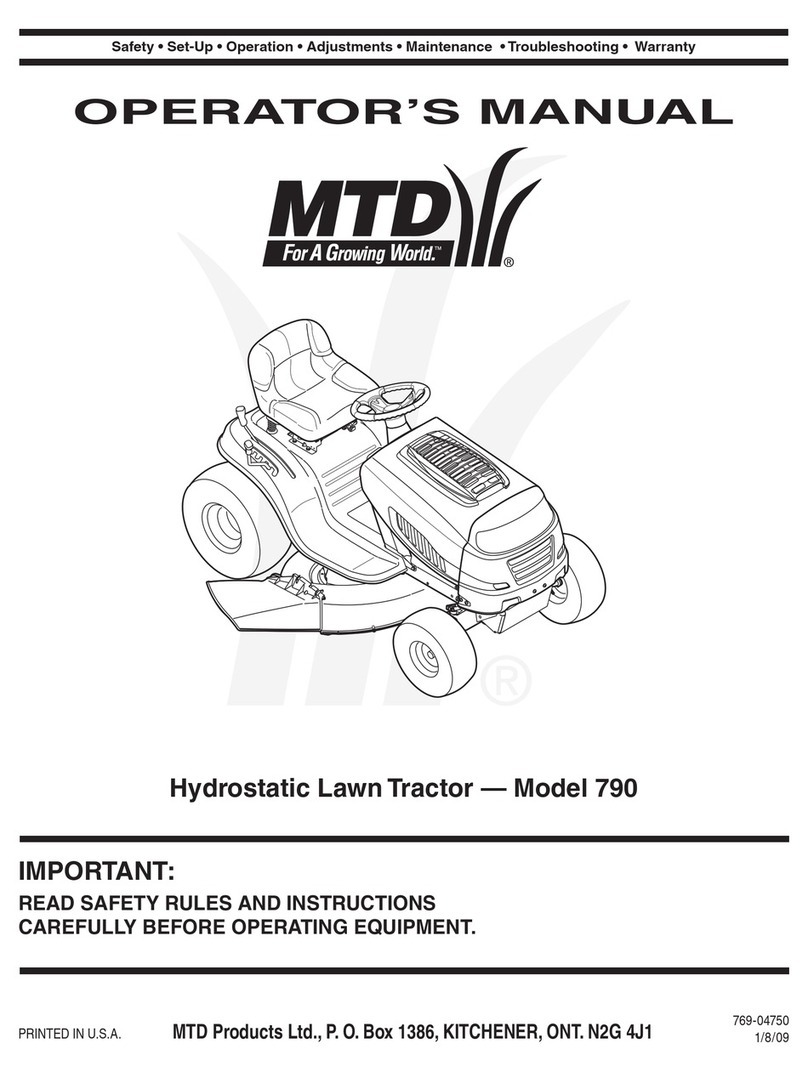

MTD Cub Cadet 1000 Series User manual

Other MTD Lawn Mower manuals

MTD

MTD 148-760 10 H.P. User manual

MTD

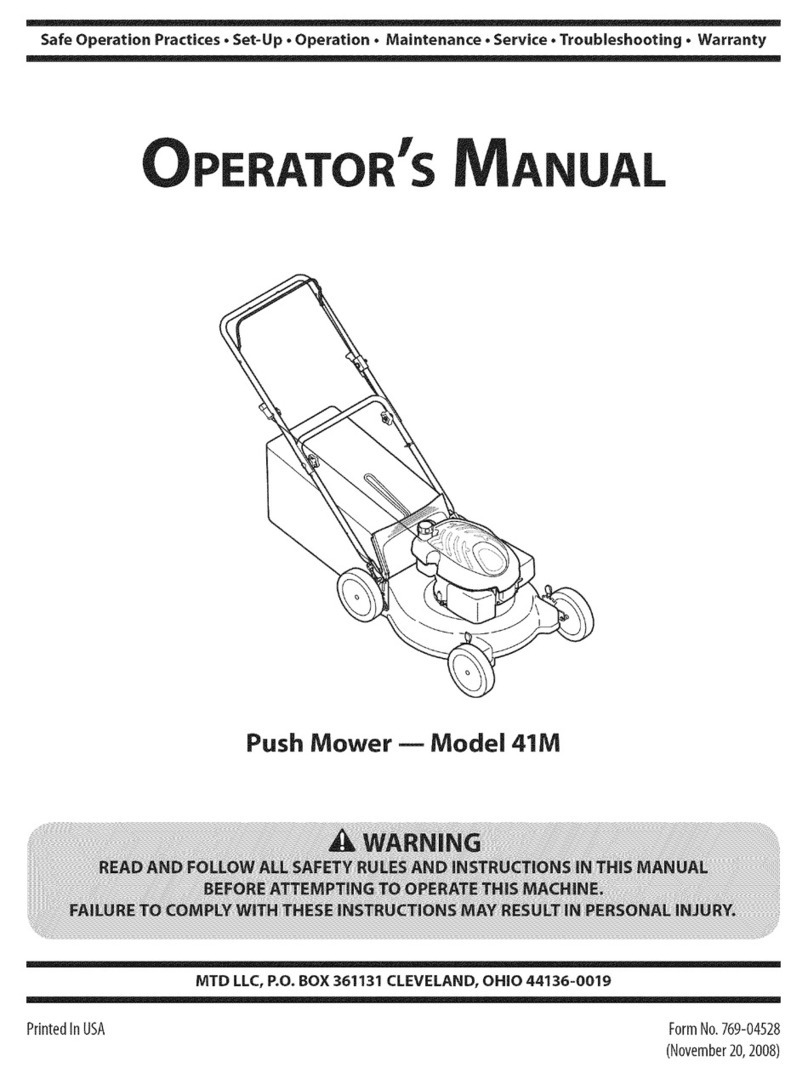

MTD 44M User manual

MTD

