SAFETY RULES AND PRECAUTIONS

Warning: To reduce the risk of fire, electric shock, and personal injury, the

following basic safety precautions should always be followed.

READ ALL INSTRUCTIONS

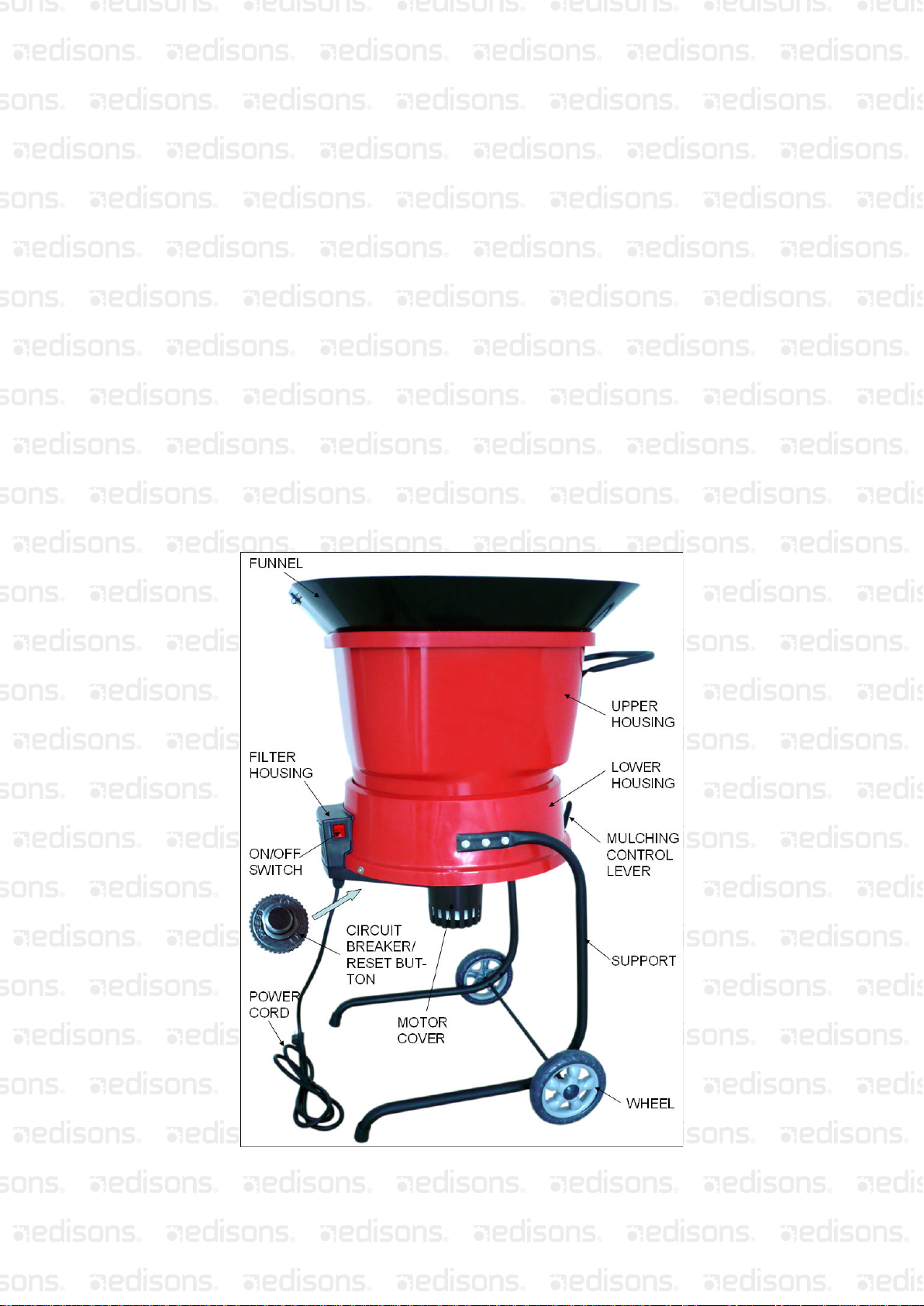

1. Become familiar with all sections of owner’s manual before attempting to operate the

shredder. This shredder should be used solely for the purpose it was intended.

2. Use only parts or accessories specifically designed for use with this shredder. Using

other parts or accessories could increase risk of injury.

3. Keep Children Away-all visitors should be kept at a distance from the work area.

4. Never allow your hands or any part of your body or clothing inside the upper housing

area.

5. Avoid Dangerous Environments-do not use shredder in damp or wet locations. Do

not operate or store shredder in wet areas. Do not operate in rain. Store indoors when

not in use, in a dry, and high or locked-up place-out of reach of children.

6. This shredder should be operated on a solid, level surface.

7. Dress Properly-do not wear loose clothing or jewelry. They can be caught in moving

parts. Use of work gloves and substantial footwear is advised when working outdoors.

Wear protective hair covering to contain long hair.

8. Stay Alert-Watch what you doing. Use common sense. Do not operate shredder

when you are tires.

