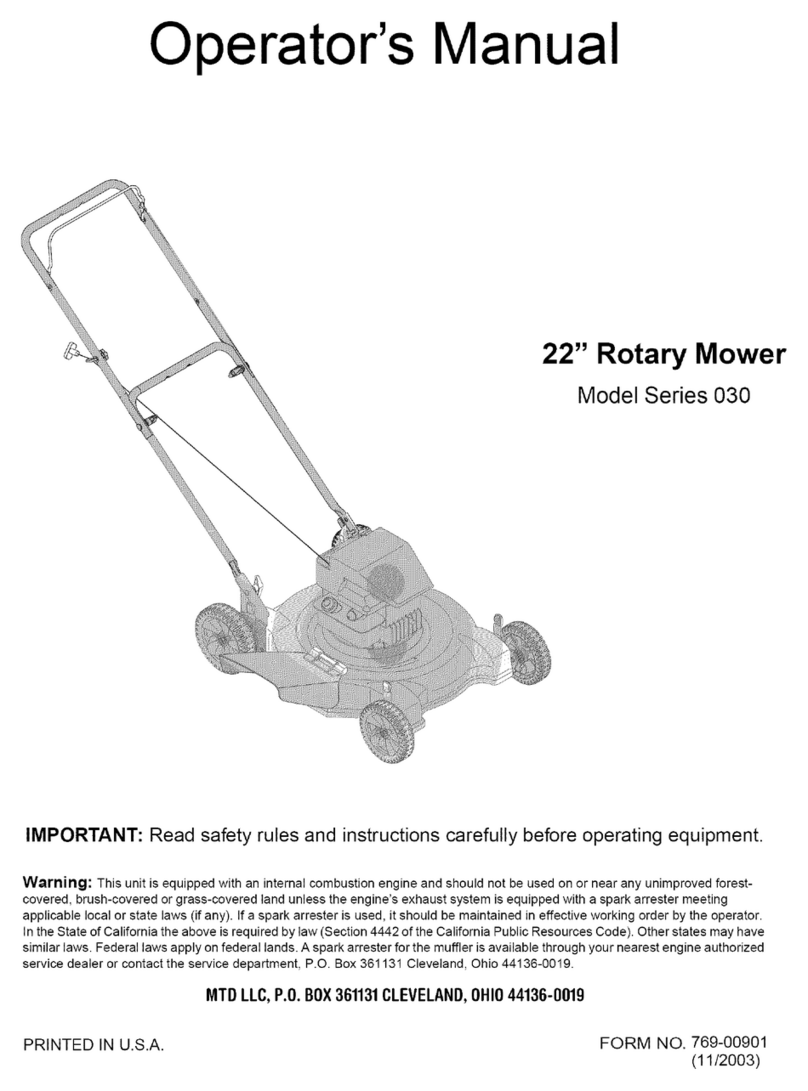

MTD 030 Series User manual

MTD

MTD 154-518A Manual

MTD

MTD Bolens 11A-414A065 Guide

MTD

MTD Cub Cadet 2000 Series User manual

MTD

MTD 132-760A User manual

MTD

MTD Series 410 thru 420 User manual

MTD

MTD 125-260A Manual

MTD

MTD 121-550A User manual

MTD

MTD 12A-98K3095 User manual

MTD

MTD Yard-Man AutoDrive 604 User manual

Popular Lawn Mower manuals by other brands

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual

Toro

Toro Groundsmaster 3505-D Service manual