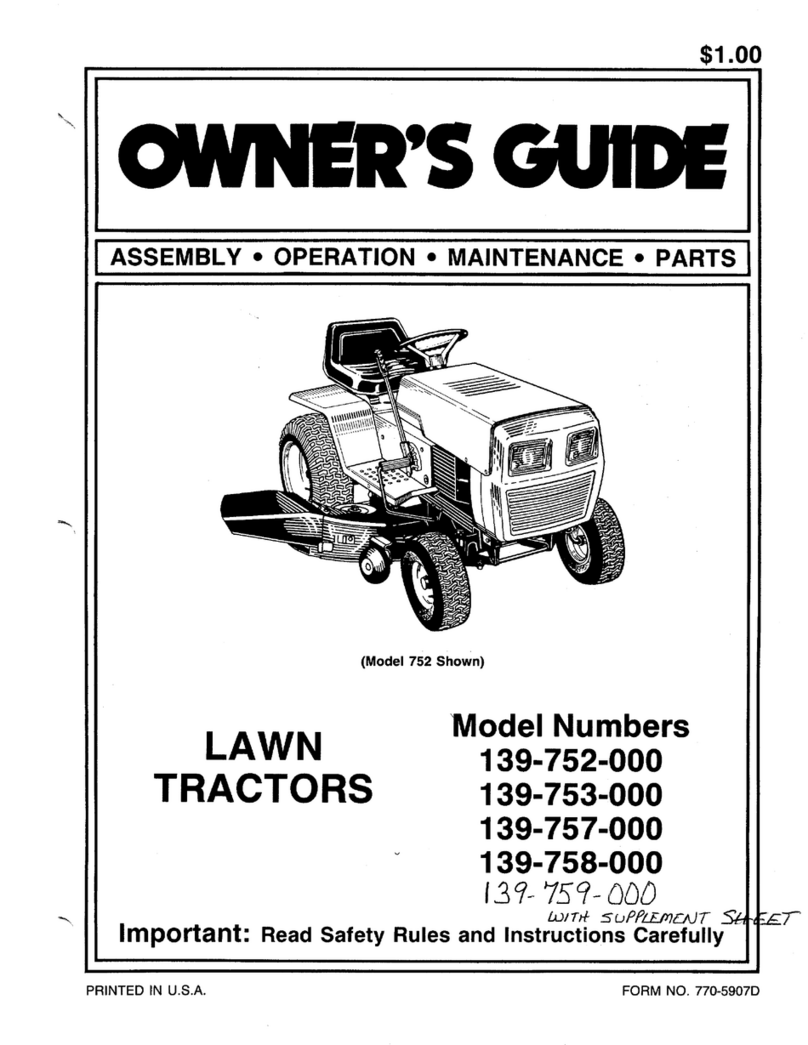

MTD 500 Series User manual

MTD

MTD 105 thru 108 User manual

MTD

MTD White Z-200 User manual

MTD

MTD Yard-Man 109 User manual

MTD

MTD 113-011A User manual

MTD

MTD PR600N21RH User manual

MTD

MTD Shift-On-The-Go 760 User manual