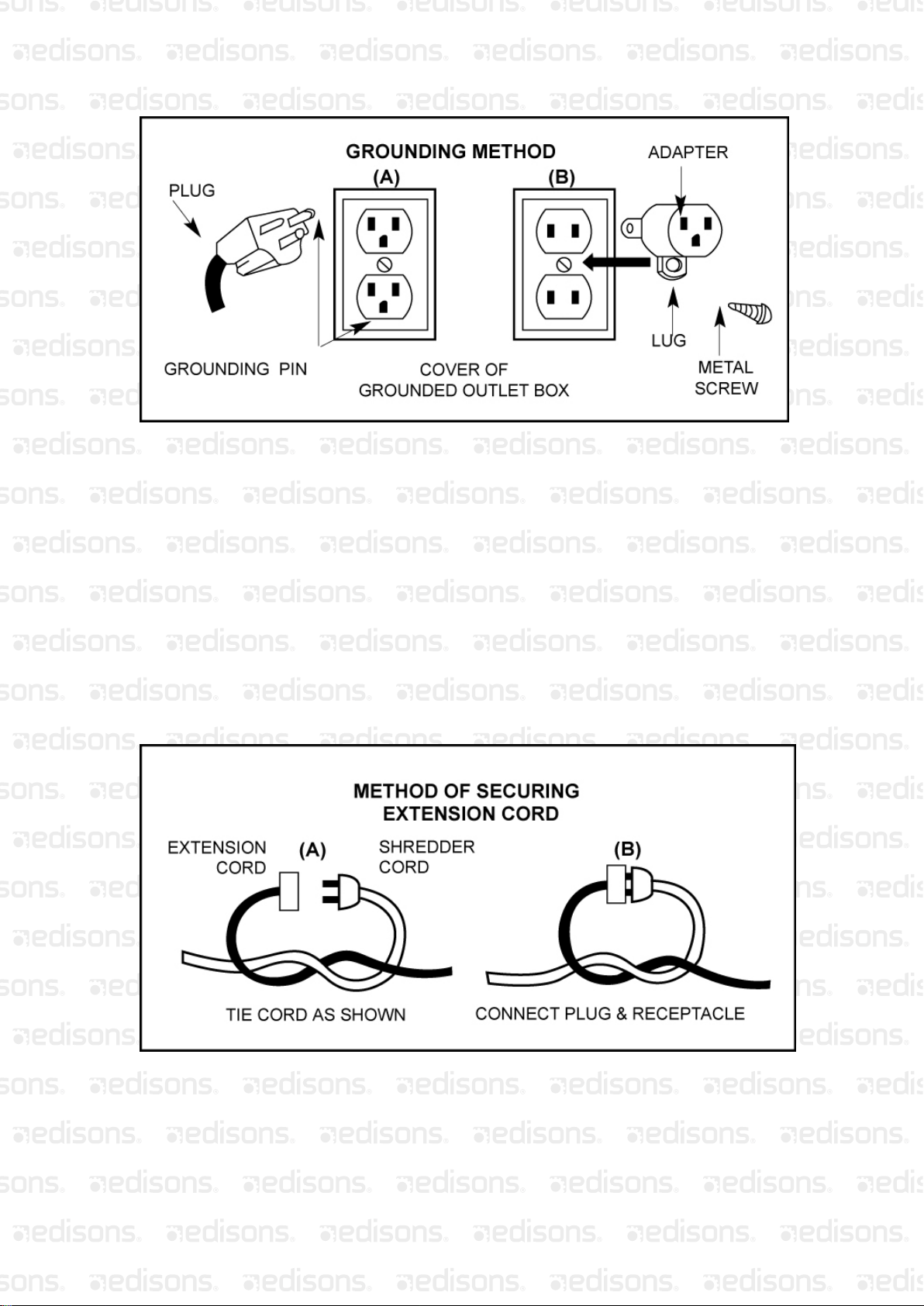

9. Do not Abuse Power or Extension Cords-Never carry unit by its power cord or yank

cord to disconnect from receptacle. Keep all cords clean and away form heat, oil and

sharp edges and inspect for damage before each use.

10. Ground unit properly. Follow instructions on page 9 when connecting to electrical

outlet.

11. Warning-To reduce the risk of electrical shock, use only an extension cord intended

for outdoor use. See page 9 for additional information on extension cords.

12. Ground fault circuit interrupter (GFCI) protection should be provided on the circuit(s)

or outlet(s) to be used for this shredder. Receptacles are available having built-in

GFCI protection and may be used for this measure of safety.

13. If it is necessary for any reason to inspect, clean or repair the shredder, turn the

shredder off and wait until it comes to a complete stop, then disconnect the power

cord before attempting such inspection or repair.

14. Disconnect shredder from the power source when not in use, before servicing, and

when changing cutting lines.

15. When feeding material into the shredder be extremely careful that pieces of metal,

rocks, bottles, cans or other foreign objects are not included.

16. Do not force the shredder. It will do the job better and with less likelihood of risk of

injury when used at the rate for which it was designed.

17. If the cutting mechanism strikes a foreign object or if your shredder should start

making an unusual noise or vibration, immediately switch it off, wait until the shredder

has come to a complete stop, then disconnect the power cord and take the following

7