MTD

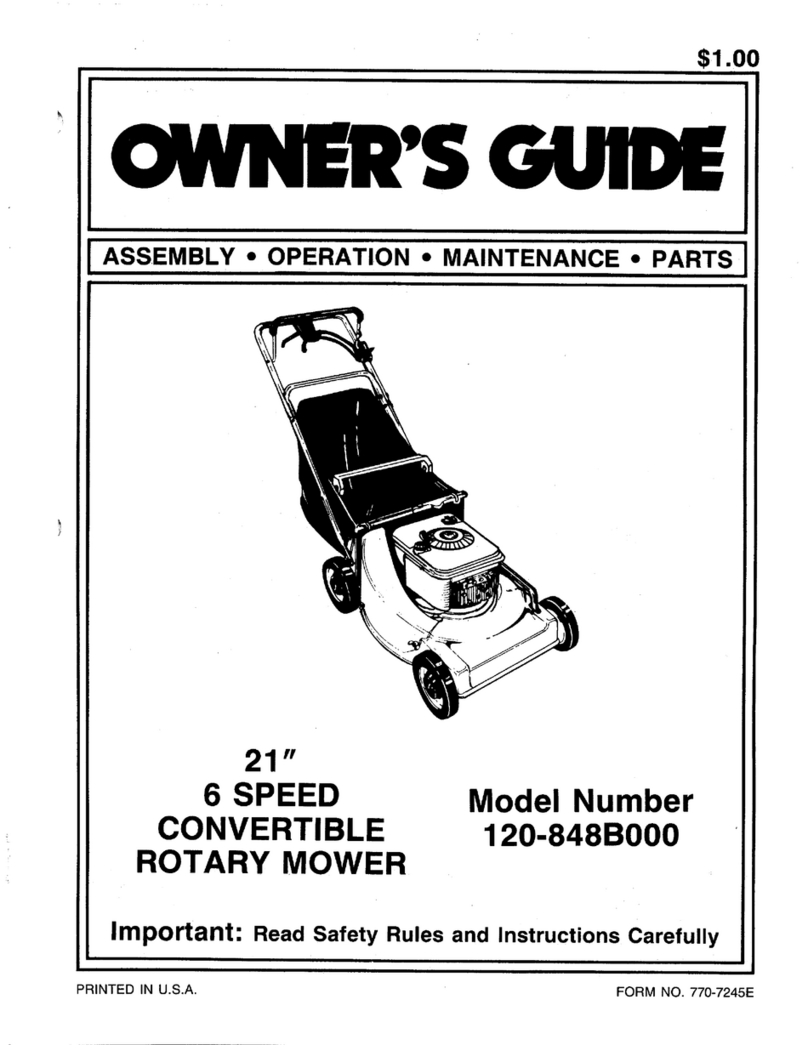

MTD 120-848B000 User manual

Popular Lawn Mower manuals by other brands

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual

Toro

Toro Groundsmaster 3505-D Service manual